Steel manipulator HEXAPOD

In the following presentation, I would like to demonstrate the implementation of the six-pointed HEXAPOD manipulator made of ship steel. The current project does not pretend to be original, innovative approaches, the implementation of complex control algorithms, the use of mathematical models of behavior, as well as the initial design of existing and effectively working hardware. In the current article I will try to state my own approach to the implementation of the manipulator from the most affordable means and materials of the peripheral city.

The main bias at this stage was made towards the hardware component and not very complex software part. In the future, it is planned to use BeagleBoard-xM, the organization of autonomous modes of operation and minimal processing of video data. It is physically not enough time to do everything at the same time. This is my first experience in robotics, so some aspects of the device were thought over and adjusted already during its implementation.

The prerequisites for creating the manipulator was the cult iconic animated film Ghost in the shell. Released almost two decades ago, this film made a lasting impression on many, and on me in particular. Over the years, having acquired a certain level of technical knowledge, having time and some amount of free funds, I decided to implement a construct from the field of robotics.

Initially, I’ll make a reservation that in my personal view the canonical concept of “robot” is inherently connected with autonomous work algorithms. Since this device cannot function (at the current software level) without human intervention, the definition of “manipulator” will be used in the current article.

One of the open projects from the site was chosen as the initial designgrabcad.com . It was a relatively long time, even before the general interest in such six-pointed devices. Therefore, the choice from existing open projects at that time was not great, and it was very difficult to develop your first robotic design of a similar level from scratch. The project was finalized in the direction of reducing the weight of the structure and simplifying the edge lines of the parts. The following is an isometric view of the manipulator in the SolidWorks software product (one of the penultimate versions of the modification; the latest, after so many years, could not be found):

As a material for the manipulator, it was originally planned to use aluminum. But to find such an opportunity in the framework of my peripheral city at that time did not work (maybe, years later, something has changed in this area, however, I doubt it). The legacy of bygone times came to the rescue - the remains of ship carbon steel and the possibility of plasma cutting along it. In addition, the project from SolidWorks 2007 was suitable as the initial data, which simplified preparation for manufacturing. Material thickness - 2mm. The manufacture of plexiglass or plastic construction was possible, but was not initially considered, because the desire to make a metal manipulator prevailed over a healthy view of things. Some time later, the details were received (I apologize for the quality, some photos in the article were taken by an old telephone):

After an external inspection of the parts, everything was neatly folded into a box and sent to the "stage of removing the residual metal tension." To put it mildly - postponed for a very long time, due to lack of free time.

After a while, I again returned to the manipulator, and began to think through the power system, communication devices, choose servo drives and control electronics. Based on the desired implementation approach, it was assumed that the final weight would be very significant, so the servo needed to be selected with some margin of effort. However, cost also played a significant role. Based on the price / quality ratio, HK15328A servos were purchased with a metal gearbox, double ball bearings, brass bushings, a force of 12.8 kg per cm, at a voltage of 6.0 V., weight 58 grams. The workmanship is tolerable, although there are no dustproof gaskets, the control board hangs freely inside the case, the wire leads are not sealed, there is practically no lubrication in half of the ordered drives, during prolonged use, slight heating is present. All of the above is offset by the cost of the drive ~ $ 7. 18 drives were ordered, all were rebuilt, graphite lubricated and tested under load. For a long time of operation, none of these failed. Below is a photo of the insides of the HK15328A servo:

