How to push the peak of uranium by 10 thousand years

... or educational program about the Closed Nuclear Fuel Cycle (NFCF).

Two of the most promising and at the same time criticized the concept of nuclear energy is controlled fusion and the closure of the nuclear fuel cycle. Sixty-odd years have passed since the emergence of these energy ideas, but the first of them did not take off the lab coat, and the second remained in the form of single experiments “tried and left”. But if thermonuclear energy is a special story , with the insidious nature and human weakness in the plot, then the nuclear fuel cycle is in its infancy for completely different reasons.

Pills from a mixture of uranium dioxide and plutonium - the basis of today's nuclear fuel cycle

The idea of NFCF is to learn how to extract energy from currently unused uranium-238 or thorium-232. They contain the same amount of energy as the U235 that "works" in reactors today - roughly 150 kWh (month of consumption of an average apartment) of electricity per 1 gram of metal. However, in natural uranium, only 0.7% of U235 (of which we get 0.5%, the rest goes to the dump when isotopes are separated), and 99.3% of the same U238. If it were possible to use two hundred and thirty-eighth uranium, it would expand nuclear fuel reserves by 200 times. And this is the first problem of the nuclear fuel cycle - that there is no particular urgent need for expanding fuel reserves in the world, it is enough due to stagnation of the total capacity of nuclear power plants.

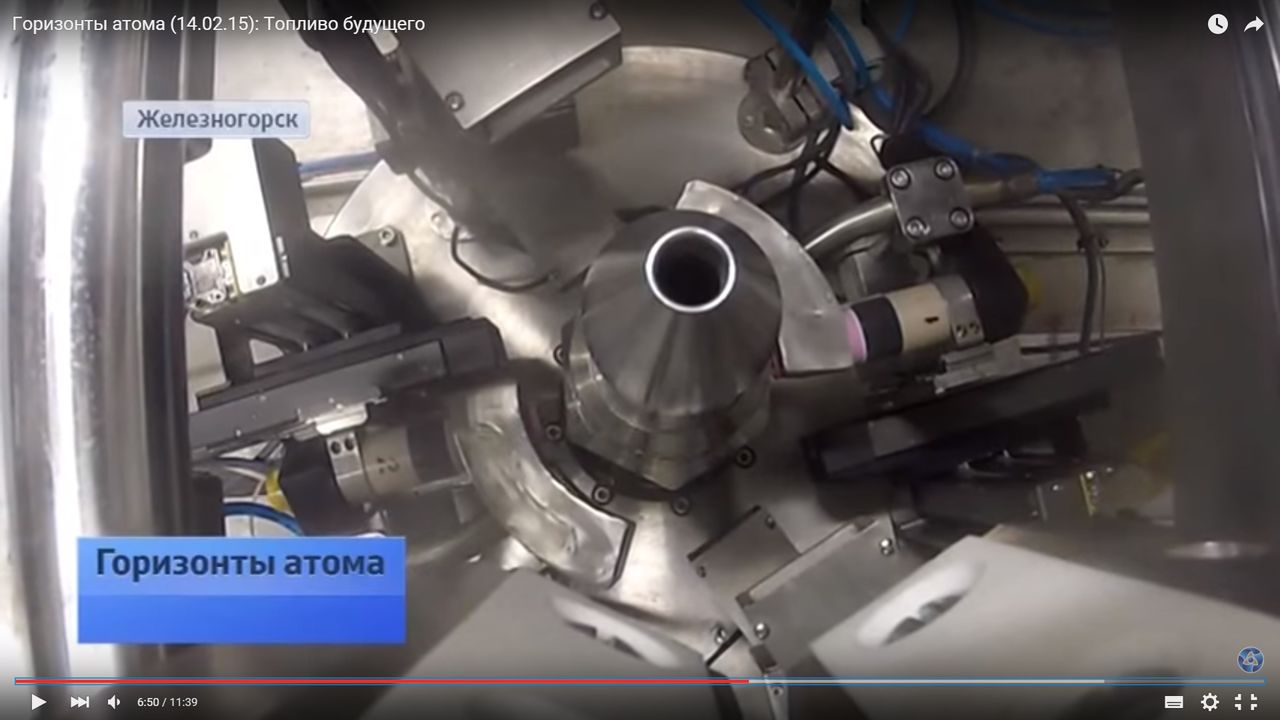

MOX assembly chamber of fuel assemblies for the BN-800 reactor. Walls and stainless steel equipment, robotics and tightness are typical components of such industries.

