How I did the layout or Crazy Pens post

In this post I will tell how I created the layout from scratch. It was important for me to do it on my own in order to have a clear idea of the pros and cons of using modules, adequate constructor sizes and other usability.

(I stole the picture from the engineer, not a good angle, but with a stretch you can understand that the work is in full swing)

At first, this method seemed to me the easiest. It was supposed to mold a model from plasticine, lower it into silicone and get a formwork, and then pour plastic into it. I watched the training videos, found out how much plastic costs and made adjustments to the plan: for the first time, you can conduct an experiment with paraffin.

As a result, I poured everything around with this very paraffin, smeared it in plasticine and got a model that failed the first crash test: it broke when removed from the formwork.

Pluses: not found.

Disadvantages: easily soiled, the model did not work.

In the framework of maximum savings, I armed myself with paper, glue and scissors. As a child, we all worked with these fail-safe tools and created masterpieces no worse than those that came out from under Michelangelo’s chisel, at least that was what we ourselves and our grateful mothers thought.

Drawing patterns of volumetric figures and subsequent bonding was rejected as a method that gives a brittle and easily creased result. The option with paper layers seemed to me more promising. He took a pack of paper, printed a 2D model on all the sheets, cut and glued it in layers. I smeared with glue more than plasticine, but, in principle, the box-parallelepiped turned out.

Pluses: inexpensive, there is a model.

Disadvantages:it is not possible to make a smooth rounding at the edges, when gluing the layers, the model is deformed (if you first cut it and then glue it, the layers separate, if you glue it first, then it is difficult to cut the resulting sandwich). A fragile model - when installing magnets, after a couple of experiments, the layout broke.

Actually, this is point 0, since getting a layout using a 3D printer is the most logical reasonable idea. The problem is that I do not have a home 3D printer, but I did not want to spend 50 thousand rubles (at the end of 2014) on it.

There are also pitfalls here: you need to draw the model as accurately as possible. I, in view of the fact that I am poorly compatible with drawing, tried to find creative partners, but in the end I got carried away and sat down for 3D modeling myself. It turns out that there are programs that allow you to code and model. In this sense, I was pleasantly surprised by a program such as OpenSCAD.

He entrusted the printout to a hired 3D printer and, finally, received the first models of the case for the main board and modules, which were further supplemented by magnets and participated in the first presentation of the product.

Advantages: the model turned out decent.

Disadvantages: I can’t make a perfect rounding, a step remains. You can resort to acetone bathing (for those who can), but it did not work out to evenly melt all the modules by eye.

I came across such a miracle of engineering thought as a polymorph. It is a self-hardening thermoplastic. When heated, it becomes ductile and convenient for molding, and when cooled, it acquires all the properties of plastic: it becomes hard, elastic and durable. It is logical that I decided to adapt the polymorph to my needs. I came up with the idea that I’ll make it constructive with my hands, and I need to make changes - I will lower the part into hot water and correct it.

But, as always, the iceberg is not completely sticking out of the water, and again I run into ice.

Make with your hands, no matter how gold they are, a homogeneous part of the correct shape did not work out. He didn’t manage to fix it with hot water either - the model swam and I remembered the song:

I remembered that polymorph is the very thing for creativity, but alas, it is not suitable for permanent details.

Pluses: simple, no special skills required, looks good, a very nice thing, with some skills you can create masterpieces.

Disadvantages: it’s difficult to get the perfect shape

At some point, it became clear: the calculated layout does not meet the necessary requirements for the presentation of the main functions of the designer. The modules turned out to be small, and their increase led to the need to increase the main device. Oddly enough, this turned out to be a plus rather than a minus: the device increased in length and width (the thickness remained the same) became more convenient to hold in hands. Considering that it will be possible to assemble the phone from our designer, ergonomics in the palm of your hand is an important thing.

For testing, I made a model from beech and polished it. It turned out to be pleasant to the touch and with an amazing smell! For a split second, I thought that the working building should be made of wood. Of course, he rejected the sudden idea, but put a tick - to release a limited natural series, connoisseurs will be found.

Advantages:You can make a smooth rounding, it looks great.

Disadvantages: the minimum wall thickness does not correspond to reality, production disadvantages.

Having remade the 3D model once again, I regained my sight and decided to cut it from polystyrenePVC . It turned out that this is an accurate, convenient, cheap, practical, etc., and other way. I did not find any flaws.

The case and modules turned out to be excellent!

Now we are waiting for magnets for the complete assembly of the layout and again in battle.

During the modeling process I constantly missed the size, the convenient online service 3dvieweronline came to the rescue , where you can twist the model and find out the sizes.

For help in creating 3D models, we say thanks to the 3Dmodelist studio can be found in VK.

(I stole the picture from the engineer, not a good angle, but with a stretch you can understand that the work is in full swing)

1. Plasticine wars

At first, this method seemed to me the easiest. It was supposed to mold a model from plasticine, lower it into silicone and get a formwork, and then pour plastic into it. I watched the training videos, found out how much plastic costs and made adjustments to the plan: for the first time, you can conduct an experiment with paraffin.

