Zbot. How the Chinese made an industrial 3D printer from a desktop

In this publication I want to share my acquaintance with Zbot FDM-i1 (i2) 3d printers , whose older brother won the Chinese Design Award 2012.

In essence, these printers are a simplified version of industrial models: Zbot FDM20-2525 and Zbot FDM35-1515

When In this, these models have completely preserved the design of the print head. And it was possible to reduce the cost of the design due to the simplification of mechanics due to more compact dimensions. (The price has decreased from 180,000 rubles to 59,000 in Russia) The

older models are used in engineering companies and are mainly focused on the domestic market of China.

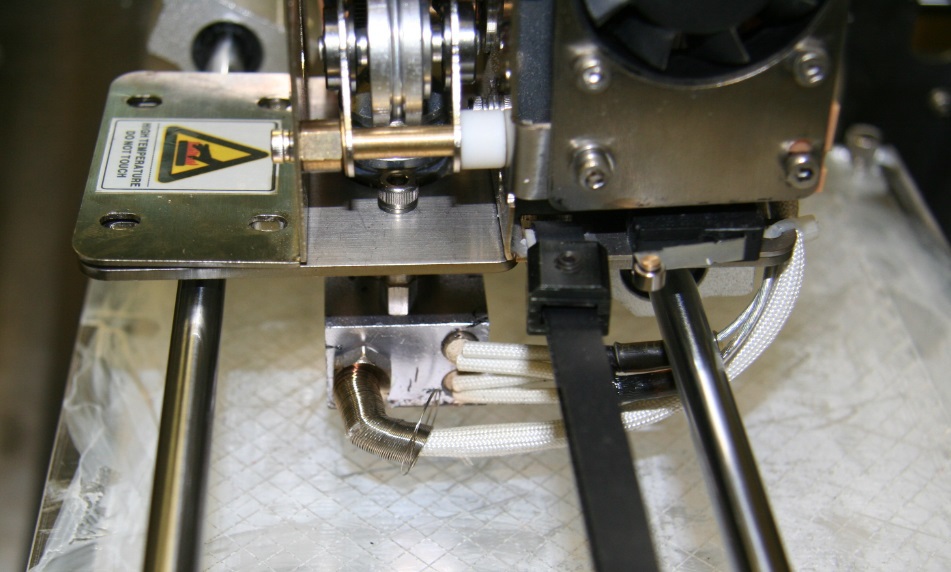

The main design features are two heating elements and an unusual clamping mechanism. Details under the cut.

Options and packaging are common for all desktop printers, there is everything you need The

printer comes fully assembled with the exception of the plastic holder and the base of the feed tube, which just need to be hung on the back of the printer.

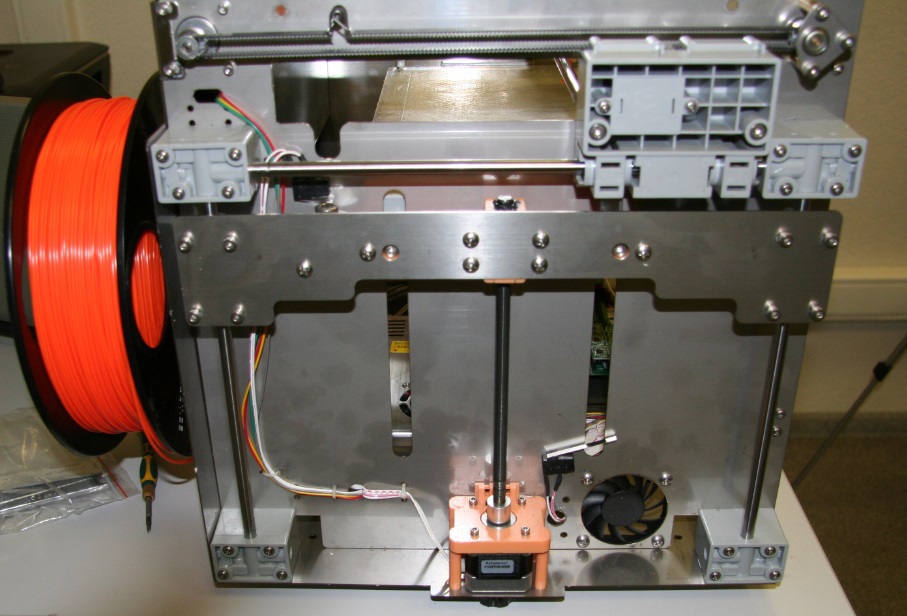

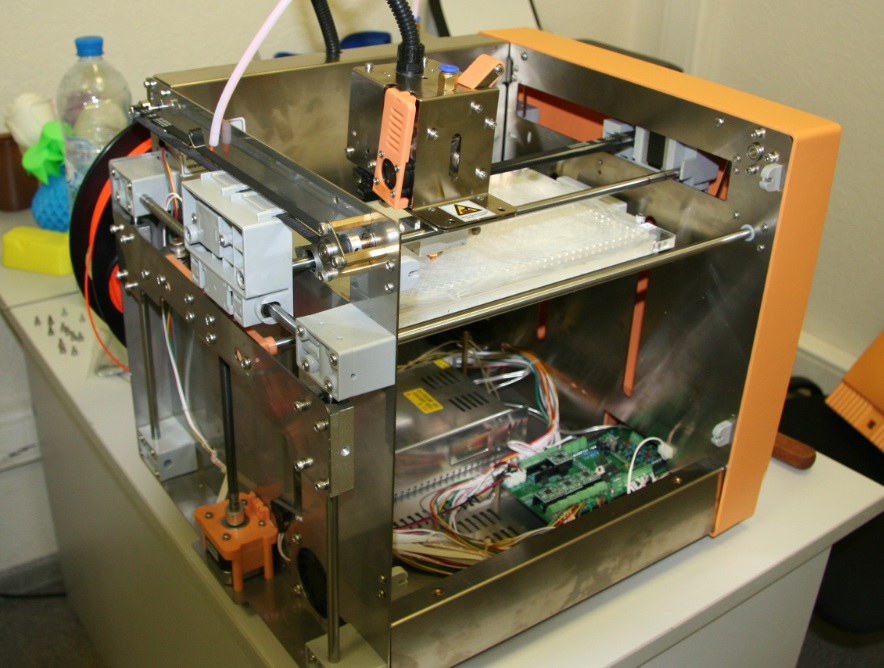

The frame of the printer is made of metal sheets forming an integral frame. All mechanics and electronics are attached to it.

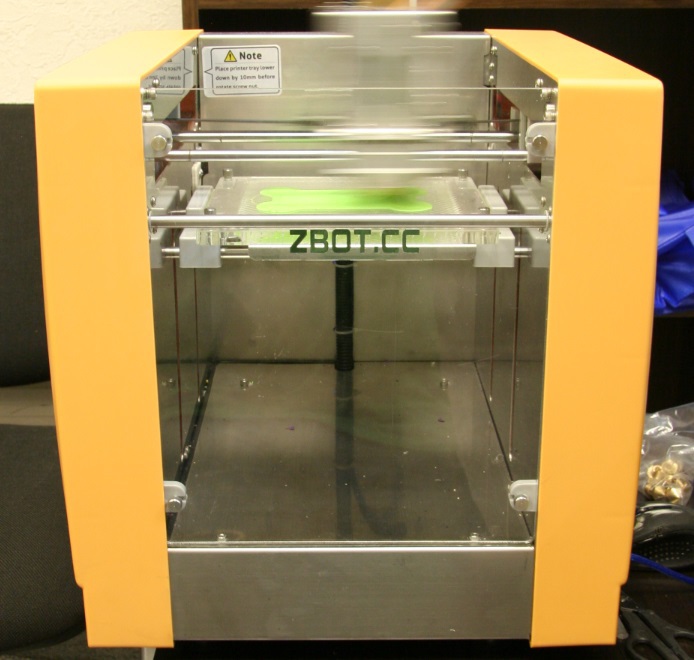

The front panel is made of transparent plexiglass, but there is one “but”. Each time you have to unscrew the 4 screws to remove it, and tighten the same 4 screws to put it back on. Those. it must be removed at the end of each print. But you can print without it.

