Test drive nanoCAD SPDS Metalwork 1.2. Part 2

- Tutorial

Test drive nanoCAD SPDS Metalwork 1.2 Part 2

We continue to publish the test drive for nanoCAD SPDS Metalware. In the first part of the test drive, we began to build a production framework. In the second part, we will look at how to create vertical ties, struts, runs and place them on the plan, as well as create a cross section. In the final part, we will look at how to create a longitudinal section, create nodes, layout drawings on a sheet format, and create specifications.

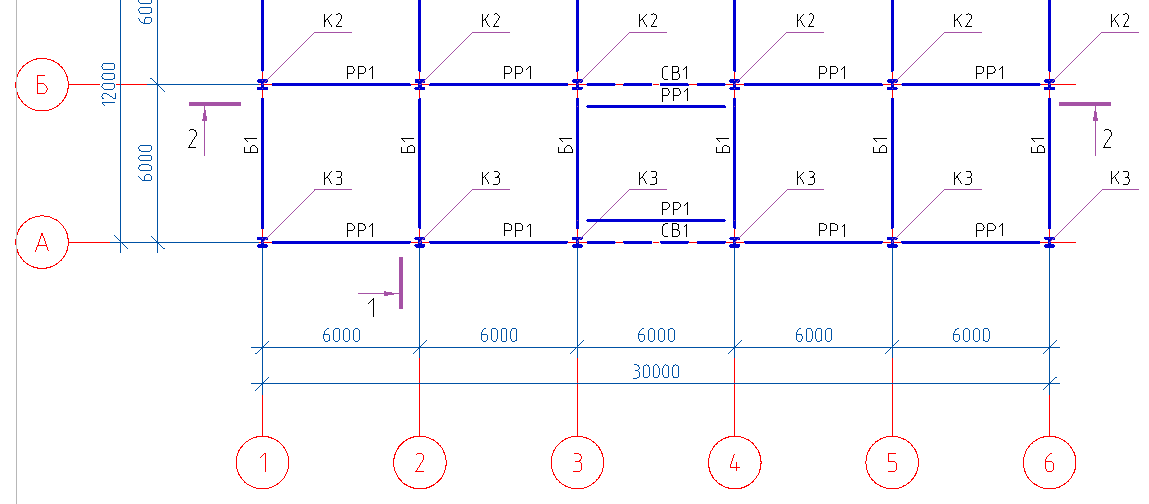

Chapter 6. Creating vertical links and placing them on the plan

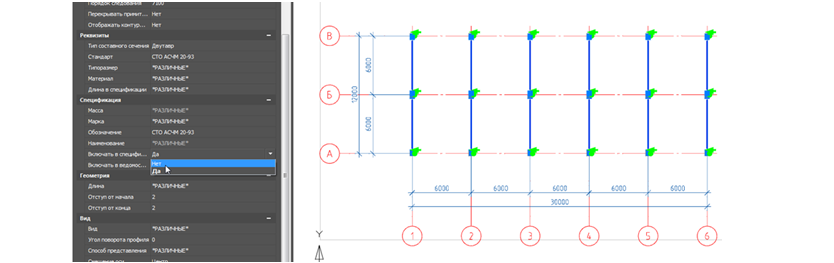

6.1. On the Metalwork toolbar, call the Beam command, then in the dialog box that appears, set the necessary parameters.

6.2. In the dialog we set the necessary parameters for the beam:

- We select a square pipe profile according to GOST 8639-82 standard size 100x5. Material of steel is C245.

- View from above".

- The mapping is "conditional."

- In the Geometry tab, leave unchanged (indicate on the drawing).

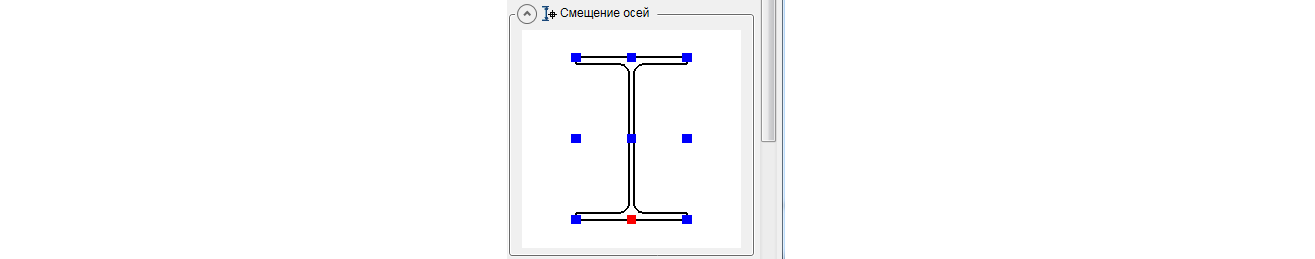

- The Axis Offset tab is left unchanged (center of section).

- The Rotation tab is left unchanged (rotation "0").

- Marking tab is left unchanged (leader of linear structures, position).

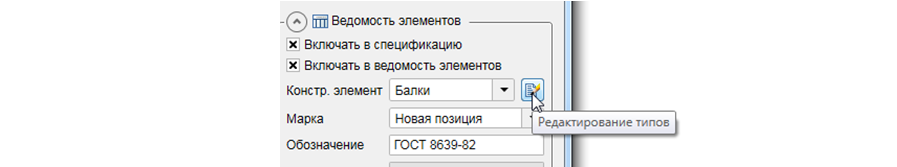

- In the List of elements tab, check the boxes Include in the specification and Include in the list of elements.

- Change the type of feature by clicking on the Type Editing icon.

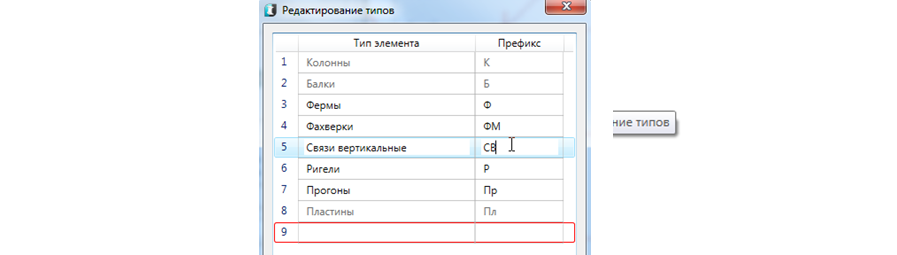

6.3. In the type editing dialog, we change the line: Element type - Vertical links, prefix - CB. After the change, click OK.

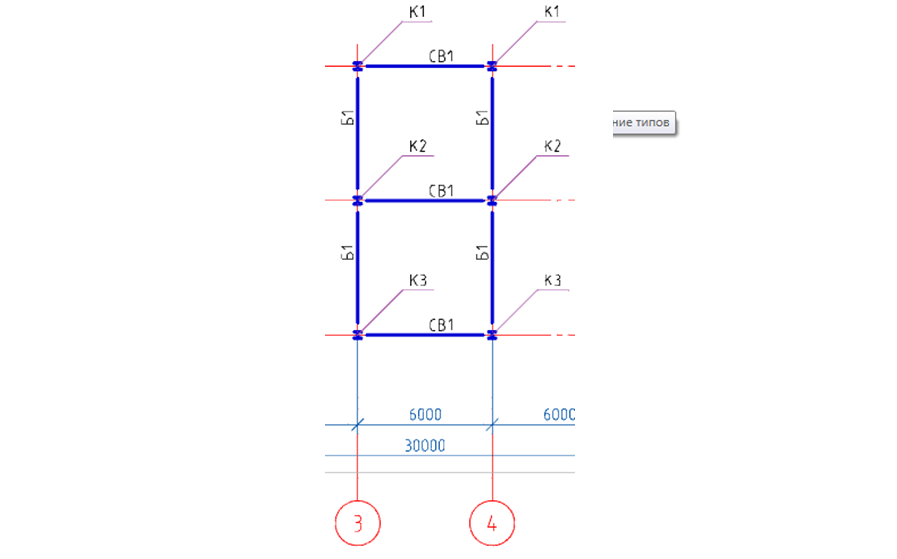

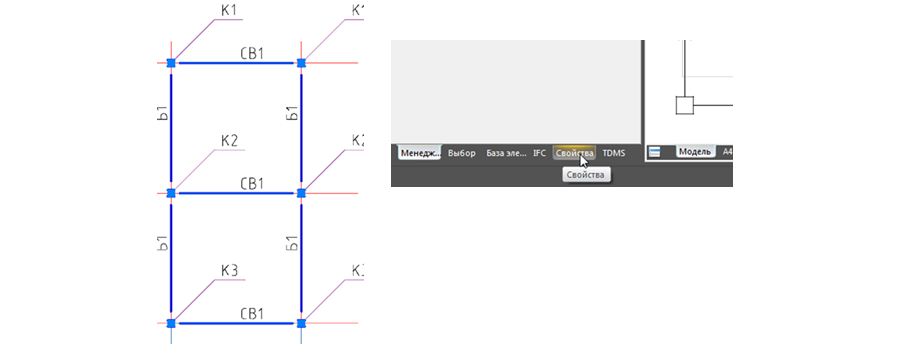

6.4. The dialog of the Beams window has changed to Vertical links, then click OK and arrange the links between the “3-4” axes.

