Promising magnetic recording technology MAMR: what awaits us in the near future?

By 2025, the global amount of stored data will reach 163 zettabyte - this is the conclusion reached by analysts from the consulting company International Data Corporation (IDC) in its report “The Data Age 2025”. For comparison, in 2016 this figure was only 16 zettabytes - thus, we will get almost a tenfold increase in the amount of stored information.

It’s not the 4K video and not computer games weighing 100 GB or more that are to blame for this: such rapid growth is associated with a heightened interest in Big Data from business. In an effort to predict the behavior of potential customers and better understand the target audience, large corporations fix literally every action that a person performs on the global web. The situation is aggravated by such promising areas as machine learning and the Internet of things: billions of devices generate a huge amount of information every second, and neural networks require more and more information for analysis and processing.

These factors determine the demand for more capacious drives, but is it possible in principle to meet the needs of the modern market? We say yes, with the advent of MAMR, nothing is impossible! Especially for those who do not have time to read voluminous materials, we have prepared a short video covering the main advantages of drives made using MAMR technology.

If you want to know the "dirty details", welcome under the cat!

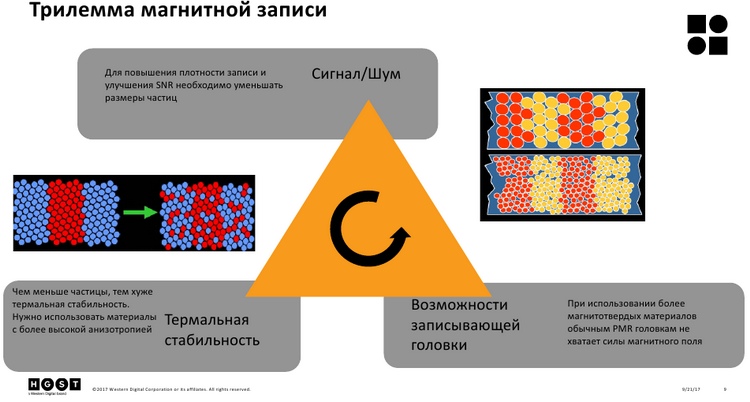

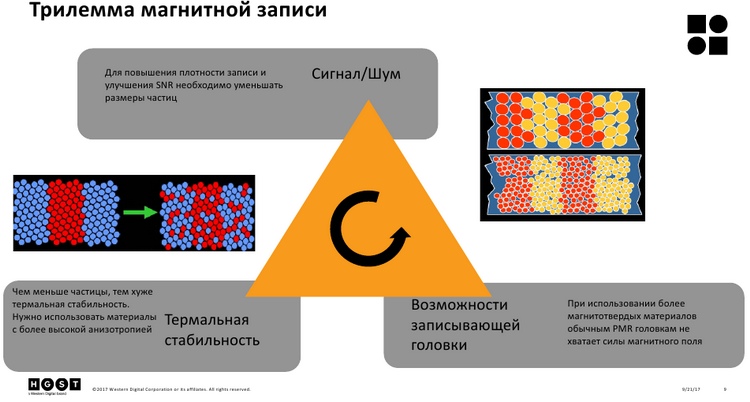

When it comes to improving data storage density, the so-called “magnetic recording trilemma” comes into play. Increasing the recording density implies a reduction in the physical dimensions of the magnetic domain — the plate segment in which 1 bit of information is stored. The problem is that the smaller the grain size, the faster its demagnetization occurs: the stored information is distorted or may be completely lost due to the thermal motion of the elementary particles.

This problem can be solved by using hard magnetic materials characterized by high values of coercive force. However, the smaller the domain, the smaller the recording head should be, which as a result cannot generate a magnetic field with a force sufficient to record information. Thus, a deadlock emerges, out of which for many years they could not find the best minds of the planet.