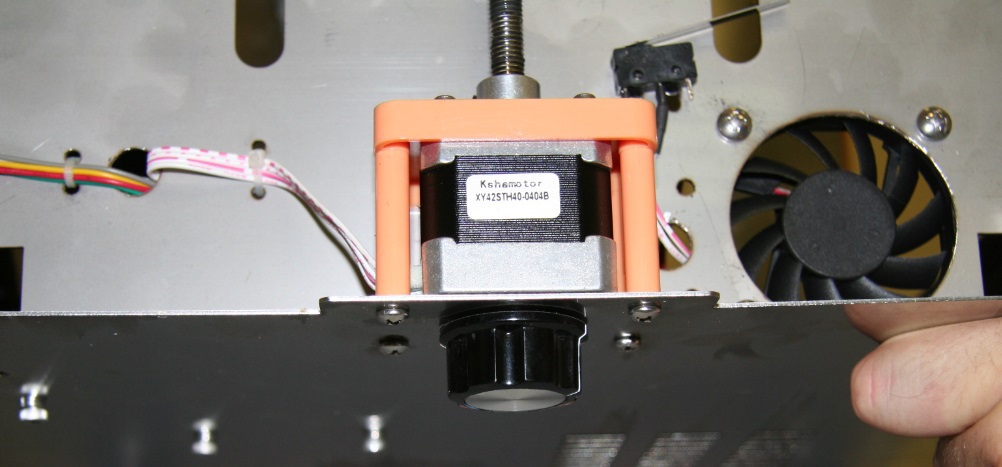

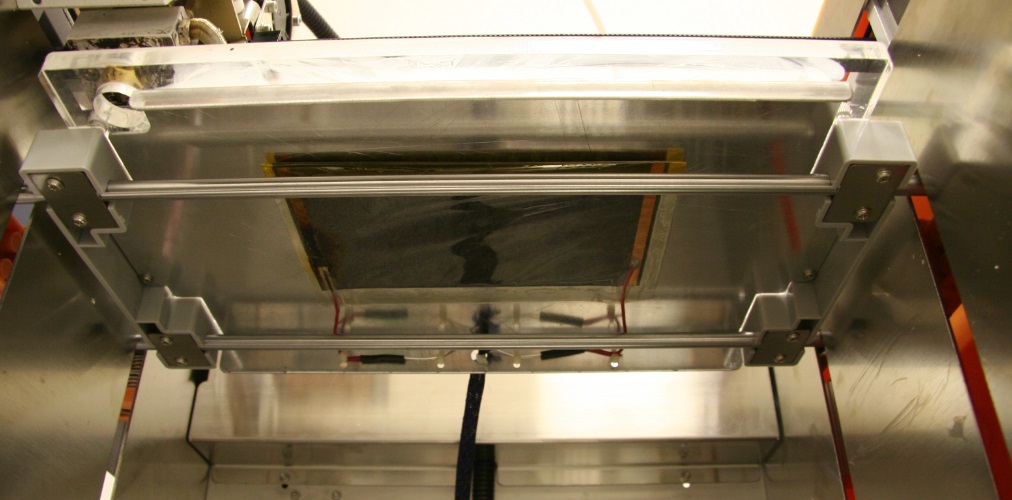

The right edge of the platform is stationary, and the left is height-adjustable using the handle on the bottom of the printer. This handle is just connected to the engine of the left axial screw. It is believed that the front-back of the platform is calibrated at the

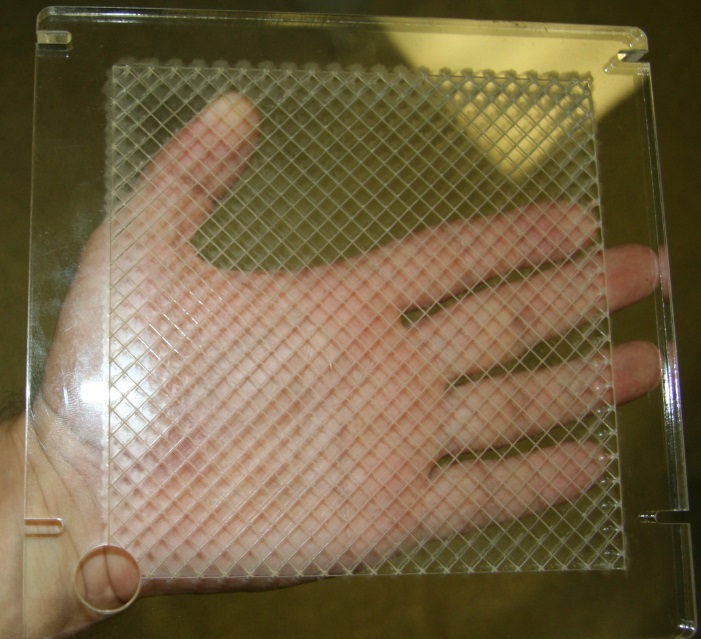

Platform factory from acrylic, lined in a mesh. The platform size is 15 cm x 15 cm. The older model Zbot FDM-i2 has a 10 cm wider platform.