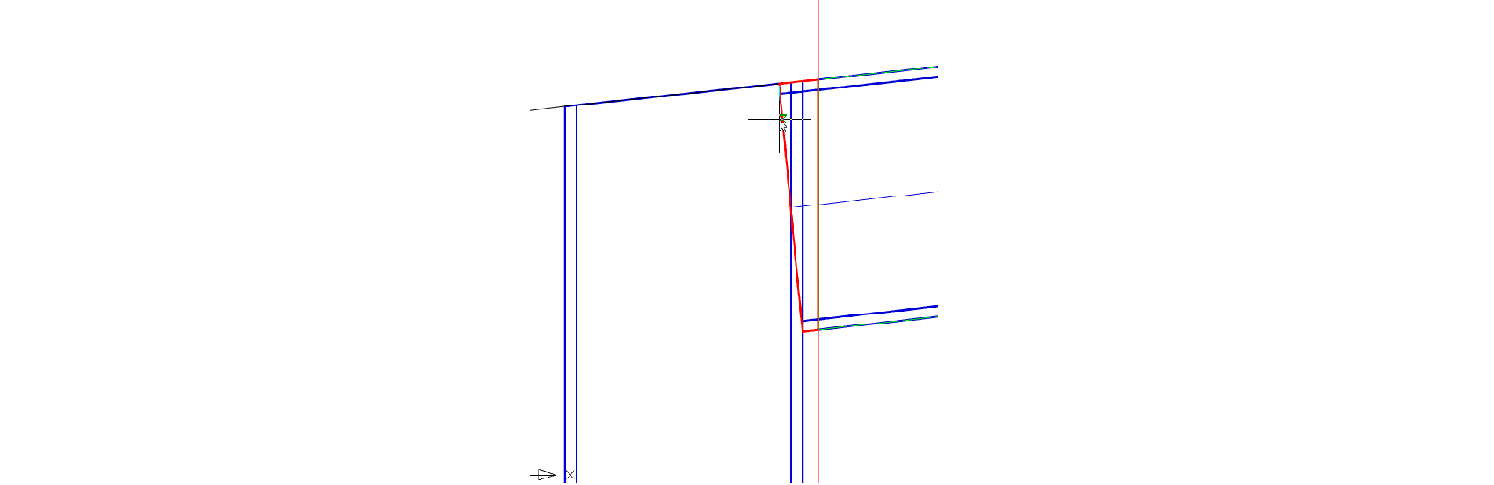

6.5. We select CB1 on the communication plan, then go to the Properties tab.

6.6. in the properties window for CB1 bonds, change the type of lines to dashed lines.

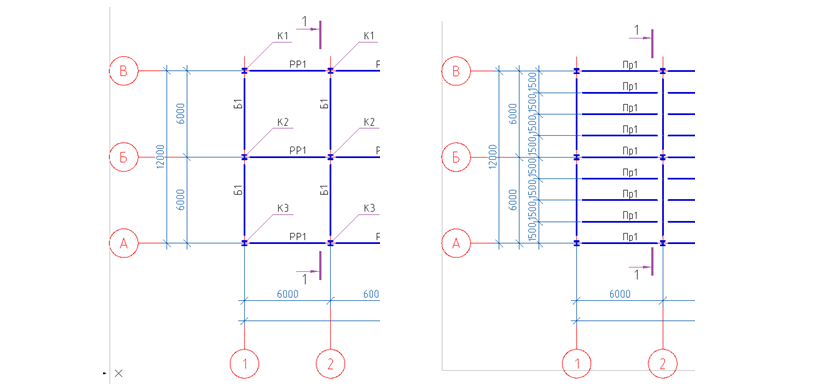

Chapter 7. Creating spacers and placing them on the plan

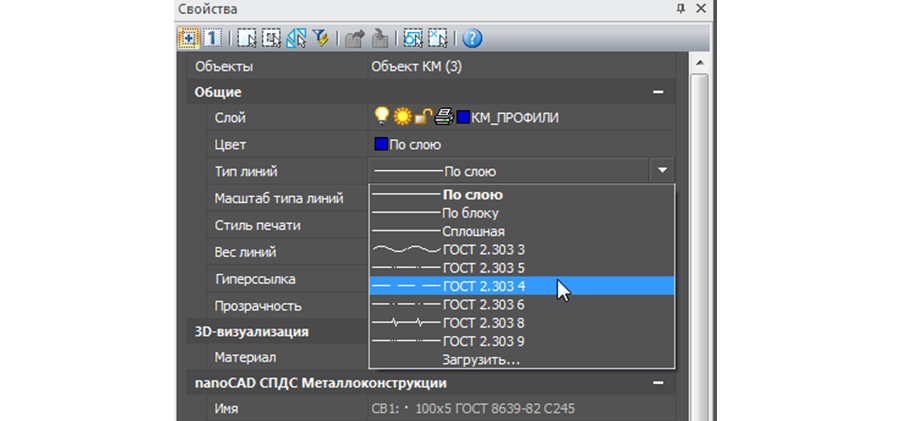

7.1. Now you need to place the spacers along the axis "A", "B", "C". To do this, call the Beam command again. In the dialog box that appears, the program has already saved the previously entered parameters (for CB1 links).

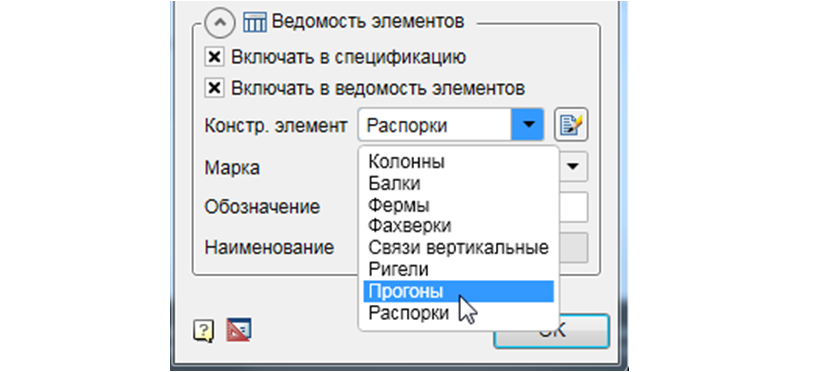

7.2. We change the type of the structural element by clicking on the Type Editing icon.

In the type editing dialog, we change the line: Element type - Spacers, Prefix - PP. After the change, click OK

7.3. The dialog window of the Vertical Links window has changed to Spacers, then click OK and arrange the spacers along the letter axes.

