Simple Scada in Python and Arduino

In continuation of the article about the possibility of building your own scada system in Python, I want to offer a practical application.

There was a need to control the air temperature in the server room of the enterprise.

Such a problem exists in small enterprises due to the limited number of personnel and technical equipment.

The problem is certainly not of a global scale, but, as a rule, at such enterprises server equipment is located in small rooms, sometimes in former copters or utility rooms.

Of course, air conditioning is installed there to effectively cool the equipment.

But this same air conditioner tends to break, as repairmen explain, either the "capacitor burned out" or the "freon is over."

After such emergency situations, IT engineers have a lot of problems; those who come across this will understand. The task is not difficult, in addition to the network there are many examples of implementation. For this purpose, it was decided to use the Arduino UNO and the temperature sensor DS18b20.

After reading the article , uploaded to Arduino

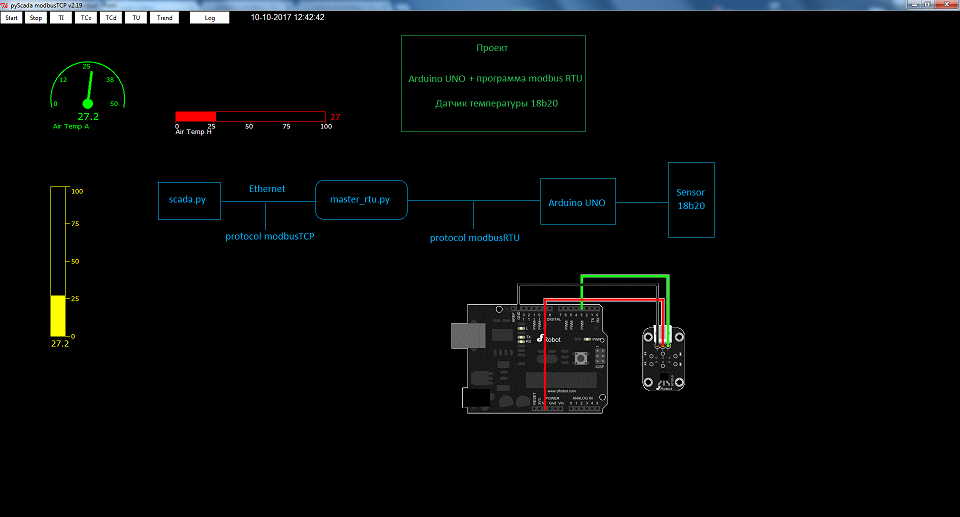

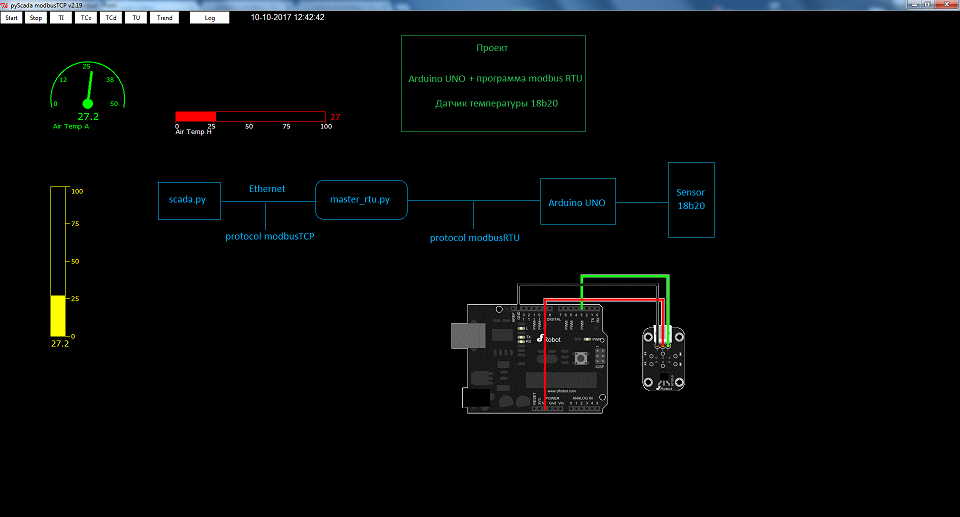

Now Arduino acts as a Slave device with address 10 and operates on the modbus RTU protocol. In addition, the program continuously polls the DS18b20 temperature sensor and records the current readings at address 2 of the READ_INPUT_REGISTERS register.

