VW study shows Golf-E eco-friendly after 100,000 km

By order of VW, one of the largest studies of the environmental “cost” of the production and operation of an electric vehicle and a similar ICE vehicle was carried out, which took into account a large number of factors, including sources of electricity used to propel the vehicle, recycling, and total CO2 emissions both during production and during operation. VW himself called this approach “Cradle to Grave” (free translation: “from the cradle to the coffin”).

To get the most accurate representation, “similar” cars were chosen, that is, electric golf, as well as golf with diesel ICE, gasoline ICE and gas ICE.

How deep and labor-intensive this study was can be seen in the calculation of data for a car tire. Not only the energy necessary for its manufacture is taken into account, but also the energy costs for producing soot, quartz sand, steel cord, nylon and other components, including energy costs for various stages of production, such as vulcanization. It was also taken into account from which sources the electricity was obtained in the places of production / production of raw materials, or where the individual stages of production took place.

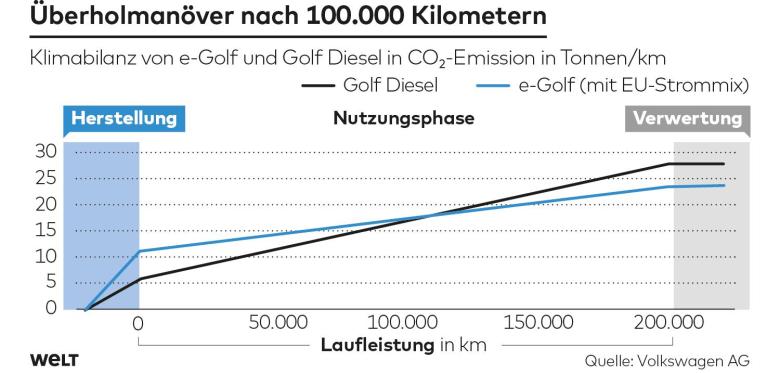

For each car, a similar calculation was made for 3000-5000 parts necessary for its manufacture in order to ultimately receive the total costs in the form of the amount of CO2 emissions. Similar calculations were made to take into account the cost of generating electricity in different regions, as well as for the fuel needed to move the car. From the point of view of VW, such an analysis shows that in the end, an electric car will be more environmentally friendly than a car with an internal combustion engine, though after 100,000 km and if we assume that the life of a modern car is 200,000 km.

In absolute terms, the cost of producing diesel golf is five tons of CO2 , while electro-golf requires twelve tons .

After 100,000 km, electro-golf will be equal in emissions to diesel golf and in the future its final eco-balance to 200,000 km will be positive in comparison with a diesel car. 25 tons of CO2 for an electric car versus 30 tons of CO2 for diesel golf.

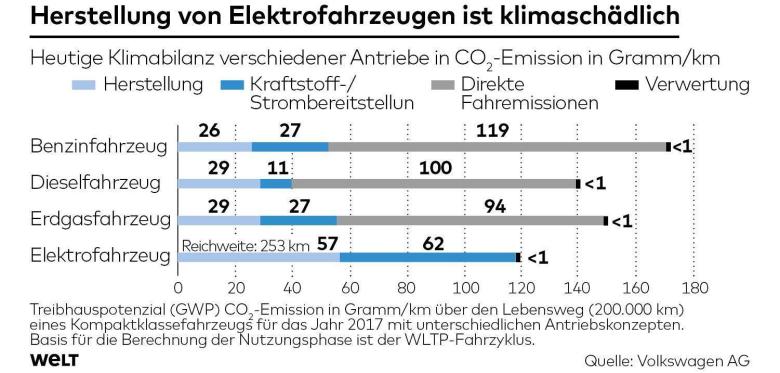

If we take into account only the cost of a kilometer, even with the current "mixed" electricity (from non-renewable and renewable energy sources), electric golf has a better eco-balance in comparison with any other types of drives. For comparison, we used the calculation according to the WLTP cycle, in which electro-golf is capable of driving 253 km on a single charge. In numbers, it looks like this: 120g / km for electro-golf, 140g / km for diesel golf, 151g/ km for LPG golf and 173g / km for gasoline golf.