As a result, I poured everything around with this very paraffin, smeared it in plasticine and got a model that failed the first crash test: it broke when removed from the formwork.

Pluses: not found.

Disadvantages: easily soiled, the model did not work.

2. Paperkat (Papercut)

In the framework of maximum savings, I armed myself with paper, glue and scissors. As a child, we all worked with these fail-safe tools and created masterpieces no worse than those that came out from under Michelangelo’s chisel, at least that was what we ourselves and our grateful mothers thought.

Drawing patterns of volumetric figures and subsequent bonding was rejected as a method that gives a brittle and easily creased result. The option with paper layers seemed to me more promising. He took a pack of paper, printed a 2D model on all the sheets, cut and glued it in layers. I smeared with glue more than plasticine, but, in principle, the box-parallelepiped turned out.

Pluses: inexpensive, there is a model.

Disadvantages:it is not possible to make a smooth rounding at the edges, when gluing the layers, the model is deformed (if you first cut it and then glue it, the layers separate, if you glue it first, then it is difficult to cut the resulting sandwich). A fragile model - when installing magnets, after a couple of experiments, the layout broke.

3. Modern 3D technology

Actually, this is point 0, since getting a layout using a 3D printer is the most logical reasonable idea. The problem is that I do not have a home 3D printer, but I did not want to spend 50 thousand rubles (at the end of 2014) on it.

There are also pitfalls here: you need to draw the model as accurately as possible. I, in view of the fact that I am poorly compatible with drawing, tried to find creative partners, but in the end I got carried away and sat down for 3D modeling myself. It turns out that there are programs that allow you to code and model. In this sense, I was pleasantly surprised by a program such as OpenSCAD.

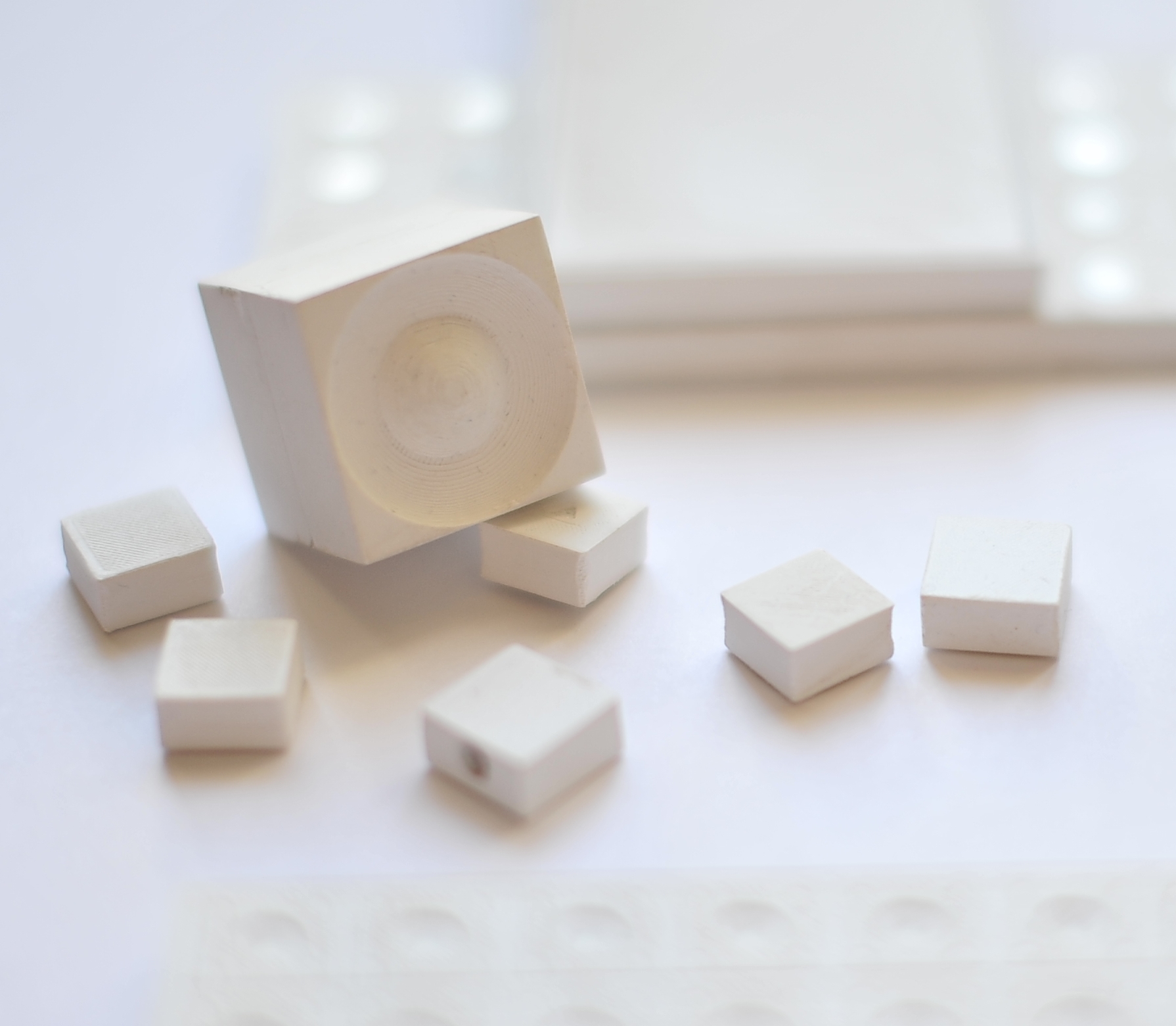

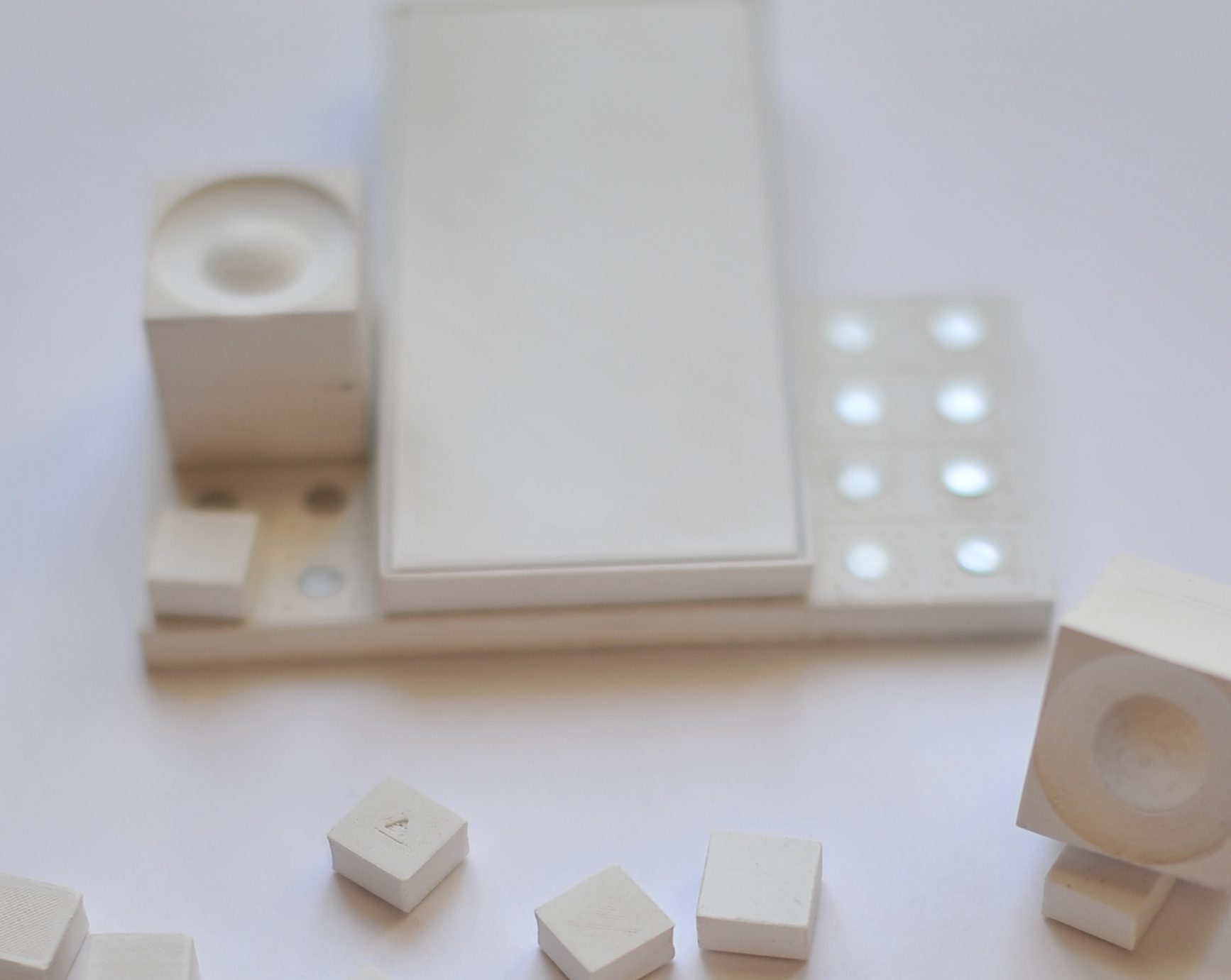

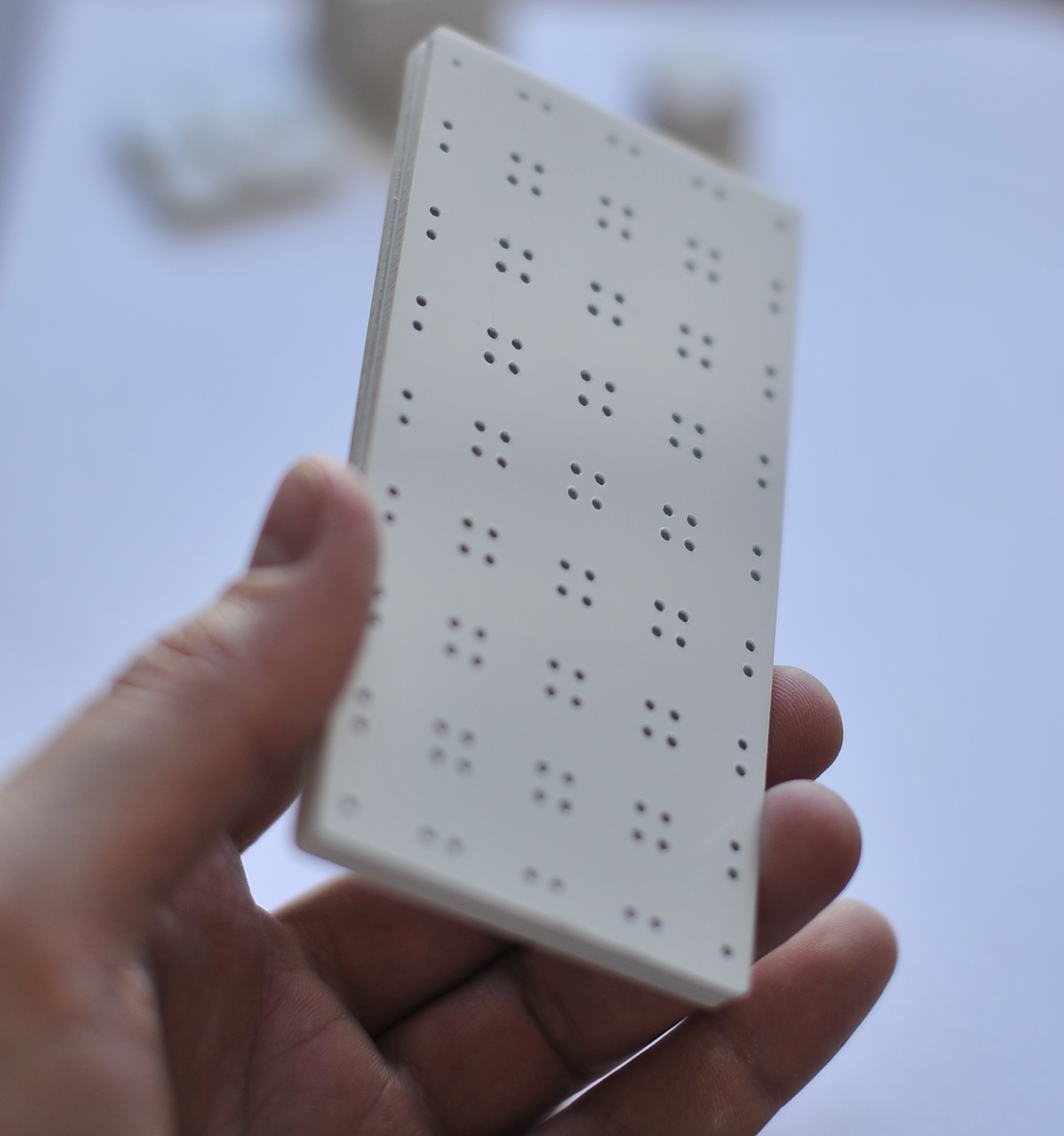

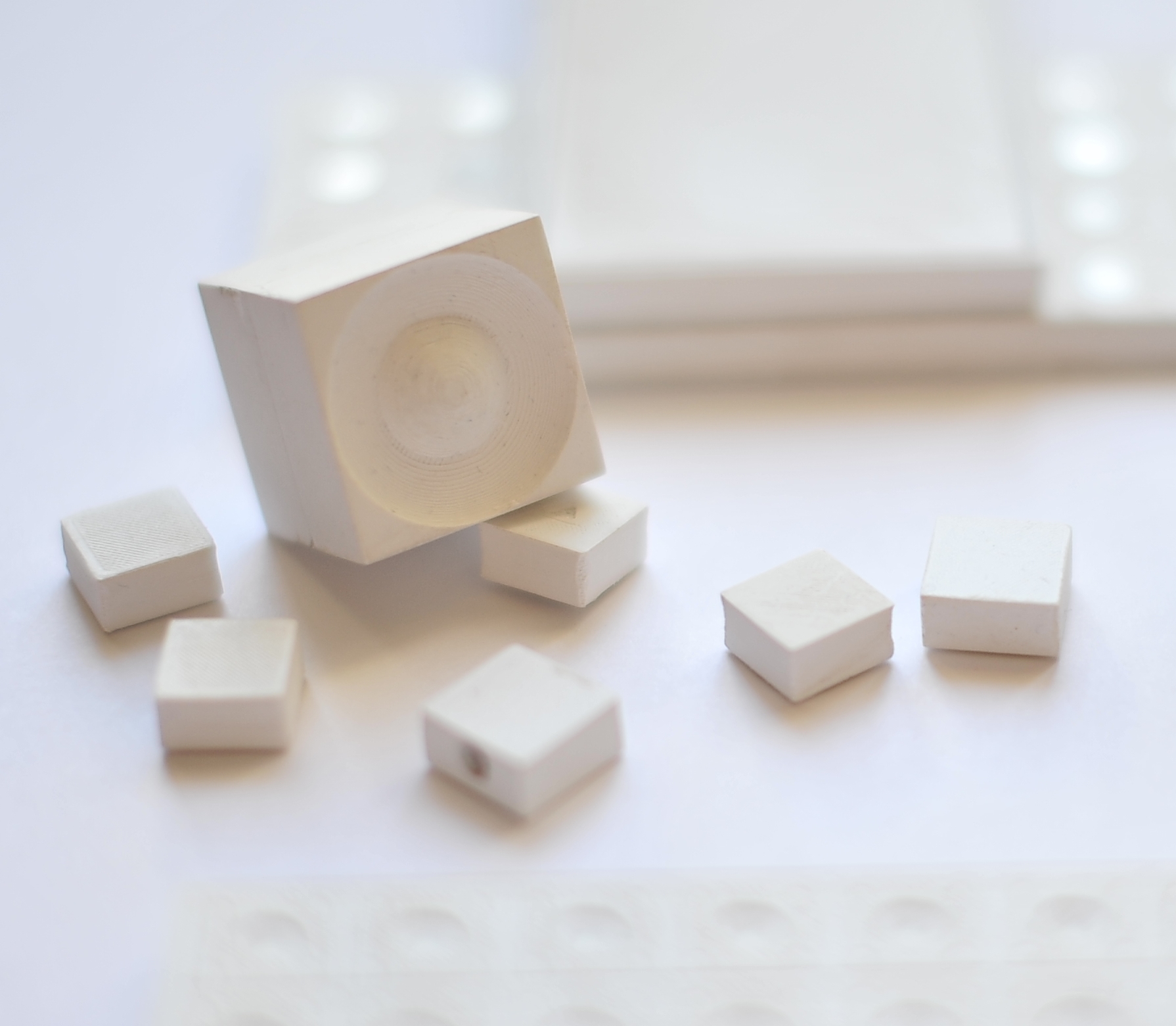

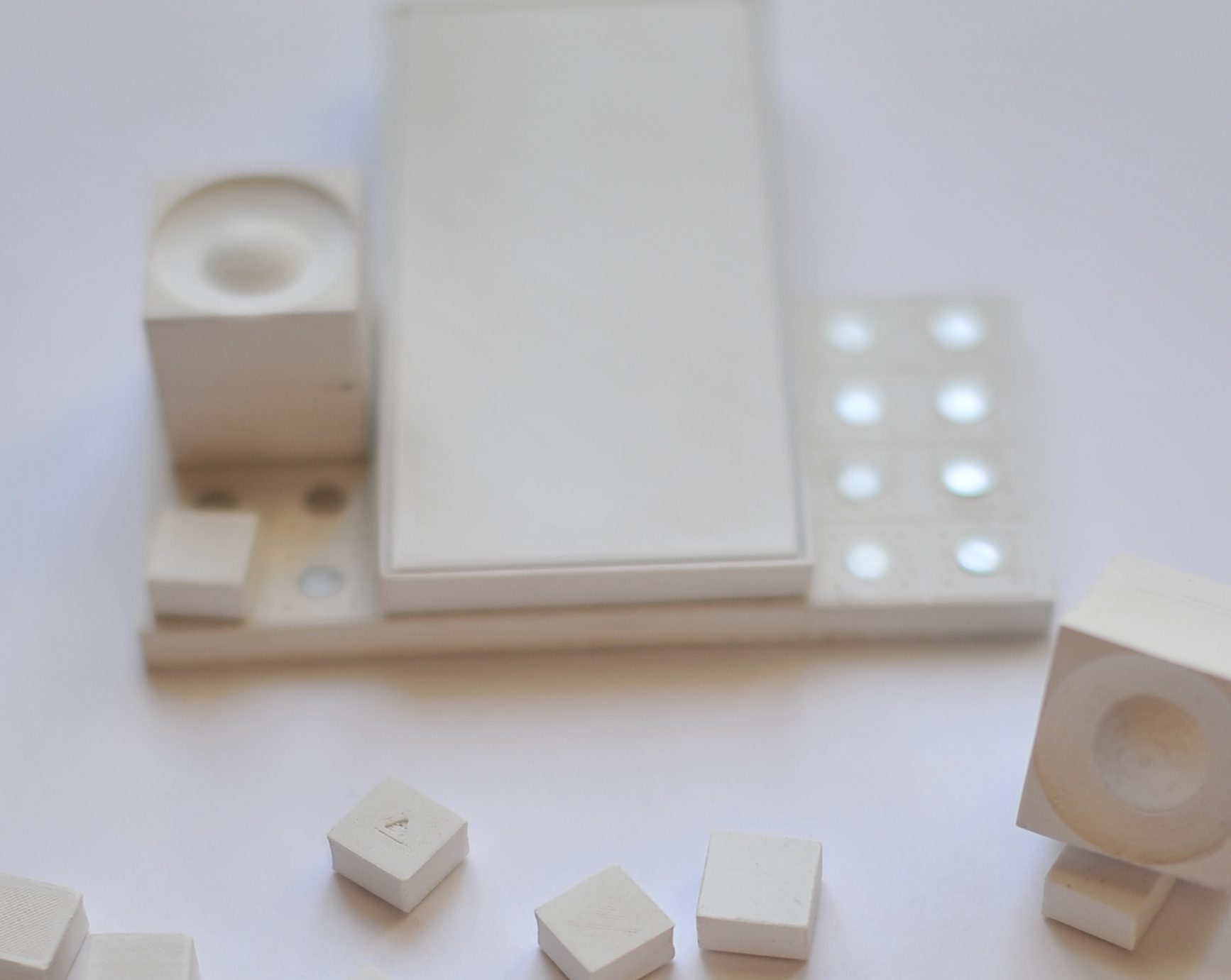

He entrusted the printout to a hired 3D printer and, finally, received the first models of the case for the main board and modules, which were further supplemented by magnets and participated in the first presentation of the product.

Advantages: the model turned out decent.

Disadvantages: I can’t make a perfect rounding, a step remains. You can resort to acetone bathing (for those who can), but it did not work out to evenly melt all the modules by eye.

4. Polymorphism is magnificent

I came across such a miracle of engineering thought as a polymorph. It is a self-hardening thermoplastic. When heated, it becomes ductile and convenient for molding, and when cooled, it acquires all the properties of plastic: it becomes hard, elastic and durable. It is logical that I decided to adapt the polymorph to my needs. I came up with the idea that I’ll make it constructive with my hands, and I need to make changes - I will lower the part into hot water and correct it.

But, as always, the iceberg is not completely sticking out of the water, and again I run into ice.

Make with your hands, no matter how gold they are, a homogeneous part of the correct shape did not work out. He didn’t manage to fix it with hot water either - the model swam and I remembered the song:

The forcemeat cannot be turned back,

And the meat from the cutlets cannot be restored.

I remembered that polymorph is the very thing for creativity, but alas, it is not suitable for permanent details.

Pluses: simple, no special skills required, looks good, a very nice thing, with some skills you can create masterpieces.

Disadvantages: it’s difficult to get the perfect shape

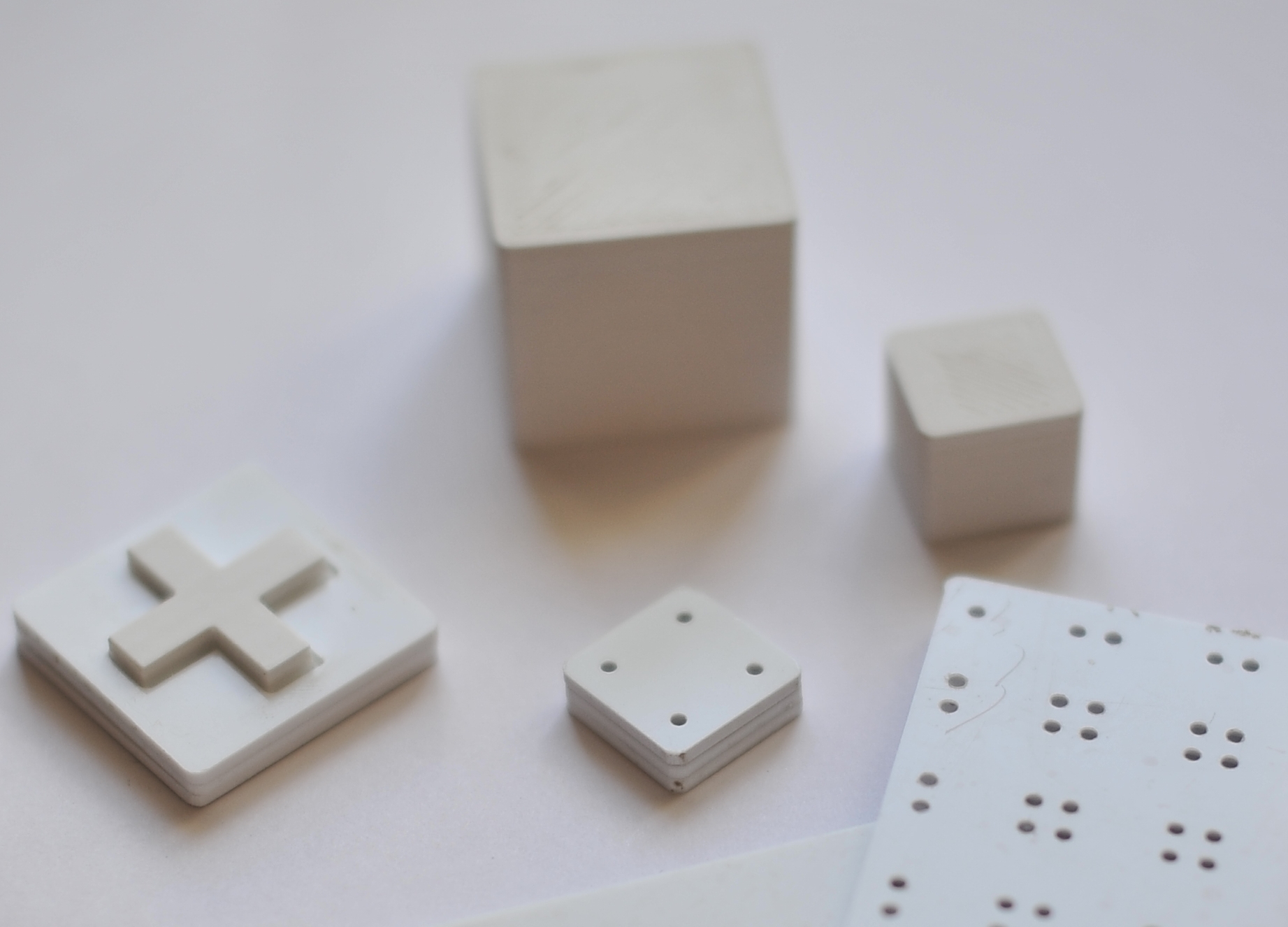

5. We do not sit still: beech wood

At some point, it became clear: the calculated layout does not meet the necessary requirements for the presentation of the main functions of the designer. The modules turned out to be small, and their increase led to the need to increase the main device. Oddly enough, this turned out to be a plus rather than a minus: the device increased in length and width (the thickness remained the same) became more convenient to hold in hands. Considering that it will be possible to assemble the phone from our designer, ergonomics in the palm of your hand is an important thing.

For testing, I made a model from beech and polished it. It turned out to be pleasant to the touch and with an amazing smell! For a split second, I thought that the working building should be made of wood. Of course, he rejected the sudden idea, but put a tick - to release a limited natural series, connoisseurs will be found.

Advantages:You can make a smooth rounding, it looks great.

Disadvantages: the minimum wall thickness does not correspond to reality, production disadvantages.