The platform is heated, but the heating temperature cannot be adjusted. It always warms up when the printer is on.

The system is similar to Replicator. But this printer along the Z axis has a platform fixed at 2 ends on the left and right. At each end there are two linear circular guides and a helical axis.

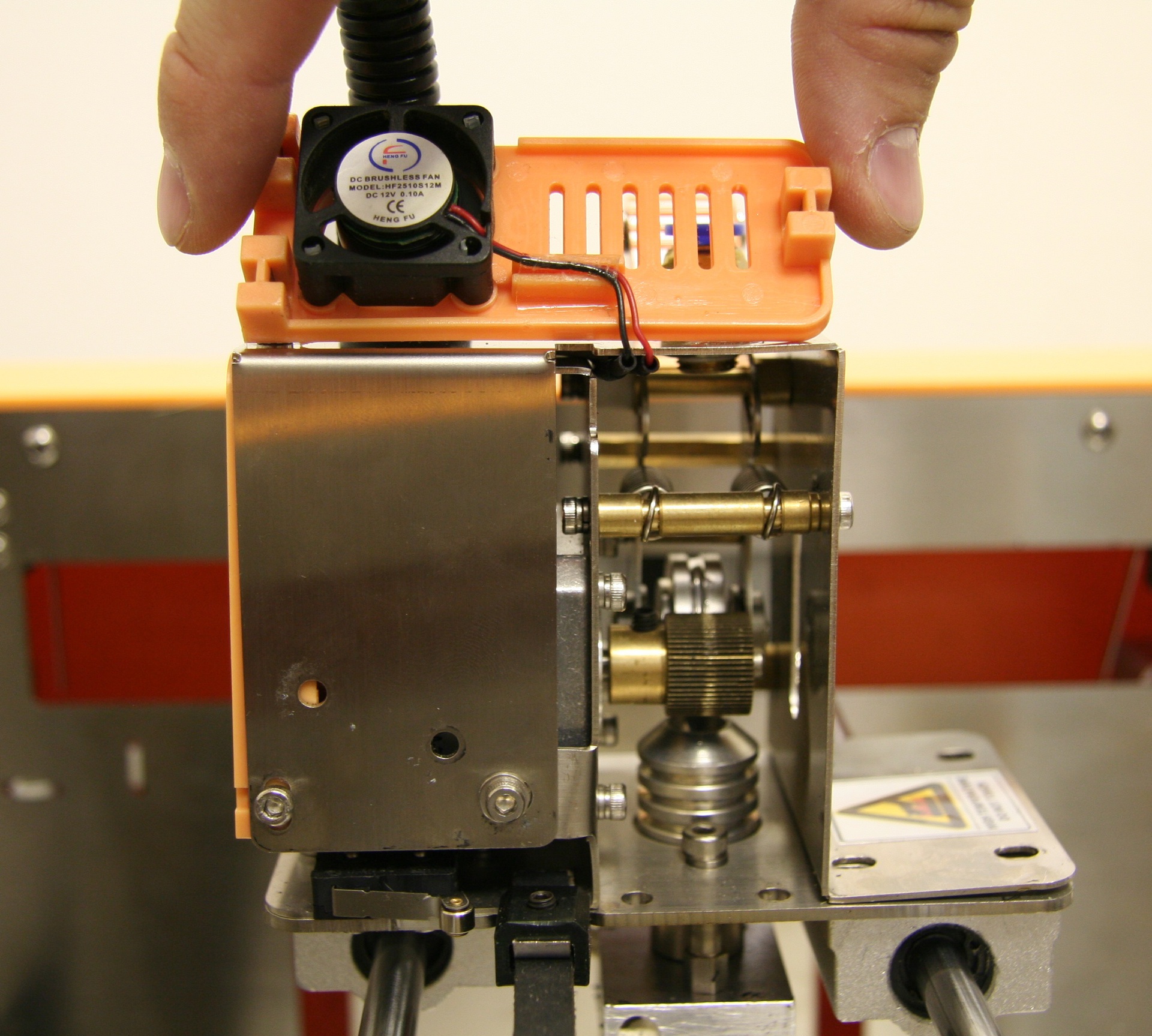

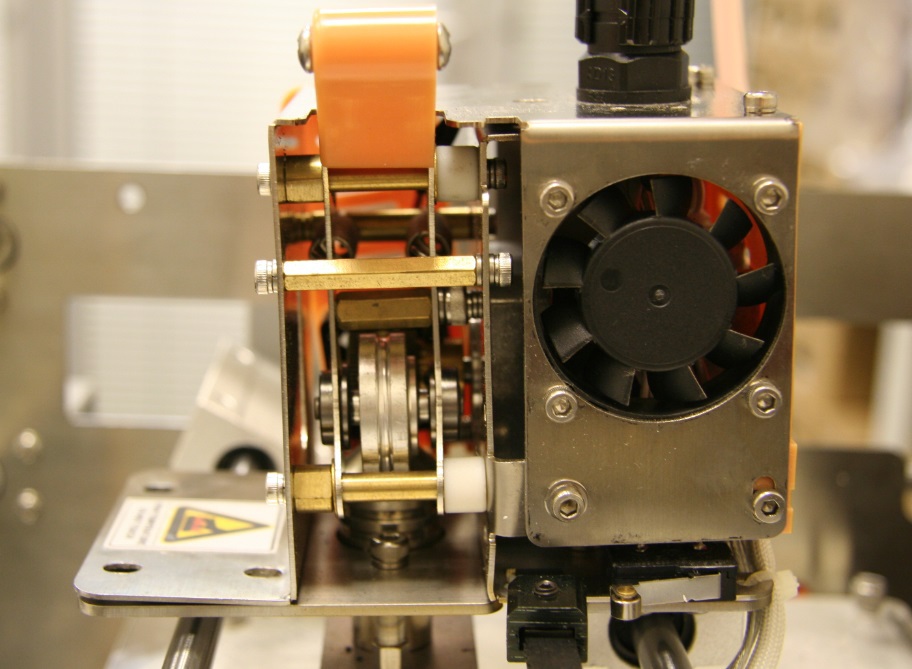

Two heating elements. The printer warms up to 240 degrees in 2-3 minutes

The clamping mechanism is durable, as it does not contain plastic parts, with the exception of the lever. The feed motor has its own fan. The chute for guiding the plastic is located on the pinch wheel, and two dense springs are strong enough so that the plastic does not slip.

massive nozzle, separate fans for the nozzle and for the engine and a curious pressure mechanism