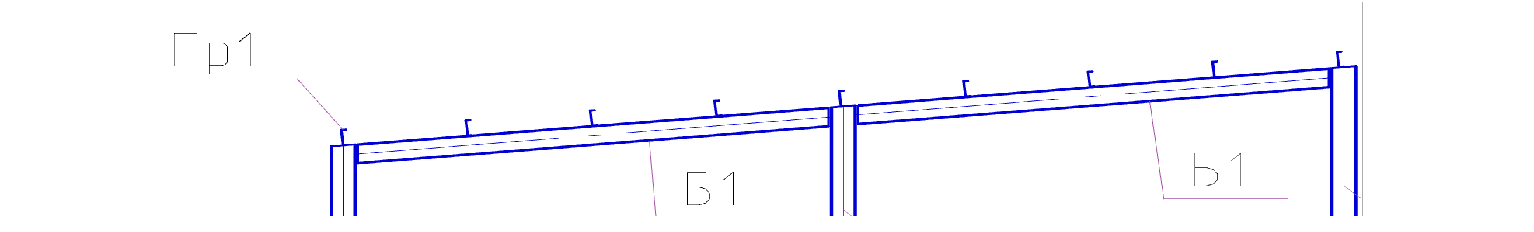

Chapter 8. Creating runs and placing them on the plan

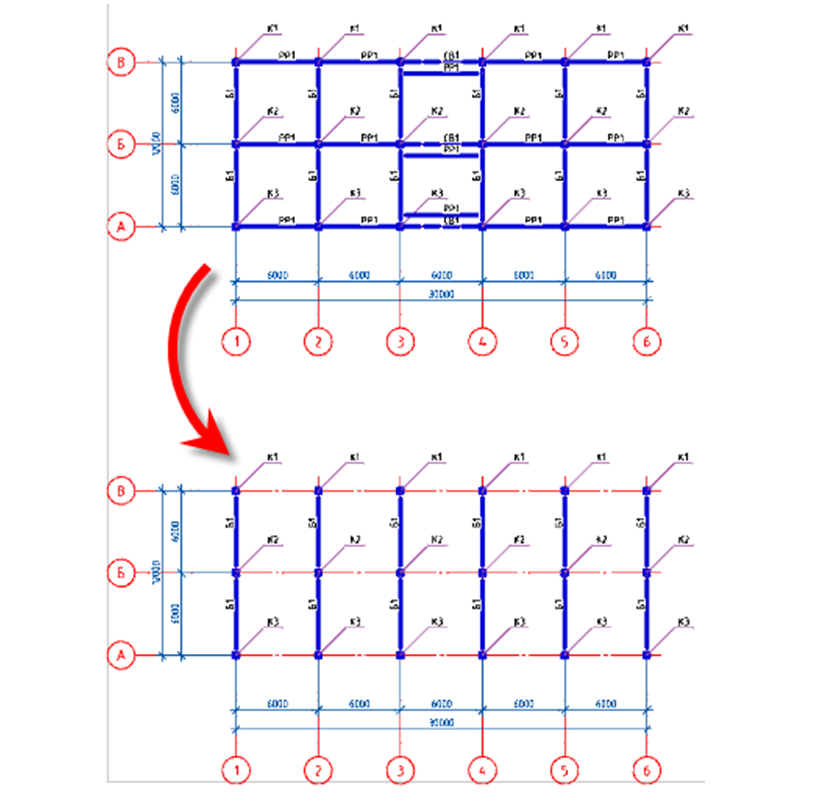

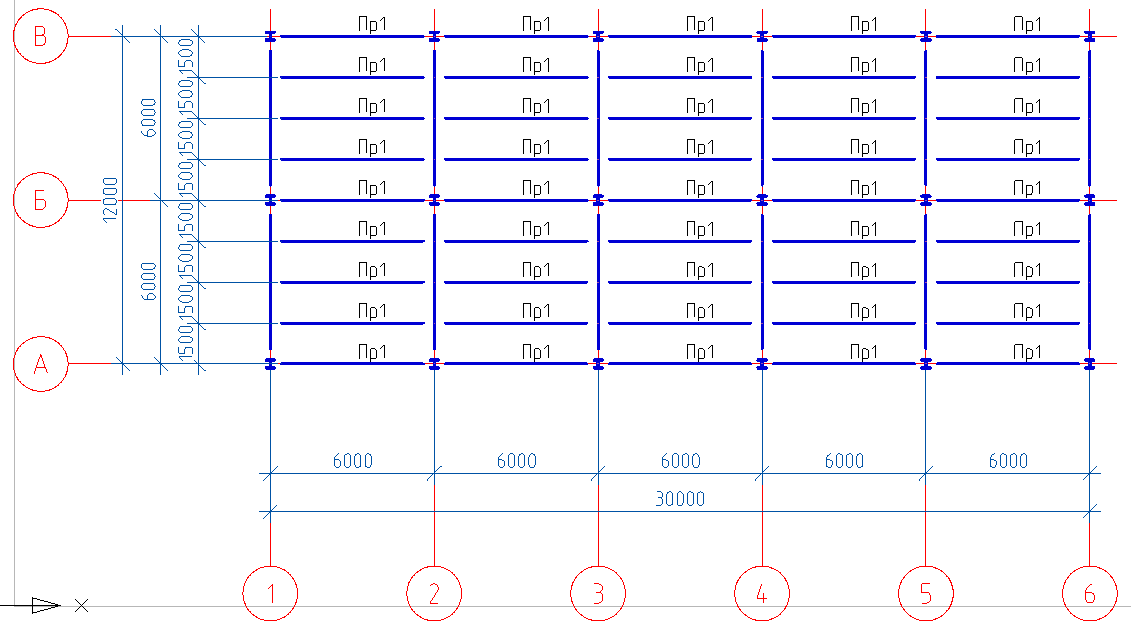

8.1. We will create a separate plan for placing the runs, for this we select a grid of axes with dimensions, columns, beams and copy them to an empty spot in the drawing model.

8.2. On the copied plan, select all the notation, and then delete them with the Delete command.

8.3. Having removed the notation, we select all columns and beams, then go to the Properties tab and for all selected elements we change the attribute Include in the specification - None. This is done so that the same elements are not included in the specification twice.

8.4. On the Metalwork toolbar, call the Beam command, then in the dialog box that appears, set the necessary parameters.

- We select the channel profile according to the standard GOST 8240-97 of standard size 24L. Material of steel is C245.

- View from above".

- The mapping is "conditional."

- In the Geometry tab, leave unchanged (indicate on the drawing).

- The Axis Offset tab is left unchanged (center of section).

- The Rotation tab is left unchanged (rotation "0").

- Marking tab is left unchanged (leader of linear structures, position).

- In the List of elements tab, check the boxes Include in the specification and Include in the list of elements.

- Change the type of feature to Runs.

8.5. Having set all the parameters, click OK and arrange the runs between the digital axes in increments of 1500 mm.

Attention! It is not necessary to insert features one at a time several times, you can insert one feature, and then simply copy it.

