How we tracked marriage in the real world and debugged board game production

Every physical game has debugging codes that are “wired” into different components. I remember that I promised a topic about debug of our production in the real world. There he is. At the same time, it can be useful for online shopping.

First about production. A typical board game is made up of dozens of components, and a lot of things are done manually. The ideas of assembly automation begin to become realistic either with very large volumes of production, or with a very expensive workforce in the country. Both of these conditions are fulfilled for Germany - and then, far from everything is automated there. How to check automated lines, we all know - hang sensors, compare readings in the accounting system and control each line parameter. What to do in case of manual production is a good question. And we started to solve it with breakpoints. And they brought the marriage rate to less than one hundredth of a percent . This is very cool, and most of the returns and replacements are thanks to the carriers who turn over the boxes with well-aimed kicks.

But I’ll start, again, from the very beginning.

Assembly

Danetok assembly line

The first level of control is to check how adequate the components themselves are. Here, for example, is the hourglass that is used in many games:

Specifically, this batch came from China (since nobody can beautifully make such a simple thing as an hourglass for 30 seconds in Russia). In winter, the carrier can trickle, and condensation may form inside the watch due to temperature differences. From this sand will cease to crumble. There are just Kotsan watches (as a rule, they can be recognized by the box with traces of falls), there are various non-standard options. All this is checked at the moment when the components arrive at the warehouse.

Each industrial batch has an acceptable level of marriage. For example, in the case of an order of 5000 hours, the good Chinese immediately put another hundred on top just in case, so as not to make a second delivery. If the marriage is typed more than this hundred, we will describe it, take a picture and demand to send another hours, or subtract the cost from the final 20-30% of the payment.

By the way, there is a wonderful joke on this subject.

There he is

IBM orders the production of next-generation processors in Japan. During the negotiations, the director reports that they have very strict quality control, and there must be exactly two failed processors for the entire batch. A few months later, the delivery comes, several containers. She is accompanied by a polite Japanese with a case. He approaches the director, presents the documents for the batch, opens the case:

- We do not quite understand the quality policy of our esteemed Western colleagues, but we did exactly what you asked and made two failed processors separately. Here they are.

The next stage of production is the grouping of components . Remember the chips that are in ziplock or shrink bags? So, you need to collect them in N pieces per package. At the same time, the errors here are unequal: if there are N + 1 chips, this is not scary, but if N-1, you will have to recall the game.

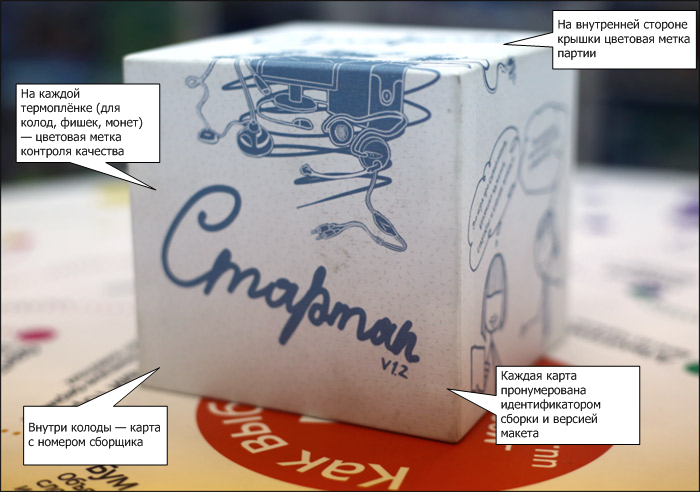

A special colored circle is applied to each bag, it means the batch number. By its color, you can set a specific collector responsible for this circulation.

These are the bags in the warehouse:

And here’s what’s similar in the game:

If you suddenly receive information that the composition is incorrect, we will know the color of the label and understand the source of the marriage. But this is only a small part of the solution to the problem.

Deck assembly- non-trivial task. We need to collect, say, exactly 150 cards. According to our suppliers, we noticed many years ago that decks with pictures are easy to assemble, but everything with letters can be mixed up. Because the cards are too similar.

