HF screens do it yourself

In the process of developing one complex thing for the Russian Internet of Things, I was faced with the need to shield the receiver from the radiation of a nearby transmitter. First I needed a couple of screens, this is normal. But then, as always, it took a little more, well, about twenty pieces.

And it was already too late to change something in the project under standard covers. And then I remembered one friend and decided to steal the idea from him.

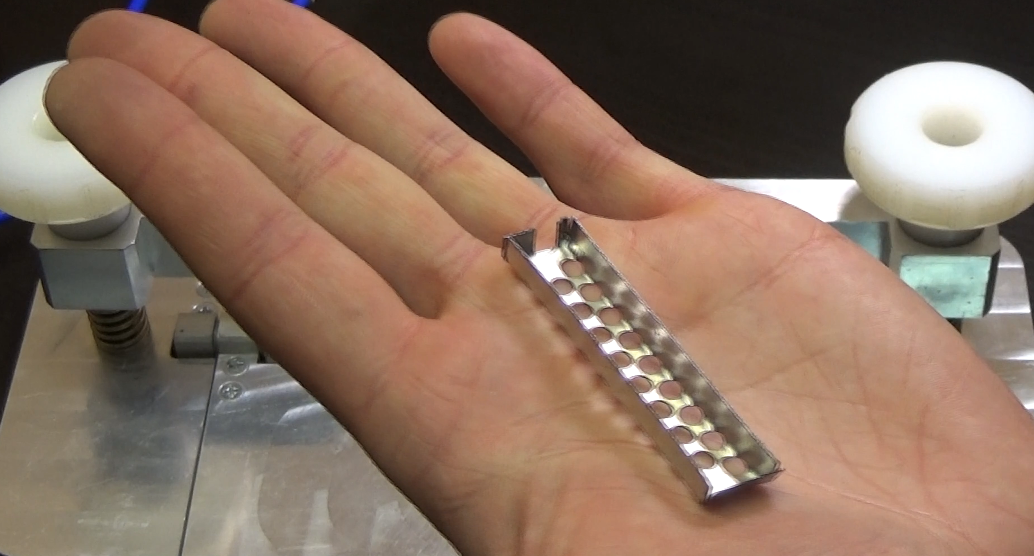

Several years ago in Minsk, in one interesting company, I saw a hand-held machine for small-scale production of covers. It was possible to cut out tin from the tin with a hand or, better, with a laser, the contour of a simple rectangular cover with walls. The limitations were: resolution in size - 2.5 mm to 50 mm and 5 mm to 100 mm, maximum wall height - 10 mm.

The usual material for these covers is tinned tin. Now there are plenty of opportunities to cut it for little money or even on its equipment. I always chose the option to do it on the side. Although something still had to be cut with scissors by hand.

The one who tried to make such covers with his hands, knows all the problems of this business. Even when cutting a reamer, not with your hands, but with a laser. I am not an experienced mechanic, self-taught. Therefore, it is easy to treat any criticism in this matter. I did this. At first I planned the fold line with a sharp knife. Then he planned it with a chisel. Then he clamped the part and with a sharp confident movement made the fold. I personally, or rather my conscience, was always strongly hampered by the noise of a hammer. A single elderly woman lived on the floor below and I didn’t want to disturb her.

In any case, the procedure is not fast and rather boring. I would not wish anyone to make twenty covers this way.

Such a life, in addition to the small draft from some unpleasant situation with this Minsk comrade, dulled the pangs of conscience and I almost shamelessly stole the idea.

I told her one familiar designer - Khazov_Andrey . He rethought it, turned the other way around. And that's what came out of it.

With this modernization, the machine has clearly become easier and cheaper. In it, of course, you can still improve a lot, but it works.

Video from simeon90 , which mastered the machine perfectly.

Without any problems and without noise, you can make twenty or more covers per hour. And the hands will remain intact.

With the writing of this article, I also hope to free myself from the remaining torments of conscience for the stolen idea. May this idea serve all people.