Making a retro game from the 80s or how to cook mock-ups for laser cutting

- Tutorial

Habr, hello! It so happened that I was asked for a long time to make an old board game from the USSR - "Battle". So the time has come to fulfill the promise, at the same time I decided to show how to create mock-ups for laser cutting and what is the result. There is no great difficulty in this, but there are some nuances.

Many articles of the Habr on the topic of DIY contain complaints: the lack of skills to work with a jigsaw, the low rigidity of the cardboard, the difficulty in creating the body. Everyone chooses how to implement their ideas, but it’s important for me to show how easy it is to make a layout in the same Inkscape, give it to work and get ready-made details.

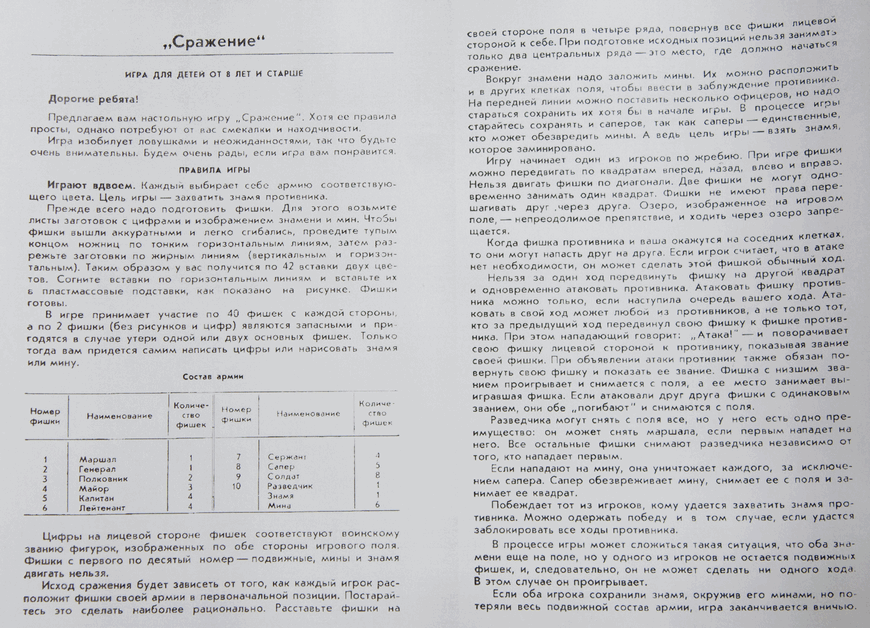

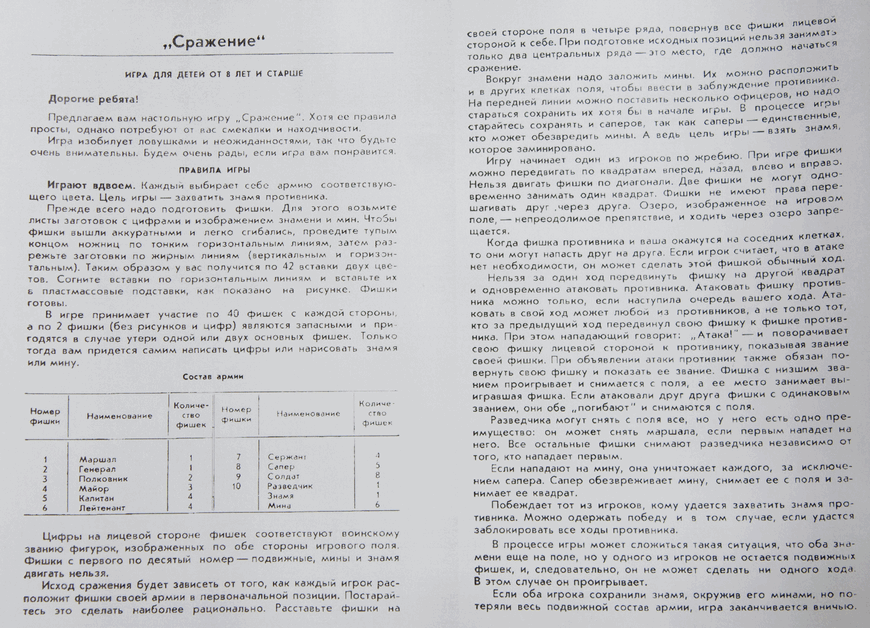

The game "Battle" itself was released in the USSR in the 80s and, obviously, was made based on the western game "Stratego". Restored the game from photos from the Internet.