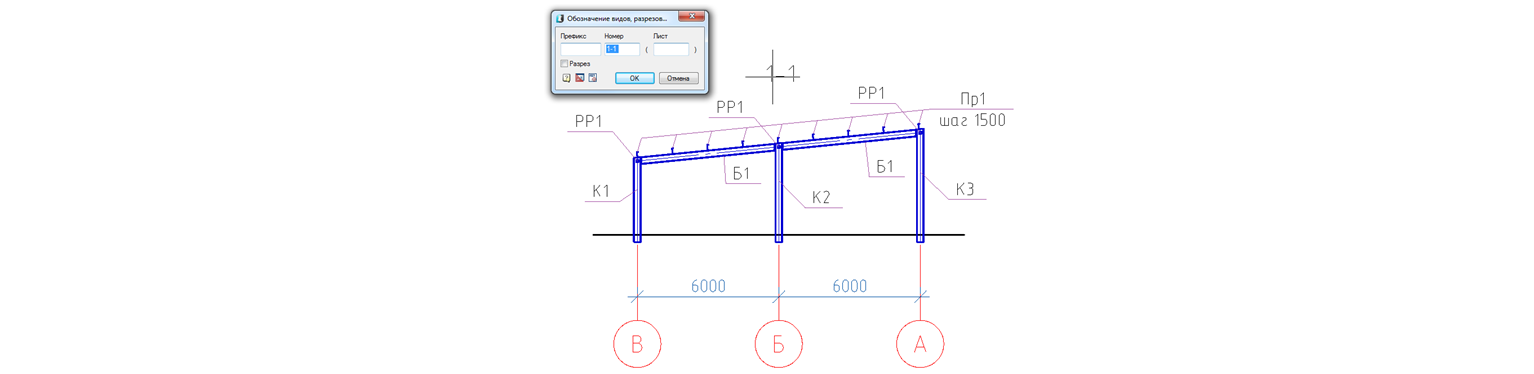

Chapter 9. Creating a cross section

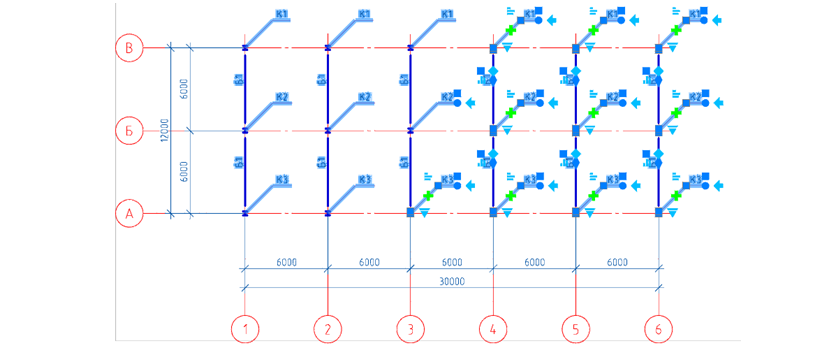

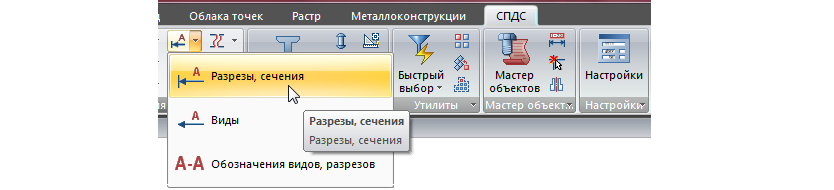

9.1. On the SPDS toolbar, call the command Sections, sections.

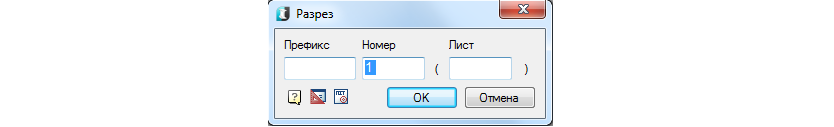

9.2. In the dialog box, specify the number - 1 and click OK.

9.3. Place the designation of the section “1-1” along the axis “2” on both plans.

9.4. Place the designation of the section “2-2” along the axis “B” on both plans.

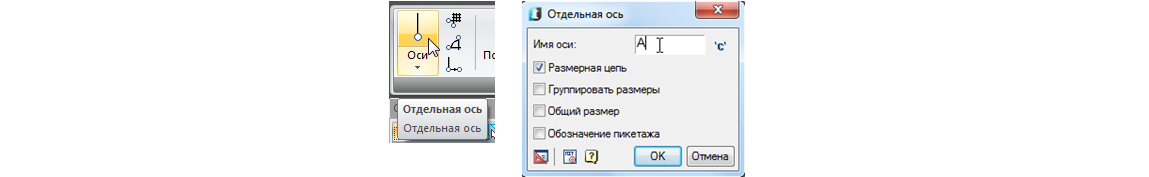

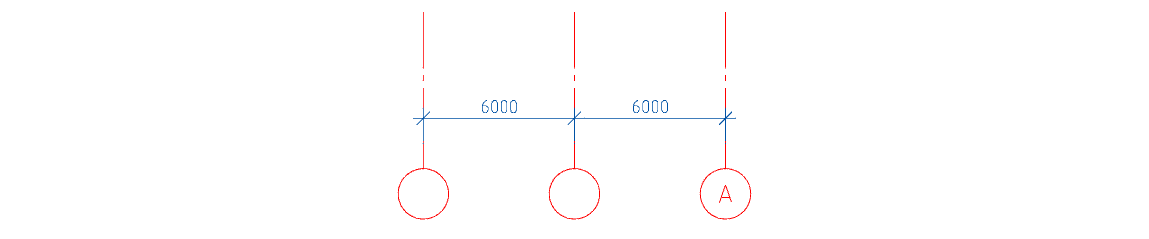

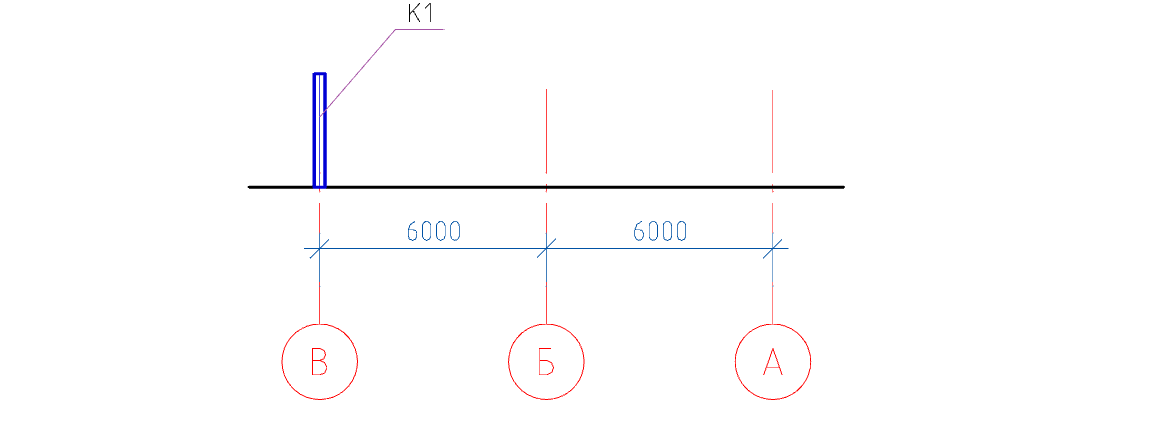

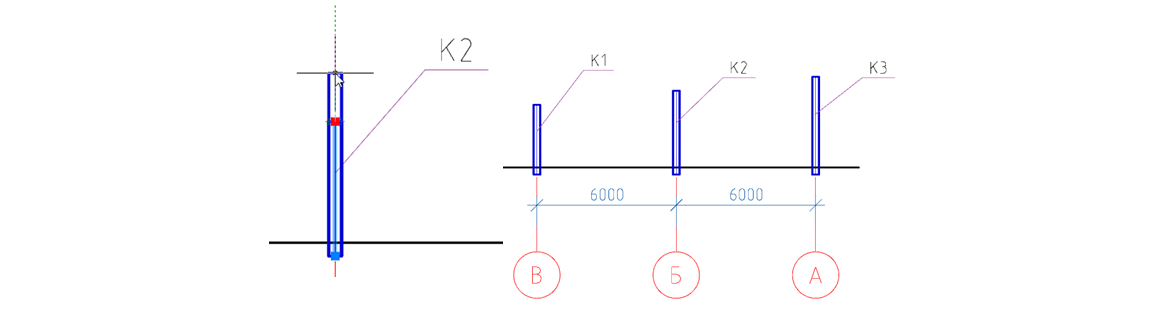

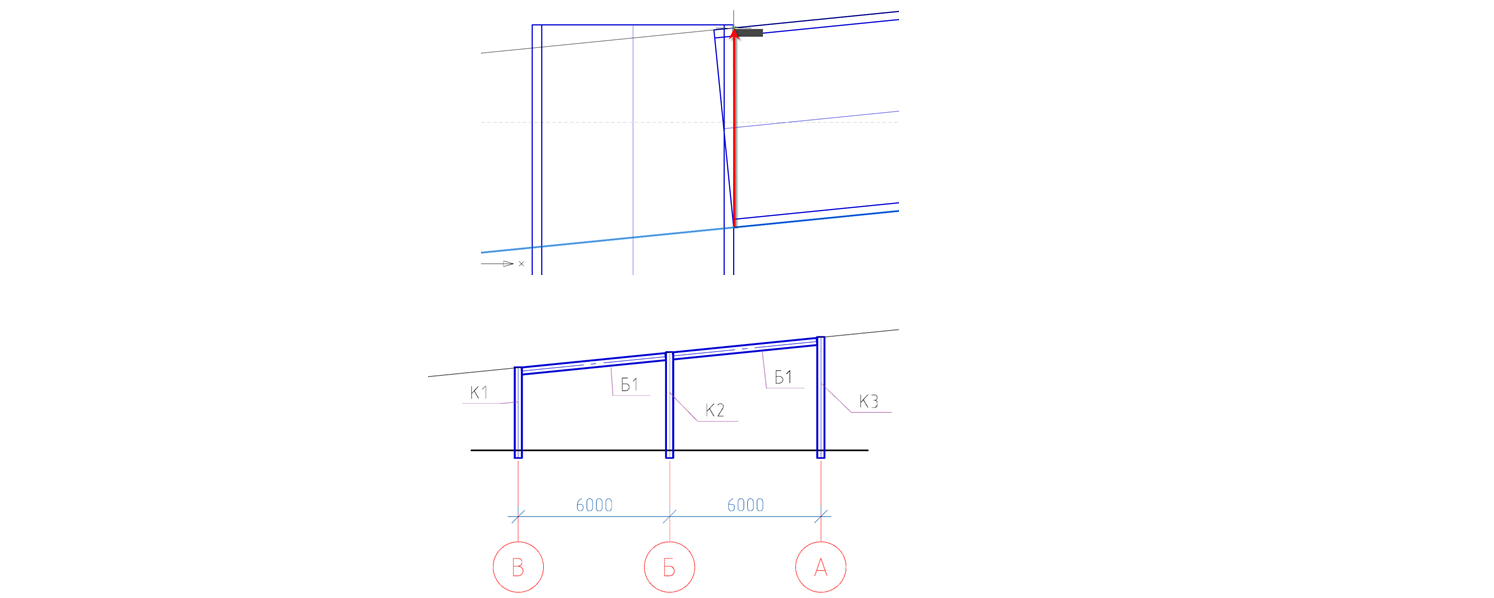

9.5. We proceed to the construction of section 1-1. On the SPDS toolbar, call the Single Axis command, set the name of the axis “A” and tick the Dimension chain.

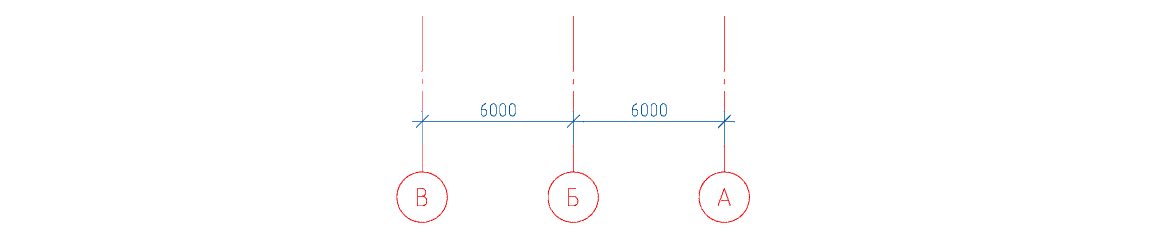

9.6. We place the individual axes from right to left indicating the value 6000 in the command line.

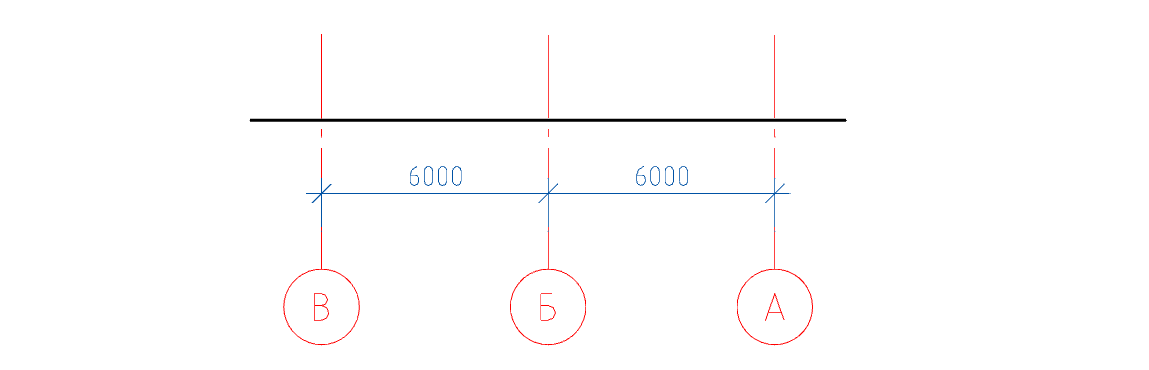

9.7. Rename the axes.

9.8. In the section, using the Line command, we show the floor level.

9.9. On the Metalwork toolbar, call the Column command, then in the dialog box that appears, set the necessary parameters

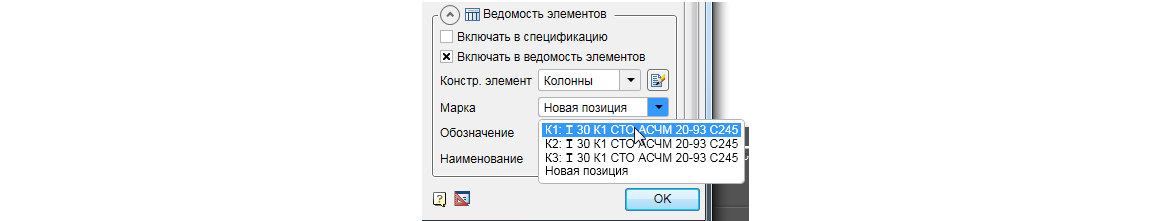

- In the List of elements tab, uncheck Include in the specification and select from the list the previously created brand of column K1.

- Front view".

- The display is “full”.

- In the Geometry tab, set the base mark to -300, and leave the head mark at default 3000 (we will adjust the mark of the head when constructing the section).

- The Axis Offset tab is left unchanged (center of section).

- The Rotation tab is left unchanged (rotation "0").

- Marking tab is left unchanged (position leader, position).