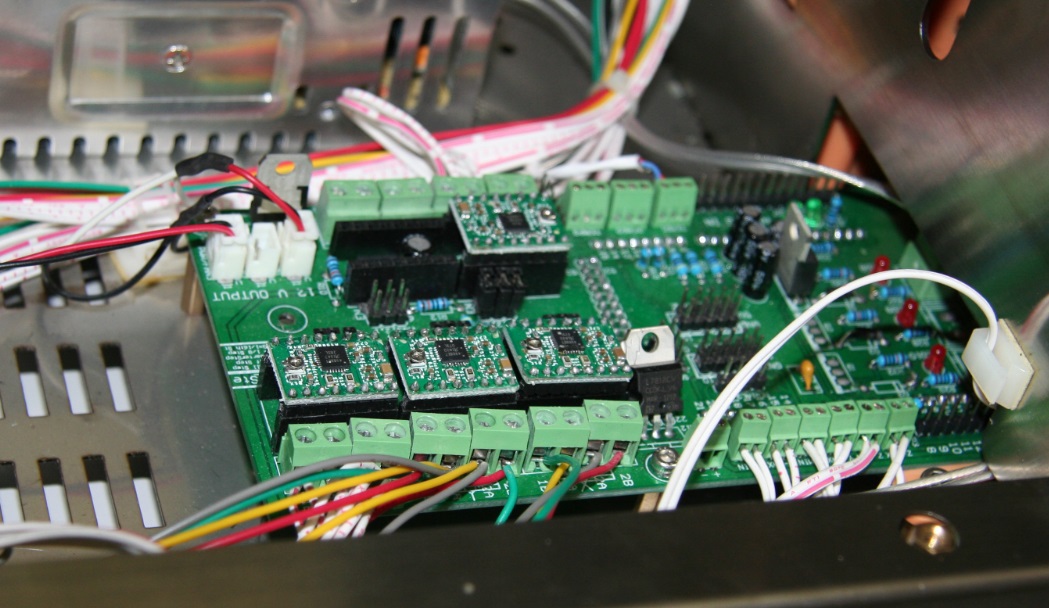

Electronics is the same as the first Ultimaker. Managed by Arduino. The firmware used is Marlin, which allows you to use all the most common applications for printing (Kissliser, pronterface (printrun), Slic3r, Cura, Repetier Host, Simplify3d, Octoprint).

Manufacturers promise that soon this printer will acquire an LCD screen and an SD card slot.

Software

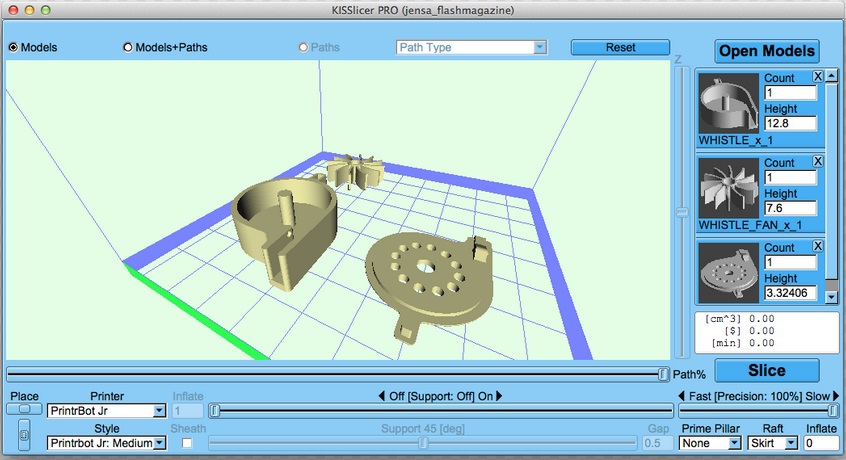

The native software is a bunch of Kisslicer + Printrun

Kisslicer is used to convert 3D models to GCode. There is in Russian. Kisslicer comes with predefined settings for Zbot FDM-i1

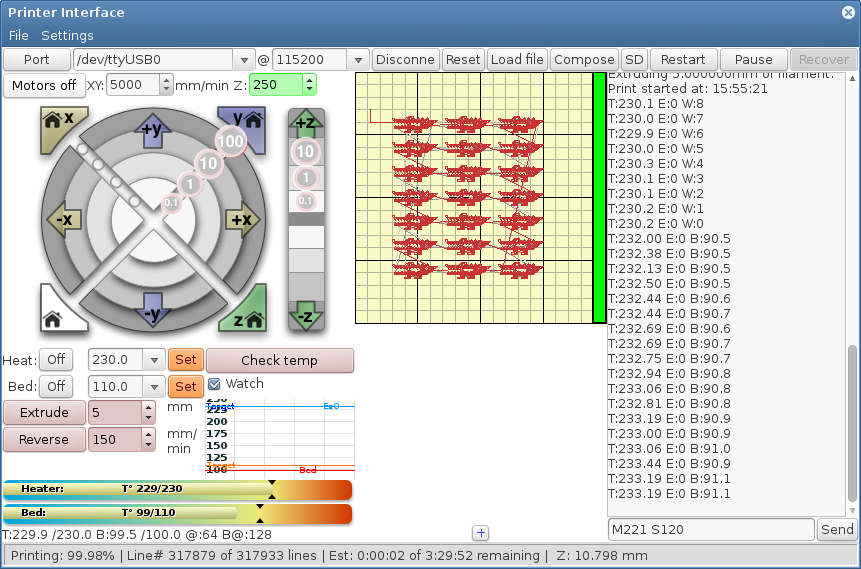

Printrun is used to send GCode to print

Choose a speed / quality ratio

The printer can print both ABS and PLA, but it was originally developed for ABS.