SamsPcbGuide Part 9: Galvanic Isolation, Security, and PCBs

This article continues consideration of the topic raised by @olartamonov , namely, security in high-voltage applications. The article will discuss the physical foundations of the breakdown of dielectrics, as well as a new safety standard.

Safety requirements apply to any electronic equipment, despite the fact that they are overhead in terms of product operation. They require the use of additional circuit solutions and electronic components, complicate the topology of printed circuit boards, increasing the mass-overall parameters of the product, the volume of tests and, thereby, its cost and time to market. Only functionality can be limited only when developing prototypes or prototypes of the device. Unfortunately, at present, in conditions of simplicity of reaching a customer (past certification centers), reducing cost and saving on testing, electronic products are losing not only reliability, but also safety.

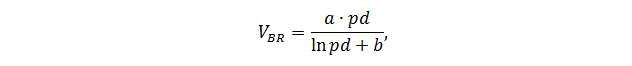

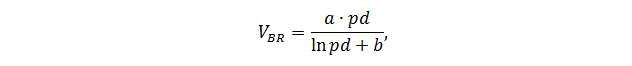

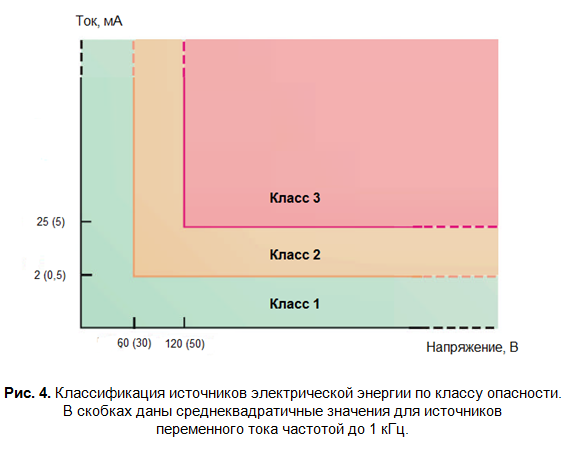

Any dielectric has electric strength - at a certain electric field strength, breakdown occurs. In gases, the breakdown voltage of spherical electrodes at a given temperature and average pressure values is described by the Paschen law:

where p is the pressure, a and b are the experimental constants depending on the gas. In fig. Figure 1 shows the Pashen curve for dry air with a relative humidity of 60% at a temperature of 20 oC. Note that the Paschen curve has a minimum value. An increase in pressure leads to an increase in density and an increase in the probability of collisions, but reduces the mean free path and, consequently, the particle energy. This leads to an increase in breakdown voltage in the high pressure region, on the right side of the graph. At low values, the breakdown mechanism depends on the ratio of the mean free path and the distance between the electrodes. The electric strength of air at normal atmospheric pressure is 3.1 kV / mm and it decreases with increasing temperature and pressure drop. As a conservative estimate, when designing electrical insulation, a value of 1-1.5 kV / mm is usually taken.

For solid dielectrics, the concept of intrinsic electric strength is introduced - the minimum value of the electric field strength in a homogeneous material, at which free or valence electrons gain enough energy so that when they collide with atoms or bound electrons, new conduction electrons are formed, which leads to breakdown. This value depends on temperature, for some materials it can reach several MV / mm and is a theoretical limit of electric strength. In practice, breakdown occurs at much lower values of the electric field strength. The main reasons for this are:

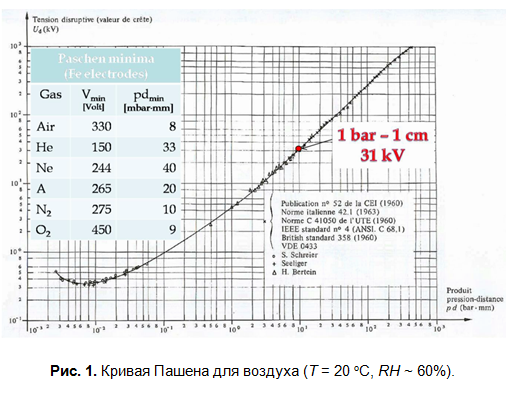

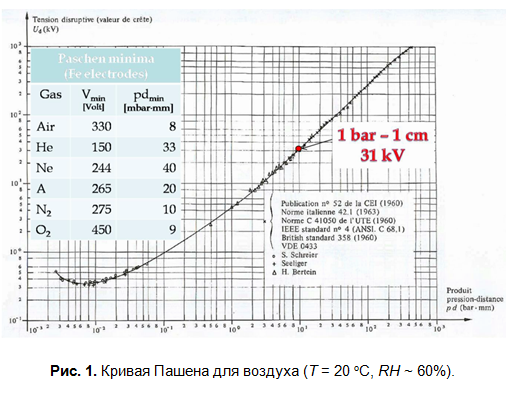

The listed inhomogeneities in the bulk of the material act as concentrators of the electric field, leading to partial breakdowns (Fig. 2). As a result of such breakdowns, the dielectric material is gradually destroyed, which can lead to a complete breakdown.

The presence of moisture or contamination on the surface can lead to the formation of conductive channels, which even with weak conductivity create equipotential surfaces, reducing the actual gap between the electrodes and thereby lead to breakdown.

A whole complex of complex physical phenomena, including a probabilistic component and depending on a large number of external factors, leads to electrical breakdown in dielectric materials. Therefore, analytical and calculation models can be built only for the simplest cases. In practice, the design should be guided by the requirements of standards, conduct insulation testing under conditions close to the actual operating conditions, and if possible, lay the margin of safety of insulation. Understanding the theoretical foundations of electrical breakdown mechanisms allows you to make decisions in the face of a compromise with the recommendations of the standards.

Each group of electronic devices has its own standard of electrical safety. The current safety standard is 62368-1 , which replaced and combines the outdated standards 60950-1 and 60065. The standard, unlike its predecessors, is very systemic and structured and is recommended for study. Also, recommendations for galvanic isolation are specified in IPC standards: in the general standard for the design of printed circuit boards IPC2221 and in the standard for voltage converters IPC9592.

The basic model of a secure system in 62368-1 looks very simple (Fig. 3). In general, protection mechanisms against the transfer of energy (electrical, chemical, kinetic, thermal, etc.) that can cause pain or cause injury include:

At the same time, protection in the standard is understood not only as technical (including individual means of user protection), but also organizational measures. The highest priority from a safety point of view is the technical means that are part of the equipment, as they minimize the requirements for user behavior.

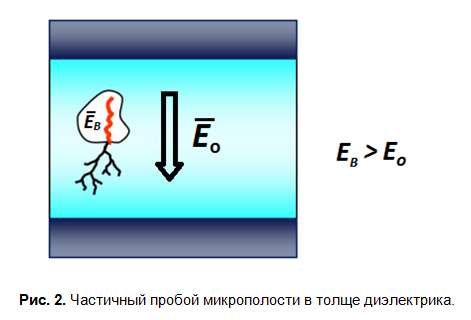

According to danger, energy sources are divided into three classes (section 4.2), each of which has its own minimum level of protection, depending on the type of equipment user. For the average user, this is:

For Class 1 sources, no protection is allowed. The standard requires protective insulation not only between the power source and the user, but also between sources of electrical energy of various hazard classes (table 12 of the standard).

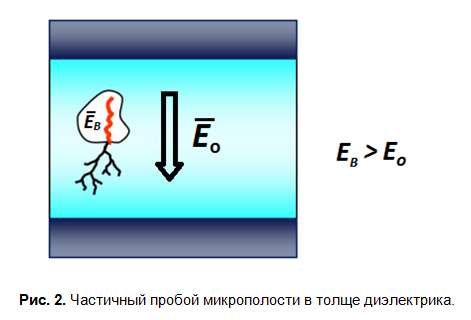

Classification of sources is discussed in section 5.2 of the standard. DC sources with an output voltage of more than 60 V are defined as dangerous and require insulation (Fig. 4). The same voltage levels are considered dangerous for single pulses and for capacitors with a capacity of more than 300 nF, when the capacitance decreases, the requirements decrease (for 4 nF this is already 1 kV, see table 7 of the standard). For AC sources, the threshold is 30 V rms voltage.