How are the NFC going to use the energy of uranium 238? This isotope does not support the fission chain reaction necessary for energy extraction. But it turns out that by absorbing one neutron, it can turn into plutonium-239, which already supports the chain reaction. Fortunately for us, when fissioning U235 and Pu239, two or three neutrons “fall out” of them and if one goes on to continue the chain reaction, then the second “superfluous” one can find a useful example: spend on converting U238 into something fissile (eg. Pu239). Thus, the concept of closure is formed - we “burn” plutonium in the reactor, simultaneously receiving new plutonium from U238.

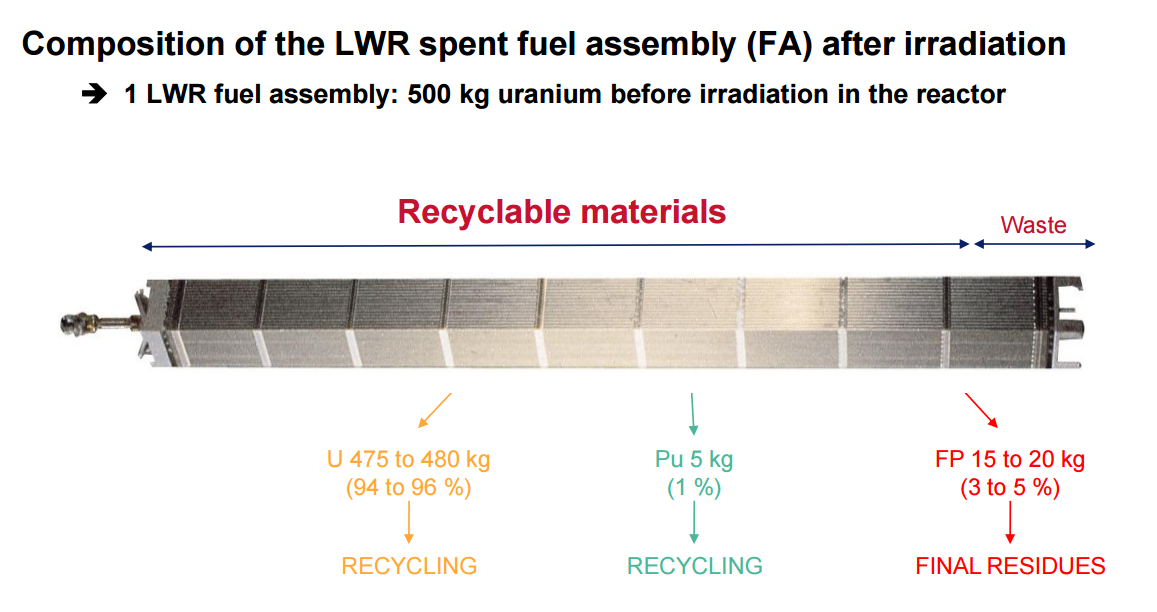

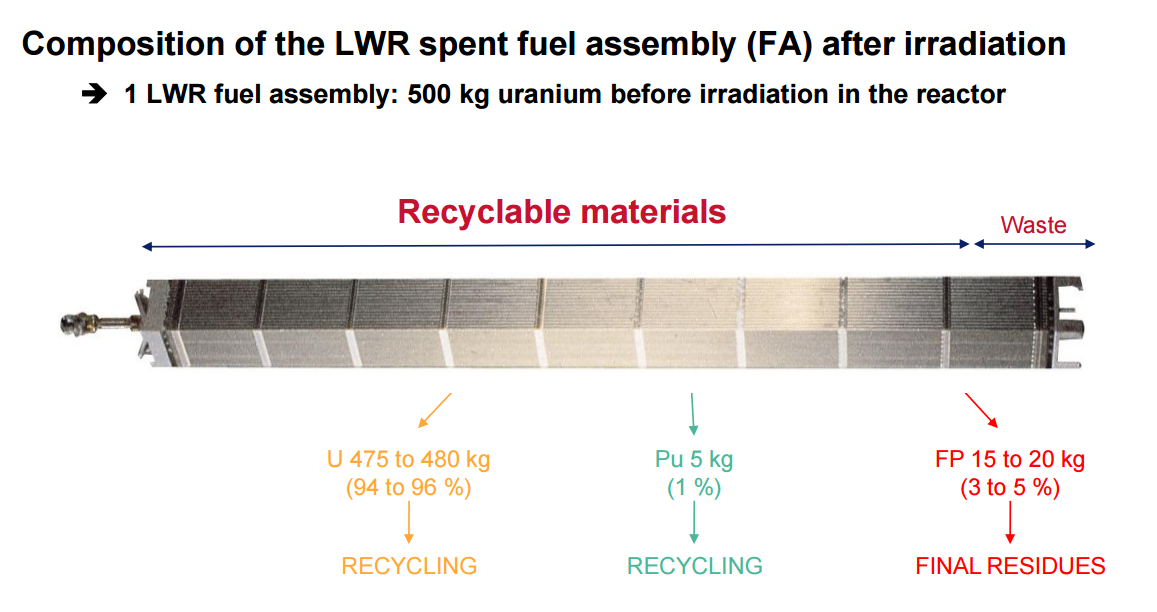

In spent nuclear fuel, only 3-5% of the radioactive fission products that need to be disposed of, and the rest (somewhat simplifying), may well be put into a new cycle.

The minimum NFCF is obtained consisting of three elements:

Where does the NFCF begin?

Where does the hoop begin? For simplicity of presentation, let’s say that thetheater begins with a hanger at the nuclear fuel cycle center begins in the reactor. The reactor is the place where energy and neutrons are extracted from fissile materials . “Spare" neutrons are absorbed by a special starting material, after which it turns into a new fissile, reproducing its consumption. The traditional pair of fissile and starting material is plutonium Pu239 (fissile) and uranium U238 (absorb), but there are several other options, for example, instead of artificial Pu239, you can use traditional fuel U235, and the conversion of U238 to Pu239 is called conversion rather than reproduction. There are many reactor designs, in which, in addition to the decay of fissile material, a new one is being produced - they can be both fast and thermal (in the case of the U233 - Th232 pair). Already at this stage it is not difficult to get confused in the abundance of forks in the nuclear fuel cycle, and we have not yet begun to consider different options for the chemistry of fuel!