Another interesting feature is that there is almost no “not reported” marriage, because the assembly process involves pushing a certain number of cards into the deck. By the way, we tried to check it on a tensometric balance, but there isn’t much sense for paper (but it’s convenient for plastic). It turned out that the collector, who had worked for a week, was able to take any of the hundreds of decks in his hands and say whether all the cards were there by weight and thickness of the pack. Like in a joke: “I have not played for a long time. Well, let's mix it up ... yes, there’s not enough six of the peak. ”

But it’s quite possible that there’s a marriage of “they put the same cards twice, but some of them didn’t enter.” This happens, for example, when for some reason another card suddenly starts in the middle of the box. This should not be (this is a printing condition), but rarely happens. We try to avoid this even in the production of cards. Therefore, in general, each card is also numbered:

These numbers are the ordinal number in the deck. For example, 98 and 16 are looking at us here.

When the layout of the card changes, we can add a hundred to the number (or a thousand if there are more than 100 cards in the deck). Cards 159 and 59 should not be found in the same deck for 80 units - these are clearly different layouts. But we did just a couple of times: it turned out to be much simpler, cheaper and more reliable to utilize the remnants of the first run and work only with the new one.

Below is a photo of how the decks are marked: a card with the collector number is added to each. Since we don’t want to spend the card just like that, there’s also a bit of advertising. Here is a game with several decks, each with its own card. As you can see, the same collector collected a large deck and one of the small ones.

Further, the assembled components can be kept in stock for some time and only after a couple of weeks can they get to the circulation assembly. The final assembly run - marking the box with a special debugging code. Also wired in color, like this (circle on the inside of the lid):

Output control

At the exit from the assembly zone, from 1% to 10% of the products are selectively opened and checked from start to finish. If everything is fine - the go-ahead is given to send to the warehouse.

Transportation

When we reduced the production defect, the number of returns fell, but not as much as we would like. I remind you that we reduced the amount of marriage to approximately 0.01% (calculation of the detected: some more may not come back when in rare cases someone decides not to return the box).

Moreover, most of the returns were related to transportation. Here is an example of a recent return to the store (a box not of our production):

It could have been someone else's gift, but did not - thanks to the loaders. Therefore, we went a little further for our production and decided that it was useless to swear with loaders (more precisely, other people are engaged in this). And for a specific warehouse, harsh Russia is just the surrounding reality, which must be accepted with all the features.

Therefore, the next step after receiving ready-made games is the assembly of special transport boxes . Each game is carefully measured before printing and a box is used to make exactly a millimeter-in-millimeter for a batch. Usually these are 8-10 games for transport corrugated packaging for standard boxes, 12 for cubic, 24 for small ones, 5 for extra large ones. The result - there are already fewer returns, but there is much to grow in this regard - and a lot.

General procedure

If a person has a defective copy in his hands, he can name the color of the mug from under the lid - this is necessary not for production, but for us, retail. We can track where this batch has gone and open another 10 boxes to see if this is a one-off marriage or a serial one. Not everyone is able to recognize the color accurately, so we ask you to send a photo or focus on the box brought. In this case, similar colors lie far from each other in runs (pink and purple will go into circulation with a difference of six months at least), so usually it turns out to solve everything by phone.

Production sends a replacement through us (Mosigra retail) or by itself. Somewhere a couple of times a month, additional sending of cards in registered letters is done, a couple of times - whole boxes are sent.

At the same time, when we have the debugging code of the box, the collector number and information about the lot from which the assembly was made, we can understand what exactly the error was. An additional plus of the system - each collector has a bonus for the absence of marriage. If his codes are not returned to production, he earns more.

A similar system in a simplified form is used on retail advertising materials:

This entire system was introduced and updated for a couple of months. Tikhon, the head of Magellan (from him, the theory), was closely involved in this, then Seryoga, the head of the production (and the assembly line), who put all this into practice, got involved.

All. Here there is still an old topic about schools of printing houses , and here - analysis of specific cases of bugs in our sales.