If class 2 and 3 sources of electrical energy are used in the operation of an electronic device, then when designing the printed circuit boards included in it, the requirements for minimum clearances (English clearance) and creepage paths (materials and components) must be observed. Printed circuit boards are dedicated to a separate section G.18 of Appendix G “Components”, which contains links to the general sections 5.4.2 “Clearances” and 5.4.3 “Creepage distances”.

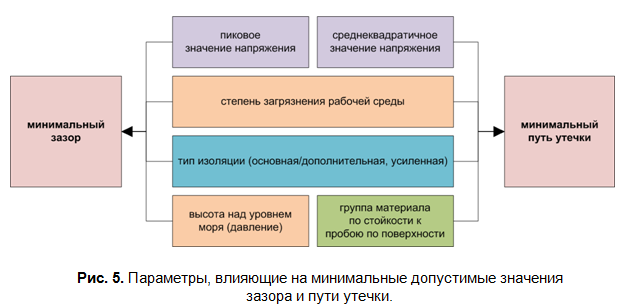

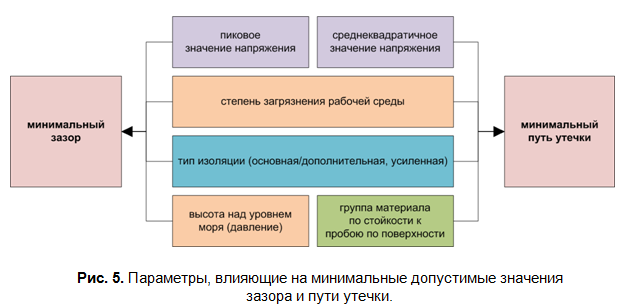

When choosing the minimum clearances and creepage distances, one should proceed not only from voltage values, but also from operating conditions and dielectric material (Fig. 5). The breakdown of the air gap is influenced by pressure, therefore, the standard introduces increasing factors for altitudes above 2000 m above sea level (table 22 of the standard). In addition, three degrees of contamination of the working environment are determined. The higher the degree of contamination, the greater the distance between the conductors must be ensured.

Another parameter that affects the value of the minimum leakage path is the group of material in terms of resistance to breakdown on the surface. The IEC 60112 standard divides dielectric materials into 4 groups depending on the value of the conditional CTI index (English Comparative Tracking Index). The higher the CTI value, the higher the breakdown resistance and the lower the minimum leakage path values are acceptable, ceteris paribus. Standard fiberglass FR4 with CTI ~ 175 ... 200 is located on the border of group IIIb, which is not recommended for use with pollution degree 3 and at rms voltage values of more than 630 V.