Since the Slave device is connected to the computer via a USB interface with a dedicated com port, you can use the program to receive data from it:

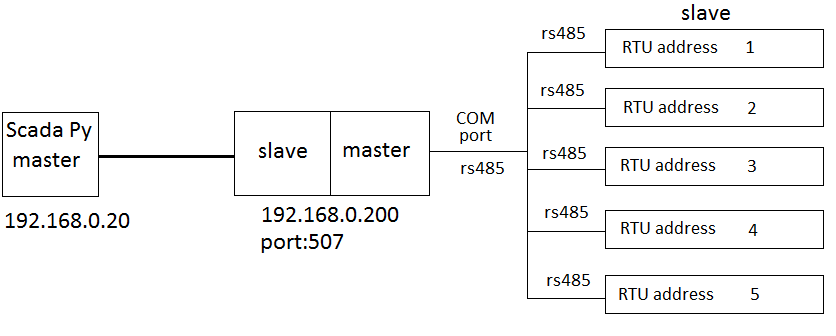

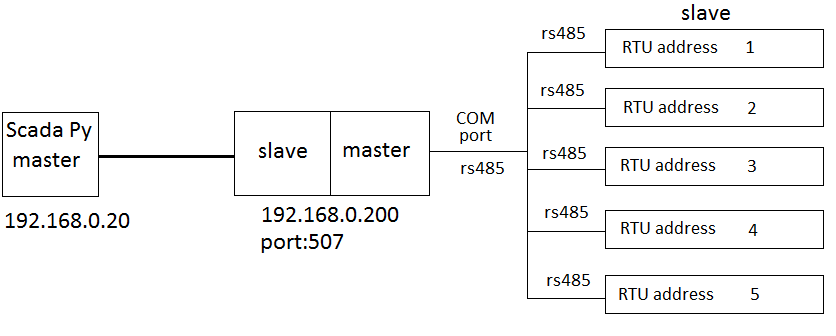

On the one hand, this program is a Master for polling slaves using the modbus RTU protocol, and on the other hand, it is a Slave device and transmits data to the upper level using the modbus TCP protocol.

The master_rtu.py program is used if you have to collect readings from several devices using the modbus RTU protocol and / or rs485 interface. The com file address and rtu address of the slave devices are indicated in the configuration file. In addition, the polling registers and the addresses of the registers into which the received data are recorded are indicated.

Description of setting.cfg settings file for master_rtu.py :

In this configuration, the modbus RTU Slave device with address 10 will be polled. In the READ_INPUT_REGISTERS register at address 2, the measured temperature value will be read and written into the READ_INPUT_REGISTERS register at address 0 slave of the program part for modbus TCP polling.

In the ai.cfg analog signal settings file, write:

Those. we will take the measured value of the temperature of the register READ_INPUT_REGISTERS at 0x00, place it on the canvas at coordinates x = 100, y = 100 and display the mnemonic diagram using the arrow object.

In the settings.cfg settings file for scada.py we write:

The measurement results can be displayed on various objects of the mnemonic diagram, including monitoring on a dynamic chart.

Source code can be downloaded here.

There was a need to control the air temperature in the server room of the enterprise.

Such a problem exists in small enterprises due to the limited number of personnel and technical equipment.

The problem is certainly not of a global scale, but, as a rule, at such enterprises server equipment is located in small rooms, sometimes in former copters or utility rooms.

Of course, air conditioning is installed there to effectively cool the equipment.

But this same air conditioner tends to break, as repairmen explain, either the "capacitor burned out" or the "freon is over."

After such emergency situations, IT engineers have a lot of problems; those who come across this will understand. The task is not difficult, in addition to the network there are many examples of implementation. For this purpose, it was decided to use the Arduino UNO and the temperature sensor DS18b20.

After reading the article , uploaded to Arduino

the program.

#include "ModbusRtu.h"

#include

#define ID 10 // адрес ведомого

Modbus slave(ID, 0, 0);

// массив данных modbus

uint16_t au16data[20];

const int analogInPin = A0;

int8_t state = 0;

int DS18S20_Pin = 2; //DS18S20 Signal pin on digital 2

OneWire ds(DS18S20_Pin); // on digital pin 2

int tmp =0;

void setup() {

// настраиваем последовательный порт ведомого

slave.begin( 9600 );

// зажигаем светодиод на 100 мс

}

void loop() {

float temperature = getTemp();

tmp= temperature * 10;

au16data[2] = tmp;

state = slave.poll( au16data, 11);

delay(10);

}

float getTemp(){

//returns the temperature from one DS18S20 in DEG Celsius

byte data[12];

byte addr[8];

if ( !ds.search(addr)) {

//no more sensors on chain, reset search

ds.reset_search();

return -1000;

}

if ( OneWire::crc8( addr, 7) != addr[7]) {

Serial.println("CRC is not valid!");

return -1000;

}

if ( addr[0] != 0x10 && addr[0] != 0x28) {

Serial.print("Device is not recognized");

return -1000;

}

ds.reset();

ds.select(addr);

ds.write(0x44,1); // start conversion, with parasite power on at the end

byte present = ds.reset();

ds.select(addr);

ds.write(0xBE); // Read Scratchpad

for (int i = 0; i < 9; i++) { // we need 9 bytes

data[i] = ds.read();

}

ds.reset_search();

byte MSB = data[1];

byte LSB = data[0];

float tempRead = ((MSB << 8) | LSB); //using two's compliment

float TemperatureSum = tempRead / 16;

return TemperatureSum;

}

Now Arduino acts as a Slave device with address 10 and operates on the modbus RTU protocol. In addition, the program continuously polls the DS18b20 temperature sensor and records the current readings at address 2 of the READ_INPUT_REGISTERS register.

Since the Slave device is connected to the computer via a USB interface with a dedicated com port, you can use the program to receive data from it:

modbus_rtu.py.

#!/usr/bin/env python

import sys

import time

import logging

import modbus_tk

import modbus_tk.defines as cst

import modbus_tk.modbus_tcp as modbus_tcp

from modbus_tk import modbus_rtu

import serial

logger = modbus_tk.utils.create_logger("console")

if __name__ == "__main__":

serverSlave=''

portSlave=0

param = []

reg=[]

startAdr=[]

rangeAdr=[]

setFrom=[]

setRange=[]

rtuAddress=[]

units=0

try:

count=0

param = []

i=0

for _ in range(256):

param.append(i)

reg.append(i)

startAdr.append(i)

rangeAdr.append(i)

setFrom.append(i)

setRange.append(i)

rtuAddress.append(i)

i = i + 1

with open('setting.cfg') as f:

for line in f:

param[count]=line.split(';')

if(param[count][0]=='server'):

serverSlave= param[count][1]

portSlave = param[count][2]

if(param[count][0]=='cport'):

serialPort= param[count][1]

if(param[count][0]=='rtu'):

rtuAddress[count] = param[count][1]

reg[count] = param[count][2]

startAdr[count] = param[count][3]

rangeAdr[count] = param[count][4]

setFrom[count] = param[count][5]

setRange[count] = param[count][6]

count=count + 1

units=count

server = modbus_tcp.TcpServer(address=serverSlave, port=int(portSlave) )

server.start()

slave = server.add_slave(1)

slave.add_block('0', cst.COILS, 0, 1000)

slave.add_block('1', cst.DISCRETE_INPUTS, 0, 1000)

slave.add_block('2', cst.ANALOG_INPUTS, 0, 1000)

slave.add_block('3', cst.HOLDING_REGISTERS, 0, 1000)

f.close()

serialPort=serial.Serial(port=serialPort, baudrate=9600, bytesize=8, parity='N', stopbits=1, xonxoff=0)

master = modbus_rtu.RtuMaster( serialPort )

master.set_timeout(1.0)

except IOError as e:

print "I/O error({0}): {1}".format(e.errno, e.strerror)

try:

print 'Starting server...'

while True:

i=0

for i in range(units):

if(reg[i] == 'READ_INPUT_REGISTERS'):

dataRIR=[]

for c in range(0, int(rangeAdr[i]) ):

dataRIR.append(c)

c+=1

try:

dataRIR= master.execute(int(rtuAddress[i]), cst.READ_INPUT_REGISTERS, int(startAdr[i]), int(rangeAdr[i]) )

slave.set_values('2', int(setFrom[i]), dataRIR)

serialPort.flushInput()

serialPort.flushOutput()

serialPort.flush()

print 'rtu' , rtuAddress[i],'READ_INPUT_REGISTERS',dataRIR

except:

for c in range(0,int(rangeAdr[i]) ):

dataRIR[c] = 0

c+=1

print 'rtu' , rtuAddress[i],'READ_INPUT_REGISTERS','Fail to connect',dataRIR

slave.set_values('2', int(setFrom[i]), dataRIR)

if(reg[i] == 'READ_DISCRETE_INPUTS'):

dataRDI=[]

for c in range(0, int(rangeAdr[i]) ):

dataRDI.append(c)

c+=1

try:

dataRDI= master.execute(int(rtuAddress[i]), cst.READ_DISCRETE_INPUTS, int(startAdr[i]), int(rangeAdr[i]) )

slave.set_values('1', int(setFrom[i]), dataRDI)

serialPort.flushInput()

serialPort.flushOutput()

serialPort.flush()

print 'rtu' , rtuAddress[i],'READ_DISCRETE_INPUTS',dataRDI

except:

for c in range(0,int(rangeAdr[i]) ):

dataRDI[c] = 0

c+=1

print 'rtu' , rtuAddress[i],'READ_DISCRETE_INPUTS','Fail to connect' ,dataRDI,len(dataRDI)

slave.set_values('1', int(setFrom[i]), dataRDI)

if(reg[i] == 'READ_COILS'):

dataRC=[]

for c in range(0, int(rangeAdr[i]) ):

dataRC.append(c)

c+=1

try:

dataRC= master.execute(int(rtuAddress[i]), cst.READ_COILS, int(startAdr[i]), int(rangeAdr[i]) )

slave.set_values('0', int(setFrom[i]), dataRC)

serialPort.flushInput()

serialPort.flushOutput()

serialPort.flush()

print 'rtu' , rtuAddress[i],'READ_COILS',dataRC

except:

for c in range(0,int(rangeAdr[i]) ):

dataRC[c] = 0

c+=1

slave.set_values('0', int(setFrom[i]), dataRC)

print 'rtu' , rtuAddress[i],'READ_COILS','Fail to connect',dataRC

if(reg[i] == 'READ_HOLDING_REGISTERS'):

dataRHR=[]

for c in range(0, int(rangeAdr[i]) ):

dataRHR.append(c)

c+=1

try:

dataRHR= master.execute(int(rtuAddress[i]), cst.READ_HOLDING_REGISTERS, int(startAdr[i]), int(rangeAdr[i]) )

slave.set_values('3', int(setFrom[i]), dataRHR)

serialPort.flushInput()

serialPort.flushOutput()

serialPort.flush()

print 'rtu' ,rtuAddress[i],'READ_HOLDING_REGISTERS',dataRHR

except:

for c in range(0,int(rangeAdr[i]) ):

dataRHR[c] = 0

c+=1

slave.set_values('3', int(setFrom[i]), dataRHR)

print 'rtu ', rtuAddress[i],'READ_HOLDING_REGISTERS','Fail to connect',dataRHR

time.sleep(0.1)

except modbus_tk.modbus.ModbusError, e:

logger.error("%s- Code=%d" % (e, e.get_exception_code()))

On the one hand, this program is a Master for polling slaves using the modbus RTU protocol, and on the other hand, it is a Slave device and transmits data to the upper level using the modbus TCP protocol.

The master_rtu.py program is used if you have to collect readings from several devices using the modbus RTU protocol and / or rs485 interface. The com file address and rtu address of the slave devices are indicated in the configuration file. In addition, the polling registers and the addresses of the registers into which the received data are recorded are indicated.

Description of setting.cfg settings file for master_rtu.py :

server;192.168.0.200;507; #

# server - идентификатор переменной

# 192.168.0.200 - IP адрес slave части modbus TCP для входящих подключений

# 507 - Порт slave части modbus TCP для входящих подключений

cport;COM5; #

# cport - идентификатор переменной

# COM5 - адрес СОМ порта для опроса терминальных устройств по протоколу modbusRTU

rtu;10;READ_INPUT_REGISTERS;0;10;0;0;comment

# rtu - идентификатор переменной

# 10 - rtu адрес slave устройства куда подключаемся

# READ_INPUT_REGISTERS -регистр для чтения slave устройства куда подключаемся

# варианты:

# READ_DISCRETE_INPUTS

# READ_COILS

# READ_HOLDING_REGISTERS

# 2 - стартовый адрес регистра с которого начинается чтение данных на slave устройстве modbus RTU

# 1 - количество адресов регистра которые считываются на slave устройстве modbus RTU

# 0 - стартовый адрес размещения полученных данных на slave части утилиты modbus TCP

# comment - комментарий

In this configuration, the modbus RTU Slave device with address 10 will be polled. In the READ_INPUT_REGISTERS register at address 2, the measured temperature value will be read and written into the READ_INPUT_REGISTERS register at address 0 slave of the program part for modbus TCP polling.

In the ai.cfg analog signal settings file, write:

ai;1;100;100;green;0.1;50;Air Temp A;ameter;Those. we will take the measured value of the temperature of the register READ_INPUT_REGISTERS at 0x00, place it on the canvas at coordinates x = 100, y = 100 and display the mnemonic diagram using the arrow object.

In the settings.cfg settings file for scada.py we write:

slaveIP=192.168.0.200 -- ip адрес modbus TCP slave устройства

slavePort=504 -- порт modbus TCP slave устройства

discretCfg=di.cfg

coilCfg=ci.cfg

analogCfg=ai.cfg

buttonCfg=bt.cfg

bgimage=bg.gif

delayTime=500

debug=False

The measurement results can be displayed on various objects of the mnemonic diagram, including monitoring on a dynamic chart.

Source code can be downloaded here.