Report from the IMTS 2016 manufacturing exhibition (USA)

Hello everyone, Vasily Kiselev, the founder and director of Top 3D Shop, who has just returned from the United States, where the insane in scale and probably the largest international production exhibition IMTS 2016 was held from September 12 to 17 .

The exhibition presented truly advanced technologies for processing metals, plastics and other materials, and of course additive technologies.

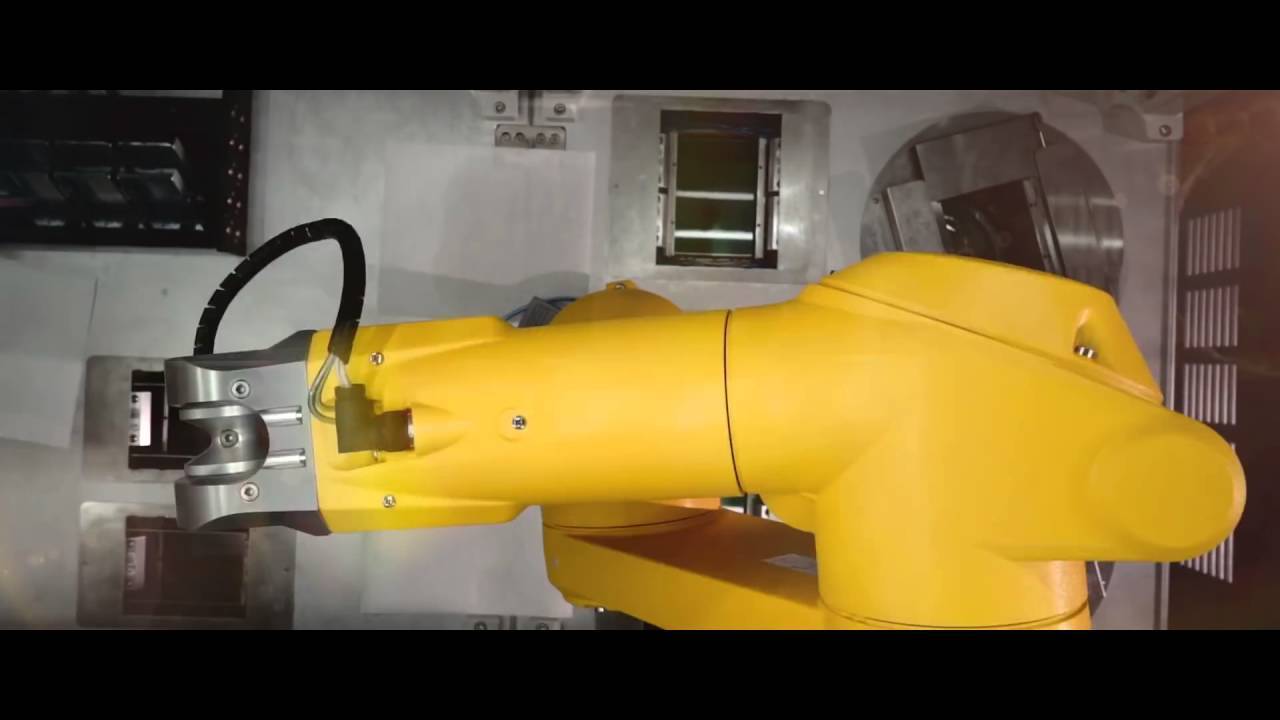

Global Robotization

Robots everywhere, in different sizes and tasks!

The most famous world manufacturers of robots are the German company KUKA-Robotics and Japanese FANUC , but there were much more at the exhibition.

Such robots are common in the automotive industry, in particular, they are installed at the TESLA factory, and many more.

Moreover, robots are positioned not only for solving standard tasks such as packaging and assembly, but also for additive production and scrap control using 3D scanners.

STRATASYS

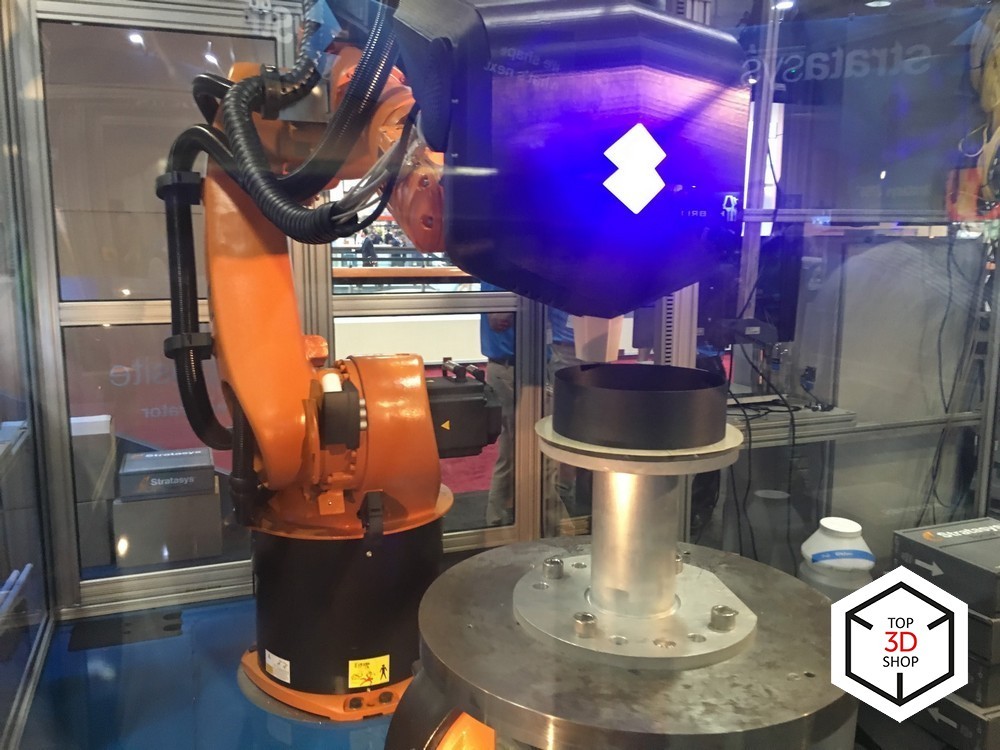

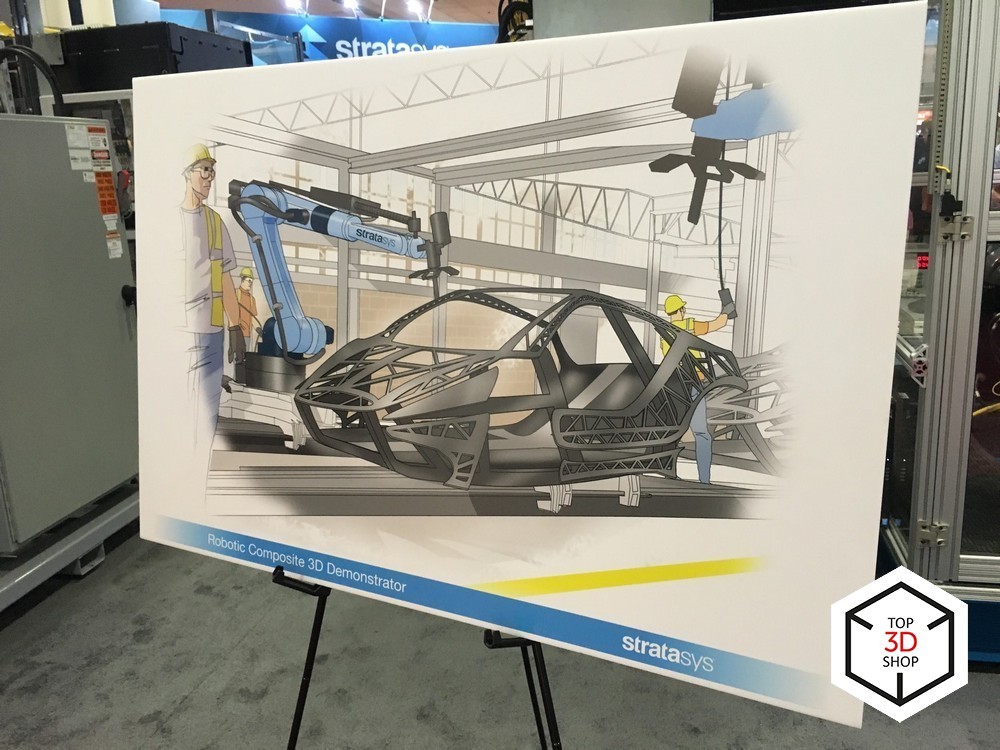

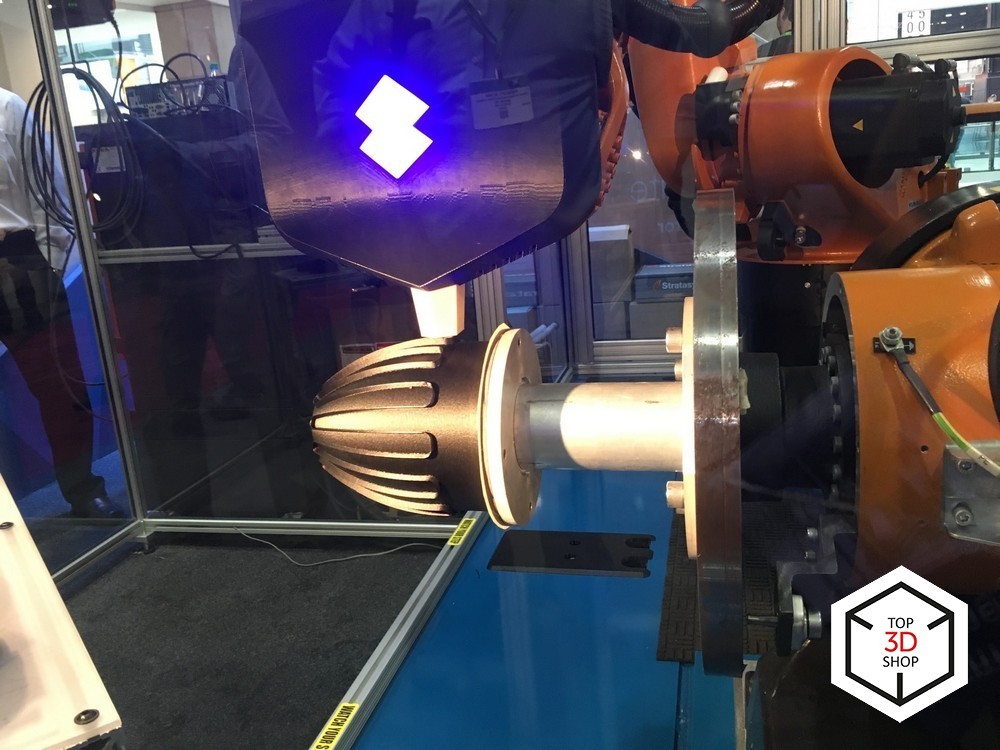

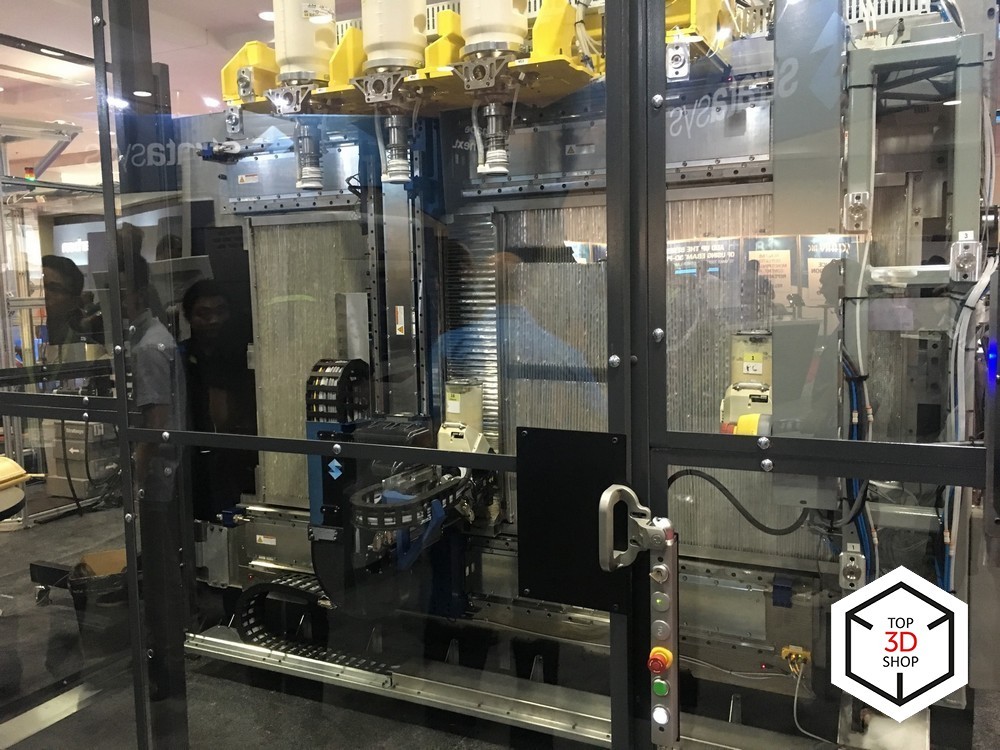

In front of you is a completely new robotic FDM 3D printer from Stratasys, created in conjunction with Siemens and KUKA.

This additive robot allows you to achieve significant strength and lightness of the product due to the combination of the layout of layers, and also allows you to save material, as it works with 8 axes and moves both the robotic arm and the table in space, adjusting the object to the desired print angle.

Such robots are designed primarily for the aerospace, defense industry and the automotive industry.

Stratasys is already partnering with Ford and is testing these conveyor machines.

Such multi-axis 3D printers in the future they want to use on assembly lines.

Of course, the technology is still raw at the moment, but this concept should be taken more as the first steps for introducing fast additive production into mass traditional.

The next novelty from Stratasys is an industrial 3d printer, which adapts to the production needs of the customer and allows you to create dimensional objects of complex shapes directly in the workshop.

This engineering miracle looks like this:

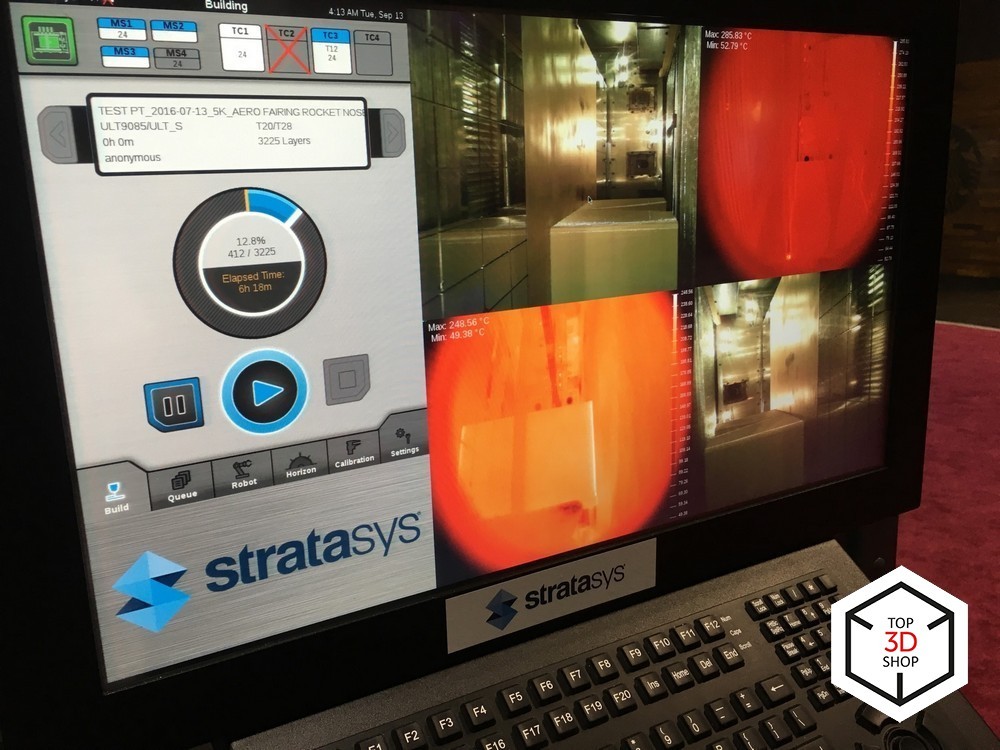

In essence, this is an FDM 3D printer that feeds on granules of a composite material and works in its own heat chamber.

Machine control panel: The

birth of the part itself from the heat chamber

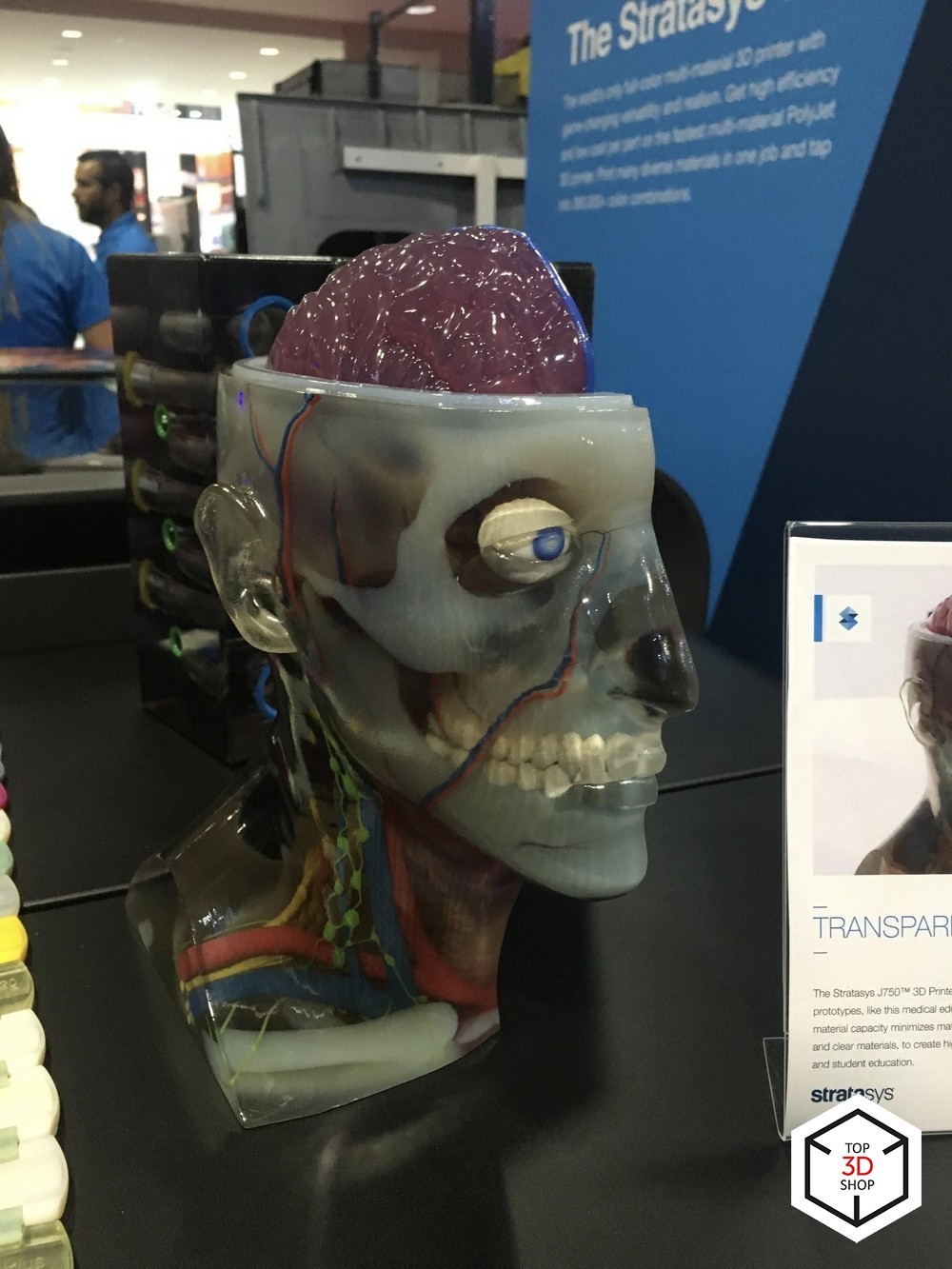

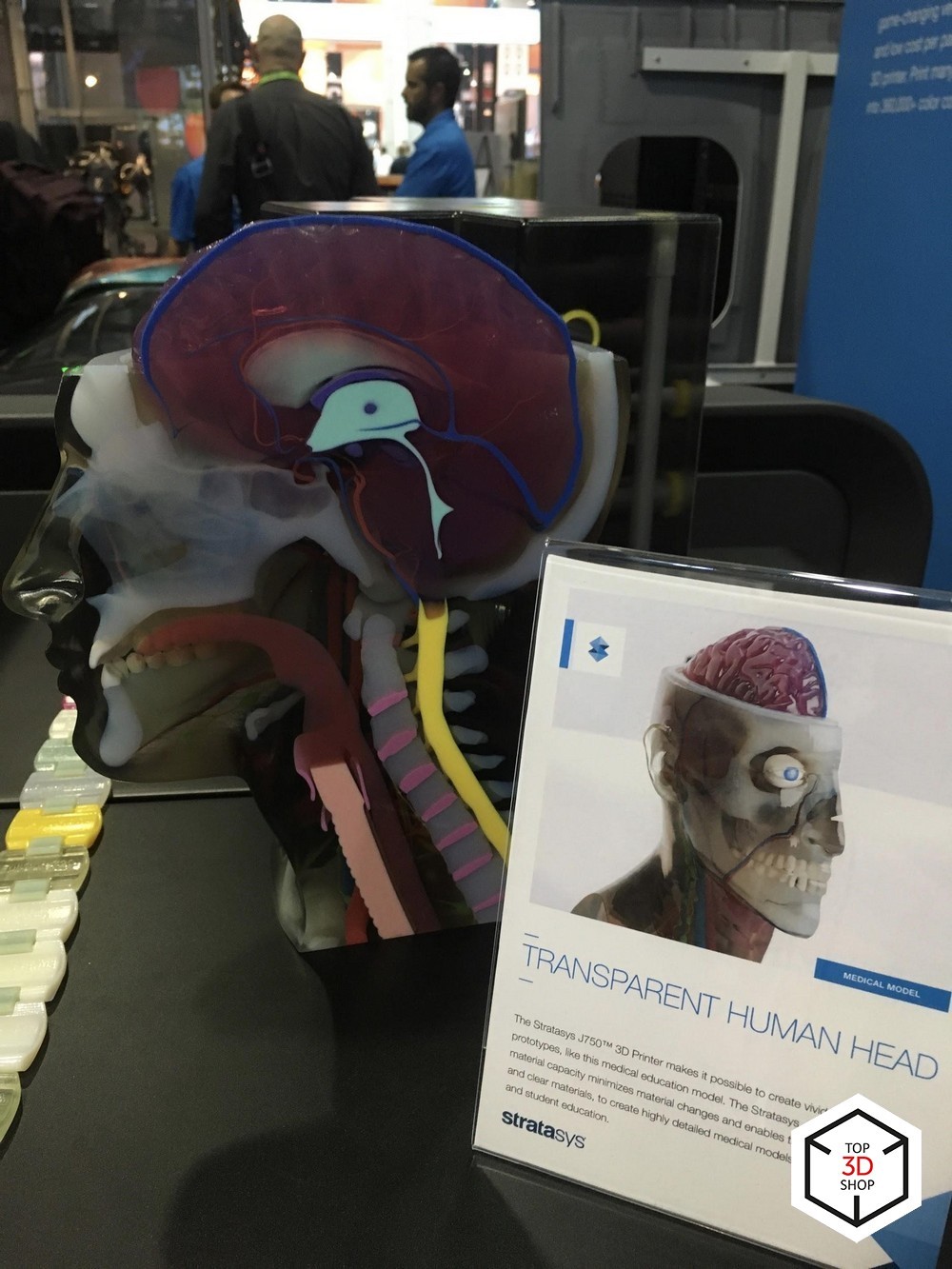

In addition to industrial solutions, Stratasys introduced the multimaterial J750 multi-color 3d printer.

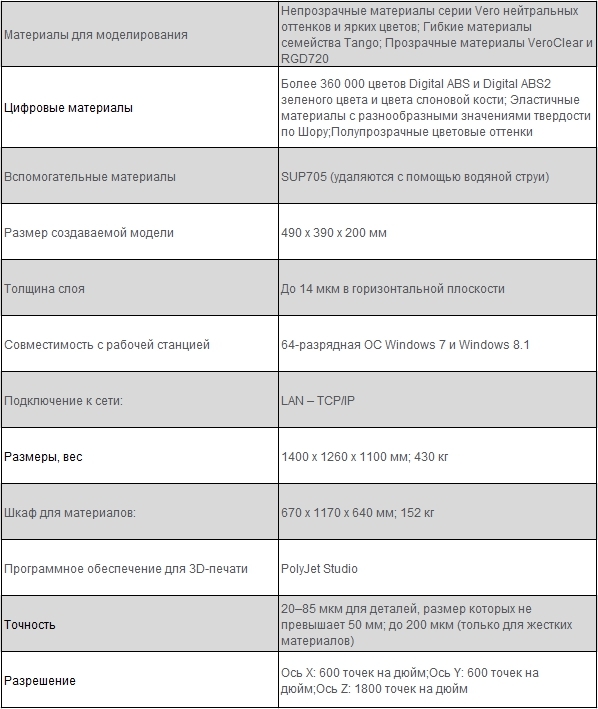

Specifications:

Its distinctive feature is the ability to use not only individual colors, but also shades in combination with a rather large working camera.

That allows you to achieve such a result:

Of the shortcomings, this is of course the price of the equipment itself and consumables.