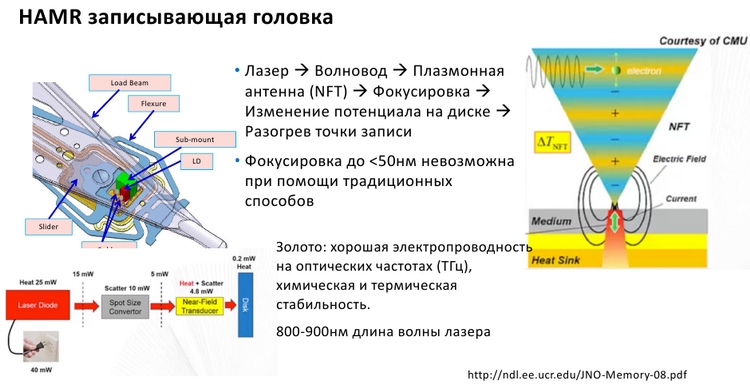

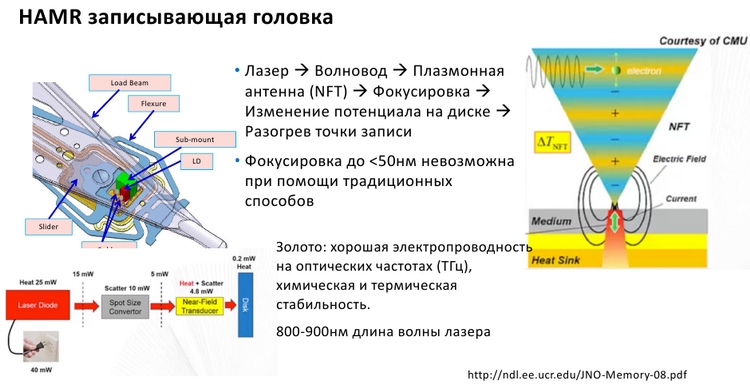

The emergence of HAMR (Heat-assisted Magnetic Recording) was supposed to revolutionize the industry, but the thermomagnetic recording technology was unprofitable. The principle of its operation consists in local heating of the surface of magnetic plates up to 450 ° C with a laser, which allows temporarily reducing the coercivity (magnetic field strength) and, as a result, reducing the area required to record 1 bit of information. In the process of developing technology, engineers faced a serious problem: it turned out that it was technically impossible to focus the laser beam on a site less than 50 nm (the minimum diameter of the thermal spot is about 120 nm), while the accuracy of the positioning of the writing head reaches 10 nm.

As a result, the HAMR system had to be significantly complicated. In the latest samples of drives using the principle of thermomagnetic recording, the laser does not directly irradiate the magnetic plate: thermal energy is transmitted through an optical near field converter (Near Field Optical Transducer, or NFT), the main component of which is a plasmon antenna made of gold. The latter is capable of conducting frequencies of the order of terahertz and generating the so-called “standing wave”, which allows one to achieve the desired spot size.

The increasing complexity of the design of the writing head in combination with the use of gold led to a significant increase in production costs. In addition, during tests it was found that the plasmon antenna quickly deforms under the action of high temperatures and does not meet modern industry standards of reliability.

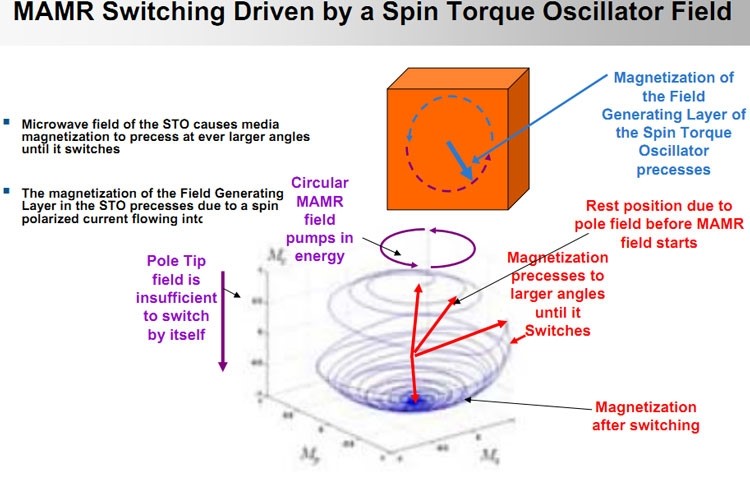

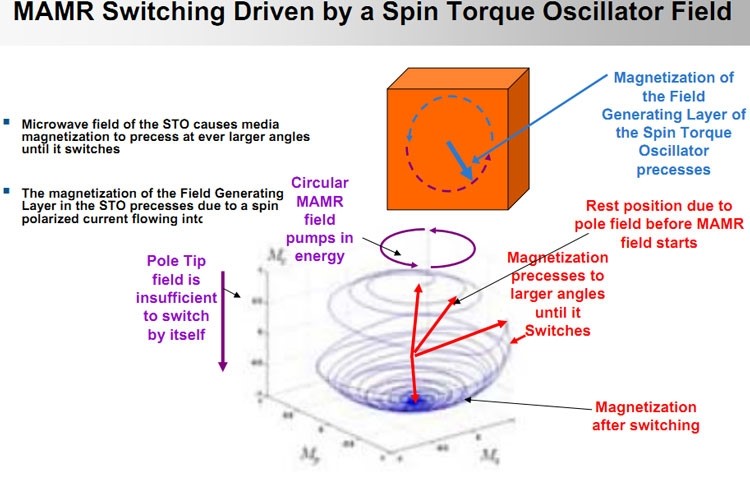

MAMR works differently. The technology is based on a spintronic oscillator, which is a multilayer thin-film generator of a high-frequency (20-40 GHz) field arising due to the polarization of electron spins under the action of direct current. The generator “pumps” the magnetic domain, due to which it is possible to significantly reduce the energy costs necessary to change the magnetization vector of a portion of the recording layer to the opposite.

In combination with the use of the Damascus manufacturing process of recording heads capable of providing accurate control of the shape and dimensions of the pole, as well as the use of a multi-stage microdrive, the grain size was reduced from 8–12 nm to a record 4 nm and significantly increased the recording density - up to 4 Tb square inch. In the future, this will allow you to create 3.5-inch HDD with a capacity of up to 40 TB, that is, surpassing modern models in terms of volume almost four times! Moreover, the transition to MAMR does not affect the reliability of the drive, since the spintronic oscillator is not exposed to extreme temperatures.

Another important advantage of MAMR is full compatibility with HelioSeal technology, which is in conflict with HAMR. Since the thermal conductivity of helium is greater than that of air, the gaseous medium will be heated sufficiently quickly during the recording process, which means that the pressure inside the disk itself will increase. Following it, the force of resistance to the rotation of the magnetic plates will also increase, that is, a more powerful drive will be needed to spin the spindle. In turn, due to the fact that the devices themselves will become hotter, the cost of conditioning the data center will also increase, which makes the massive use of thermomagnetic storage devices even more doubtful. In the case of MAMR, there are no such problems: the transition to new drives will not require the owners of data centers to upgrade the cooling system and will not affect the electricity bills.

It’s not the 4K video and not computer games weighing 100 GB or more that are to blame for this: such rapid growth is associated with a heightened interest in Big Data from business. In an effort to predict the behavior of potential customers and better understand the target audience, large corporations fix literally every action that a person performs on the global web. The situation is aggravated by such promising areas as machine learning and the Internet of things: billions of devices generate a huge amount of information every second, and neural networks require more and more information for analysis and processing.

These factors determine the demand for more capacious drives, but is it possible in principle to meet the needs of the modern market? We say yes, with the advent of MAMR, nothing is impossible! Especially for those who do not have time to read voluminous materials, we have prepared a short video covering the main advantages of drives made using MAMR technology.

If you want to know the "dirty details", welcome under the cat!

When it comes to improving data storage density, the so-called “magnetic recording trilemma” comes into play. Increasing the recording density implies a reduction in the physical dimensions of the magnetic domain — the plate segment in which 1 bit of information is stored. The problem is that the smaller the grain size, the faster its demagnetization occurs: the stored information is distorted or may be completely lost due to the thermal motion of the elementary particles.

This problem can be solved by using hard magnetic materials characterized by high values of coercive force. However, the smaller the domain, the smaller the recording head should be, which as a result cannot generate a magnetic field with a force sufficient to record information. Thus, a deadlock emerges, out of which for many years they could not find the best minds of the planet.

The emergence of HAMR (Heat-assisted Magnetic Recording) was supposed to revolutionize the industry, but the thermomagnetic recording technology was unprofitable. The principle of its operation consists in local heating of the surface of magnetic plates up to 450 ° C with a laser, which allows temporarily reducing the coercivity (magnetic field strength) and, as a result, reducing the area required to record 1 bit of information. In the process of developing technology, engineers faced a serious problem: it turned out that it was technically impossible to focus the laser beam on a site less than 50 nm (the minimum diameter of the thermal spot is about 120 nm), while the accuracy of the positioning of the writing head reaches 10 nm.

As a result, the HAMR system had to be significantly complicated. In the latest samples of drives using the principle of thermomagnetic recording, the laser does not directly irradiate the magnetic plate: thermal energy is transmitted through an optical near field converter (Near Field Optical Transducer, or NFT), the main component of which is a plasmon antenna made of gold. The latter is capable of conducting frequencies of the order of terahertz and generating the so-called “standing wave”, which allows one to achieve the desired spot size.

The increasing complexity of the design of the writing head in combination with the use of gold led to a significant increase in production costs. In addition, during tests it was found that the plasmon antenna quickly deforms under the action of high temperatures and does not meet modern industry standards of reliability.

MAMR works differently. The technology is based on a spintronic oscillator, which is a multilayer thin-film generator of a high-frequency (20-40 GHz) field arising due to the polarization of electron spins under the action of direct current. The generator “pumps” the magnetic domain, due to which it is possible to significantly reduce the energy costs necessary to change the magnetization vector of a portion of the recording layer to the opposite.

In combination with the use of the Damascus manufacturing process of recording heads capable of providing accurate control of the shape and dimensions of the pole, as well as the use of a multi-stage microdrive, the grain size was reduced from 8–12 nm to a record 4 nm and significantly increased the recording density - up to 4 Tb square inch. In the future, this will allow you to create 3.5-inch HDD with a capacity of up to 40 TB, that is, surpassing modern models in terms of volume almost four times! Moreover, the transition to MAMR does not affect the reliability of the drive, since the spintronic oscillator is not exposed to extreme temperatures.

Another important advantage of MAMR is full compatibility with HelioSeal technology, which is in conflict with HAMR. Since the thermal conductivity of helium is greater than that of air, the gaseous medium will be heated sufficiently quickly during the recording process, which means that the pressure inside the disk itself will increase. Following it, the force of resistance to the rotation of the magnetic plates will also increase, that is, a more powerful drive will be needed to spin the spindle. In turn, due to the fact that the devices themselves will become hotter, the cost of conditioning the data center will also increase, which makes the massive use of thermomagnetic storage devices even more doubtful. In the case of MAMR, there are no such problems: the transition to new drives will not require the owners of data centers to upgrade the cooling system and will not affect the electricity bills.