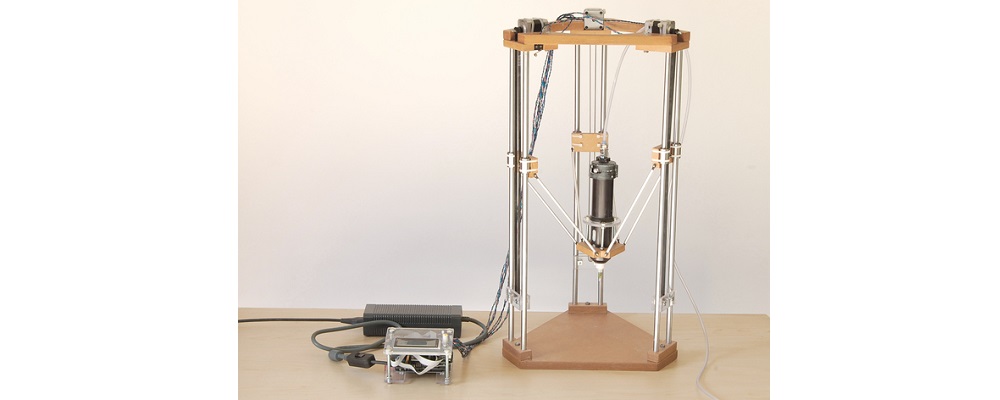

Do-it-yourself Delta 3D printer for ceramics

We talk about creating a simple 3D printer for printing clay products, with your own hands and from available materials.

An article from 3ders.org has been translated for you by the Top 3D Shop .

All photos in the article: Jonathan Keep.

The Belgian design studio Unfold modified the RapMan 3D printer and began printing porcelain dishes back in 2012. The printer could print in thin layers and allowed you to make new forms that are almost impossible to produce using traditional methods in pottery production.

Jonathan Kip was inspired by Unfold, but by then 3D Systems had bought Bits From Bytes - manufacturer RapMan - and ceased production of this printer.. Jonathan decided to develop his own 3D printer , which could replace RapMan.

Jonathan Kip, Model Maker:

“I made this 3D printer specifically for clay printing. I wanted other people - sculptors, designers and potters - to build similar machines for themselves. All parts can be made independently, if you know how to work with your hands at least a little, or order online. I made parts from the simplest materials at hand, I did not want to rely on printed plastic parts. The working area of the printer is 20x20x20 cm, the extruder works with compressed air . "

A 3D printer designed by Jonathan is well suited for layering clay printing. a printerruns on Marlin Firmware firmware. To create models using the free graphic 3D-editor Blender. For slicing models, the Repetier-Host print preparation program can work with slicers like Skeinforge and Slic3R.

Jonathan clay extruder made parts from the Techcon Systems TS Series Dosing Glue Gun. Cartridges went into business, the holder case with a cover, but without a handle. Clay is squeezed out of the cartridge by compressed air, under a pressure of 1.97 atmospheres (approximately 2 kgf / cm2). The printhead holder and cartridge (237 ml) weigh about 650 g with clay. This stock lasts for 1 hour of printing, then the next portion is loaded.

A complete specification of the materials used and assembly instructions can be found on the Jonathan website .

In the video, you can see the process of assembling and connecting the printer and the start of printing:

“By the standards of 3D printers, this is a fairly primitive tool, but it offers an accessible path to an exciting new way to work with clay,” Jonathan writes.

What other 3D printers are easier to develop yourself or upgrade from serial models? What other applications of 3D printing have large manufacturers forgotten? Share your opinion in the comments.