The original game consists of a playing field, chips and boxes. All elements of the game were made of cardboard, only chip stands were plastic. Unlike the original game, all the details of our implementation will be made of plywood 2.9 mm thick and processed by laser cutting.

Why it is from plywood and laser cutting, because plywood is a good material for game parts and I have experience working with a laser machine. It should turn out no worse than from cardboard, only with scissors you won’t have to cut pieces for chips.

All game layouts are posted in the github repository .

Below in the article there will be links to SVG files from this repository.

Layout Preparation

To perform laser cutting, it is necessary to prepare vector files, we will use the free Inkscape editor. Before you begin, it’s important to set up the editor correctly.

By default, Inkscape considers the size of objects along with the thickness of the stroke line; for laser cutting, this calculation method is not suitable.

Sequentially select the desired settings panel:

Preferences (Shift + Ctrl + P) -> Tools and switch the “Bounding box to use” parameter to “Geometry bounding box” (instead of the default selected “Visual bounding box”)

(In the Russian version of the interface, the settings are called so: Parameters (Shift + Ctrl + P) - Tools -> Used area (BB) - "Geometric area").

It’s also advisable to set millimeters in the document settings as the basic units: File -> Document Properties ... -> Display units: mm.

Game field

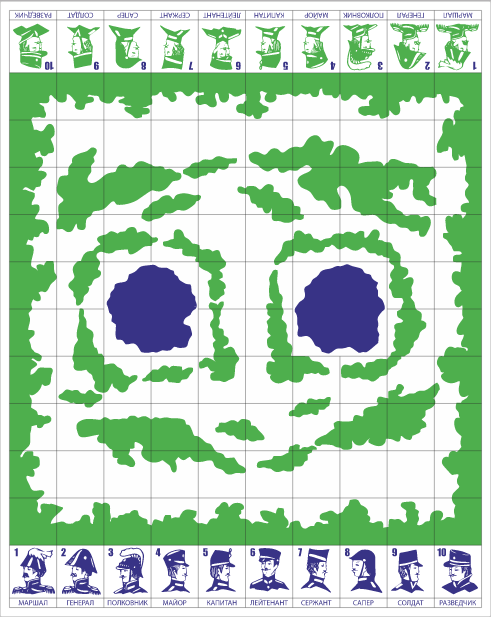

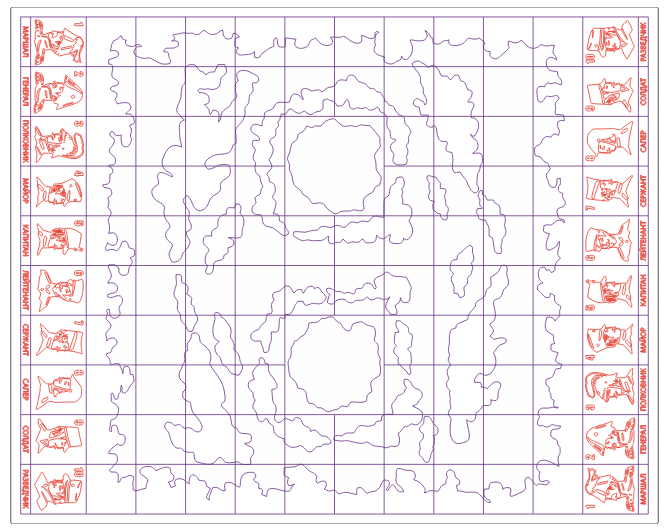

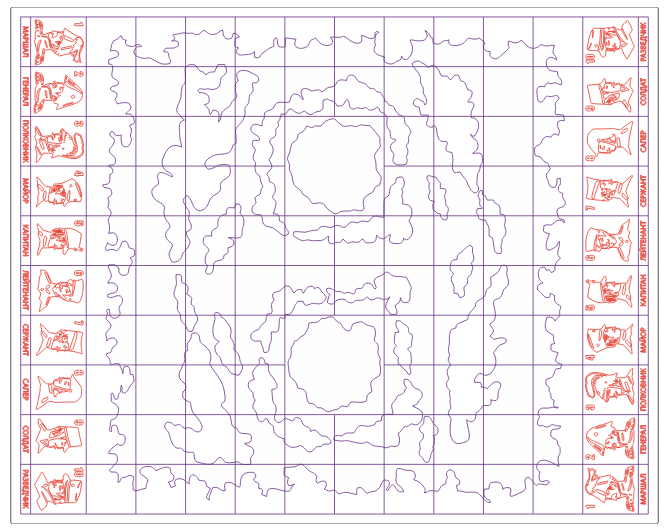

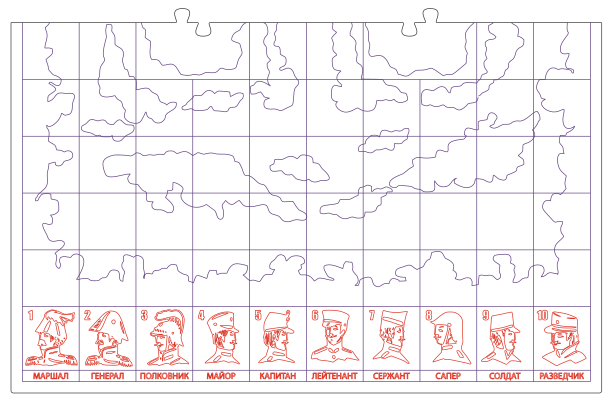

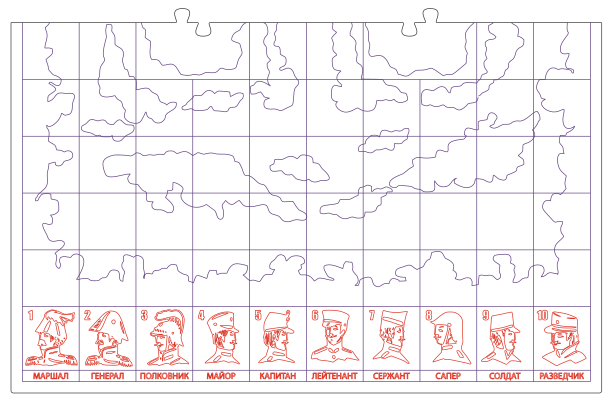

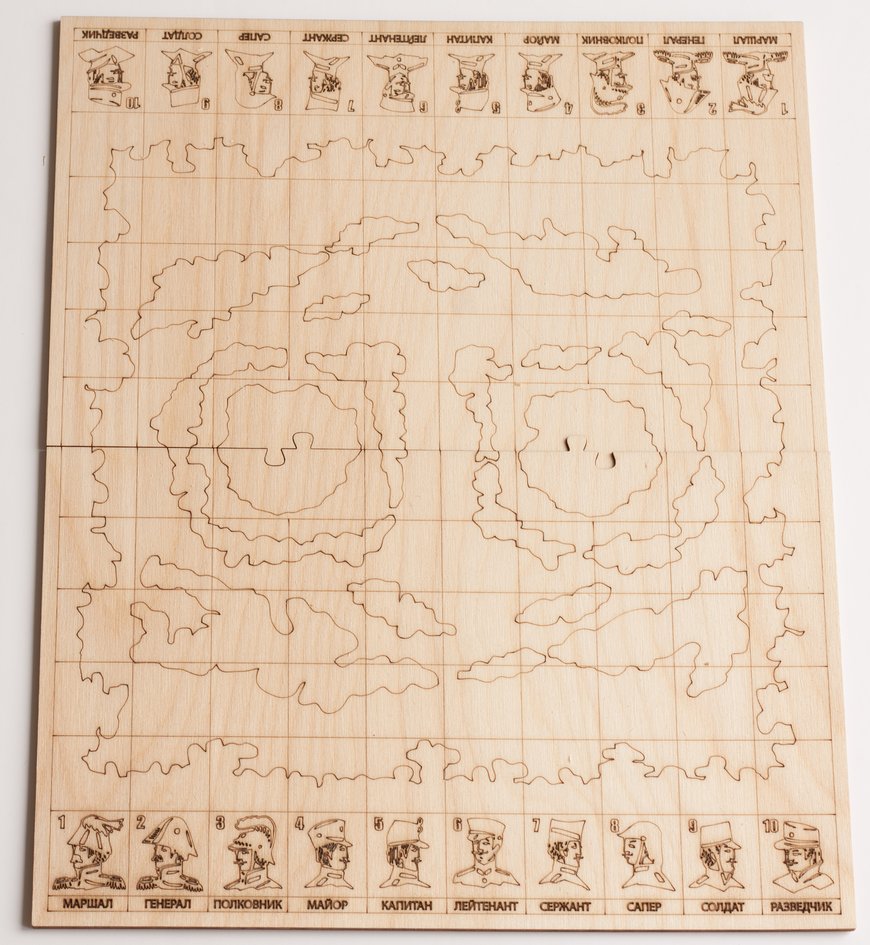

The original field of the game was made of cardboard and bent in half, the image on the field was formed only in two colors blue and green. These colors were used both as the colors of the enemy troops and the colors of the map (lakes and forests).

From the found old photograph of the game, we obtain vectors for groups of images: persons of military ranks, forests and lakes. For each group, we prepare a separate raster file in which there will be no other images except the selected group. We get three raster images: with one row of faces, with two central lakes and with the contours of greenery (forests). We add the received images to Inkscape and vectorize them individually, in the vectorization parameters we set the vectorization from two colors.

There is no need to vectorize the game grid, numbers and titles of titles - they are easier to create new ones.

Create a vector document for the game field. To begin, we form a grid of the future game from vector lines, then add vectorized images to their respective places.

Manually add texts with the numbers of military ranks and with the names of ranks. All texts are converted to curves.

A number of ranks on one side of the field are copied to the opposite side.

As a result, we get a vector image of the playing field ready for printing. But we plan not to print the field, but to cut and engrave. It is required to indicate on the sketch for each line the method of its processing. Processing methods are specified by indicating the unique (within the sketch) line color.

Our playing field has only one contour for cutting - its outer edge - we set it to black. For the grid lines, the contours of greenery and lakes, we set the purple color - we will engrave them with a line. We will set the portraits, names and numbers of military ranks in the third color - red, this is also an engraving, but for now we leave the choice to make continuous engraving for them or just a line, so we select a separate processing color.

We remove the entire fill from objects, only color contours remain.

The playing field turned out to be large 260x326 mm, so that the game was more convenient to store and a smaller box was required - we divide the field into two collapsible parts that are interconnected by the type of puzzles.

As a result, we get two SVG files: game_field_part1.svg and game_field_part2.svg.

