My Marble Machine 3D Printed

I'm trying to master 3D printing - I got a FLSUN-QQ printer, I installed 3D editors for myself: Fusion 360, Blender, I try Compass 3D. Something happens, something does not work. This Marble Machine on video is one of my first successful projects. The project, although visually not large, but its implementation required considerable effort from me. 3D editors had to master the mechanics and come up with and configure-debug this device.

Next, I will tell you what parts this machine consists of.

The most important part is undoubtedly the lifting spiral. She had the most problems. I developed many different types of spirals and many versions were rejected for either aesthetic or technical reasons. Yes, even because the promised printing time was too long, I had to give up various ideas ... I wanted to get something airy, beautiful and that I could print on my printer at a reasonable time.

The final model of the spiral looks like this: The

spiral installed on the machine:

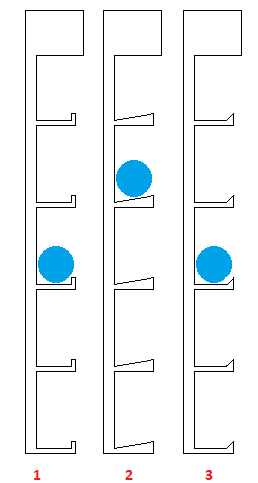

There were several problems with the spiral. First - it was necessary to decide what should be the profile of the spiral. Several options were considered. The simplest of them can be schematically represented in the context as follows:

There’s such a thing - in the first version, if the border on the shelf protrudes strongly, then the printer software, and I use Ultimaker Cura, will give me support that will need to be removed manually, and then if it’s poorly cleaned, they will also prevent the ball from rolling . If you take the second option with a thickening shelf so that the ball rolls as it were to the plane of the spiral, then there will definitely not be any support, but it is not known how well the ball will be held. I even printed a fragment of such a spiral to see how it will be in real life. But all the same, the third option won, the intermediate one, with a border / curb in the form of a corner. If it is not made very large, then the printer manages to print it without supports.

Another problem with spiral printing was purely manufacturing. I did not manage to print it in its entirety. I’m not sure what the reason is - it is possible that such a figure has too much cooling surface. While the extruder passes along the entire trajectory, part of the model probably has cooled significantly. But these are just my guesses. Moreover, which is strange, at the very table, which is being heated up, the print is going fine, but the print rises higher and layering of the plastic appears. At the same time, printing of small test models occurred without problems. It’s not very pleasant when I started to print and everything seems to be going well for an hour. Leave it to print for the whole day (another 13 hours of printing) until you leave for work. You come home, the seal is over, but the marriage has turned out - the model is stratified on the upper layers. I even thought about printing a spiral into sectors, and then gluing them together. However, then I managed to choose the printing modes, temperature and speed, when the printing went completely from start to finish with an acceptable result. A little toffee hairs were assigned, it would be necessary to clean them all, but here it was a little too lazy.