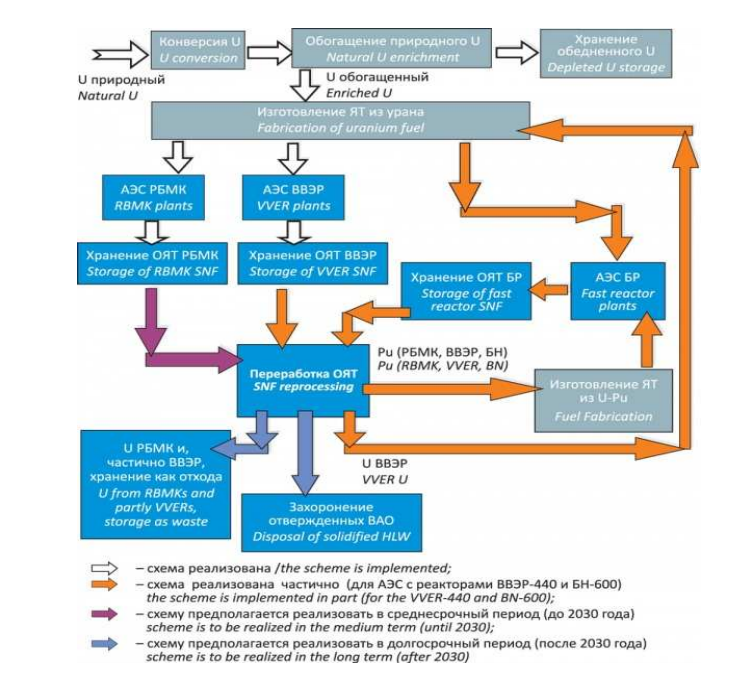

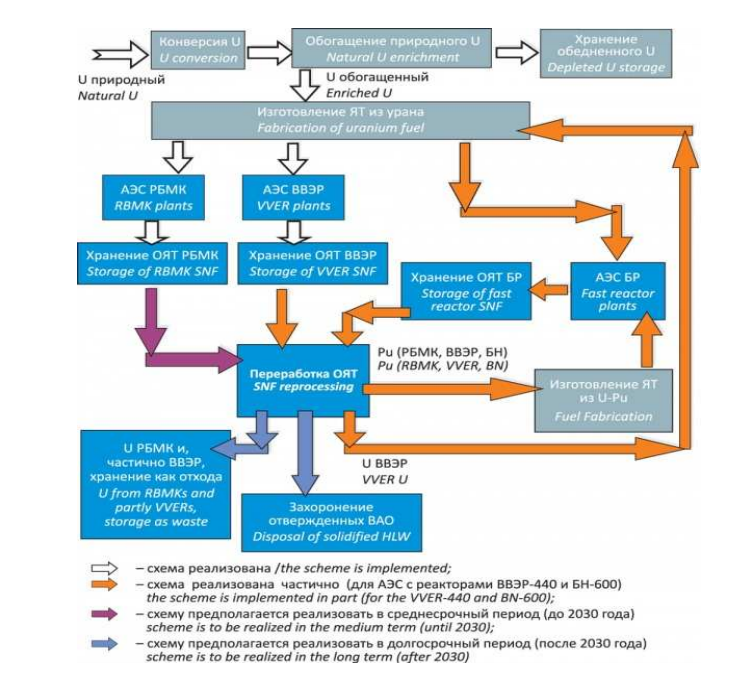

Typical NFCF schemes. And it is very enlarged!

More or less traditional versions of the breeder reactor from the previous paragraph provide for the physical separation of the division and reproduction zones. Since, again, traditionally, the core is recruited from special cassettes, it turns out that after the fuel campaign, say, once a year, we remove irradiated nuclear fuel from the reactor, in some of which we have less fissile material, and in part - much more.

Russian developers of the nuclear fuel cycle center now see the BN-1200 reactor as a key element. Plutonium will be taken from the reprocessed spent nuclear fuel from the VVER and RBMK reactors, which solves the problem of its storage.

Why cannot this accumulated fissile material (DM) be used immediately in a reactor? Mainly for technological reasons - it is located inside insulating elements (fuel elements), which have a certain resource of being inside the core. In addition, the part of the DM that was shared with the generation of energy and neutrons leaves behind fission products, which are neutron poisons and gradually degrade the characteristics of the reactor.

The world's largest SNF reprocessing plant - French La-Haug, capable of reprocessing the annual amount of SNF from 90 power units - all European spent fuel.

Grains from the chaff. Recycling.

Further, this fuel must be processed and divided:

Traditionally, radiochemical plants, such as Lighthouse, do this. And if there are about a dozen options for breeder reactors, then there are more than a hundred technological options for processing.

For example, it looks like a very advanced process for reprocessing SNF of the BREST-300 reactor , which is carried out directly at nuclear power plants. The word "pyro" here refers to the hellish process of electrolysis of the melt of irradiated nuclear fuel in cadmium.