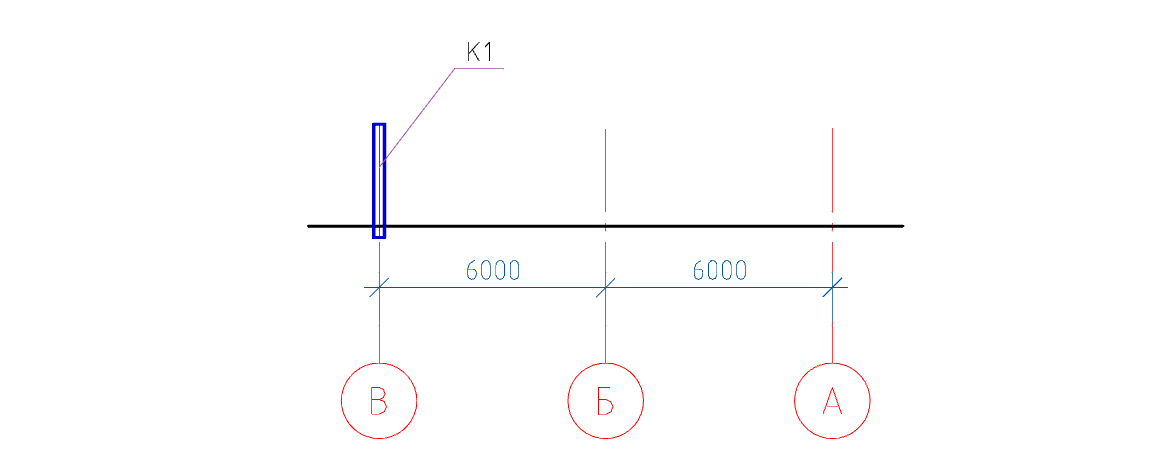

9.10. Having set all the parameters, click OK and place the column along the "B" axis.

9.11. Move the column 300 mm down.

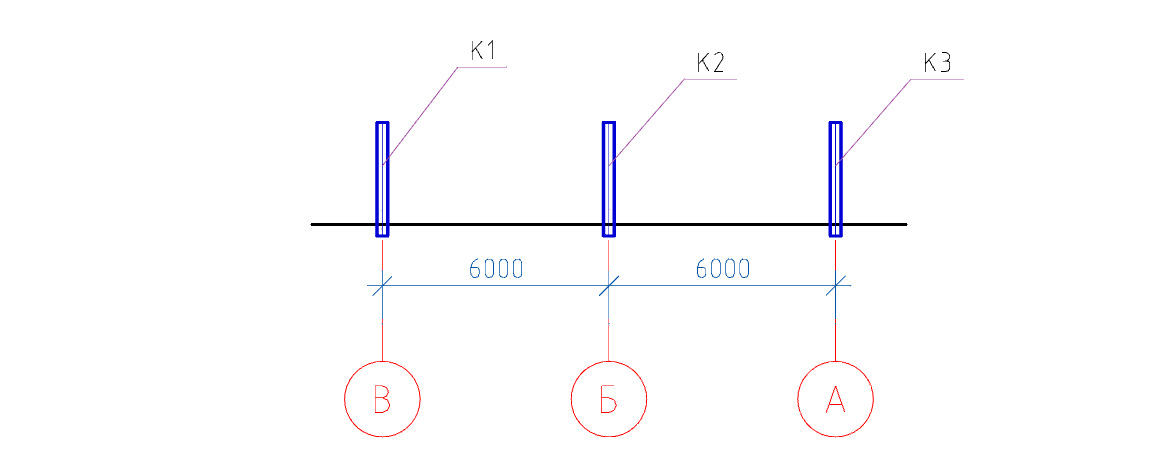

9.12. According to the description of the actions in paragraphs 9.9-9.11, insert and displace the columns K2, K3.

9.13. Using the extension handles, we increase the length of the K2 column by 600 mm, K3 by 1200 mm.

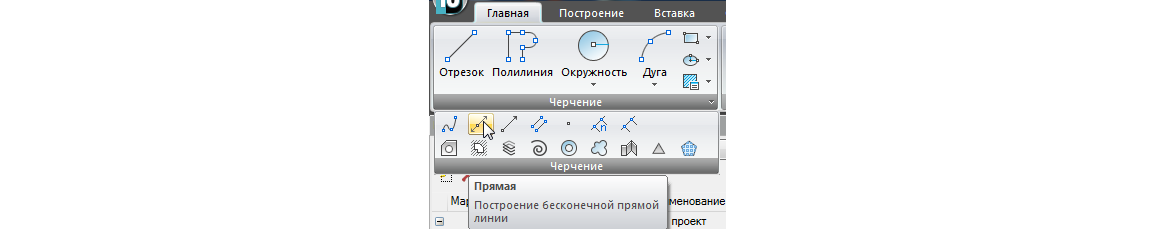

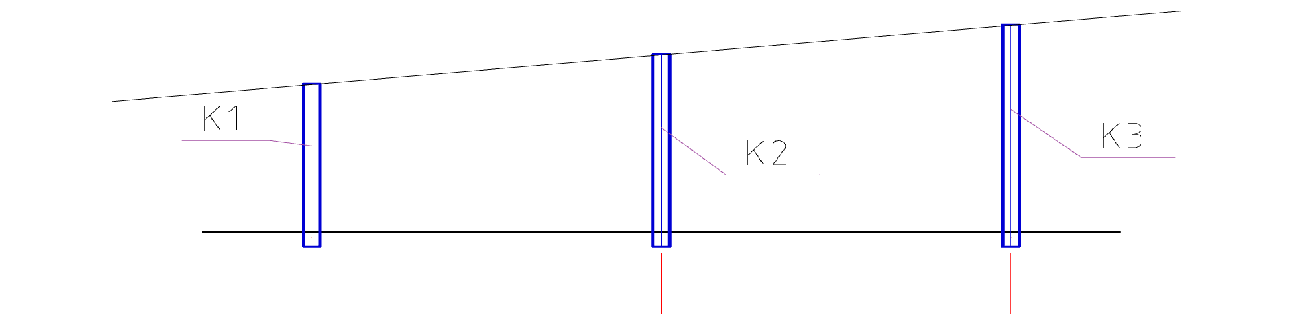

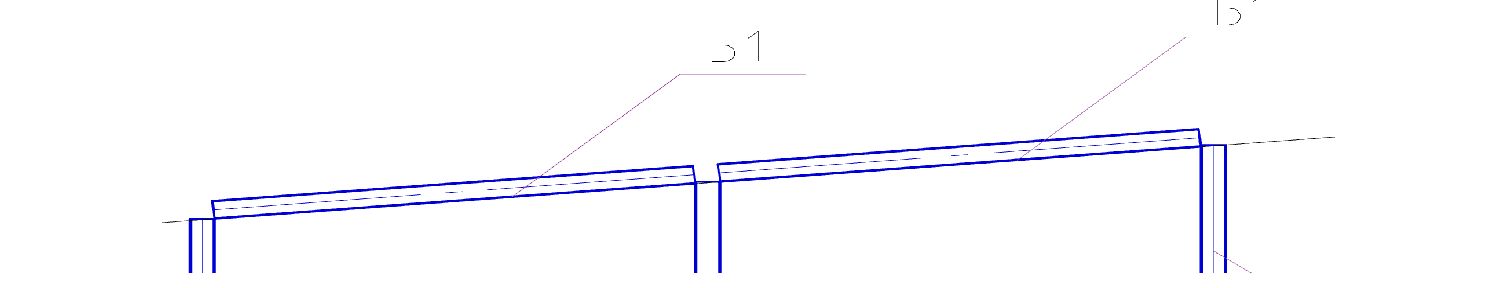

9.14. Using the Direct command, create a slope for the beams by connecting the upper right corner of the columns K1 and K3.

9.15. On the Metalwork toolbar, call the Beam command, then in the dialog box that appears, set the necessary parameters.

9.16. First, at the top of the dialog, you must click on the Insert several icon so that with several successive inserts in the drawing of this beam its mark does not automatically change (the beam will be inserted with one mark).

- In the List of elements tab, change the Type of a structural element to (beams).

- Select the previously created brand B1.

- Front view".

- The display is “full”.

- In the Geometry tab, leave unchanged (indicate on the drawing).

- Set the Axis Offset tab (bottom to center).

- The Rotation tab is left unchanged (rotation "0").

- Marking tab is changed to (position leader, position).

- In the List of elements tab, the Include in the specification checkbox should be unchecked.

