The device for spot welding on the basis of Arduino Nano

In some cases, instead of soldering, it is more advantageous to use spot welding. For example, this method may be useful for repairing batteries consisting of several batteries. Soldering causes excessive heating of the cells, which can lead to their failure. But spot welding heats the elements not so much, as it acts for a relatively short time.

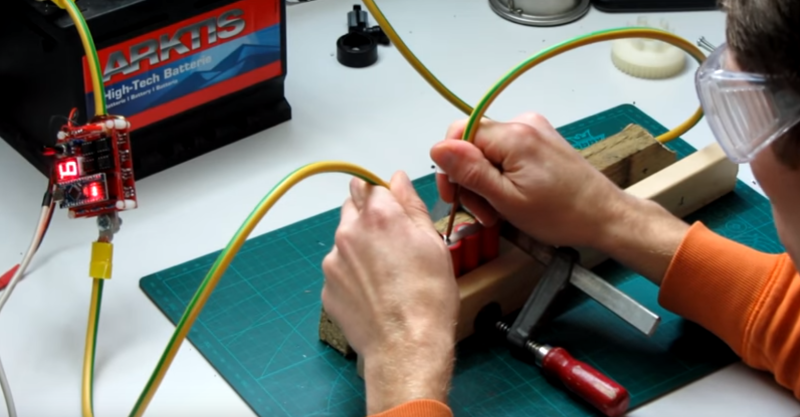

To optimize the entire process, the system uses Arduino Nano. This is a control unit that allows you to effectively manage the power supply of the installation. Thus, each welding is optimal for a particular case, and energy is consumed as much as necessary, no more, and no less. The contact elements here are copper wire, and the energy comes from a conventional car battery, or two, if a greater current is required.

The current project is almost perfect in terms of the complexity of the creation / work efficiency. The author of the project showed the main stages of creating the system, putting all the data on Instructables .

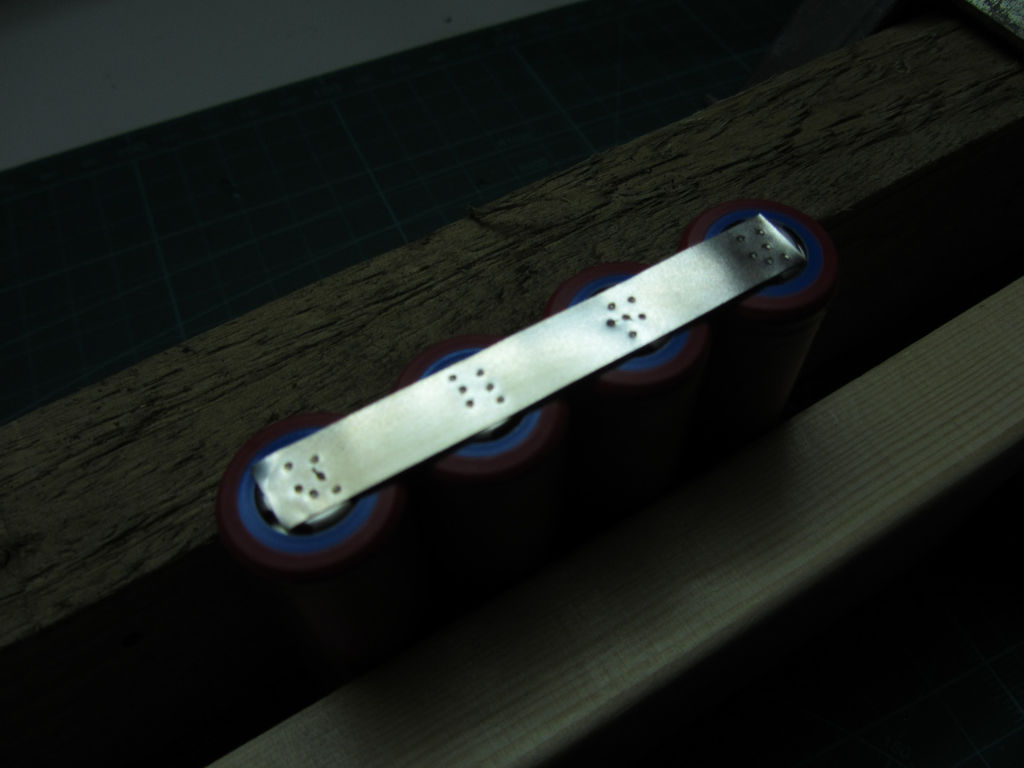

According to the author, the standard battery is enough for spot welding two nickel strips 0.15 mm thick. For thicker metal strips, two batteries will be required, assembled into a circuit in parallel. The pulse time of the welding machine is adjustable, and ranges from 1 to 20 ms. This is quite enough for welding the nickel strips described above.