To begin with, the type of fuel that runs in the reactor is important. It can be either metallic uranium and plutonium (or an alloy with zirconium, molybdenum, etc., etc.), or a chemical compound: oxide, nitride, carbide - i.e. compound of uranium and plutonium with oxygen, nitrogen, carbon, etc. In traditional energy, uranium oxide UO2 is used, which has some convenient characteristics (for example, in retaining the gaseous fission products of xenon, helium and iodine). The chemistry of the fuel is determined by the neutron-physical requirements from the breeder reactor and in turn determines the technology that will be used at the SNF reprocessing plant. The processing of nuclear fuel in the form of solutions in nitric acid, or the PUREX process, is traditionally and relatively widely used.

By the way, PUREX can be made at home.

However, in the future NFCF, radio chemists would like to move away from oxide fuel by switching to carbide or nitride (more precisely, a mixture of plutonium and uranium carbides / nitrides), and from liquid radiochemistry, switching to processing irradiated mass in the form of molten salts or even ionized gas (!) . On the one hand, such a transition gives noticeable bonuses to the entire NFCF project, for example, when working on nitride, a reactor can be made without reproduction zones (which means two SNF reprocessing schemes), and a ton of SNF reprocessing will not leave tens of cubic meters of liquid radioactive waste behind. On the other hand, it is necessary to simultaneously solve a huge range of issues, both in the reactor, in the reprocessing of spent nuclear fuel, and also in the fabrication of fresh fuel, which we will talk about below.

Miscellaneous equipment used to process spent nuclear fuel. After debugging, it forever leaves the world of people to work in sealed chambers, and then become radioactive waste and be buried.

And here is the designed equipment that will process “hot” nuclear fuel in the form of melts

It is nitride fuel that is the basis for the Proryv nuclear fuel cycle project, which provides for a fast reactor with a lead coolant and on-site liquid-free fuel refining and fabrication. Such a set of technologies makes the “Breakthrough” very much from the mainstream nuclear fuel cycle, in which the reactor is sodium, the fuel is oxide, and the processing is liquid, so there’s no point in mixing, for example, the nitride fuel plant that is being built in Seversk and BN-800 - it's like two parallel lines.

