California-based company develops high-strength ceramic 3D printing technology

Researchers from the private company HRL Laboratories have developed and demonstrated a new additive manufacturing method (3D printing), which allows the creation of products from ceramic material of high strength. The resulting material withstands record temperatures and loads.

A ceramic product, unlike metal or plastic, is not so easy to give the desired shape. 3D printing allows you to create products of almost any shape, but with its help it has not yet been possible to make ceramics.

“3D printing is a very important new technology, but so far it was impossible to make high-strength products suitable for engineering developments with its help,” says the co-author, Tobias Schaedler. “We wanted to adapt 3D printing to create high-strength and heat-resistant ceramics.”

Tobias is not quite right - 3D printing is already used, for example, to create rocket engines that can withstand temperatures up to 3000 degrees Celsius. But ceramics on the printer, indeed, has not yet been printed.

A special polymer acts as a semi-finished product for the material. After giving the product the desired shape, it is subjected to high-temperature processing, after which it becomes ceramic. As a result, it acquires the ability to withstand temperatures of at least 2000 K (the authors simply did not have the ability to test samples at higher temperatures).

The foundations of the technology are not new - back in the 1960s, polymer-derived ceramics was invented. In such polymers, the main constituents of ceramics (silicon, nitrogen) are present. After heating, methane, carbon dioxide and the like evaporates from the polymer, leaving a ceramic structure consisting of silicon, carbon and nitrogen. The resulting product is reduced in size, but retains its shape.

A novelty in this process was the use of substances that polymerize when exposed to ultraviolet light. And this means that you can print the desired product on virtually any serial 3D printer (the authors did just that: they just ordered a ready-made printer).

In addition to the traditional additive technology, in which the polymer is extruded layer by layer onto a substrate, the authors also tried a method called “self-propagating wave-guide technology”. The bottom line is that the finished polymer is capable of transmitting ultraviolet radiation, while the semi-finished product can not. As a result, when using carefully designed templates, it is possible to polymerize rather large areas of the workpiece faster than "print" them on a 3D printer.

The polymerized preforms were then heated in a furnace and ceramic products were obtained at the outlet, which contained 36% oxygen, 26% silicon, 33% carbon, and 4% sulfur.

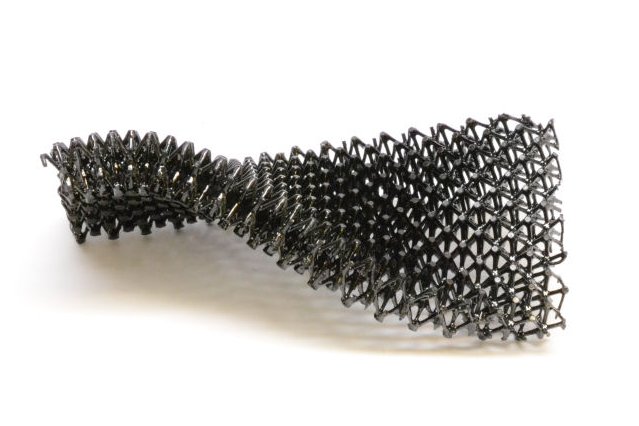

In addition to high heat resistance, the products are also very durable - the authors compare their strength with “honeycomb” structures made of aluminum alloys. According to scientists, lattice structures due to their high strength and low weight can be used in the manufacture of "supersonic aircraft and jet engines."