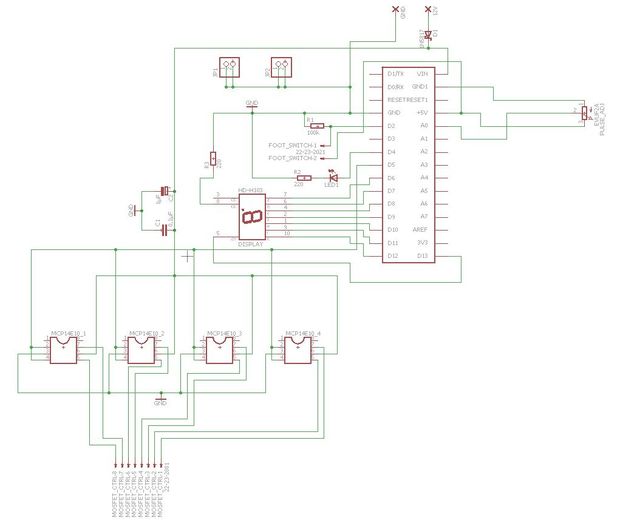

All project data is posted on Github .

The author recommends to pay to make to order from the manufacturer. The cost of ordering 10 such boards is about 20 euros.

Further, according to the scheme provided by the author, the control module itself is built on the Arduino Nano.

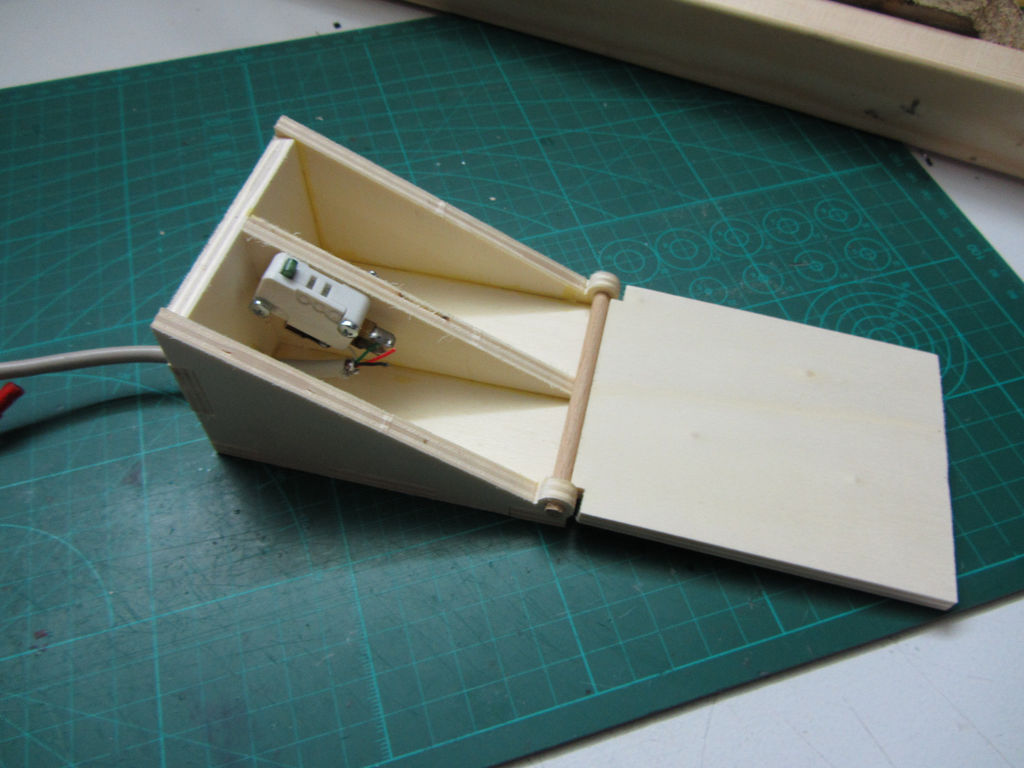

During welding, both hands will be occupied. How to manage the whole system? Of course, with the help of a foot switch. It is very simple.

But the result of the work:

All the steps for assembling the system are collected by the author in one video: