Chinese scientists have developed practical rewritable thermal paper

For many years, various companies and individuals have been struggling with the problem of creating alternatives to plain paper. Researchers from China, it seems, came close to solving this issue - they developed a “paper”, which can be written on using temperature changes. Paper changes color, so this method is suitable both for creating drawings and for printing.

It differs from analogs in that it can withstand hundreds of rewriting cycles without losing its properties. The applied images and text are not saved for too long - about six months. However, for most tasks this is quite enough - for example, in the office draft contracts, documents on turnover, etc. can be printed on such paper.

It was developed by scientists from the Fujian Pedagogical University under the direction of Wei Zhang. The structure of this paper is quite complicated and consists of three layers. In fact, this is a “sandwich”, where plain paper is used as a filling. On one side, a heat-sensitive toner is applied to the paper, and on the other, a thermochromic layer. The latter provides the possibility of rewriting information.

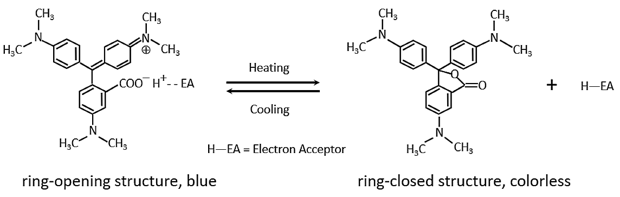

In turn, this layer consists of such elements as solvent, developer, and color former. Under normal conditions (up to 65 degrees Celsius), the color of the layer is blue. If the temperature is raised to a level of 70 degrees Celsius, the solvent becomes liquid, the other two components are separated, the layer becomes colorless.

After that, the color former and the developer react with the solvent, as a result of which the temperature of the solution decreases. All this is true for room temperature - substances begin to react again only when the temperature drops to minus 10 degrees Celsius. In this case, the recrystallization of the three components occurs and the thermal properties are restored.

As mentioned above, such paper can not be used everywhere and not always; it cannot become a full-fledged replacement of plain paper. Nevertheless, it is possible to write on it - for example, a thermo hand, where the tip heats up. A possible inconvenience will be the color of the paper - it is blue. In this case, the letters and pictures will be white.

You can print using a thermal printer. There is also a variant of drawing pictures - in this case, you can use an ordinary stencil and heat. Images are sharp enough - for example, you can easily apply a barcode or plain text. According to the developers, after hundreds of rewriting cycles, the properties of the alternative paper are saved, there are no problems with it.

As for e-paper, its color version (full) has developedcompany E Ink, which has created and ordinary electronic paper used in a very wide range of devices. The advantage of this type of paper is that for each pixel you can display an arbitrary color without using several layers of color filters. Paper energy consumption is extremely low, so there are no problems with maintaining the paper charge.

Now flexible screens are also developed that do not deteriorate due to various deformations (folding and stretching).

In 2016, Chinese scientists developed graphene e-paper. She created the company Guangzhou OED Technologies. A distinctive feature of the invention is the thickness of just 0.335 nm, so graphene electronic paper can be used as the basis for creating flexible displays.

The cost of such paper is not very high - because it is produced from carbon, although through a series of chemical and physical transformations. Another advantage of graphene paper is its ability to conduct electrical current.

In principle, developments in the "paper" sphere are not so few - there are many alternatives that are based on different principles. Some systems are also heat-sensitive, some react to physical effects (for example, pressure) or chemicals. Unfortunately, in most cases we are talking only about test development, most of which are not included in the series - the commercial use of such prototypes is impossible for various reasons, from production costs to the complexity of the technological cycle.