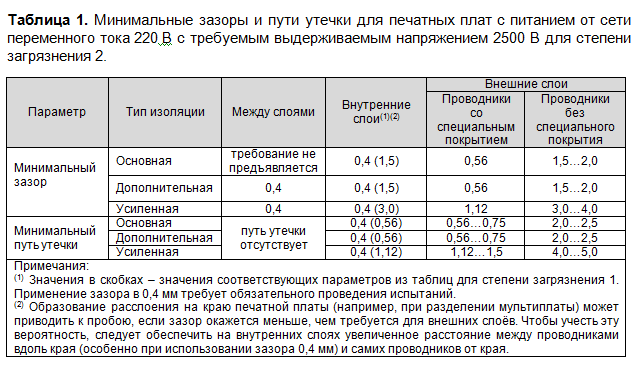

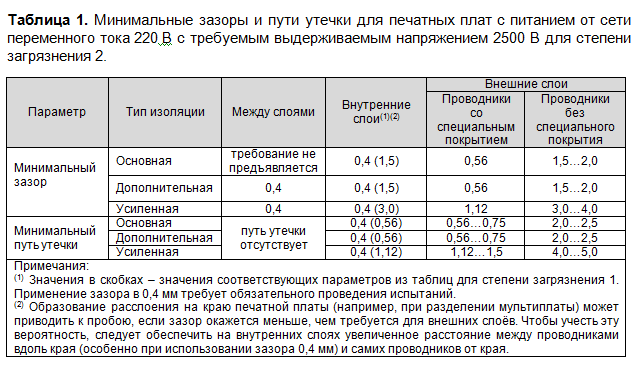

After the parameters affecting the choice of the minimum clearances and creepage distances are determined, the values themselves are determined using tables 17-19, 23, G.12 of the standard. These minimum distances must be maintained for all conductors if there is an appropriate voltage between them: in the primary circuit, between the primary and secondary circuit, as well as in the secondary circuits. Table 1 shows the minimum clearances and creepage distances for printed circuit boards that are part of devices powered by 220 V mains voltage category II in conditions of pollution degree 2.

For external layers, the values depend on the presence of coating, however, it should be borne in mind that the standard mask is not a specialized insulating coating and does not provide the possibility of applying reduced requirements for gaps. The mask has an uneven thickness and may contain cavities and cracks that reduce the reliability of such insulation.

As for the inner layers, the minimum gap for conductors on adjacent layers is 0.4 mm for solid (English solid insulation) single-layer insulation, and for conductors on one layer the insulation is considered as a bonded joint (English cemented joint). According to the standard, for such insulation the values of minimum clearances and creepage distances for pollution degree 2, for pollution degree 1 or a gap for continuous insulation of 0.4 mm can be used. Moreover, in the last two cases, the standard requires testing, including thermal cycling and electric strength test. The fact is that there is a possibility (and for reliable applications it must be taken into account) that a gap will arise as a result of thermal, mechanical load or over time along the separation of adjacent layers of the printed circuit board. And then the distance is 0,

It is worth noting that in most cases the requirement for the distance through the insulation between the layers is minimal, therefore one of the strategies for designing printed circuit boards with a limited size is to separate the insulated conductors and components into different layers.

Observance of the distances required by the standard when designing the topology of the printed circuit board may be insufficient, since the presence of components and structural elements of the product makes the task three-dimensional. Therefore, the use of 3D-models of components and the general assembly of the product is a prerequisite for the design of products with dangerous voltage levels.

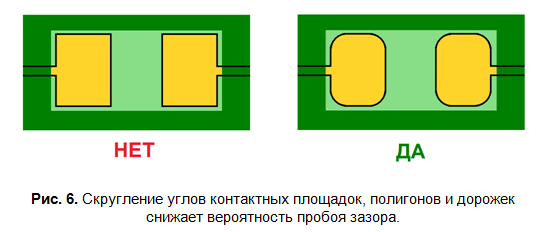

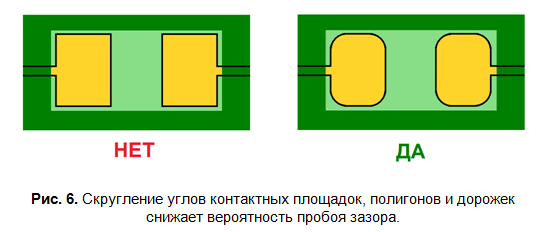

In addition to meeting the requirements for minimum distances, when developing printed circuit boards for high-voltage applications, it is recommended to avoid sharp corners in the geometry of the conductive layers (Fig. 6), since they are concentrators of the electric field strength.

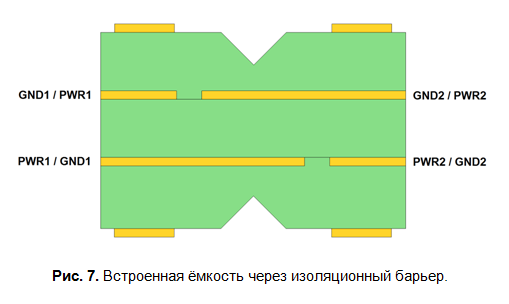

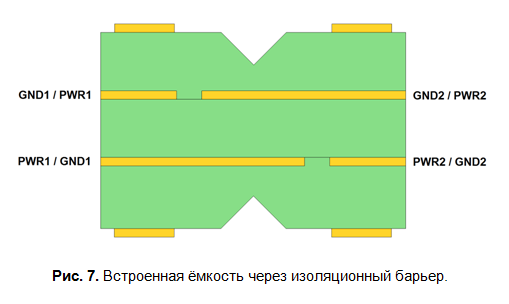

From the point of view of EMC, the isolation barrier is a gap in the path of the return current, which, without special measures, leads to an increased level of radiation, especially in the case of isolated power sources. As in the case of discontinuities in the support layer, capacitors are used to ensure the path of return currents through the insulation barrier. The requirements for discrete capacitors and examples of their application are described in section G.15 of Appendix G “Components” of the standard. In isolation of hazardous voltage levels, only class Y capacitors are used, failure of which leads to an open circuit: for 220 V AC voltage class II, this is one capacitor of subclass Y1 or two series-connected capacitors of subclass Y2. The safety of such capacitors is guaranteed by the manufacturer, however, the stray inductance of the compound and the localized location limit their effectiveness at frequencies above 100 MHz. The capacity built into the circuit board, distributed between two overlapping polygons on the inner layers, is deprived of this drawback (Fig. 7).

It is important to understand that even full compliance with the recommendations of the standard in terms of minimum distances between conductors does not guarantee electrical safety. Only the results of insulation tests for electric strength (section 5.4.11 of the standard) can confirm the conformity of the printed circuit board topology, the materials and components used, the product design and its manufacturing technology to safety requirements for specific application conditions.

Extended and more detailed versions of this and a previous publication are included in the new release of the full version of the book.. The #SamsPcbGuide project is developing, including through feedback (both positive and negative), so I will be grateful for constructive criticism. Good luck to everyone, people (let safety not depend on good luck, everything is strictly by standards)!

Safety requirements apply to any electronic equipment, despite the fact that they are overhead in terms of product operation. They require the use of additional circuit solutions and electronic components, complicate the topology of printed circuit boards, increasing the mass-overall parameters of the product, the volume of tests and, thereby, its cost and time to market. Only functionality can be limited only when developing prototypes or prototypes of the device. Unfortunately, at present, in conditions of simplicity of reaching a customer (past certification centers), reducing cost and saving on testing, electronic products are losing not only reliability, but also safety.

Fundamentals of the theory of electrical breakdown in gases and solids

Any dielectric has electric strength - at a certain electric field strength, breakdown occurs. In gases, the breakdown voltage of spherical electrodes at a given temperature and average pressure values is described by the Paschen law:

where p is the pressure, a and b are the experimental constants depending on the gas. In fig. Figure 1 shows the Pashen curve for dry air with a relative humidity of 60% at a temperature of 20 oC. Note that the Paschen curve has a minimum value. An increase in pressure leads to an increase in density and an increase in the probability of collisions, but reduces the mean free path and, consequently, the particle energy. This leads to an increase in breakdown voltage in the high pressure region, on the right side of the graph. At low values, the breakdown mechanism depends on the ratio of the mean free path and the distance between the electrodes. The electric strength of air at normal atmospheric pressure is 3.1 kV / mm and it decreases with increasing temperature and pressure drop. As a conservative estimate, when designing electrical insulation, a value of 1-1.5 kV / mm is usually taken.

For solid dielectrics, the concept of intrinsic electric strength is introduced - the minimum value of the electric field strength in a homogeneous material, at which free or valence electrons gain enough energy so that when they collide with atoms or bound electrons, new conduction electrons are formed, which leads to breakdown. This value depends on temperature, for some materials it can reach several MV / mm and is a theoretical limit of electric strength. In practice, breakdown occurs at much lower values of the electric field strength. The main reasons for this are:

- heterogeneity of the material (mechanical microdamage, contamination and cavities inside the material, damage to the atomic lattice when exposed to radiation, change in properties as a result of chemical reactions);

- the presence of bypass paths of breakdown, most often along the boundary of the material (surface contamination, moisture on the surface and in the boundary layer), along cracks;

- aging of the material over time - the accumulation of these effects, including in conditions of elevated temperature.

The listed inhomogeneities in the bulk of the material act as concentrators of the electric field, leading to partial breakdowns (Fig. 2). As a result of such breakdowns, the dielectric material is gradually destroyed, which can lead to a complete breakdown.

The presence of moisture or contamination on the surface can lead to the formation of conductive channels, which even with weak conductivity create equipotential surfaces, reducing the actual gap between the electrodes and thereby lead to breakdown.

A whole complex of complex physical phenomena, including a probabilistic component and depending on a large number of external factors, leads to electrical breakdown in dielectric materials. Therefore, analytical and calculation models can be built only for the simplest cases. In practice, the design should be guided by the requirements of standards, conduct insulation testing under conditions close to the actual operating conditions, and if possible, lay the margin of safety of insulation. Understanding the theoretical foundations of electrical breakdown mechanisms allows you to make decisions in the face of a compromise with the recommendations of the standards.

New security standard

Each group of electronic devices has its own standard of electrical safety. The current safety standard is 62368-1 , which replaced and combines the outdated standards 60950-1 and 60065. The standard, unlike its predecessors, is very systemic and structured and is recommended for study. Also, recommendations for galvanic isolation are specified in IPC standards: in the general standard for the design of printed circuit boards IPC2221 and in the standard for voltage converters IPC9592.

The basic model of a secure system in 62368-1 looks very simple (Fig. 3). In general, protection mechanisms against the transfer of energy (electrical, chemical, kinetic, thermal, etc.) that can cause pain or cause injury include:

- attenuation of the level or speed of energy transfer;

- energy redirection;

- power source shutdown;

- creating a barrier between the energy source and the user.

At the same time, protection in the standard is understood not only as technical (including individual means of user protection), but also organizational measures. The highest priority from a safety point of view is the technical means that are part of the equipment, as they minimize the requirements for user behavior.

According to danger, energy sources are divided into three classes (section 4.2), each of which has its own minimum level of protection, depending on the type of equipment user. For the average user, this is:

- basic protection (for hazard class 2) - ensures safety in normal and abnormal operating conditions,

- additional protection (for class 3) - is used in addition to the main one, providing protection in case of its malfunction,

- reinforced protection (for class 3) - provides safety in normal and abnormal operating conditions (for example, reverse polarity of the power supply), as well as in case of a single fault (for example, breakdown of insulation).

For Class 1 sources, no protection is allowed. The standard requires protective insulation not only between the power source and the user, but also between sources of electrical energy of various hazard classes (table 12 of the standard).

Classification of sources is discussed in section 5.2 of the standard. DC sources with an output voltage of more than 60 V are defined as dangerous and require insulation (Fig. 4). The same voltage levels are considered dangerous for single pulses and for capacitors with a capacity of more than 300 nF, when the capacitance decreases, the requirements decrease (for 4 nF this is already 1 kV, see table 7 of the standard). For AC sources, the threshold is 30 V rms voltage.

If class 2 and 3 sources of electrical energy are used in the operation of an electronic device, then when designing the printed circuit boards included in it, the requirements for minimum clearances (English clearance) and creepage paths (materials and components) must be observed. Printed circuit boards are dedicated to a separate section G.18 of Appendix G “Components”, which contains links to the general sections 5.4.2 “Clearances” and 5.4.3 “Creepage distances”.

When choosing the minimum clearances and creepage distances, one should proceed not only from voltage values, but also from operating conditions and dielectric material (Fig. 5). The breakdown of the air gap is influenced by pressure, therefore, the standard introduces increasing factors for altitudes above 2000 m above sea level (table 22 of the standard). In addition, three degrees of contamination of the working environment are determined. The higher the degree of contamination, the greater the distance between the conductors must be ensured.