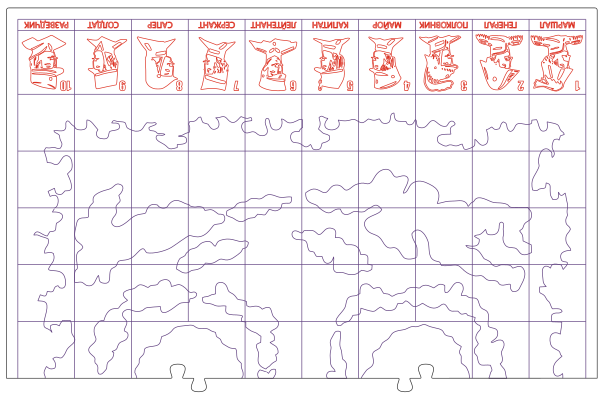

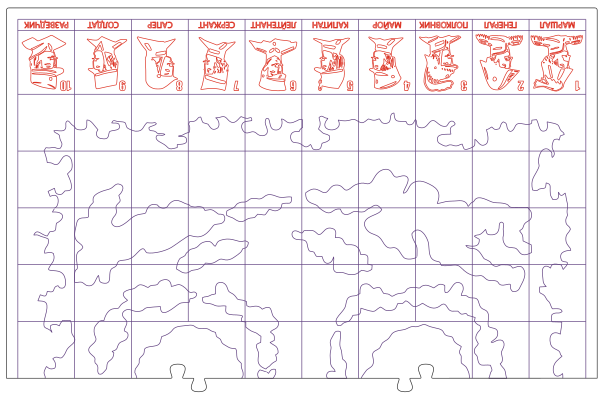

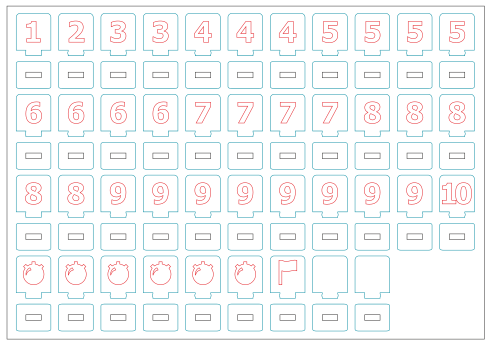

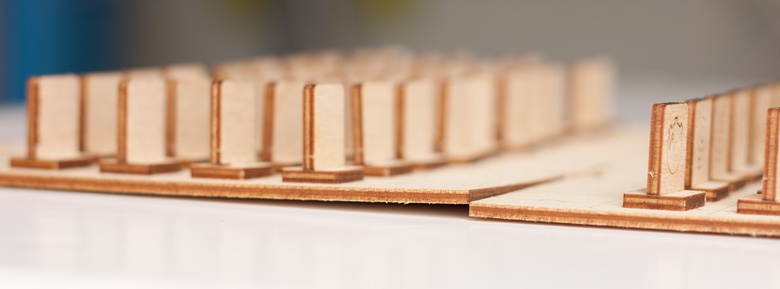

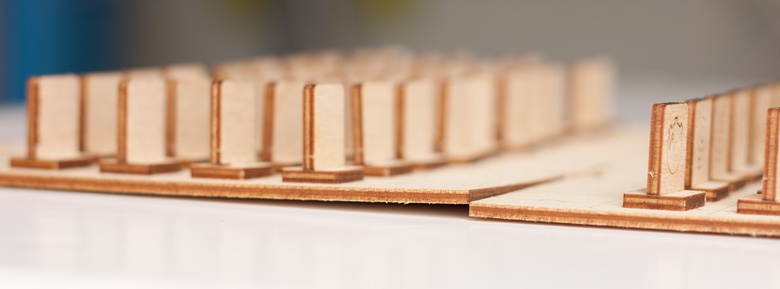

Chips

In the original game, the chips are bent from cardboard and inserted into plastic coasters. From plywood, the design of the chips will be different, we will make a rectangular base-base and vertically place the part with the unit number on it. We connect the upper and lower parts using the standard spike groove method. The height of the tenon and the width of the groove should be equal to the thickness of the material, in our case it is 2.9 mm. The lengths of the groove and tenon coincide, but their dimensions after cutting will differ by the thickness of the cut line, i.e. the spike will fit into the groove with a gap.

So that the parts can be joined without glue, we add special thickenings in the form of arcs (protruding from each side of 0.25 mm) to the spike, which will ensure the connection of the parts with light effort.

We need to make 42 chips for each of the players, to make each chip as a separate piece is low-tech and expensive. It is hard to work with small parts that fall to the bottom of the machine when cutting, they must be assembled, sorted, counted and packaged. The smaller the part, the more difficult it is to work with it. But for such cases, cutting parts with a chipboard is well suited when there is one large parent blank, and there are many daughter small parts in which the contours are not completely cut and they are kept in jumpers in the parent part. Child parts can be squeezed out of the parent part with a little effort.

On the sketch, cutting with a chipboard can be realized as gaps in conventional cutting lines. The width of the gap depends on the thickness of the laser cut and the material for processing. For plywood 2.9, I use 0.17 mm breaks for parts that have either side smaller than 50 mm and 0.22 mm for larger parts.

But the formation of cutting by the “chipboard” is automated, it’s enough to specify your type-color for such lines.