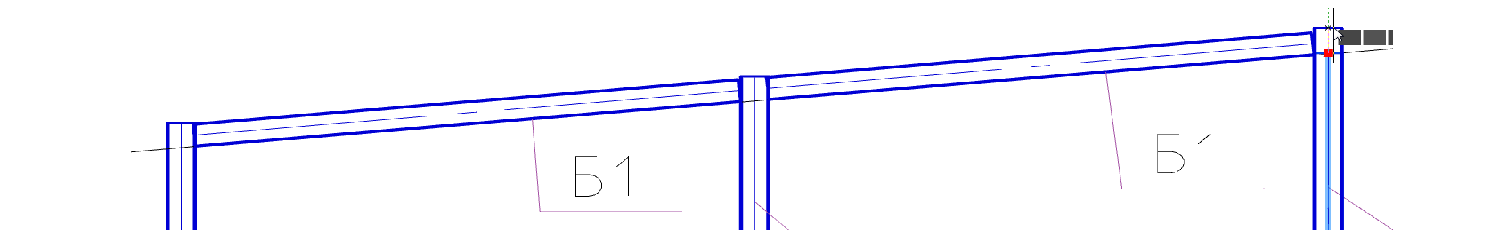

9.17. Having set all the parameters, click OK and place the beams on the auxiliary line between the axes "BB and BA".

9.18. Using the handles of stretching, we extend the columns upwards by 300 mm.

9.19. Move the auxiliary line to the upper shelf of beam B1.

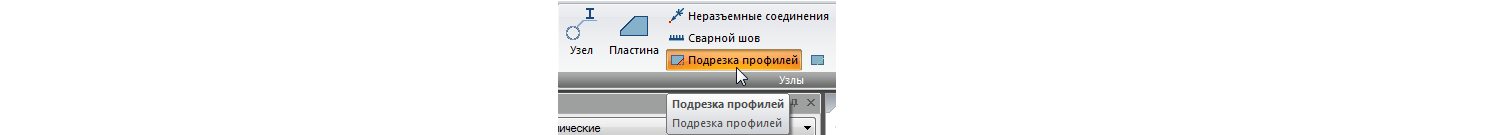

9.20. We will trim the top of the columns, for this we will call the Trimming profiles command.

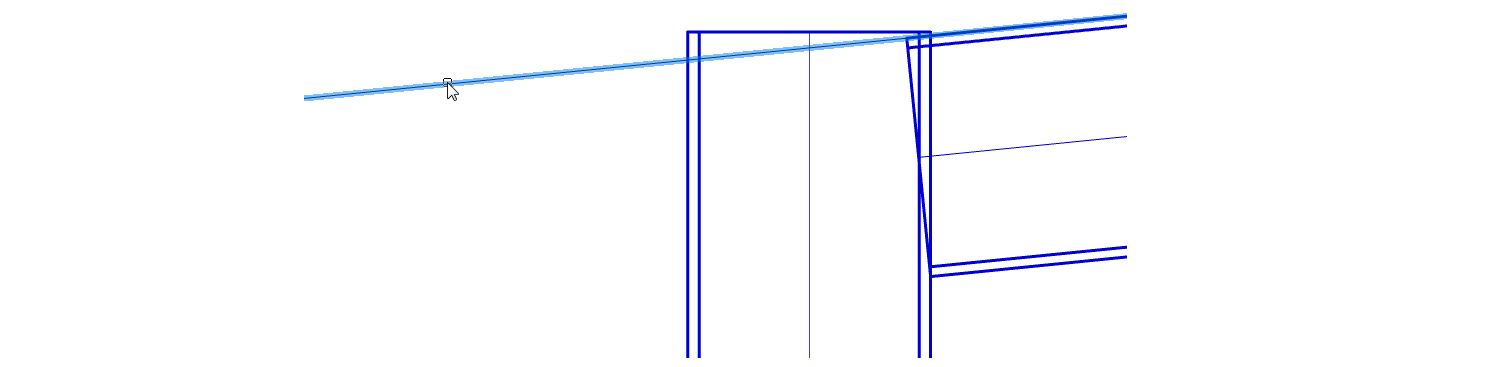

9.21. Specify the auxiliary line as the clipping path.

9.22. Press Enter and point to the cursor to trim the top of the columns. By clicking the left mouse button, we trim.

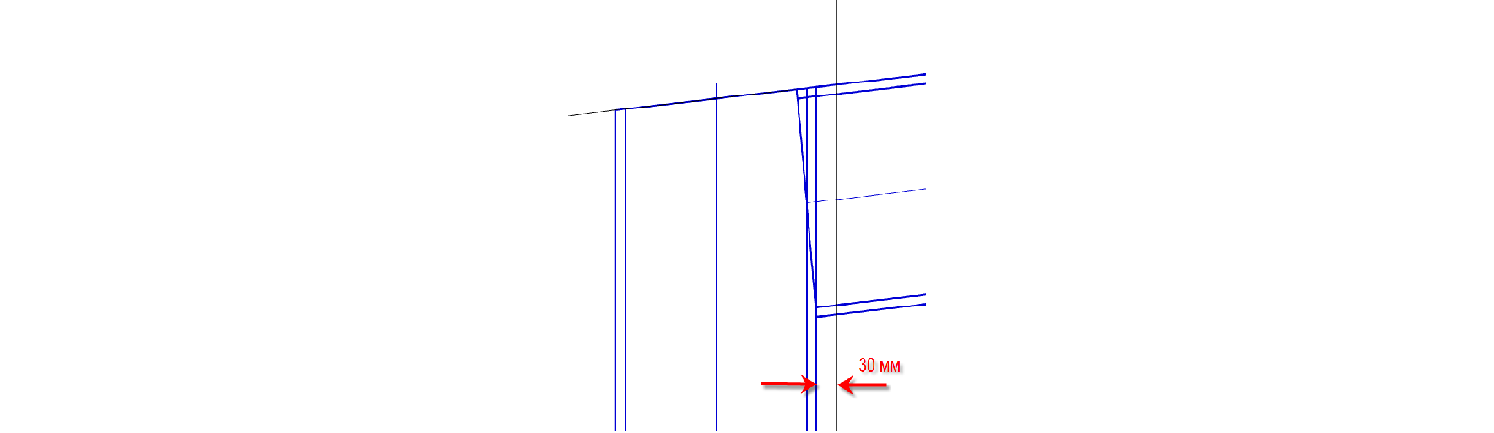

9.23. Create auxiliary lines (see clause 9.14) for trimming beams.

The auxiliary lines will be indented from the edge of the column by 30 mm.

9.24. We will trim the B1 beams, for this we will call the Profile Trimming command.

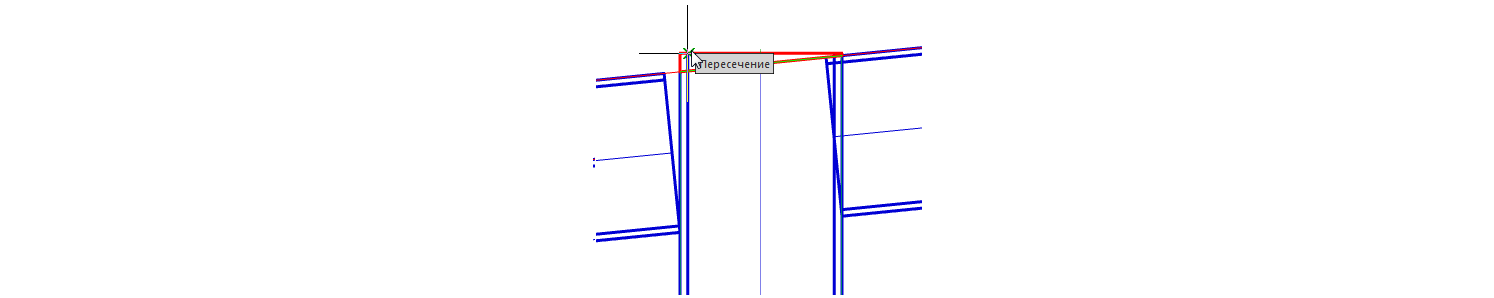

9.25. Specify a vertical auxiliary line as the clipping path.

9.26. Press Enter and point to the cursor where the beam is trimmed. By clicking the left mouse button, we trim.

9.27. After trimming the beams B1, we remove the auxiliary lines.

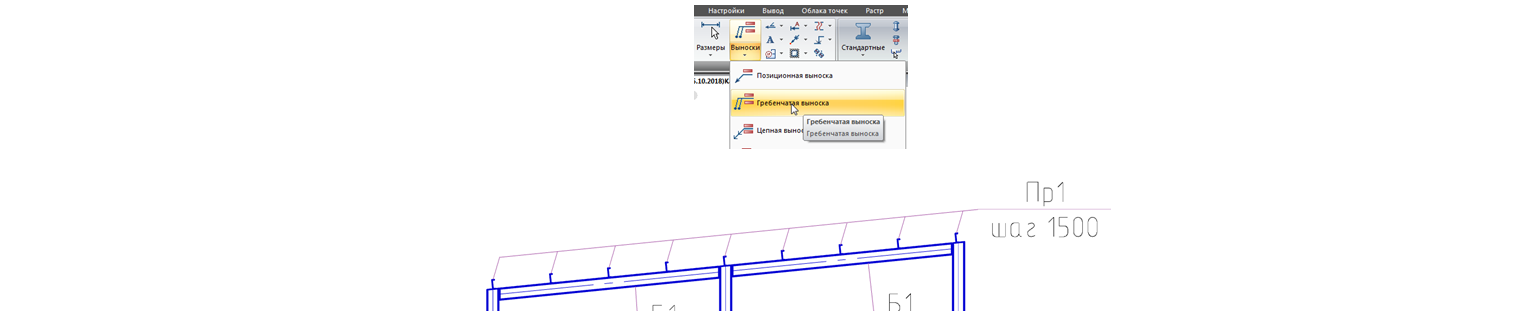

9.28. We show the runs in the section, for this we call the Beam command, then in the dialog box that appears, set the necessary parameters.

- In the List of elements tab, select the type of the structural element Runs.

- We select the previously created brand Pr1.

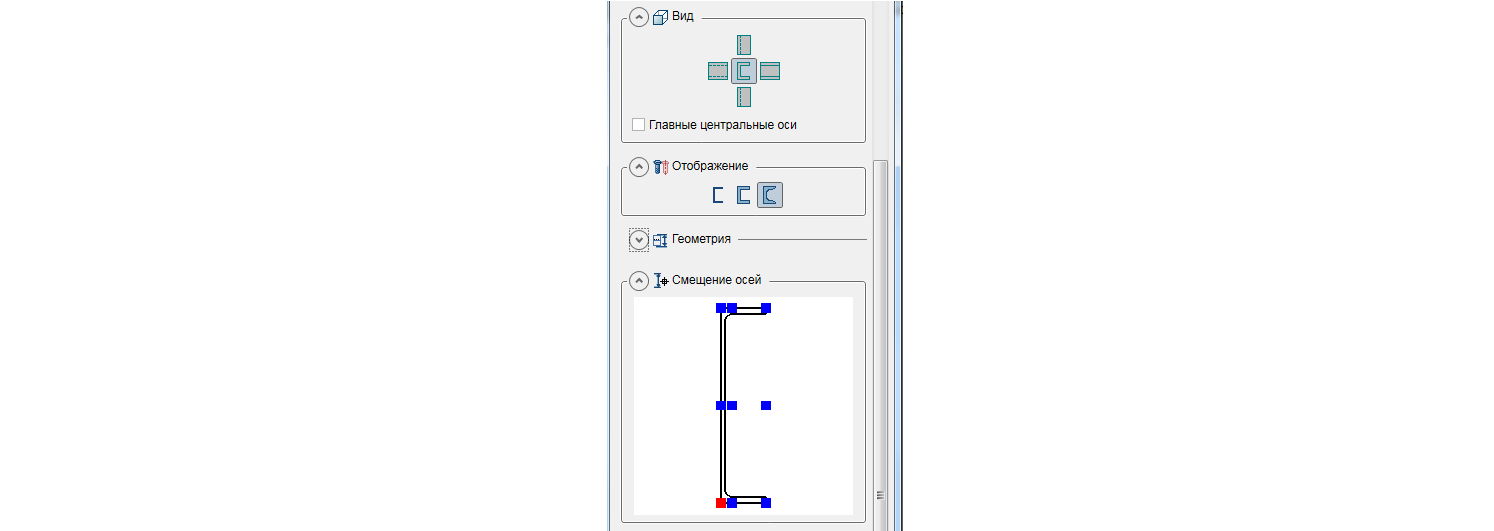

- View - "section". The main central axis - uncheck.

- The display is “full”.

- In the Geometry tab, leave unchanged (indicate on the drawing).

- In the Axis Offset tab, set (bottom on the left corner).

- In the Rotation tab, leave it unchanged (rotation "0").

- In the Marking tab, remove the designation (no).

- In the List of elements tab, the Include in the specification checkbox should be unchecked.