For example, an experimental line where you can produce up to 20 kilograms per month of tablets from a mixture of uranium, plutonium and neptunium. Those. the line is inside, and we see only protective boxes in which it is in an oxygen-free and anhydrous atmosphere.

Third leg of the NFCF. Fuel fabrication

Fabrication is the assembly of fuel cartridges (fuel assemblies) from the frame, fuel rods pre-packed with uranium fuel (usually in the form of tablets). Of course, every reactor in the world that does not think about nuclear fuel cycle consumes these fuel assemblies every year, so fabrication is a well-developed industrial process. which includes technologically advanced stages of grinding UO2 powder, compressing this powder into tablets, and sintering tablets.

So, the fabrication of fuel for the nuclear fuel cycle breaks all the broad industrial traditions of the fuel assembly plants. Firstly, fuel assemblies collected from the remains of irradiated nuclear fuel are radioactive, which means that all processes must take place without the participation of people. Secondly, plutonium oxide powder is different from uranium. Thirdly, if we nevertheless decided to use nitrides or carbides of uranium-plutonium instead of oxides, an unpleasant discovery awaits us - they self-ignite in air or in the presence of moisture. So grinding, pressing, sintering will have to be carried out in isolated boxes filled with dry nitrogen.

For example, in the right-hand side of the frame there is a box with a press making MOX tablets for BN-800 fuel assemblies.

As a result, fabrication of fuel in the nuclear fuel cycle turns out to be no less important and as difficult as the two previous stages.

The result of the “correct” closure should be the consumption of starting material (U238 or Th232) at the FA factory, the generation of electricity by the reactor, and the flow of highly radioactive waste (fission products and some technological absorbents) from the SNF reprocessing factory. The material balance of all this will be very small - for a gigawatt reactor, about 2.5 tons of U238 per year will be needed and approximately the same amount of fission fragments will be obtained that will have to be buried for tens of thousands of years.

There is also a variant of the nuclear fuel cycle, beloved by publicists, in which in each cycle of the substance circulation in the reactor more fissile materials are obtained than they are loaded - the nuclear fuel storage center with expanded reproduction. There is an important term for it, “fuel doubling time”, i.e. the time period in which in a closed system of two factories and a reactor the plutonium becomes twice as long and one more unit can be launched. For the options under consideration, this period is usually about 30 years, which on the lips of some turns into the main drawback of the nuclear fuel cycle: the amount of starting plutonium is limited and with such a doubling time, say, 100 gigawatts of fast reactors can be built in 100 years or less. However, do not forget about the thousands of tons of U235, which now lies in the composition of natural uranium somewhere in the rocks of the contoured deposits, as well as the last key point of the nuclear fuel cycle,

In 2020, it is planned to launch a SNF reprocessing plant (RBF) from RBMK-1000 and VVER-1000, next to existing repositories.

NFCF - today

This point is quite simple - the NFCF has long existed and works. True, it is not full-fledged, but a kind of "half-money", but technologically everything is in place. We are talking about MOX fuel and SNF reprocessing of conventional energy (usually with water under pressure and thermal neutron spectrum) reactors. Today, this practice is most widely used by France, which processes fuel with ~ 100 gigawatts of reactors from all over Europe and fabricates fuel assemblies with plutonium separated from SNF for loading into the same reactors. There are all the elements here - reactors operating on uranium-plutonium fuel (actually MOX - this is Mixed Oxides - mixed oxides of plutonium and uranium), reprocessing of spent nuclear fuel with plutonium accumulated as a result of irradiation of starting U238, fabrication of new plutoniumMOX-TVS. Moreover, France has a unique experience in fabricating fuel assemblies from plutonium, which was developed in MOX-fuel assemblies, i.e. doubling the use of natural uranium energy.

And of course, one should not forget the small production of MOX fuel for BN-800, launched at the MCC this year. In the frame, automatic welding of the fuel assembly head to the beam of fuel rods.

Why is this a “MISCLE"? Thermal reactors have a too “wrong” neutron spectrum, so for every fission event there are only 0.4-0.5 accumulated atoms. In addition, in such a spectrum in plutonium not only target isotopes 239 and 241 appear, but also neutron poisons 240, 242, and the same poison U236 is produced in uranium. It turns out that the starting material and the target fissile material in the reactor in the thermal spectrum are too “dirty” and too little to support the cycle, absorbing only U238.