3D SYSTEMS

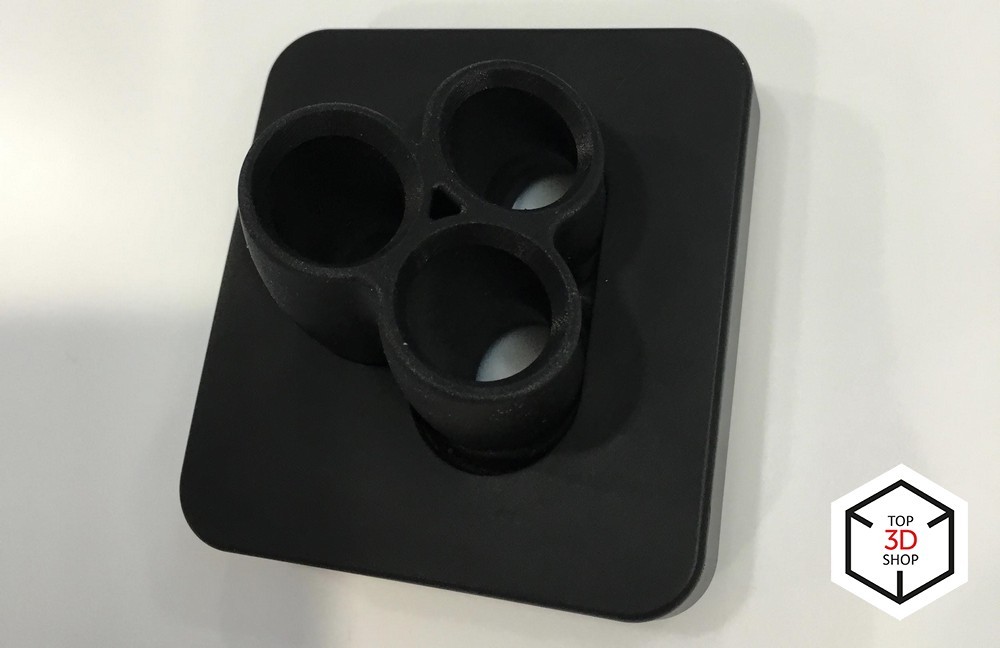

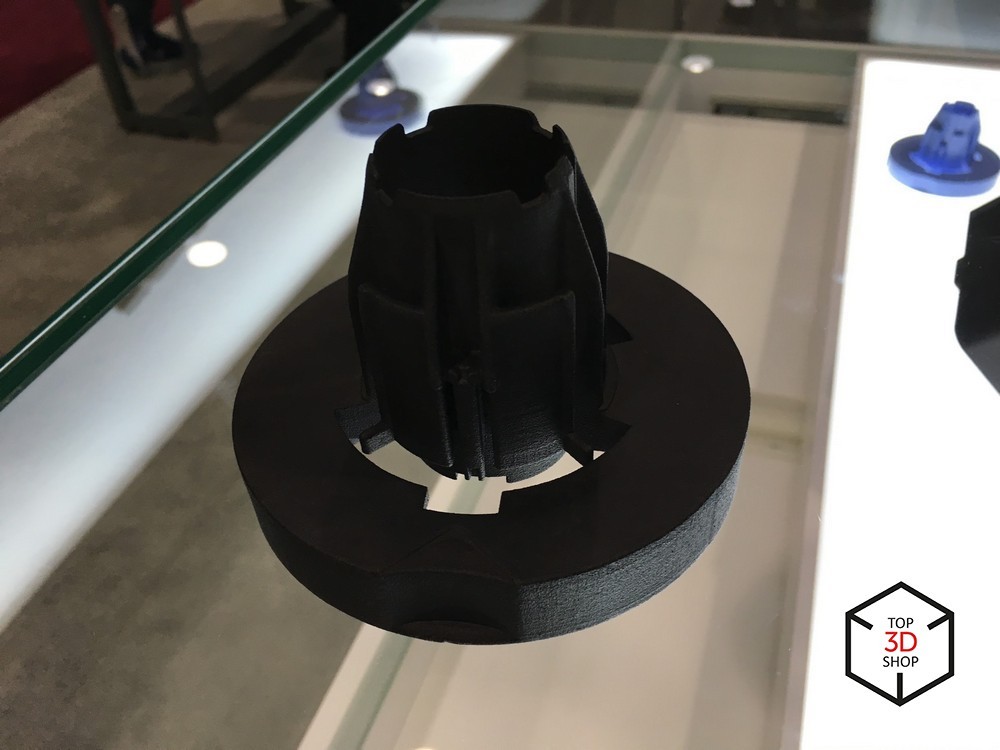

This Major presented a decent answer Carbon 3D, which will be discussed below. Robotic solution for fast and high-precision modular mini-production - Figure 4 (Figure 4).

The name of the installation refers to the element included in the old 3D Systems patent from 1984, filed by Chuck Hall himself, an element called “Figure 4”.

The installation can create objects with jewelry accuracy with the speed of Carbon 3D (not in hours, but in minutes), and a robotic arm provides the collection of construction platforms, cleaning objects from the polymer and transfers the grown parts to the geometry control unit (comparison with the original CAD model) for marriage control.

At the same time, the quality of the models remains at the level. No defects were noticed, despite the very fast printing speed.

3D Systems considers it possible to replace Fugure 4 with a direct replacement for injection molding.

I saw for myself that the new prof. cars of the middle price segment ProJet MJP 2500.

CARBON

The notorious startup Carbon 3D (recently just Carbon) has already invested more than $ 222,000,000 from BMW, Nikon, General Electric, Autodesk, and even Yuri Milner for the first time unveiled its legendary 3D printer M1, powered by ultra-fast CLIP technology (100 times faster than competitors SLA-DLP)

The printer supports a large number of materials (standard, detailed, heat-resistant, flexible and elastic resins) and is distributed so far only in the USA by subscription only - a completely new scheme for this business.

I held demo objects in my hands and they impressed me with their quality.

HP

I managed to see a car, the announcement of which was already in 2014! Meet: HP 3D Jet Jet Fusion Printer:

The process itself is reminiscent of SLS technology:

After picking up the sample, there is no doubt - this is a powder printer. The only question is how the granules join: sintering, gluing or chemical reaction?

In any case, we are assured that it is at least 10 times faster than competitors. Well, we are waiting for the first cars in Russia.

That's all about high-profile updates.

Despite the fact that additive technologies at the exhibition occupied a very small part, this time they managed to impress and the vendors show the correct vector of development needed by the market.

Vasily Kiselev , CEO of Top 3D Shop