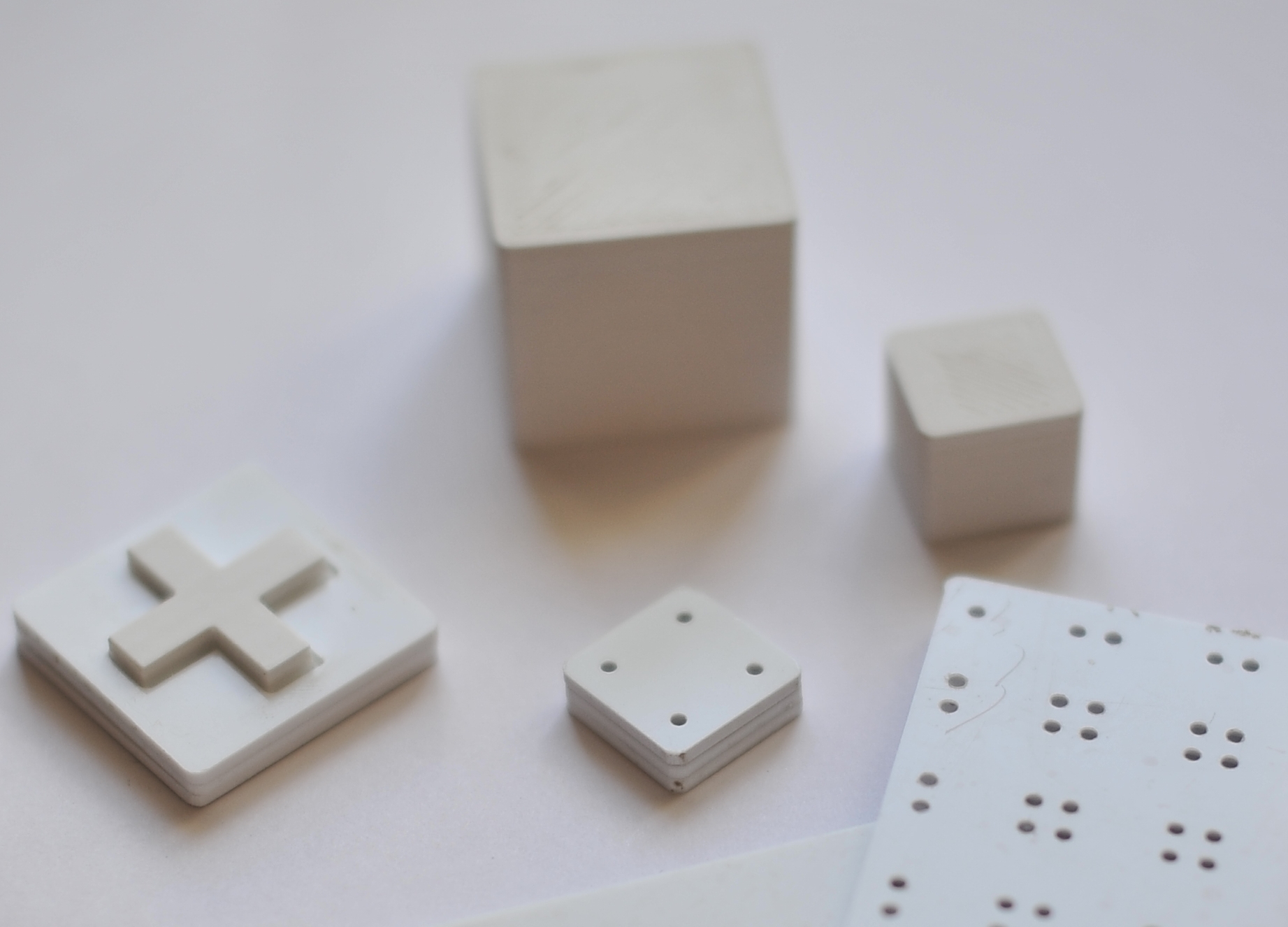

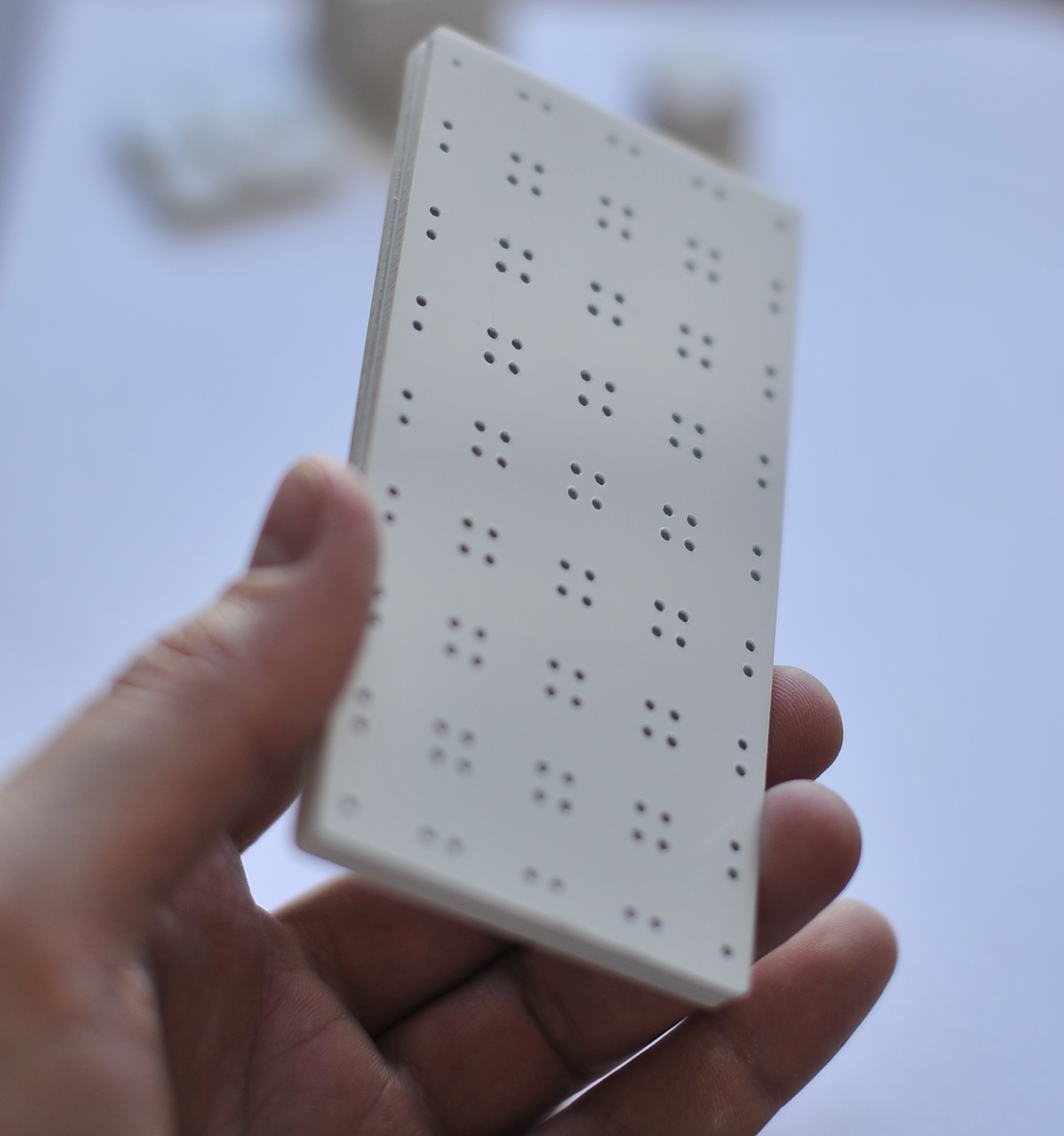

6. All ingenious is simple

Having remade the 3D model once again, I regained my sight and decided to cut it from polystyrene

The case and modules turned out to be excellent!

Now we are waiting for magnets for the complete assembly of the layout and again in battle.

During the modeling process I constantly missed the size, the convenient online service 3dvieweronline came to the rescue , where you can twist the model and find out the sizes.

For help in creating 3D models, we say thanks to the 3Dmodelist studio can be found in VK.