Online Data Science Championship

Optimization of equipment operation, predictive monitoring, building the dependencies of real profits on the technological mode, and many other tasks in the field of digital chemistry are already being solved using DataScience-technologies. Within the framework of the digital transformation of industrial and business processes, the Advanced Analytics direction is working on this.

Is it possible to correctly predict production volumes, taking into account all the features of the process and technological parameters? We will find out soon.

SIBUR, together with the AI-Community, is launching an online championship in Data Science, which runs until November 19th. Those wishing to participate must register before November 16. Decisions are made until 19, and November 24 - the final.

The total prize fund is more than 600,000 rubles: 1st place - 200,000 rubles, 2nd place - 150,000 rubles, 3rd place - 70,000 rubles, 4, 5 and 6 places - 40,000 rubles. The best projects of additional tracks - 20 000 rubles and quadrocopters. A team can have from 1 to 4 members.

Alexey Vinnichenko, Head of Advanced Analytics:

“We had the idea not only to make a challenge competition, but to take a real production task, which is now on the radar, not simple and not abstract, and give it to the community - to show what interesting things you can do at SIBUR. The task is voluminous, it consists of five subtasks, which in the end should develop into a single puzzle. It should be interesting. And, of course, we will be grateful for fresh, non-standard ideas. ”

Attention, the task:

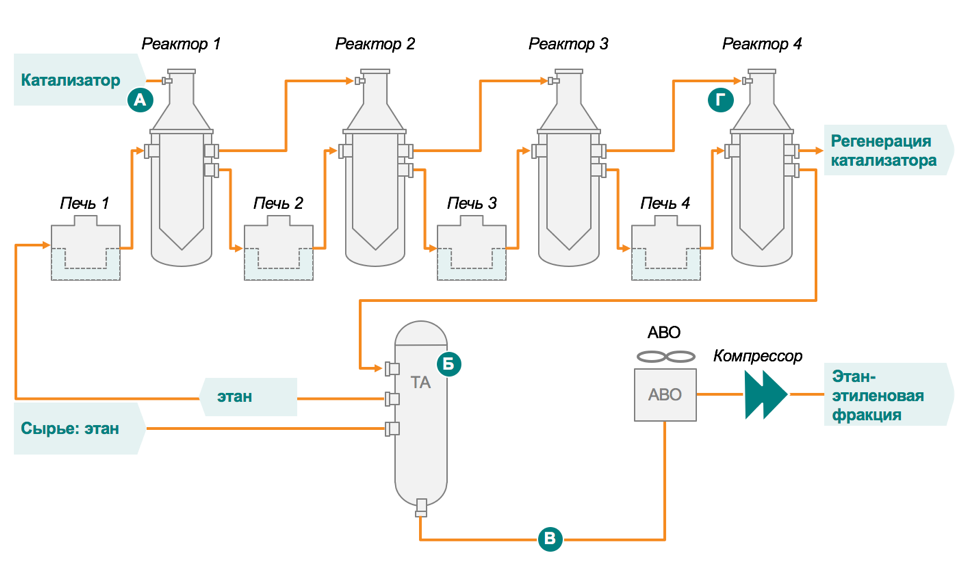

During the chemical reaction at the ethylene production plant, in addition to the target useful product, a number of by-products are formed. One of the undesirable but unavoidable reaction products is carbon (coke), which is deposited on the walls of the reactors and on the catalyst. For ethylene production planning it is necessary to be able to predict the volume and efficiency of production, which depends on the state of the equipment, mode limitations, external factors. It is necessary to implement several predictive models that will help in solving the global task of forecasting production volumes.

→ Details and registration by reference