VW tried to extrapolate the calculations for all drive options until 2030. Given the further development of batteries, which will increase mileage up to 438 km from a single charge and increase the share of electricity from renewable sources, we get a reduction in emissions to 95 g / km of track for electric golf.

ICEs should also improve their readings primarily through the introduction of an additional electric motor. (Note: most likely referring to the mild-Hybrid version with a 48-volt on-board network, when using a hybrid starter-generator that can effectively use recovery during braking, a similar system is already installed on some German cars). Then the estimated amount of CO2 emissions for diesel and gas golf will decrease to 114g / km of track, for gasoline - to 135g / km of track.

Note from the translator: at one time, we drove over 50,000 km on an Audi A2 car with a 1.4 TDI diesel engine at 75 hp. The car entered the market back in 1999. From the very beginning of the operation, the actual fuel consumption by checks from the gas station was recorded, therefore it is quite simple to calculate the CO2 emissions per kilometer of the way. In our case, it turned out 118g / km. And this is not the most economical version, since the A2 3L 1.2 TDI, the so-called “drei Liter Auto”, was produced, which in the combined cycle was content with three liters of diesel per 100 km of track. If you look at the data on spritmonitor, then the average emission in the region of 87g/ km of track for such a car is a very real story. This car in terms of comfort (in the four-seater version) is still somewhat more convenient than even the seventh golf course and is not inferior to it in the size of the trunk.

The fact that the production of an electric car is noticeably more expensive than a car with an internal combustion engine is mainly associated with the cost of producing an electric battery. It accounts for more than 40% of total emissions. VW assumes that, due to further improvement of production technologies, by 2030 the amount of emissions in the battery manufacturing process will be reduced by 30%, and by 2050 - by 50%.

One of the important factors when taking into account the amount of CO2 emissions from both the production and operation of an electric vehicle is how the electricity was generated. At present, electric golf produced in Germany and driving 200,000 km in Germany will be responsible for the emission of 142 g / km of track (in the USA - exactly the same), on average in the EU countries - 119 g / km of track (Note: Germany is still quite actively using coal stations to produce electricity, although their percentage is decreasing every year). If you operate an electric vehicle exclusively using wind power, then it will be responsible for the emission of 59g / km of track. In China, where the prevailing share of non-renewable energy power plants is 183g / km of track.

VW intends to reduce CO2 emissions from battery production through the use of recyclable materials. Thus, only during cathode production is it possible to reduce the emission level by 30%. If, for processing, electricity from renewable sources is also used, then the savings will reach 50%.

Note 1.

Recently there was news that Audi will not be able to assemble the planned 55,000 e-tron electric vehicles this year, instead it is planned to assemble 45,000 cars. The reason is the battery supplier LG-Chen is unable to supply the required number of batteries. The Volvo Polestar division also faced the same problems. The provider is the same.

Note 2

In Germany at the beginning of 2018 very strong winds blew and a paradoxical situation developed when more electricity was generated due to wind energy than was necessary. Since there are currently no systems capable of storing large amounts of electricity, this has led to negative electricity prices on the spot electricity market on such days. In total , negative electricity prices operated for 140 hours .

Here you can see in the tablet by month when there was a negative price.

Note 3

The consequence of the fact that there are no systems capable of storing a large amount of electricity, and the generation of wind / solar energy is poorly predicted, is the need for a complete duplication of all alternative energy sources, since there are often cases when alternative energy produces too little of it. The most popular solution for duplication is the use of gas power plants, since they allow you to quickly regulate the generation of electricity. Unfortunately, the ecological balance of CO2 in this case is worse than if the gas-fired power plant was constantly operating in optimal mode without alternative energy sources. The second consequence of the need for duplication is one of the highest electricity prices in the European Union.

A full report in PDF format is available atlink .

Source .