Where do the best rocket engines in the world do

I had the opportunity to be at the enterprise where rocket engines were created and are being created, which pulled almost the entire Soviet space program, and now they are pulling the Russian, Ukrainian, South Korean and, in part, even American. Meet: NPO Energomash, recently included in the United Rocket and Space Corporation of Russia, a place where they make the best and most powerful liquid-propellant rocket engines in the world.

These words are not pathos. Judge for yourself: here, in Khimki near Moscow, engines for the Soviet-Russian missiles Soyuz and Proton have been developed; for the Russian Angara; for the Soviet-Ukrainian Zenith and Dnipro; for the South Korean KSLV-1 and for the American Atlas-5 rocket. But first things first…

After checking the passport and the arrival of an escort, we advance to the museum of the factory from the entrance, or as it is called the "Showroom".

Hall keeper Vladimir Sudakov - head of the Information Department. Apparently, he copes with his duties well - he was one of all my interlocutors who knew who Zelenyikot was.

Vladimir conducted a short but capacious tour in the museum.

See on the table 7 centimeters zhikalku? So the whole Soviet and Russian space grew from it.

NPO Energomash evolved from a small group of rocket science enthusiasts, formed in 1921, and in 1929 called the Gas Dynamic Laboratory , the head there was Valentin Petrovich Glushko , later he became the general designer of the NGO "

A disk with a sphere in the center is not a model of the solar system, as I thought, but a model of an electric rocket spaceship. The disk was supposed to place solar panels. In the background are the first models of liquid propellant rocket engines developed by the GDL.

For the first concepts of the 20-30s. went real work on government funding. Here the GDL was already working together with the Royal GIRD . In wartime, the "sharashka" developed rocket boosters for serial military aircraft. They created a whole line of engines, and believed that they were one of the world leaders in liquid engine manufacturing.

But the Germans spoiled the weather, who created the first A4 ballistic missile, better known in Russia under the name V-2.

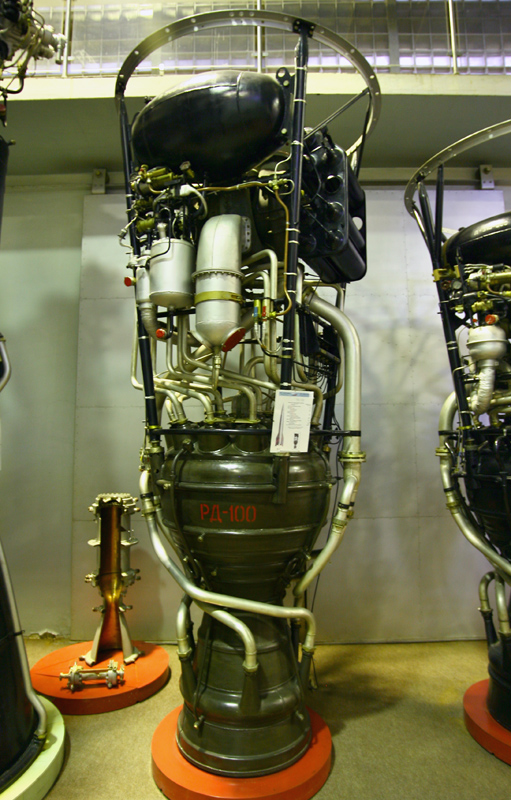

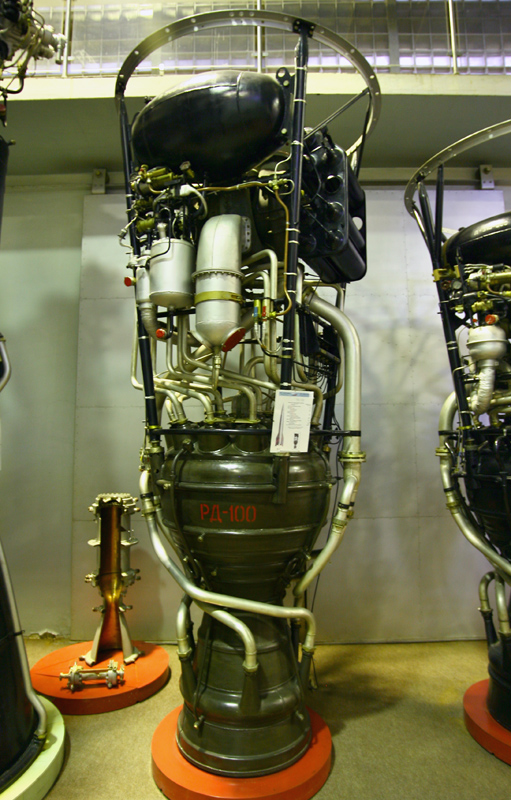

Its engine was more than an order of magnitude superior to Soviet developments (25 tons versus 900 kg), and after the war, engineers began to catch up.

First, they created a full A4 replica called R-1, but using completely Soviet materials. At this period, our engineers were still helped by the German. But they tried not to allow secret developments, so ours further worked on their own.

First of all, the engineers began to force and lighten the German design, and achieved considerable success in this - the thrust increased to 51 tf.

But further there were problems of instability of fuel combustion in a larger spherical combustion chamber. Glushko realized that this was a dead end and began to develop engines with a cylindrical chamber.

In this field, he succeeded. In the hands of the keeper of the museum - the first working prototype, which confirmed the fidelity of the chosen scheme. What is most surprising - the inside of the combustion chamber is a copper alloy. It seems that an element where the pressure exceeds hundreds of atmospheres and the temperature is a thousand degrees Celsius should be made of some refractory titanium or tungsten. But it turned out to be easier to cool the camera, and not to achieve unlimited heat resistance. The chamber was cooled by liquid fuel components, and copper was used because of its high thermal conductivity.

The first developments with a new type of combustion chamber were military. In the showroom, they are hidden in the farthest and darkest corner. And in the world - pride - the engines RD-107 and RD-108, which provided the Soviet Union with superiority in space, and allow Russia to lead in manned space exploration to this day.

Vladimir Sudakov shows steering cameras - additional rocket engines that allow you to control the flight.

In further developments, such a design was refused - they decided to simply reject the entire mid-flight chamber of the engine.

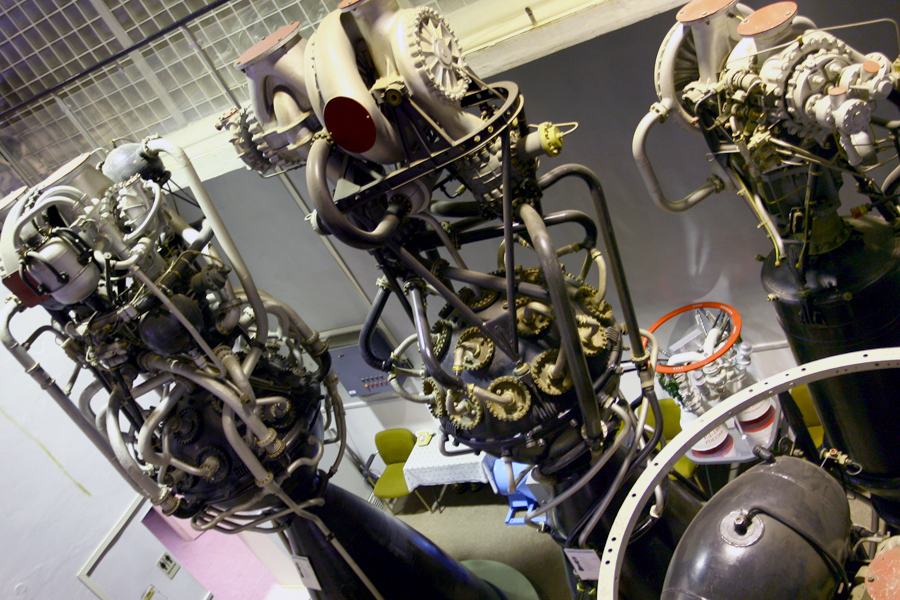

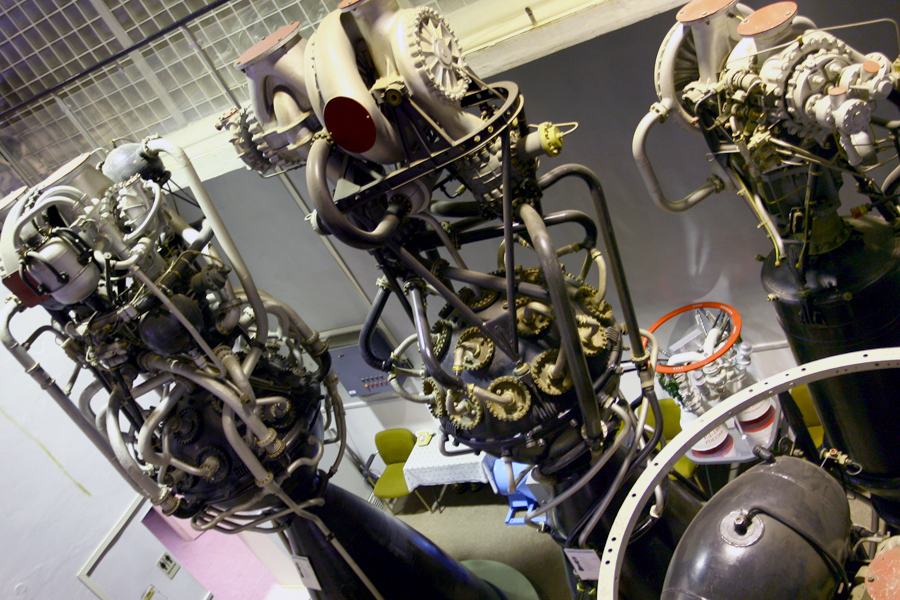

Problems with the instability of combustion in large chambers have not been completely resolved, therefore, most of the engines of the Glushko Design Bureau are multi-chamber.

There is only one single-chamber giant in the hall, which was developed for the lunar program, but did not go into the series - the competing version of the NK-33 for the H1 rocket won.

Their difference is that H1 was run on oxygen-kerosene, and Glushko was ready to run people on dimethylhydrazine-nitrogen tetroxide. Such a mixture is more effective, but much more toxic than kerosene. In Russia, only the cargo Proton flies on it. However, this does not prevent China from launching its own taikonauts precisely on such a mixture.

You can look at the engine "Proton".

And the engine for the R-36M ballistic missile still stands on combat duty in the Voyevoda missiles, commonly known under the NATO name Satan.

However, now they, under the name "Dnepr", are also being launched for peaceful purposes.

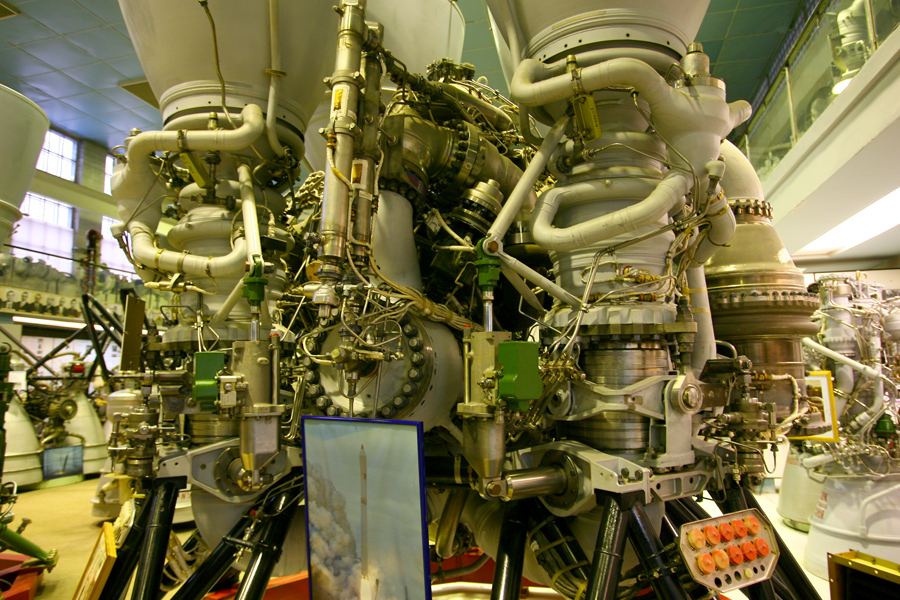

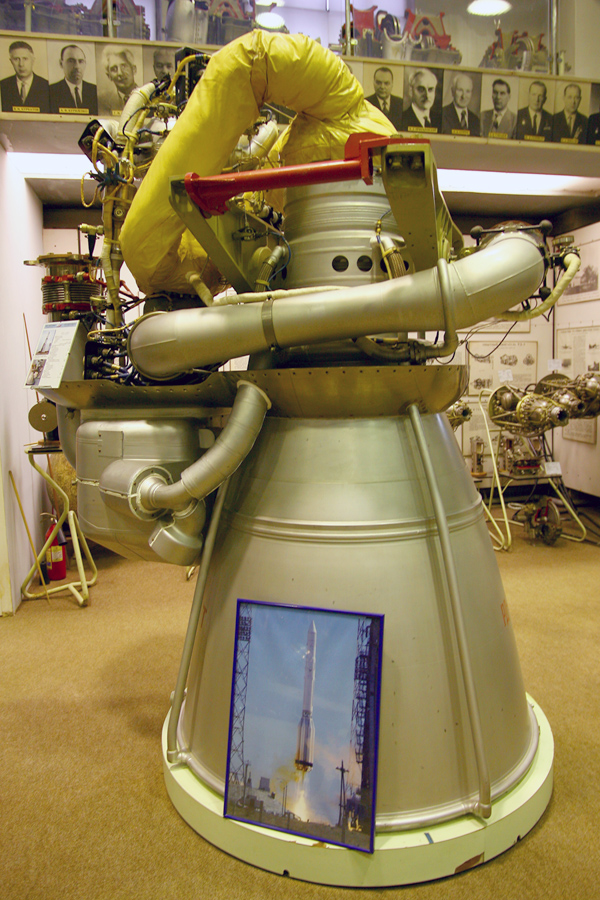

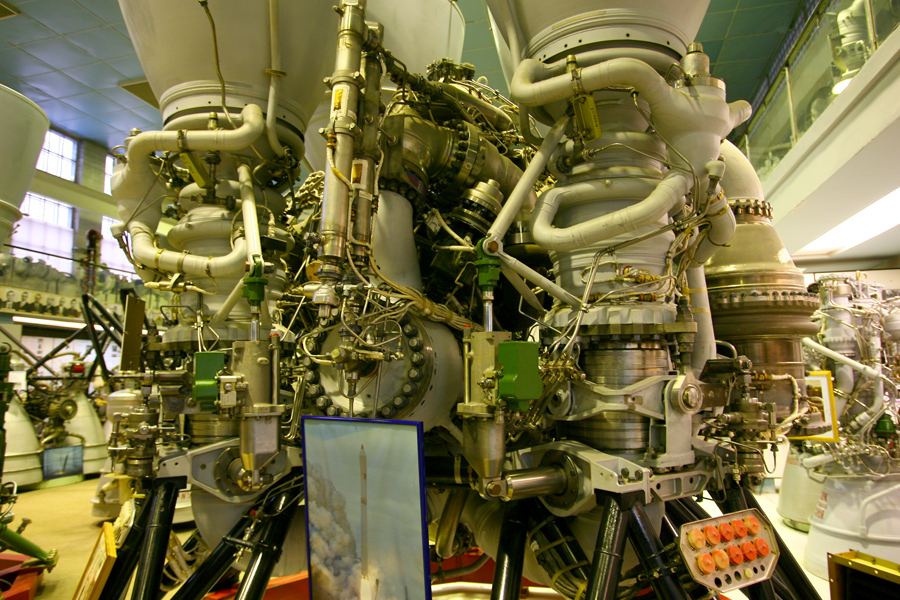

Finally, we get to the pearl of KB Glushko and the pride of NPO Energomash - the RD-170/171 engine .

Today - it is the most powerful oxygen-kerosene engine in the world - a thrust of 800 tf. It surpasses the American lunar F-1 by 100 tf, but achieves this due to four combustion chambers, against one in F-1.

RD-170 was developed for the Energia-Buran project, as side accelerator engines. According to the initial design, reusability of the accelerators was assumed, so the engines were designed and certified for tenfold use. Unfortunately, the accelerator return was never realized, but the engines retain their capabilities. After the closure of the Buran program, the RD-170 was more lucky than the lunar F-1 - it found more utilitarian use in the Zenit rocket. In Soviet times, it, like the Voivode, was developed by the Yuzhnoye Design Bureau, which, after the collapse of the USSR, was abroad. But in the 90s, politics did not interfere with Russian-Ukrainian cooperation, and by 1995, the Sea Launch project began to be implemented jointly with the USA and Norway.". Although it did not reach profitability, it was reorganized and its fate is being decided now, but rockets flew and orders for engines were supported by Energomash during the years of spaceless money of the 90s and early 2000s.

Vladimir Sudakov demonstrates the fantastic development of engineers "Energomash" - an integral bellows unit swing engine.

How to achieve node mobility at high pressures and extreme temperatures Yes garbage question, only 12 metal layers and additional booking rings fill with liquid oxygen between the layer and n? t problems ...

This design allows the engine rigidly fix, but control the flight deviation of the combustion chamber and the nozzle by means of the gimbal. The engine it is visible just below and to the right of center of the panel with red covers.

Americans about their cosmos love to repeat "We stand on the shoulders of giants." Looking at such creations of Soviet engineers, you understand that this phrase fully applies to Russian cosmonautics. The same "Angara", although the brainchild of already Russian designers, but its engine - RD-191 evolutionarily goes back to RD-171.

In the same way, the “half” of the RD-171, under the name RD-180, contributed to the American space program when Energomash won the Lockheed Martin competition in 1995. I asked if there was a propaganda element in this victory - whether the Americans could sign a contract with the Russians, to demonstrate the end of the era of rivalry and the beginning of cooperation in space. They didn’t answer me, but they told me about the awesome eyes of American customers when they saw the creations of the gloomy Khimki genius. According to rumors, the characteristics of the RD-180 were almost double the characteristics of competitors. The reason is that the United States has not mastered closed-cycle rocket engines . In principle, it is possible without it, the same F-1 was open-cycle or Merlinfrom SpaceX. But in the power-to-mass ratio, closed-loop engines win, although they lose in price.

Here on the video of the tests of the Merlin-1D engine it is seen how a jet of generator gas gushes from the tube next to the nozzle:

In a closed cycle, this gas returns to the combustion chamber, which allows more efficient use of fuel. The museum has a separately installed rotor of the oxidizer booster pump unit. We will meet such rotors more than once on tours of NPO Energomash.

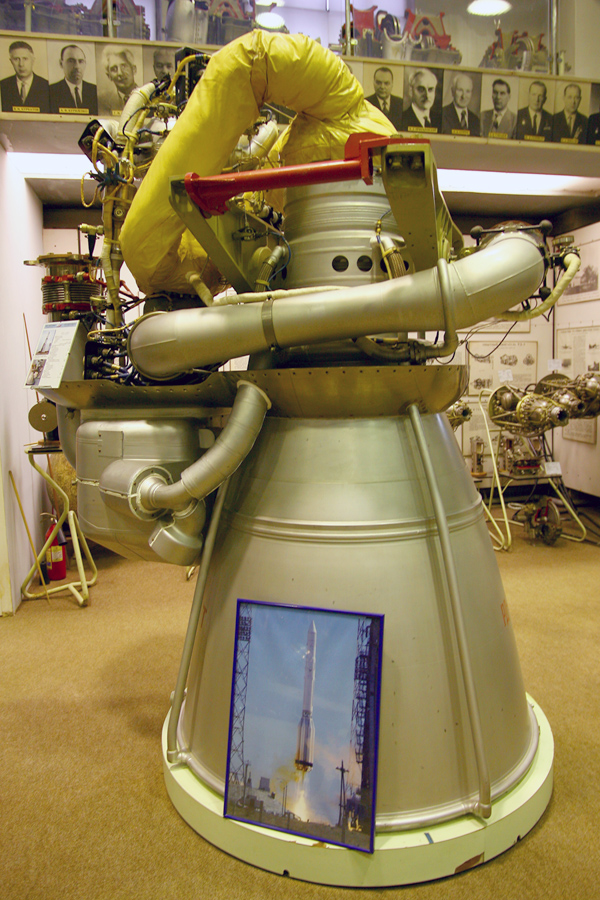

Finally, the completion of the exposition - the hope of the enterprise - is the RD-191 engine. This is still the youngest model in the family. It was created for the Angara rocket, managed to work in the Korean KSLV-1, and it is considered as one of the options by the American company Orbital Scienses, which needed to replace the Samara NK-33 after the Antares rocket accident in October.

At the factory, this trinity RD-170, RD-180, RD-191 is jokingly called the "liter", "half liter" and "quarter".

Wow, something voluminous turned out excursion. Let's postpone the inspection of the plant the next day. There is also a lot of interesting things, and most importantly it turned out to see how such a miracle of engineering is created from a pile of steel and aluminum ingots.

I express gratitude to the Department of Information Policy and Mass Media of the United Rocket and Space Corporation and the press service of NPO Energomash for their help in organizing the shootings .

These words are not pathos. Judge for yourself: here, in Khimki near Moscow, engines for the Soviet-Russian missiles Soyuz and Proton have been developed; for the Russian Angara; for the Soviet-Ukrainian Zenith and Dnipro; for the South Korean KSLV-1 and for the American Atlas-5 rocket. But first things first…

After checking the passport and the arrival of an escort, we advance to the museum of the factory from the entrance, or as it is called the "Showroom".

Hall keeper Vladimir Sudakov - head of the Information Department. Apparently, he copes with his duties well - he was one of all my interlocutors who knew who Zelenyikot was.

Vladimir conducted a short but capacious tour in the museum.

See on the table 7 centimeters zhikalku? So the whole Soviet and Russian space grew from it.

NPO Energomash evolved from a small group of rocket science enthusiasts, formed in 1921, and in 1929 called the Gas Dynamic Laboratory , the head there was Valentin Petrovich Glushko , later he became the general designer of the NGO "

A disk with a sphere in the center is not a model of the solar system, as I thought, but a model of an electric rocket spaceship. The disk was supposed to place solar panels. In the background are the first models of liquid propellant rocket engines developed by the GDL.

For the first concepts of the 20-30s. went real work on government funding. Here the GDL was already working together with the Royal GIRD . In wartime, the "sharashka" developed rocket boosters for serial military aircraft. They created a whole line of engines, and believed that they were one of the world leaders in liquid engine manufacturing.

But the Germans spoiled the weather, who created the first A4 ballistic missile, better known in Russia under the name V-2.

Its engine was more than an order of magnitude superior to Soviet developments (25 tons versus 900 kg), and after the war, engineers began to catch up.

First, they created a full A4 replica called R-1, but using completely Soviet materials. At this period, our engineers were still helped by the German. But they tried not to allow secret developments, so ours further worked on their own.

First of all, the engineers began to force and lighten the German design, and achieved considerable success in this - the thrust increased to 51 tf.

But further there were problems of instability of fuel combustion in a larger spherical combustion chamber. Glushko realized that this was a dead end and began to develop engines with a cylindrical chamber.

In this field, he succeeded. In the hands of the keeper of the museum - the first working prototype, which confirmed the fidelity of the chosen scheme. What is most surprising - the inside of the combustion chamber is a copper alloy. It seems that an element where the pressure exceeds hundreds of atmospheres and the temperature is a thousand degrees Celsius should be made of some refractory titanium or tungsten. But it turned out to be easier to cool the camera, and not to achieve unlimited heat resistance. The chamber was cooled by liquid fuel components, and copper was used because of its high thermal conductivity.

The first developments with a new type of combustion chamber were military. In the showroom, they are hidden in the farthest and darkest corner. And in the world - pride - the engines RD-107 and RD-108, which provided the Soviet Union with superiority in space, and allow Russia to lead in manned space exploration to this day.

Vladimir Sudakov shows steering cameras - additional rocket engines that allow you to control the flight.

In further developments, such a design was refused - they decided to simply reject the entire mid-flight chamber of the engine.

Problems with the instability of combustion in large chambers have not been completely resolved, therefore, most of the engines of the Glushko Design Bureau are multi-chamber.

There is only one single-chamber giant in the hall, which was developed for the lunar program, but did not go into the series - the competing version of the NK-33 for the H1 rocket won.

Their difference is that H1 was run on oxygen-kerosene, and Glushko was ready to run people on dimethylhydrazine-nitrogen tetroxide. Such a mixture is more effective, but much more toxic than kerosene. In Russia, only the cargo Proton flies on it. However, this does not prevent China from launching its own taikonauts precisely on such a mixture.

You can look at the engine "Proton".

And the engine for the R-36M ballistic missile still stands on combat duty in the Voyevoda missiles, commonly known under the NATO name Satan.

However, now they, under the name "Dnepr", are also being launched for peaceful purposes.

Finally, we get to the pearl of KB Glushko and the pride of NPO Energomash - the RD-170/171 engine .

Today - it is the most powerful oxygen-kerosene engine in the world - a thrust of 800 tf. It surpasses the American lunar F-1 by 100 tf, but achieves this due to four combustion chambers, against one in F-1.

RD-170 was developed for the Energia-Buran project, as side accelerator engines. According to the initial design, reusability of the accelerators was assumed, so the engines were designed and certified for tenfold use. Unfortunately, the accelerator return was never realized, but the engines retain their capabilities. After the closure of the Buran program, the RD-170 was more lucky than the lunar F-1 - it found more utilitarian use in the Zenit rocket. In Soviet times, it, like the Voivode, was developed by the Yuzhnoye Design Bureau, which, after the collapse of the USSR, was abroad. But in the 90s, politics did not interfere with Russian-Ukrainian cooperation, and by 1995, the Sea Launch project began to be implemented jointly with the USA and Norway.". Although it did not reach profitability, it was reorganized and its fate is being decided now, but rockets flew and orders for engines were supported by Energomash during the years of spaceless money of the 90s and early 2000s.

Vladimir Sudakov demonstrates the fantastic development of engineers "Energomash" - an integral bellows unit swing engine.

How to achieve node mobility at high pressures and extreme temperatures Yes garbage question, only 12 metal layers and additional booking rings fill with liquid oxygen between the layer and n? t problems ...

This design allows the engine rigidly fix, but control the flight deviation of the combustion chamber and the nozzle by means of the gimbal. The engine it is visible just below and to the right of center of the panel with red covers.

Americans about their cosmos love to repeat "We stand on the shoulders of giants." Looking at such creations of Soviet engineers, you understand that this phrase fully applies to Russian cosmonautics. The same "Angara", although the brainchild of already Russian designers, but its engine - RD-191 evolutionarily goes back to RD-171.

In the same way, the “half” of the RD-171, under the name RD-180, contributed to the American space program when Energomash won the Lockheed Martin competition in 1995. I asked if there was a propaganda element in this victory - whether the Americans could sign a contract with the Russians, to demonstrate the end of the era of rivalry and the beginning of cooperation in space. They didn’t answer me, but they told me about the awesome eyes of American customers when they saw the creations of the gloomy Khimki genius. According to rumors, the characteristics of the RD-180 were almost double the characteristics of competitors. The reason is that the United States has not mastered closed-cycle rocket engines . In principle, it is possible without it, the same F-1 was open-cycle or Merlinfrom SpaceX. But in the power-to-mass ratio, closed-loop engines win, although they lose in price.

Here on the video of the tests of the Merlin-1D engine it is seen how a jet of generator gas gushes from the tube next to the nozzle:

In a closed cycle, this gas returns to the combustion chamber, which allows more efficient use of fuel. The museum has a separately installed rotor of the oxidizer booster pump unit. We will meet such rotors more than once on tours of NPO Energomash.

Finally, the completion of the exposition - the hope of the enterprise - is the RD-191 engine. This is still the youngest model in the family. It was created for the Angara rocket, managed to work in the Korean KSLV-1, and it is considered as one of the options by the American company Orbital Scienses, which needed to replace the Samara NK-33 after the Antares rocket accident in October.

At the factory, this trinity RD-170, RD-180, RD-191 is jokingly called the "liter", "half liter" and "quarter".

Wow, something voluminous turned out excursion. Let's postpone the inspection of the plant the next day. There is also a lot of interesting things, and most importantly it turned out to see how such a miracle of engineering is created from a pile of steel and aluminum ingots.

I express gratitude to the Department of Information Policy and Mass Media of the United Rocket and Space Corporation and the press service of NPO Energomash for their help in organizing the shootings .