Nevertheless, spent fuel from thermal reactors contains about 20% of the starting content of U235 (conversion coefficient is 0.4-0.5, but some of it burns out in the reactor during operation). By reprocessing spent nuclear fuel of 100 gigawatt reactors, the French are able to load 15 gigawatts of power “for free,” without spending natural uranium. Although in reality these “free MOX-fuel assemblies” are three times more expensive than those made from enriched natural uranium, it’s more important for the French to not have to store a huge amount of spent nuclear fuel from their reactors (as is the case in the United States, where almost 100 thousand tons of spent fuel is stored ), and to bury a relatively small amount of fission products.

An important illustration of the benefits of spent nuclear fuel reprocessing: the proportion of radiotoxicity of different components over the years. It can be seen that if plutonium, uranium and minor actinides are separated, the radiotoxicity of the fuel is greatly reduced, especially after 100 years. Unprocessed SNF will have to be stored for hundreds of thousands of years.

Summing up under the educational program on the NFC, I would like to formulate the main points :

1. The NFC exists and the presence / absence of fast reactors is a small part on a large canvas. Today, NFCF is being introduced not because uranium will end soon, but to reduce the amount of radioactive waste being disposed of.

2. Fuel obtained in the NFC cycle is three times more expensive today than that obtained from natural uranium, which is the most important brake on the cycle closure. The second important aspect is the problem of the possible proliferation of nuclear weapons on the planet along with the NFCF.

3. NFCF has the potential for improvement with the transition to new chemistry and technical processes (which is the basis of the BREAKTHROUGH project), but this transition requires a lot of R&D and construction.

Two of the most promising and at the same time criticized the concept of nuclear energy is controlled fusion and the closure of the nuclear fuel cycle. Sixty-odd years have passed since the emergence of these energy ideas, but the first of them did not take off the lab coat, and the second remained in the form of single experiments “tried and left”. But if thermonuclear energy is a special story , with the insidious nature and human weakness in the plot, then the nuclear fuel cycle is in its infancy for completely different reasons.

Pills from a mixture of uranium dioxide and plutonium - the basis of today's nuclear fuel cycle

The idea of NFCF is to learn how to extract energy from currently unused uranium-238 or thorium-232. They contain the same amount of energy as the U235 that "works" in reactors today - roughly 150 kWh (month of consumption of an average apartment) of electricity per 1 gram of metal. However, in natural uranium, only 0.7% of U235 (of which we get 0.5%, the rest goes to the dump when isotopes are separated), and 99.3% of the same U238. If it were possible to use two hundred and thirty-eighth uranium, it would expand nuclear fuel reserves by 200 times. And this is the first problem of the nuclear fuel cycle - that there is no particular urgent need for expanding fuel reserves in the world, it is enough due to stagnation of the total capacity of nuclear power plants.

MOX assembly chamber of fuel assemblies for the BN-800 reactor. Walls and stainless steel equipment, robotics and tightness are typical components of such industries.

How are the NFC going to use the energy of uranium 238? This isotope does not support the fission chain reaction necessary for energy extraction. But it turns out that by absorbing one neutron, it can turn into plutonium-239, which already supports the chain reaction. Fortunately for us, when fissioning U235 and Pu239, two or three neutrons “fall out” of them and if one goes on to continue the chain reaction, then the second “superfluous” one can find a useful example: spend on converting U238 into something fissile (eg. Pu239). Thus, the concept of closure is formed - we “burn” plutonium in the reactor, simultaneously receiving new plutonium from U238.

In spent nuclear fuel, only 3-5% of the radioactive fission products that need to be disposed of, and the rest (somewhat simplifying), may well be put into a new cycle.

The minimum NFCF is obtained consisting of three elements:

- Reactor

- Factory for reprocessing irradiated nuclear fuel

- Plant for the production of fresh fuel with fissile materials obtained in paragraph 2.

Where does the NFCF begin?

Where does the hoop begin? For simplicity of presentation, let’s say that the

Typical NFCF schemes. And it is very enlarged!

More or less traditional versions of the breeder reactor from the previous paragraph provide for the physical separation of the division and reproduction zones. Since, again, traditionally, the core is recruited from special cassettes, it turns out that after the fuel campaign, say, once a year, we remove irradiated nuclear fuel from the reactor, in some of which we have less fissile material, and in part - much more.

Russian developers of the nuclear fuel cycle center now see the BN-1200 reactor as a key element. Plutonium will be taken from the reprocessed spent nuclear fuel from the VVER and RBMK reactors, which solves the problem of its storage.

Why cannot this accumulated fissile material (DM) be used immediately in a reactor? Mainly for technological reasons - it is located inside insulating elements (fuel elements), which have a certain resource of being inside the core. In addition, the part of the DM that was shared with the generation of energy and neutrons leaves behind fission products, which are neutron poisons and gradually degrade the characteristics of the reactor.

The world's largest SNF reprocessing plant - French La-Haug, capable of reprocessing the annual amount of SNF from 90 power units - all European spent fuel.

Grains from the chaff. Recycling.

Further, this fuel must be processed and divided:

- metal passive cassette designs

- starting material (Th232, U238)

- fission products

- accumulated material (Pu239)

- residual fissile material.

Traditionally, radiochemical plants, such as Lighthouse, do this. And if there are about a dozen options for breeder reactors, then there are more than a hundred technological options for processing.

For example, it looks like a very advanced process for reprocessing SNF of the BREST-300 reactor , which is carried out directly at nuclear power plants. The word "pyro" here refers to the hellish process of electrolysis of the melt of irradiated nuclear fuel in cadmium.

To begin with, the type of fuel that runs in the reactor is important. It can be either metallic uranium and plutonium (or an alloy with zirconium, molybdenum, etc., etc.), or a chemical compound: oxide, nitride, carbide - i.e. compound of uranium and plutonium with oxygen, nitrogen, carbon, etc. In traditional energy, uranium oxide UO2 is used, which has some convenient characteristics (for example, in retaining the gaseous fission products of xenon, helium and iodine). The chemistry of the fuel is determined by the neutron-physical requirements from the breeder reactor and in turn determines the technology that will be used at the SNF reprocessing plant. The processing of nuclear fuel in the form of solutions in nitric acid, or the PUREX process, is traditionally and relatively widely used.

By the way, PUREX can be made at home.

However, in the future NFCF, radio chemists would like to move away from oxide fuel by switching to carbide or nitride (more precisely, a mixture of plutonium and uranium carbides / nitrides), and from liquid radiochemistry, switching to processing irradiated mass in the form of molten salts or even ionized gas (!) . On the one hand, such a transition gives noticeable bonuses to the entire NFCF project, for example, when working on nitride, a reactor can be made without reproduction zones (which means two SNF reprocessing schemes), and a ton of SNF reprocessing will not leave tens of cubic meters of liquid radioactive waste behind. On the other hand, it is necessary to simultaneously solve a huge range of issues, both in the reactor, in the reprocessing of spent nuclear fuel, and also in the fabrication of fresh fuel, which we will talk about below.

Miscellaneous equipment used to process spent nuclear fuel. After debugging, it forever leaves the world of people to work in sealed chambers, and then become radioactive waste and be buried.

And here is the designed equipment that will process “hot” nuclear fuel in the form of melts

It is nitride fuel that is the basis for the Proryv nuclear fuel cycle project, which provides for a fast reactor with a lead coolant and on-site liquid-free fuel refining and fabrication. Such a set of technologies makes the “Breakthrough” very much from the mainstream nuclear fuel cycle, in which the reactor is sodium, the fuel is oxide, and the processing is liquid, so there’s no point in mixing, for example, the nitride fuel plant that is being built in Seversk and BN-800 - it's like two parallel lines.

For example, an experimental line where you can produce up to 20 kilograms per month of tablets from a mixture of uranium, plutonium and neptunium. Those. the line is inside, and we see only protective boxes in which it is in an oxygen-free and anhydrous atmosphere.

Third leg of the NFCF. Fuel fabrication

Fabrication is the assembly of fuel cartridges (fuel assemblies) from the frame, fuel rods pre-packed with uranium fuel (usually in the form of tablets). Of course, every reactor in the world that does not think about nuclear fuel cycle consumes these fuel assemblies every year, so fabrication is a well-developed industrial process. which includes technologically advanced stages of grinding UO2 powder, compressing this powder into tablets, and sintering tablets.

So, the fabrication of fuel for the nuclear fuel cycle breaks all the broad industrial traditions of the fuel assembly plants. Firstly, fuel assemblies collected from the remains of irradiated nuclear fuel are radioactive, which means that all processes must take place without the participation of people. Secondly, plutonium oxide powder is different from uranium. Thirdly, if we nevertheless decided to use nitrides or carbides of uranium-plutonium instead of oxides, an unpleasant discovery awaits us - they self-ignite in air or in the presence of moisture. So grinding, pressing, sintering will have to be carried out in isolated boxes filled with dry nitrogen.

For example, in the right-hand side of the frame there is a box with a press making MOX tablets for BN-800 fuel assemblies.

As a result, fabrication of fuel in the nuclear fuel cycle turns out to be no less important and as difficult as the two previous stages.

