$ 250 room-sized 3D printer

Why not make a 3D printer out of a garage or empty room ? An open source project from Sweden makes this possible for $ 250. Who is less? Glenn MacDonald's

article from Seeker.com has been translated for you by the Top 3D Shop .

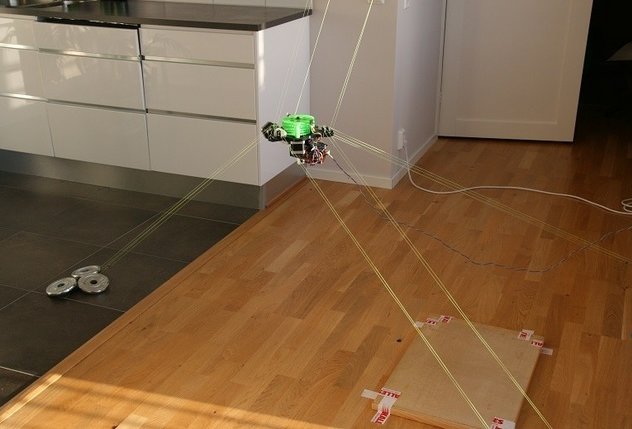

Swedish inventor Thorbjörn Ludwigsen has spent the last three years developing a new type of large-format 3D printer that can create large objects. His invention can print furniture directly in a room - it is very easy and relatively cheap. Ludwigsen’s invention, “Hangprinter,” uses a system of cables attached to walls, floors, and ceilings and computer-controlled drives on a print head unit. As a 3D printer housing the device uses the room itself.

Hangprinter is not the first wide-format 3D printing system, but it is unique. Firstly, it is cheap. All hardware and firmware components can be purchased for about $ 250. In addition, this is an open project, which means that any user can improve the system and use third-party updates. Finally, Hangprinter is self-sufficient - most of the components necessary for its creation can be printed by it.

All this adds up to a system that Ludwigsen hopes will unlock the potential of 3D printing for a large number of people. The developer believes that 3D printing should not be an expensive privilege. According to him, Hangprinter is not only a technical, but also a social experiment.

“In particular, I want 3D printing to avoid the fate of 2D printing, where machines are programmed to self-destruct after a certain number of manufactured objects. The best chance to do this is not only to use open source code, but also to create self-reproducing equipment. Hangprinter makes most of the necessary elements for itself

, ”he said.

The Hangprinter project is part of a larger initiative in the 3D printer community known as RepRap. All developers are trying to optimize the process of creating prototypes. The idea is to spread 3D printing technology among low- and middle-income people, using open design solutions and self-reproducing mechanisms.

“Open technologies can provide new opportunities for middle- and low-income families, and I grew up in one of these families ,” Ludwigsen said.

The innovator takes this project very seriously. As a physics student at Umeå University in Sweden, he recently wrote a master's thesis on the subject.