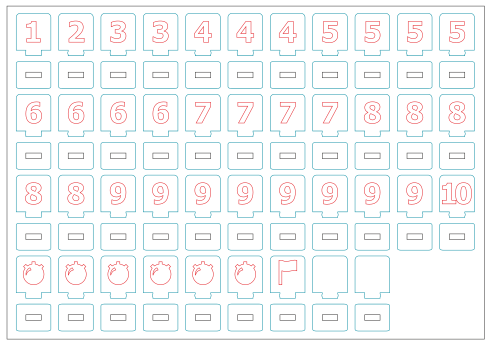

Create a rectangular parent block and place all 42 chips on it - two parts for each chip (upper and lower). We place on the chips the numbers of ranks, the figures of mines and the flag. Two spare chips are left without images.

Set processing colors:

- for chip contours - blue-green color (cyan) - cutting with a chipboard,

- for the contour of the base part and the grooves-slots - black - conventional cutting,

- for images on chips - red - line engraving.

SVG file: game_chips.svg

This preparation will need to be done in duplicate (for each player).

Box

We make a box with a lid for storing the game using the same “tongue-and-groove” technology, but I have a ready-made generator of boxes in size, and I'll use it. We set the internal dimensions of the box: 270x178x32 mm and get ready-made box layouts.

On the cover of the box we apply an image based on the original box. Unfortunately, the box pattern is not suitable for automatic vectorization, so I had to spend time and draw the necessary image lines manually.

It’s convenient to make the sides of the box and lid a chipboard, so that instead of 8 parts you get two. As a result, 4 blanks were received for the box:

- box bottom (box_bottom.svg)

- sidewalls of the box (box_sides.svg)

- top of cover with image (cover_top.svg)

- sidewalls of a cover (cover_sides.svg)

Choice of engraving method

When laser processing plywood, two methods of applying the image are possible: line engraving and continuous engraving (Scan).

Engraving with a line for the machine is the usual cutting mode along a given contour, but the parameters of the laser power and processing speed are set so that the laser does not cut through the material, but only leaves a noticeable mark on it (as a burner).

Continuous engraving is a special processing mode when a machine fills a interior of an engraved contour with a series of parallel lines (usually horizontal). The distance between these lines and the thickness of the laser beam determine the level of detail of the pattern and the processing time. Continuous engraving is performed only for closed loops. Continuous engraving is always longer and more expensive than line engraving. Processing time for large engraving areas can be up to several hours.