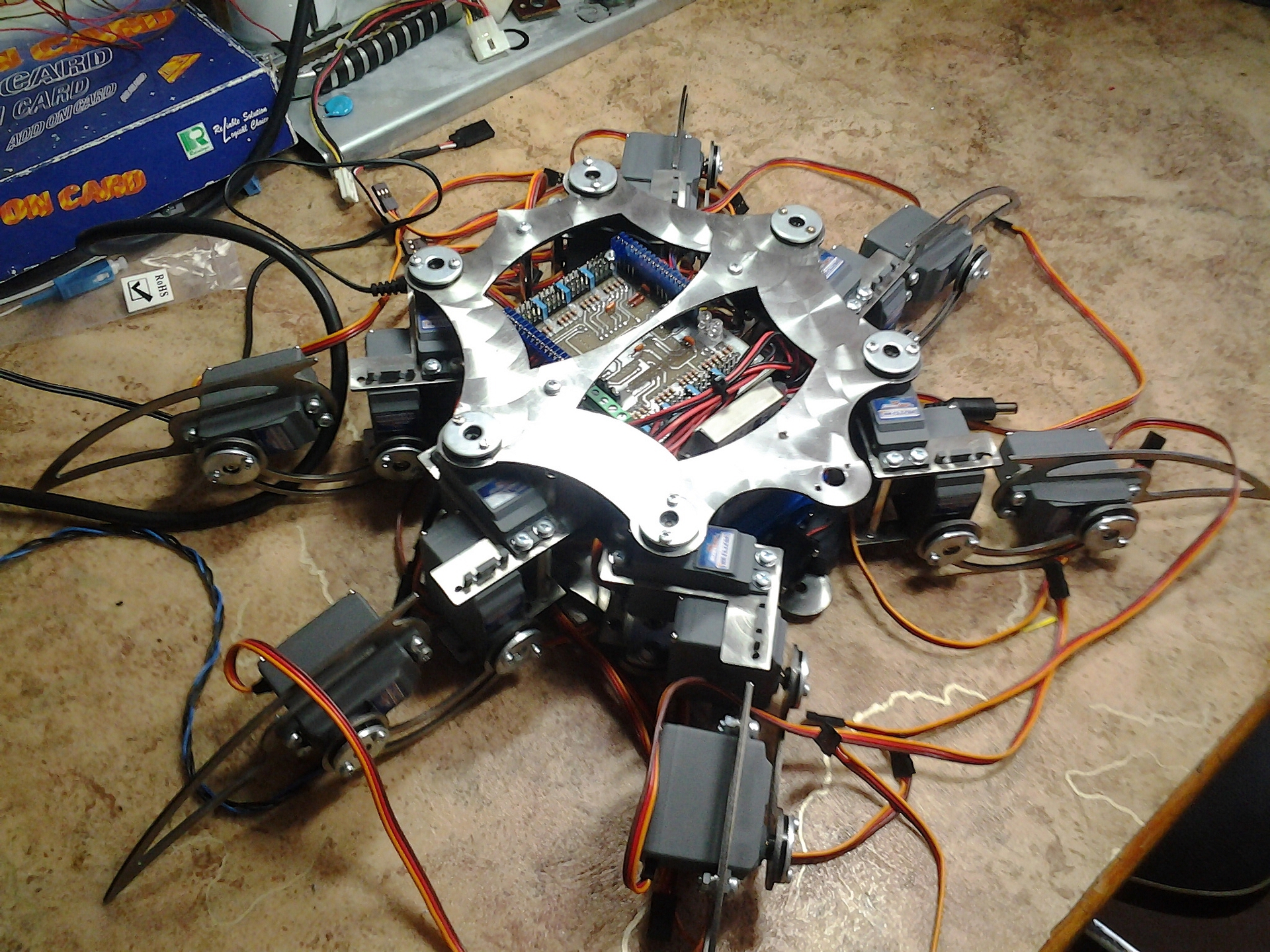

At the time of ordering the aluminum rocking chair was not in stock. It was decided to use the plastic rocking horses that came with the drive, secured with metal washers of suitable size. After finalizing with a file and grinding parts, working on a drilling machine, using taps and fastening servos, the manipulator frame acquired the following form:

A lithium-polymer battery 12.6 V., 9800 mAh, 360 grams was used as a battery. The battery consists of 3 elements connected by a very cheap thin wire, charge controllers for each of the elements, a charging plug and a switch:

Charge controllers also limited the battery current to 1A. It was planned to use the iMAX B6 as a charger, so the charge controllers were removed, and the conductors connecting the elements were replaced. Conductors from each element were also withdrawn, for the possibility of a balanced battery charging. Of the voltage converters, DC-DC Turnigy UBEC-15A, DC-DC Turnigy UBEC-7.5A, DC-DC Turnigy Micro UBEC 5V / 3A were available. The first two are used to power the servos, the last inverter to power the control electronics.

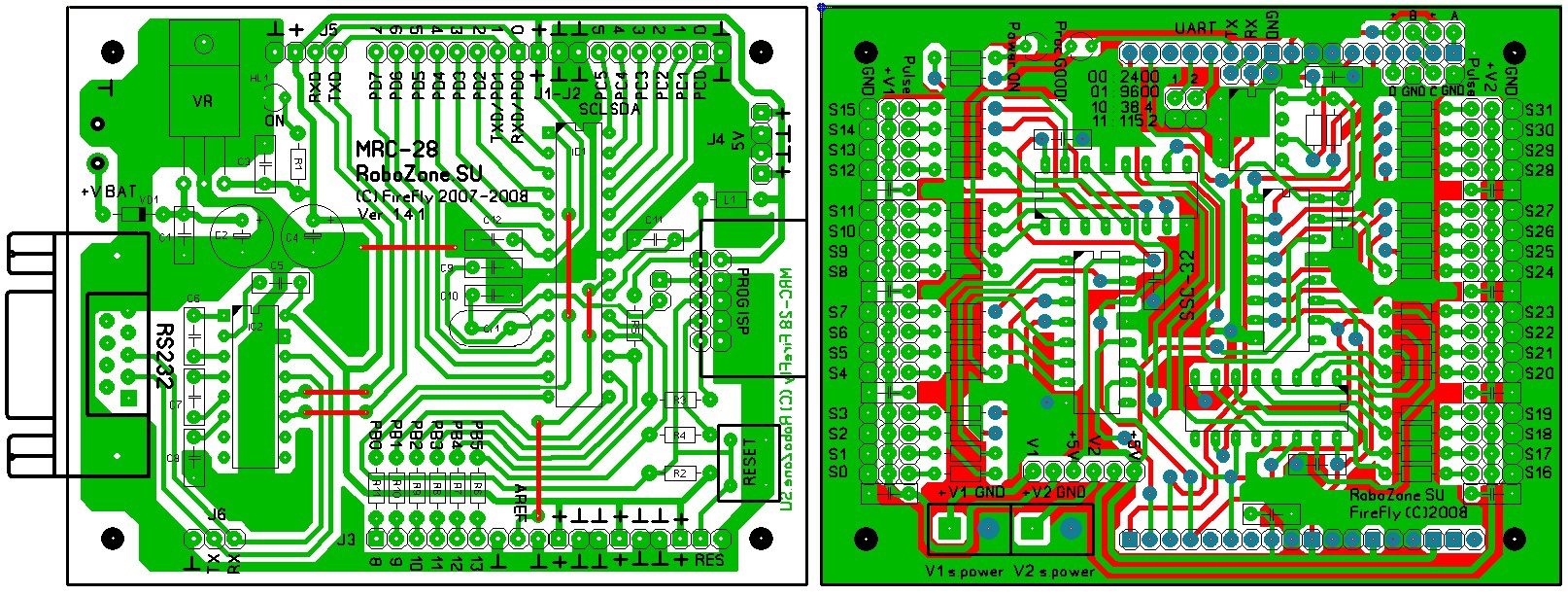

In the role of control electronics, it was customary to use a very common project from LynxMotion - SSC-32. Since there was a MRC28 robotic controller board taken at one time from the RoboZone.su website, it was decided to build on it. On the same site, an expansion board for MRC28 was found for the SSC-32 project:

An expansion board was made and connected to the controller board, fixed with double-sided tape on the battery. Voltage converters were connected, and the control part was pre-installed in the manipulator frame:

For lower limb attachment, small bearings were used, removed from Japanese stepper motors (disassembling old Japanese printers) and mounted in a metal mount. Loctite 480 glue was used for maximum reliable contact. A metal washer was used for a small clearance between the bearing and the lower part of the frame. Mounting screw M5:

Limb and mount are interconnected by type of clamp. So it was easier to implement and allowed to vary slightly when setting the alignment between the servo shaft and the bearing:

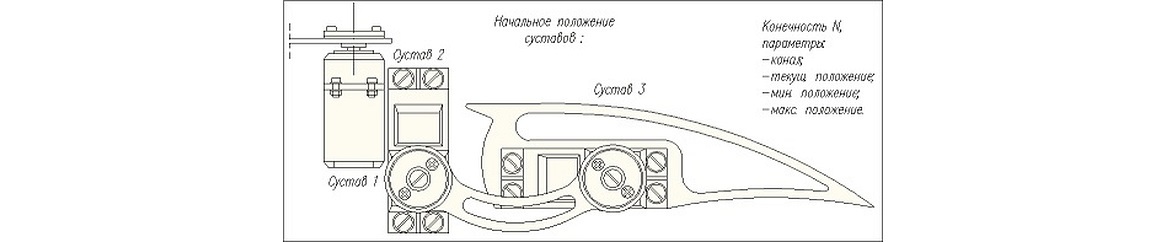

The general structure of one limb acquired the following form:

To connect the manipulator with a PC, the HC-05 Bluetooth module and the Class 1 Bluetooth adapter were used. The simplest Chinese wireless analog camera 2.4 GHz with a receiver connected to the PC via the USB EasyCAP TV tuner was used for video transmission. Image resolution 720x576. To control the manipulator, a SpeedLink STRIKE FX wireless controller was purchased.

After desoldering the supply conductors with connectors, all the wires were grouped and fixed with ties. The wires from the servos were covered in nylon mesh. A 9V voltage converter was used to power the camera. with an LC-filter from improvised means, which allowed to almost completely get rid of the induced interference.

To mount the battery (and all control electronics attached to it) to the body of the manipulator, an aluminum bracket was arranged.

Below is a photograph of the front of the manipulator:

On the back of the manipulator are the power on and battery charging connectors:

The battery is charged by an external iMAX B6 controller set to a balanced charge mode and the RXN-305D power supply:

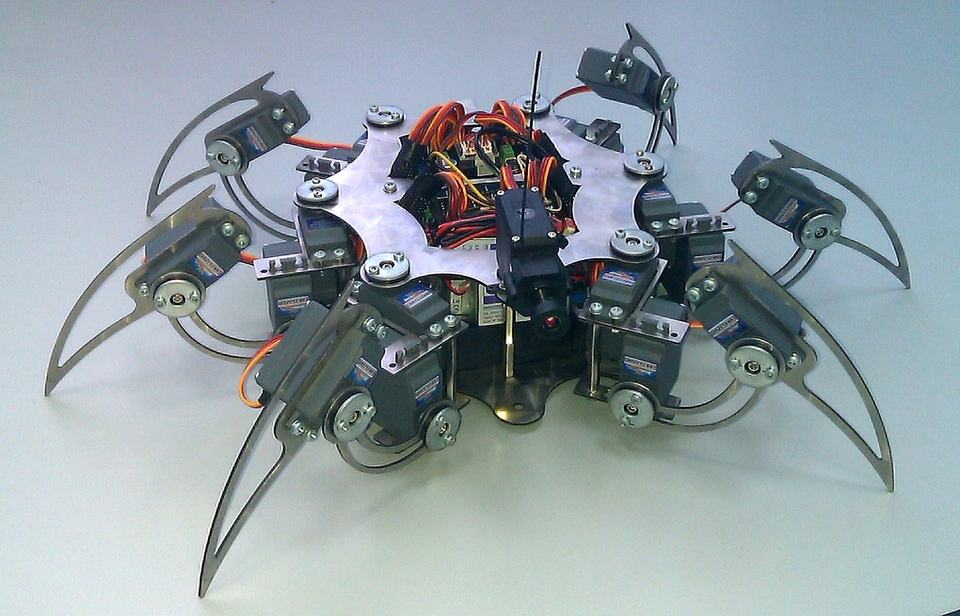

After flashing the controller, installing all the necessary modules and calibrating the limbs the manipulator has acquired the final form below:

The final weight of the manipulator was ~ 3kg. To rotate the camera was installed on a servo MG995. Operating time from one battery charge ~ 40 minutes. The video signal freely breaks through 3-4 reinforced concrete walls. Communication range in open space ~ 30 meters.

Software for PC was developed in Microsoft Visual Studio 2008 and is a functional management, calibration and display of video data. The program allows you to control both a single servo drive and a group of joints.

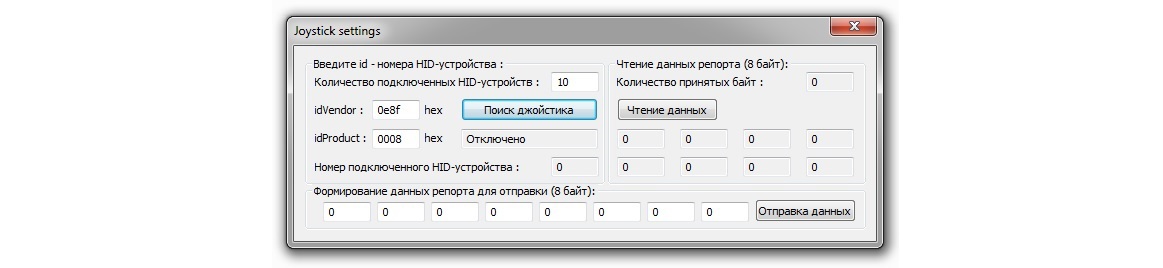

All parameters used in the algorithms are displayed on a graphical interface. It is possible to save / load calibration data for each limb. To obtain video data from the TV tuner, DirectShow was used (attempts to obtain a picture using OpenCV were unsuccessful). It was also necessary to install DXSDK_Jun10, and connect the gdiplus graphics library to the project. The virtual COM port, implemented via Bluetooth, adequately worked with the Chinese Bluetooth adapter only using the SerialGate.dll library (most likely the problem is in the drivers or adapter, but did not experiment with other adapters / drivers). To work with the gamepad (HID device), the libraries hid.lib, hidpi.h, hidsdi.h, hidusage.h were connected.

To determine the values used by the gamepad keys, an additional software module was implemented:

Below is a video of the first movements of the manipulator and its further calibration with optimization of the algorithm and reduction of delays:

After minor modifications to the design and control program, the final implementation of the device is given in the following video:

The approximate cost of the entire kit is ~ $ 400.

In conclusion, I would like to add that after conducting the above stages of the development of the manipulator, some experience was gained and the corresponding conclusions were drawn. As in terms of mechanics of movement, layout, filtering supply voltage and in the software part. When creating such a design in the future, the design of the case will be taken into account, as well as lighter materials, faster servos, more correct movement algorithms, and autonomous modes of processing video data. But all this in the presence of free time in the future.

Thank you for your attention.