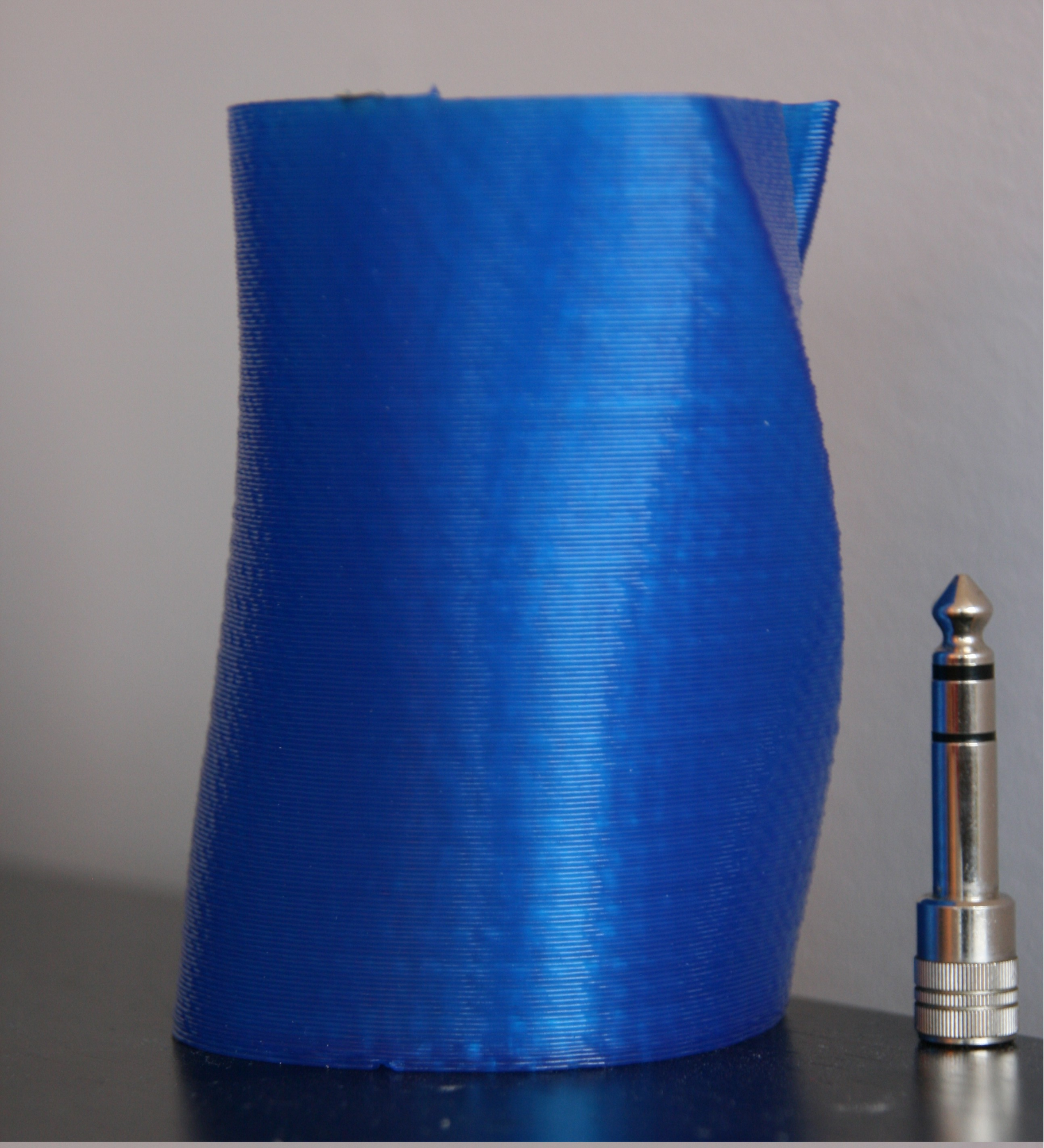

In a video demonstrating the operation of Hangprinter, Ludwigsen demonstrated how a 3D printer creates a relatively simple and functional object - a lampshade.