Another parameter that affects the value of the minimum leakage path is the group of material in terms of resistance to breakdown on the surface. The IEC 60112 standard divides dielectric materials into 4 groups depending on the value of the conditional CTI index (English Comparative Tracking Index). The higher the CTI value, the higher the breakdown resistance and the lower the minimum leakage path values are acceptable, ceteris paribus. Standard fiberglass FR4 with CTI ~ 175 ... 200 is located on the border of group IIIb, which is not recommended for use with pollution degree 3 and at rms voltage values of more than 630 V.

After the parameters affecting the choice of the minimum clearances and creepage distances are determined, the values themselves are determined using tables 17-19, 23, G.12 of the standard. These minimum distances must be maintained for all conductors if there is an appropriate voltage between them: in the primary circuit, between the primary and secondary circuit, as well as in the secondary circuits. Table 1 shows the minimum clearances and creepage distances for printed circuit boards that are part of devices powered by 220 V mains voltage category II in conditions of pollution degree 2.

For external layers, the values depend on the presence of coating, however, it should be borne in mind that the standard mask is not a specialized insulating coating and does not provide the possibility of applying reduced requirements for gaps. The mask has an uneven thickness and may contain cavities and cracks that reduce the reliability of such insulation.

As for the inner layers, the minimum gap for conductors on adjacent layers is 0.4 mm for solid (English solid insulation) single-layer insulation, and for conductors on one layer the insulation is considered as a bonded joint (English cemented joint). According to the standard, for such insulation the values of minimum clearances and creepage distances for pollution degree 2, for pollution degree 1 or a gap for continuous insulation of 0.4 mm can be used. Moreover, in the last two cases, the standard requires testing, including thermal cycling and electric strength test. The fact is that there is a possibility (and for reliable applications it must be taken into account) that a gap will arise as a result of thermal, mechanical load or over time along the separation of adjacent layers of the printed circuit board. And then the distance is 0,

It is worth noting that in most cases the requirement for the distance through the insulation between the layers is minimal, therefore one of the strategies for designing printed circuit boards with a limited size is to separate the insulated conductors and components into different layers.

Observance of the distances required by the standard when designing the topology of the printed circuit board may be insufficient, since the presence of components and structural elements of the product makes the task three-dimensional. Therefore, the use of 3D-models of components and the general assembly of the product is a prerequisite for the design of products with dangerous voltage levels.

The minimum distances required by the standard must be maintained in all directions, taking into account the presence of components on the printed circuit board, as well as structural elements of the product.

In addition to meeting the requirements for minimum distances, when developing printed circuit boards for high-voltage applications, it is recommended to avoid sharp corners in the geometry of the conductive layers (Fig. 6), since they are concentrators of the electric field strength.

From the point of view of EMC, the isolation barrier is a gap in the path of the return current, which, without special measures, leads to an increased level of radiation, especially in the case of isolated power sources. As in the case of discontinuities in the support layer, capacitors are used to ensure the path of return currents through the insulation barrier. The requirements for discrete capacitors and examples of their application are described in section G.15 of Appendix G “Components” of the standard. In isolation of hazardous voltage levels, only class Y capacitors are used, failure of which leads to an open circuit: for 220 V AC voltage class II, this is one capacitor of subclass Y1 or two series-connected capacitors of subclass Y2. The safety of such capacitors is guaranteed by the manufacturer, however, the stray inductance of the compound and the localized location limit their effectiveness at frequencies above 100 MHz. The capacity built into the circuit board, distributed between two overlapping polygons on the inner layers, is deprived of this drawback (Fig. 7).

It is important to understand that even full compliance with the recommendations of the standard in terms of minimum distances between conductors does not guarantee electrical safety. Only the results of insulation tests for electric strength (section 5.4.11 of the standard) can confirm the conformity of the printed circuit board topology, the materials and components used, the product design and its manufacturing technology to safety requirements for specific application conditions.

Extended and more detailed versions of this and a previous publication are included in the new release of the full version of the book.. The #SamsPcbGuide project is developing, including through feedback (both positive and negative), so I will be grateful for constructive criticism. Good luck to everyone, people (let safety not depend on good luck, everything is strictly by standards)!