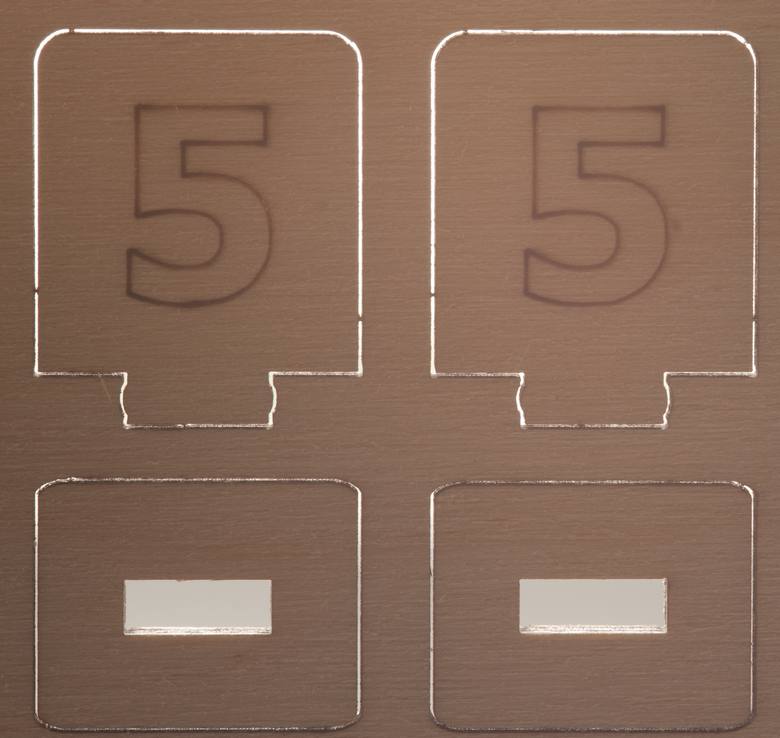

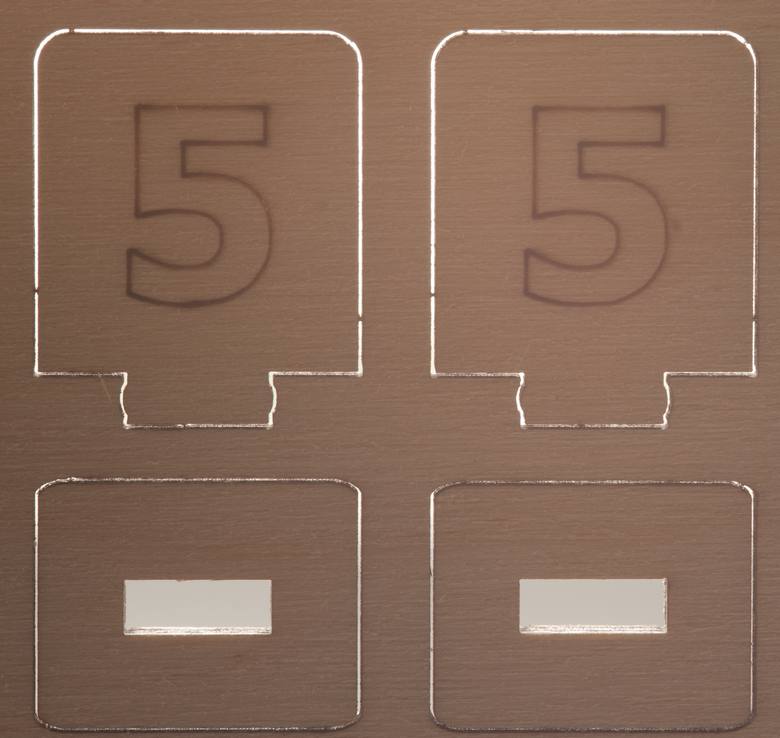

An example of two types of engraving has been specially prepared to demonstrate the differences. Two rows of images: the top row - line engraving, the bottom - continuous engraving. The step between the lines of continuous engraving is 0.1 mm.

Initial layout

Engraving result

Macro shot of engraving elements

Engraving models mock up images on the playing field and on chips (red lines), for them you can specify both line engraving and solid engraving. As a result, we choose line engraving to be able to simply paint over certain areas of the picture with paint.

Finished Parts

As a result of processing, we get 7 separate parts that correspond to our layouts.

Photos of all parts

(Plates with chips - 2 pcs.)

(Plates with chips - 2 pcs.)

All parts are presented without any additional processing and cleaning. It can be seen that there is almost no deposit on plywood. With the right settings for laser cutting processes, there is no carbon deposit on the parts or it is minimal.

Sometimes light burn-on defects occur on the back surface of the material, where the laser beam passing through the part is reflected from the table lamellas. The formation of a slight halo around figures with continuous engraving is also possible. These defects, if they appear, can be corrected by light grinding.

Assembly

We connect the two parts of the playing field, check that everything is going fine.

We squeeze out the details of the chips from the chipboard.

We connect the upper and lower parts of the chips.

By the way, here are a few close-up photos of what the chip detail carved out of the chipboard represents.

Front

Back

To the lumen A

small ledge from the jumper is visible from above the finished chip

Back

To the lumen A

small ledge from the jumper is visible from above the finished chip

We collect the top and bottom of the game box. The lid had to be glued, and the bottom of the box was assembled without glue.

We put all the components of the game into a box.

Add a listing of the rules of the game.

The game is ready. We

checked the product in the game, even in unpainted form, it is quite playable!

Known Issues

1. The game requires painting, but my strength and skills on it have not yet been enough. Therefore, the game in this article is presented as "colorless."

2. The playing field constructively consists simply of a sheet of plywood and all defects of the sheet material are not compensated in any way. Plywood - “living” material and its sheets may differ from the plane.

As a result, some edges of the field are markedly curved upwards.

I think that for the field it was possible to choose a thicker plywood, in which these defects appear less. Still material defects can be corrected constructively, for example, add a border from the side parts (like a box) to the field, the mutual connection of the parts straightens the curvatures.

3. A little miscalculated with the height of the box - it was necessary to do a little higher, otherwise you have to turn all the chips sideways, otherwise the box does not completely close.