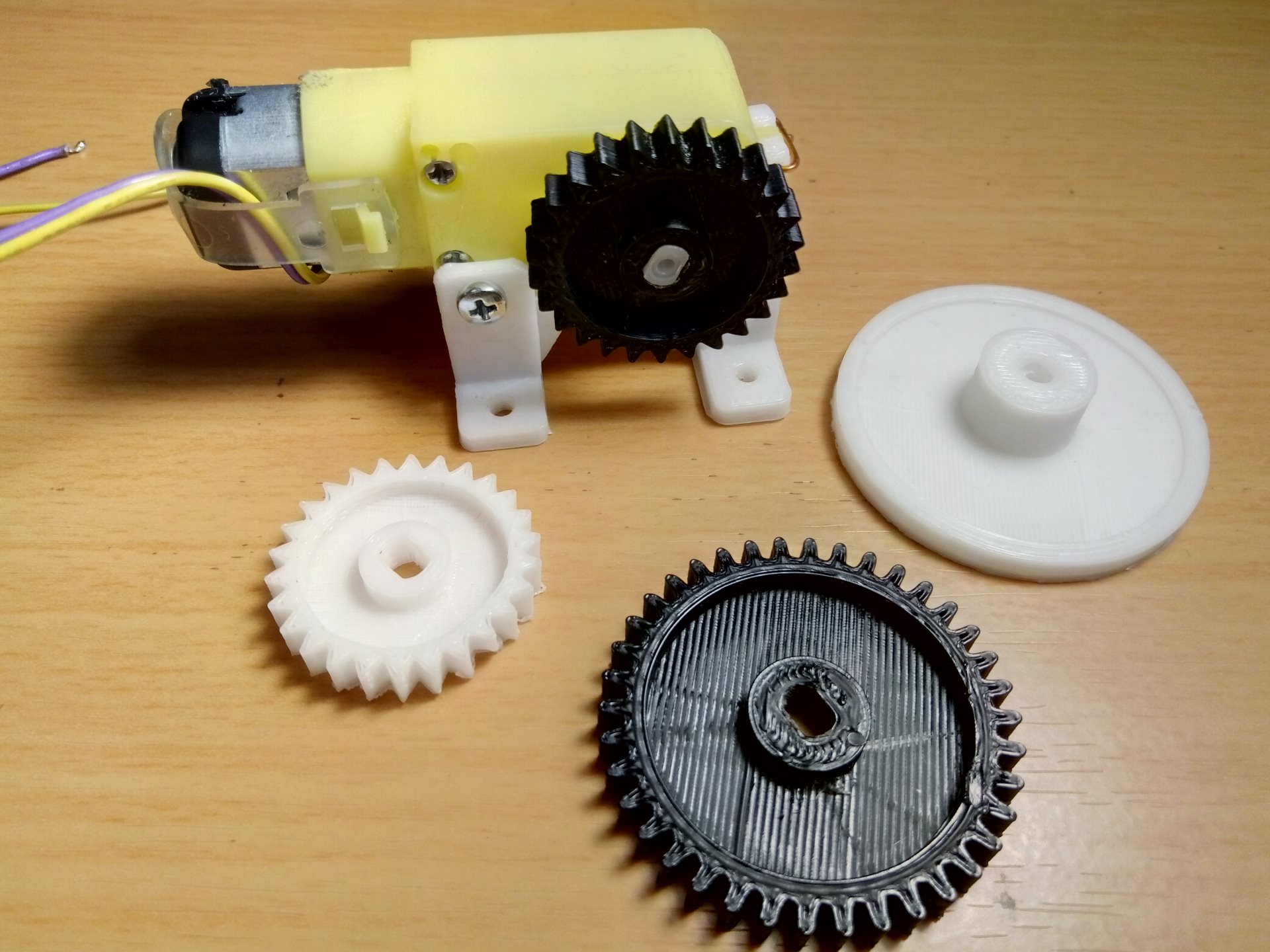

Another question was how to bring the spiral into rotation. As you can see, a gear goes along the edge of the spiral. I honestly didn’t expect it much. I thought the main thing is to make the cloves on the edge of the spiral, and then somehow give rotation from the toy collector engine with another gear. This idea did not work for me for several reasons. First, gears still need to be pre-calculated. Secondly, the idea was almost implemented like this:

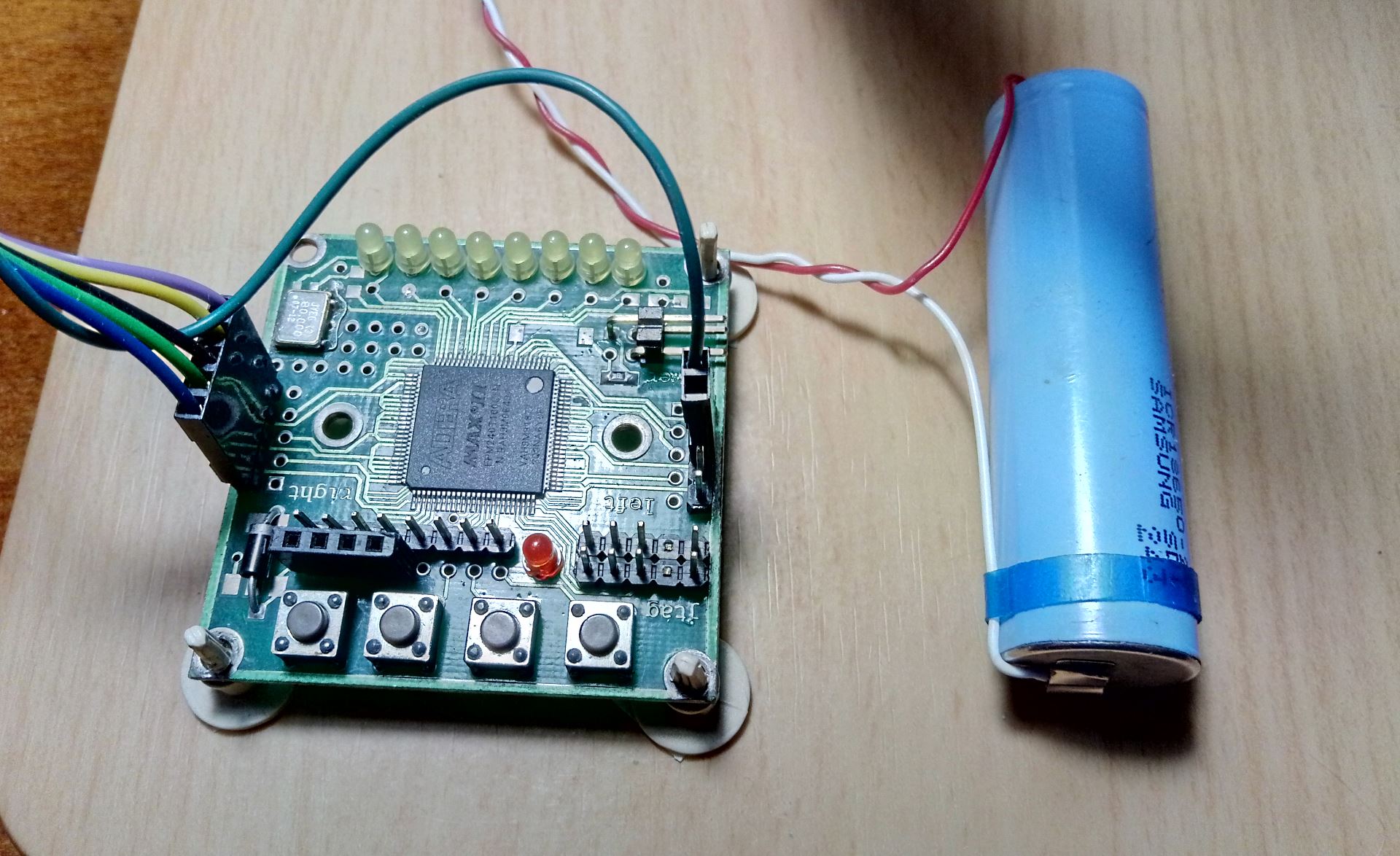

But it turned out that it was not easy to regulate the speed of the collector engine, then, the shaft of the toy engine is quite loose, and it makes noise in operation unpleasantly. In general, I refused this idea. I took a 28BYj-48 stepper motor with an engine driver: I

did the steps on Verilog in the FPGA of the Mars rover:

If anyone is interested in how to program stepper motor control on Verilog, then this is the topic of a separate article . Now speed can be easily programmed and runs almost silently. Only now it’s a pity that when printing a spiral, a significant printing time was spent on printing gears. I think without it 2 hours of printing would have saved.

So, the 28BYj-48 stepper motor is installed in a special rack. The rack model that I developed looks like this:

In a car, the engine rack looks like this:

Since the stand is located somewhere behind and is not particularly visible, when printing, I set the layer thickness to be larger, 0.25 mm, where accuracy and beauty are not particularly needed, but at least a little printing time should be saved. Although, what kind of time saving is there, if you recall that the first version of the rack, which was supposed to be used in the version with a collector motor, was like this:

The problem with this rack is a large backlash of the spiral shaft. Well, again, as I already wrote, the option with a collector motor and gear did not work, so I had to do a new stand for the stepper motor.

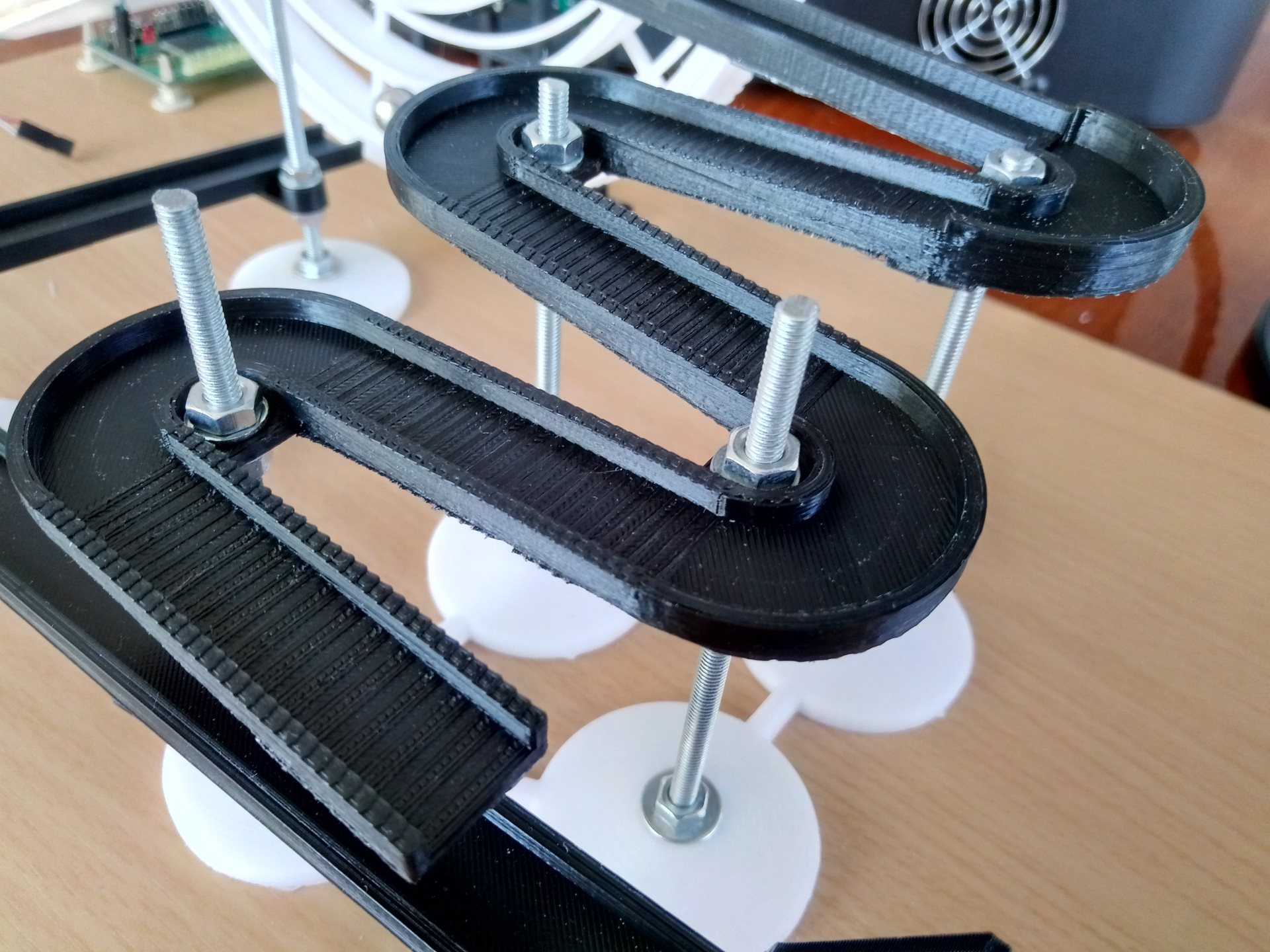

It just so happens that almost every detail I printed at least twice. The first option, even if almost the worker had to often be rejected. Here, for example, is the “snake” detail:

It would seem that this might not be so, but it turned out that when the ball descends in a straight line, it accelerates decently and flies out due to centrifugal force. I had the first turn to increase the height of the side. Well, at the same time, when re-printing, I reduced the height of the print layer. Let it print longer and better. Here is the "snake" installed in the car:

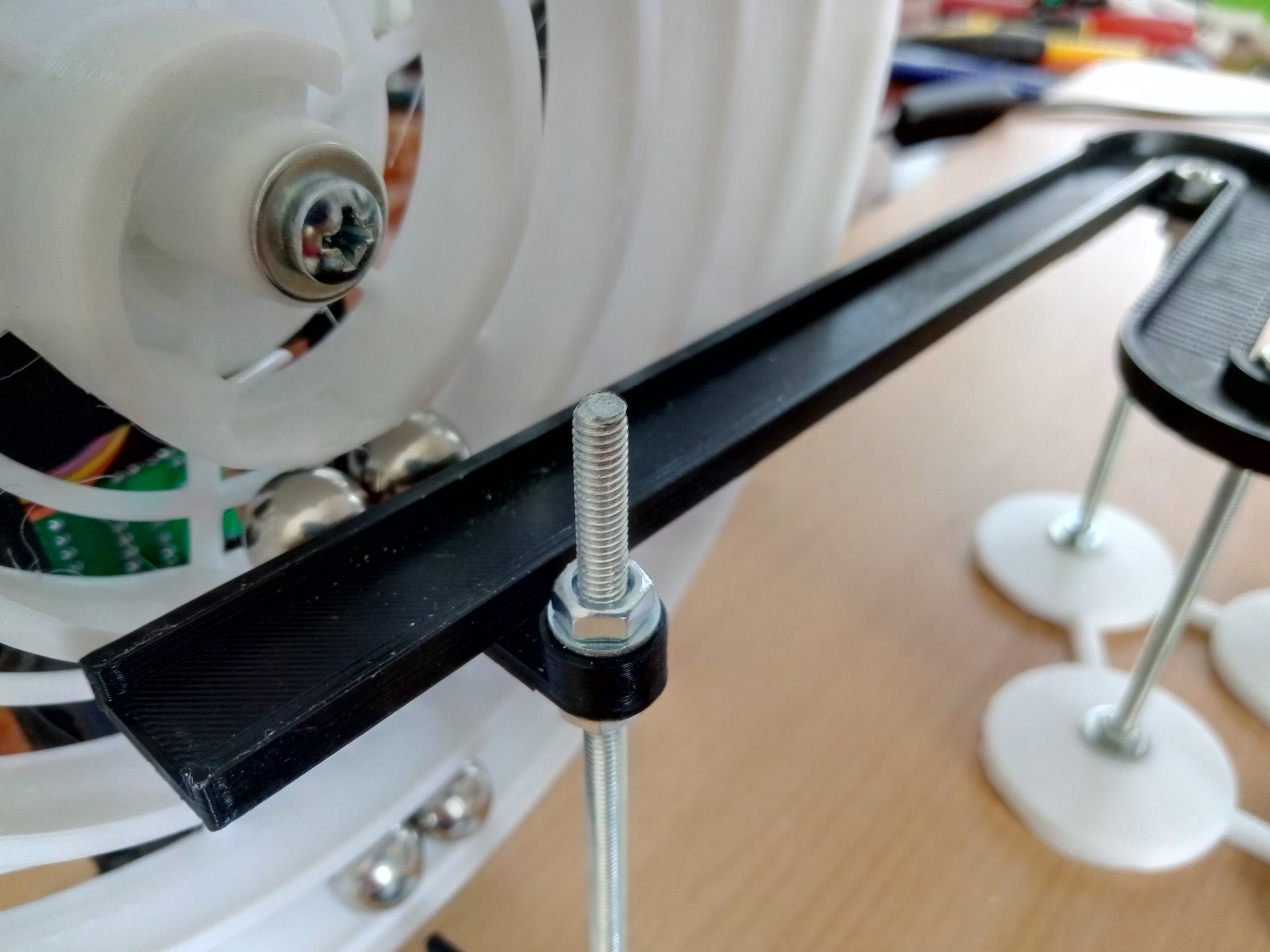

Another project required buns for attaching M4 studs:

These buns are attached to the board with double-sided tape - it worked pretty hard. It’s funny that I also printed quadruple buns twice. First printed in black plastic and with a little filling. The model stuck to the 3D printer desk so tightly that while tearing it off, it bent a little. And that’s it - she’s not standing on the table straight. But it’s good that I retyped it, it seemed to me to combine white and black color was a good idea.

Gutters:

Single U-turn:

Well, a number of minor details. In general, I had to print and reprint a lot. Nevertheless, I am glad that I completed this project. Perhaps after some time I will be able to expand this Marble Machine, add new lifts and descents, because there is still room for the next car on the board on the right.

I thought about placing the source codes of my models, but then I decided that this makes no sense, because each Marble Machine is first and foremost a fantasy of its creator. It is unlikely that someone will want to repeat everything exactly as it is here. It can be done better or just differently.