Energy-efficient production of polymers and composites using frontal polymerization

The curious use of frontal polymerization for 3D printing the other day was published in Nature.

Researchers from the University of Illinois, Urbana-Champaign (University of Illinois, Urbana-Champaign), have developed a new cost-effective method for producing thermosetting polymers and reinforced polymer composite products promising for industrial applications.

This method can be used to obtain materials such as composite panels for the fuselage of an aircraft, spending 10 times less energy than modern industrial technology. At the same time, new polymers and composites have comparable properties - strength, thermal stability, bending resistance and chemical resistance.

Modern methods for producing high-quality thermosetting polymers require the use of an autoclave, which is necessary for curing the monomer. The use of the autoclave is quite energy-intensive (about 180 ° C for several hours and low pressure), limits the size of the product to the dimensions of the autoclave and requires certain financial investments. According to researchers, the traditional production of a small portion of the fiber-reinforced Boeing 787 composite fuselage requires 96,000 kilowatt-hours of electric energy (~ annual consumption of 9 residential buildings).

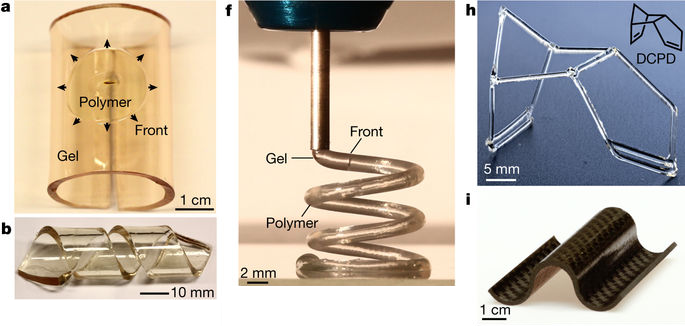

To simplify the process, the researchers turned to the increasingly popular frontal polymerization reaction. In frontal polymerization, the monomer and initiator solution is locally heated until the initiator is activated, which will lead to the polymerization of the monomer. The heat released from the polymerization reaction will start the next cycle of activation of the initiator-polymerization of the monomer until the reagents are exhausted. The name of the process was due to the rapid progress of the line (front) of the reaction through the thickness of the monomer.

UV-initiated frontal polymerization (a random example from youtube) The

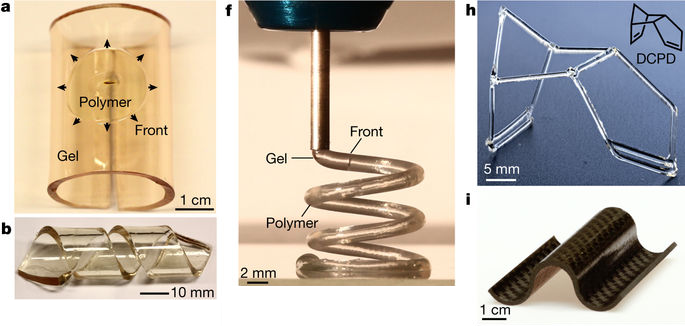

researchers found the use of ruthenium-catalyzed metathesis polymerization (FROMP) solutions of dicyclopentadiene (DCPD).

DCPD monomer is capable of polymerizing into a thermosetting product in 30 minutes when heated. Further optimization of the conditions made it possible to find alkylphosphite inhibitors and expanded the polymerization range from 30 minutes to 30 hours. Frontal polymerization of DCPDs results in highly efficient crosslinked thermosetting polydicyclopentadiene (pDCPD) polymers or polymer composites.

An example of continuous 3D printing and frontal polymerization of a spiral from pDCPD.

Researchers are in the process of obtaining a patent and in finding ways to commercialize the development.

Researchers from the University of Illinois, Urbana-Champaign (University of Illinois, Urbana-Champaign), have developed a new cost-effective method for producing thermosetting polymers and reinforced polymer composite products promising for industrial applications.

This method can be used to obtain materials such as composite panels for the fuselage of an aircraft, spending 10 times less energy than modern industrial technology. At the same time, new polymers and composites have comparable properties - strength, thermal stability, bending resistance and chemical resistance.

Modern methods for producing high-quality thermosetting polymers require the use of an autoclave, which is necessary for curing the monomer. The use of the autoclave is quite energy-intensive (about 180 ° C for several hours and low pressure), limits the size of the product to the dimensions of the autoclave and requires certain financial investments. According to researchers, the traditional production of a small portion of the fiber-reinforced Boeing 787 composite fuselage requires 96,000 kilowatt-hours of electric energy (~ annual consumption of 9 residential buildings).

To simplify the process, the researchers turned to the increasingly popular frontal polymerization reaction. In frontal polymerization, the monomer and initiator solution is locally heated until the initiator is activated, which will lead to the polymerization of the monomer. The heat released from the polymerization reaction will start the next cycle of activation of the initiator-polymerization of the monomer until the reagents are exhausted. The name of the process was due to the rapid progress of the line (front) of the reaction through the thickness of the monomer.

UV-initiated frontal polymerization (a random example from youtube) The

researchers found the use of ruthenium-catalyzed metathesis polymerization (FROMP) solutions of dicyclopentadiene (DCPD).

DCPD monomer is capable of polymerizing into a thermosetting product in 30 minutes when heated. Further optimization of the conditions made it possible to find alkylphosphite inhibitors and expanded the polymerization range from 30 minutes to 30 hours. Frontal polymerization of DCPDs results in highly efficient crosslinked thermosetting polydicyclopentadiene (pDCPD) polymers or polymer composites.

An example of continuous 3D printing and frontal polymerization of a spiral from pDCPD.

Links to other examples

Nature is in no hurry to keep up with the times, so only links. (Hint, you can use Imagus).

Video 1: Frontal polymerization of an elastic pDCPD gel rolled into a cylinder.

Video 2: Continuous 3D printing and frontal polymerization of a pDCPD helix.

Video 3: In-plane frontal curing of a 12-ply carbon fiber composite initiated by one resistive heating wire.

FROMP of a 12-ply composite is initiated by powering a single embedded resistive heating wire for 20 seconds.

Video 4: In-plane frontal curing of a 12-ply carbon fiber composite initiated by two resistive heating wires.

Video 5: Through-thickness frontal curing of a 12-ply carbon fiber composite initiated by a surface heater.

Video 1: Frontal polymerization of an elastic pDCPD gel rolled into a cylinder.

Video 2: Continuous 3D printing and frontal polymerization of a pDCPD helix.

Video 3: In-plane frontal curing of a 12-ply carbon fiber composite initiated by one resistive heating wire.

FROMP of a 12-ply composite is initiated by powering a single embedded resistive heating wire for 20 seconds.

Video 4: In-plane frontal curing of a 12-ply carbon fiber composite initiated by two resistive heating wires.

Video 5: Through-thickness frontal curing of a 12-ply carbon fiber composite initiated by a surface heater.

Researchers are in the process of obtaining a patent and in finding ways to commercialize the development.