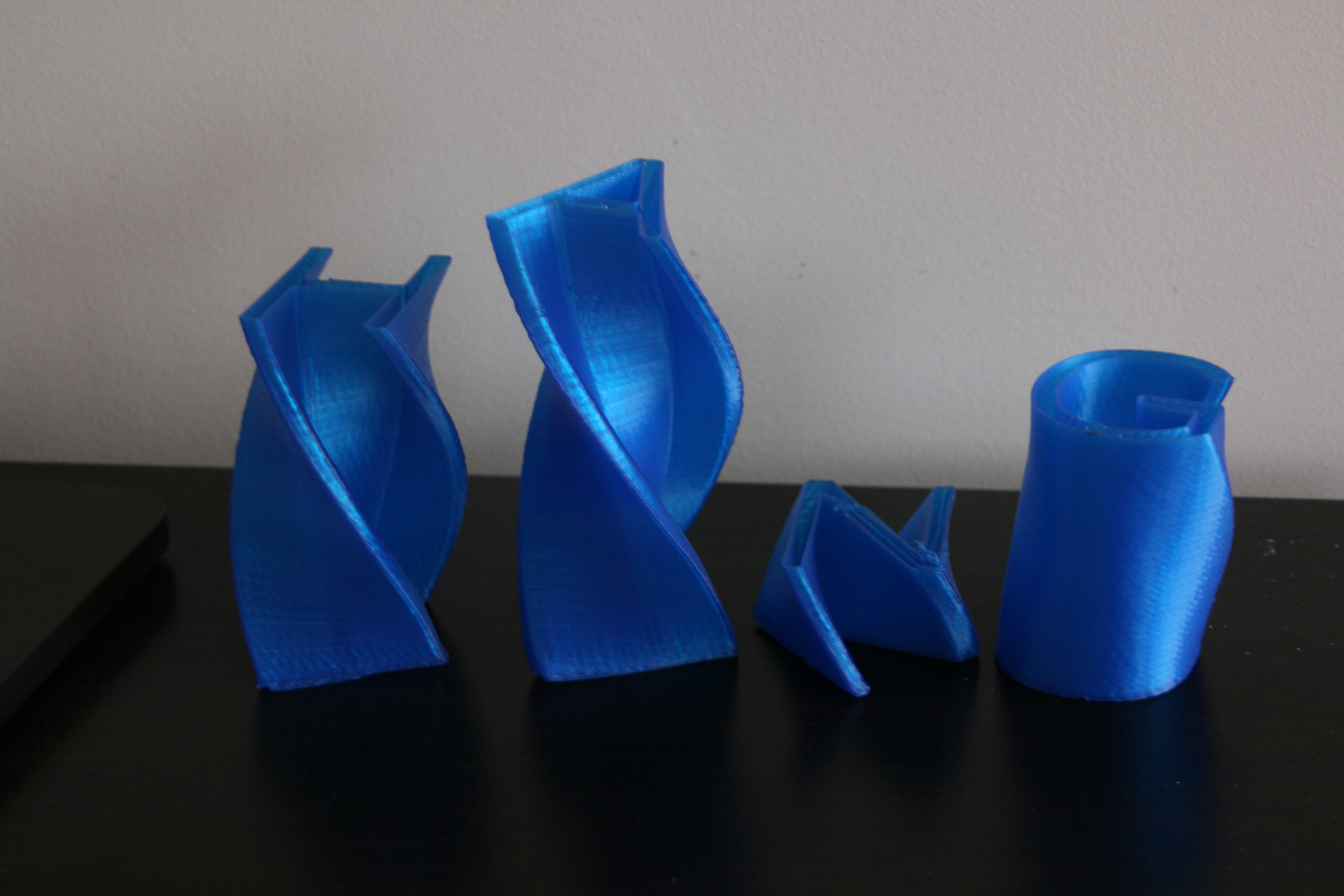

Hangmaker was also involved in more artistic projects - Ludwigsen recently used this system to build a five-foot sculpture of the Tower of Babel.

Hangmaker prints a sculpture of the Tower of Babel. Posted by Thorbjörn Ludwigsen

As the device optimizes, Ludwigsen hopes that Hangprinter will become versatile enough to print furniture, tools, and possibly fully functional mechanisms with moving parts. He also hopes to raise money through crowdfunding to continue research and development in this direction.

Although the current version of Hangprinter is fully functional, there are many upgrades ahead of the device, according to its author. In fact, improvements are another reason why the author decided to develop the project as open-source.

“This is a flexible production technology, so it will be useful in various situations that I cannot foresee. Some of them can be very important / cool / useful. I would not want to hinder important and useful discoveries ,

”he said.

Share your opinion in the comments.