The result of the “correct” closure should be the consumption of starting material (U238 or Th232) at the FA factory, the generation of electricity by the reactor, and the flow of highly radioactive waste (fission products and some technological absorbents) from the SNF reprocessing factory. The material balance of all this will be very small - for a gigawatt reactor, about 2.5 tons of U238 per year will be needed and approximately the same amount of fission fragments will be obtained that will have to be buried for tens of thousands of years.

There is also a variant of the nuclear fuel cycle, beloved by publicists, in which in each cycle of the substance circulation in the reactor more fissile materials are obtained than they are loaded - the nuclear fuel storage center with expanded reproduction. There is an important term for it, “fuel doubling time”, i.e. the time period in which in a closed system of two factories and a reactor the plutonium becomes twice as long and one more unit can be launched. For the options under consideration, this period is usually about 30 years, which on the lips of some turns into the main drawback of the nuclear fuel cycle: the amount of starting plutonium is limited and with such a doubling time, say, 100 gigawatts of fast reactors can be built in 100 years or less. However, do not forget about the thousands of tons of U235, which now lies in the composition of natural uranium somewhere in the rocks of the contoured deposits, as well as the last key point of the nuclear fuel cycle,

In 2020, it is planned to launch a SNF reprocessing plant (RBF) from RBMK-1000 and VVER-1000, next to existing repositories.

NFCF - today

This point is quite simple - the NFCF has long existed and works. True, it is not full-fledged, but a kind of "half-money", but technologically everything is in place. We are talking about MOX fuel and SNF reprocessing of conventional energy (usually with water under pressure and thermal neutron spectrum) reactors. Today, this practice is most widely used by France, which processes fuel with ~ 100 gigawatts of reactors from all over Europe and fabricates fuel assemblies with plutonium separated from SNF for loading into the same reactors. There are all the elements here - reactors operating on uranium-plutonium fuel (actually MOX - this is Mixed Oxides - mixed oxides of plutonium and uranium), reprocessing of spent nuclear fuel with plutonium accumulated as a result of irradiation of starting U238, fabrication of new plutoniumMOX-TVS. Moreover, France has a unique experience in fabricating fuel assemblies from plutonium, which was developed in MOX-fuel assemblies, i.e. doubling the use of natural uranium energy.

And of course, one should not forget the small production of MOX fuel for BN-800, launched at the MCC this year. In the frame, automatic welding of the fuel assembly head to the beam of fuel rods.

Why is this a “MISCLE"? Thermal reactors have a too “wrong” neutron spectrum, so for every fission event there are only 0.4-0.5 accumulated atoms. In addition, in such a spectrum in plutonium not only target isotopes 239 and 241 appear, but also neutron poisons 240, 242, and the same poison U236 is produced in uranium. It turns out that the starting material and the target fissile material in the reactor in the thermal spectrum are too “dirty” and too little to support the cycle, absorbing only U238.

Nevertheless, spent fuel from thermal reactors contains about 20% of the starting content of U235 (conversion coefficient is 0.4-0.5, but some of it burns out in the reactor during operation). By reprocessing spent nuclear fuel of 100 gigawatt reactors, the French are able to load 15 gigawatts of power “for free,” without spending natural uranium. Although in reality these “free MOX-fuel assemblies” are three times more expensive than those made from enriched natural uranium, it’s more important for the French to not have to store a huge amount of spent nuclear fuel from their reactors (as is the case in the United States, where almost 100 thousand tons of spent fuel is stored ), and to bury a relatively small amount of fission products.

An important illustration of the benefits of spent nuclear fuel reprocessing: the proportion of radiotoxicity of different components over the years. It can be seen that if plutonium, uranium and minor actinides are separated, the radiotoxicity of the fuel is greatly reduced, especially after 100 years. Unprocessed SNF will have to be stored for hundreds of thousands of years.

Summing up under the educational program on the NFC, I would like to formulate the main points :

1. The NFC exists and the presence / absence of fast reactors is a small part on a large canvas. Today, NFCF is being introduced not because uranium will end soon, but to reduce the amount of radioactive waste being disposed of.

2. Fuel obtained in the NFC cycle is three times more expensive today than that obtained from natural uranium, which is the most important brake on the cycle closure. The second important aspect is the problem of the possible proliferation of nuclear weapons on the planet along with the NFCF.

3. NFCF has the potential for improvement with the transition to new chemistry and technical processes (which is the basis of the BREAKTHROUGH project), but this transition requires a lot of R&D and construction.