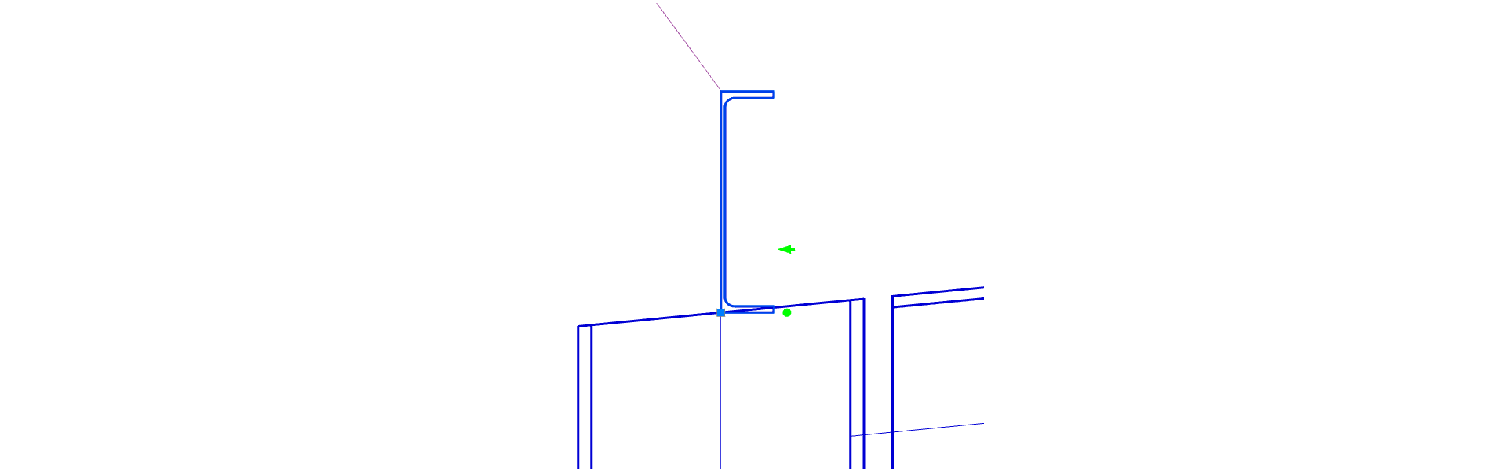

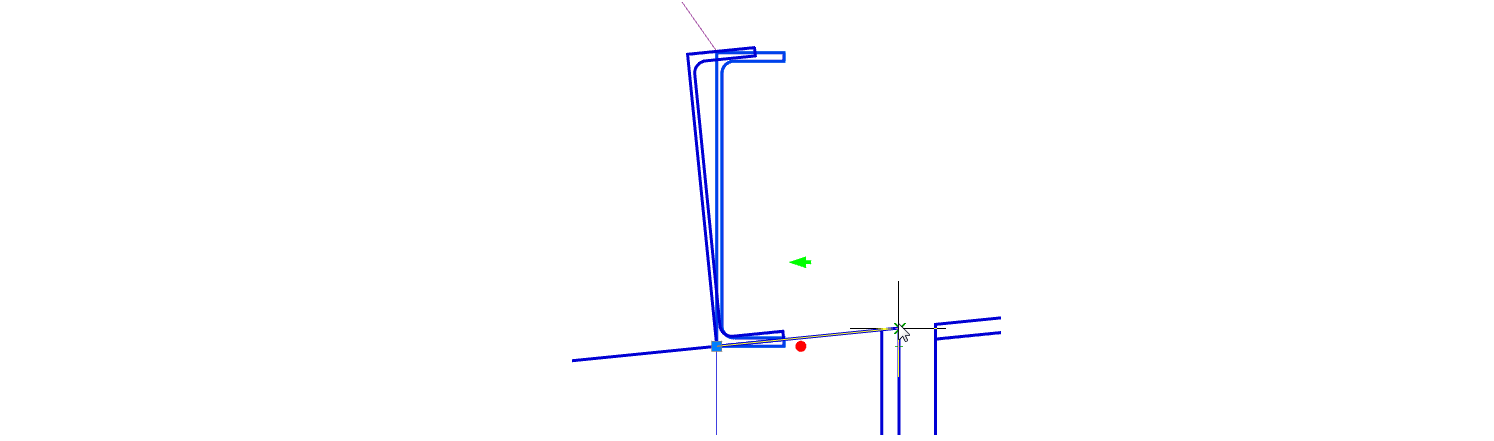

9.29. Having set all the parameters, click OK and place the run along the “B” axis

9.30. Change the position of the run with the rotary knob.

9.31. Copy the slope run in increments of 1500 mm.

9.32. Using the SPDS tools, set the comb leader to runs

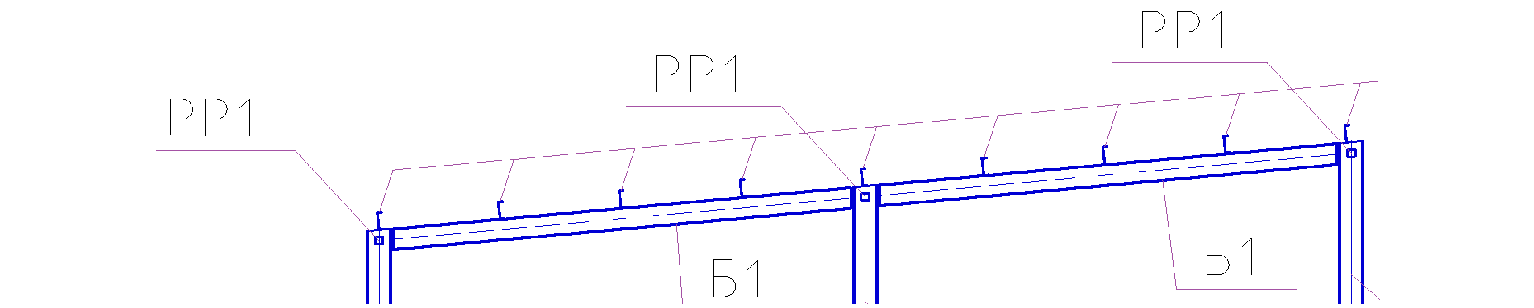

9.33. We show on the cross-section of the strut, for this we call the Beam command, then in the dialog box that appears, set the necessary parameters.

- In the List of elements tab, select the type of structural element Spacers.

- Select the previously created brand PP1.

- View - "section". The main central axis - uncheck

- The display is “full”.

- In the Geometry tab, leave unchanged (indicate on the drawing).

- In the Axis Offset tab, set (in the center).

- In the Rotation tab, leave it unchanged (rotation "0").

- In the Marking tab, remove the designation (no).

- In the List of elements tab, the Include in the specification checkbox should be unchecked.

9.34. Having set all the parameters, click OK and place the spacers along the A-B-V axes. Spacers are placed 150 mm below the top of the columns.

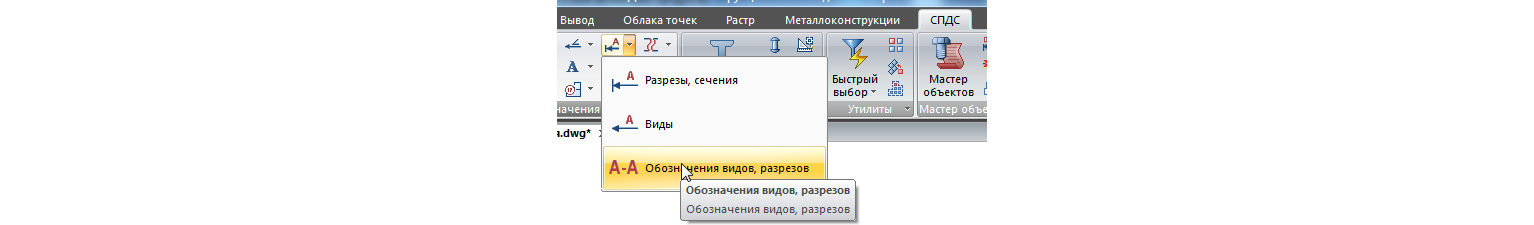

9.35. We put the notation “1-1” for the section, for this we call the command Designations of views, sections

9.36. In the window that appears, enter the number "1-1", then click OK and place the designation on top of the drawing.

In the next part, we will look at how to create a longitudinal section.

We invite you to participate in the free webinar "Creating a metal truss in nanoCAD SPDS Metal Structures ".

The purpose of the webinar- Demonstrate to CAD users how the efficiency of design engineers is enhanced by using specialized nanoCAD SPDS Metalware software. Participants in the webinar will get acquainted with the updated functionality of the program, see two-way automatic communication between the project manager, the drawing and the specification. As part of the webinar, the tools of the nanoCAD SPDS Metal Structures program will be considered, which allow you to design various elements of metal structures. An example will be shown how, with the help of parametric objects, you can quickly design a truss metal truss and automatically generate a list of elements and a metal rolling specification on it.

Dmitry Gostev, Leading Engineer, Magma-Computer LLC

Dmitry Gostev, Leading Engineer, Magma-Computer LLC