We sit, do not touch anyone, we fix the old headphones

So the moment came when the next headphones were out of order. They would have worked for a hundred years, but the weakest point of modern headphones - the wire in the area of the connector - again made itself felt. Back to the store? Well, no, hands are too straight. In addition, you will have to look for exactly such a model, which is not easy, because the inserts are gradually replaced by hateful (by me) in-ear hookers. And their sound is unexpectedly good for this class of headphones.

So, pick up the tool, and let's go. Under the cut photo at 800 kB.

Using this technology, I have already repaired several pairs of headphones. The life time after such a repair still depends on the quality of the wire itself, but it is noticeably longer than from the factory. Old monitor headphones have been living with such a connector for five years, and some Japanese have lived only 3 weeks (one and a half worked before the repair).

From the materials we need:

Of the tools we need, first of all, a soldering iron and pliers for delicate work.

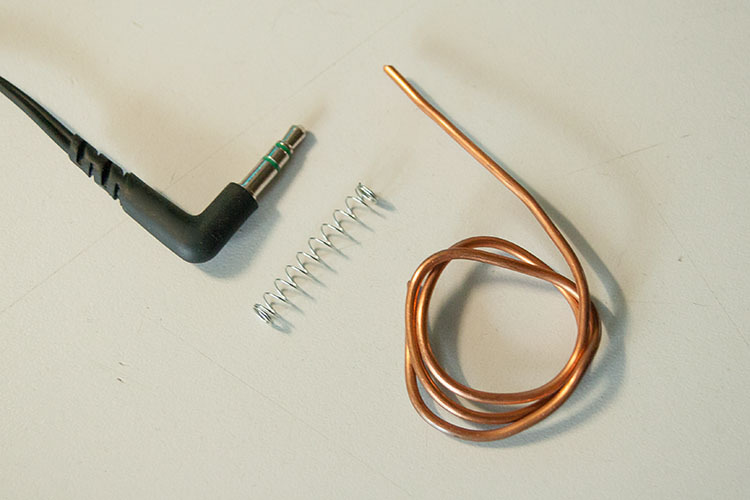

So, the patient in the first photo. First you need to release the plug itself from the rubber casing. To do this, we make such an incision:

Usually the wires soldered to the plug are filled with plastic, from which a small barrel is formed. This design is then inserted into a pre-molded rubber casing. At the same headphones, the casing was cast, apparently right on this barrel, and tightly stuck to it. It’s impossible to disassemble step-by-step accurately, therefore, having made an incision, we break out the necessary part from plastic. The wires are thin enough to come off almost imperceptibly. Result:

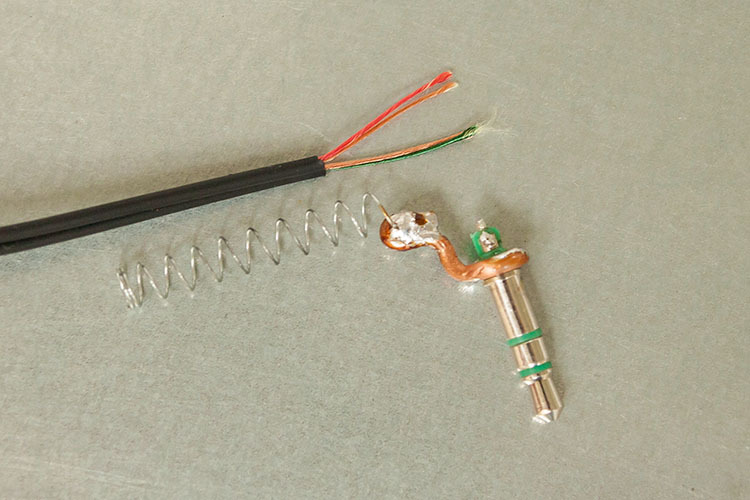

Now we need to make the basis of the design of copper wire. Before that, it is worth cleaning it with sandpaper. First, we bend this loop:

It should be tightly worn on the part from the side of the solder contacts. Next, we give the base the following form:

The base is ready. The resulting hook will serve to secure the spring, which will serve as protection against excessive bending of the wire. Now we take a spring, and unwind a few turns: We

straighten the straightened part of the spring again. This time, the diameter of the turns should be slightly less than the diameter of the copper wire. We put the spring on the hook and clamp it with pliers like this:

Solder the plug and spring to the base. On the basis of it, we immediately trickle a small area to which the common wire is soldered. Despite the fact that the spring is made of steel, it is soldered remarkably with a simple rosin flux:

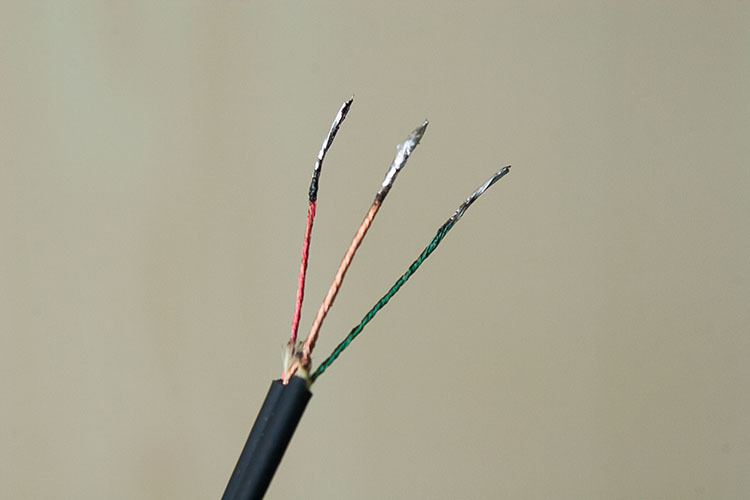

Now we take up the wires. We clean a small section from insulation:

The most disgusting thing is to get rid of the fiber onto which the wires are wound. To do this, I clamp the wire between the thumbnail and the index pad, and with a movement similar to stripping the wire, I disintegrate the wires. I collect the veins in a bunch of tweezers and twist them together, and burn the fiber. I used to burn immediately, but after that the wires became brittle, the varnish burned over a long length.

For tinning, I used an aspirin tablet as a flux. Acetylsalicylic acid perfectly removes varnish. Important: her fumes are very caustic, do not allow them to inhale or get in eyes !

This is how the result should be:

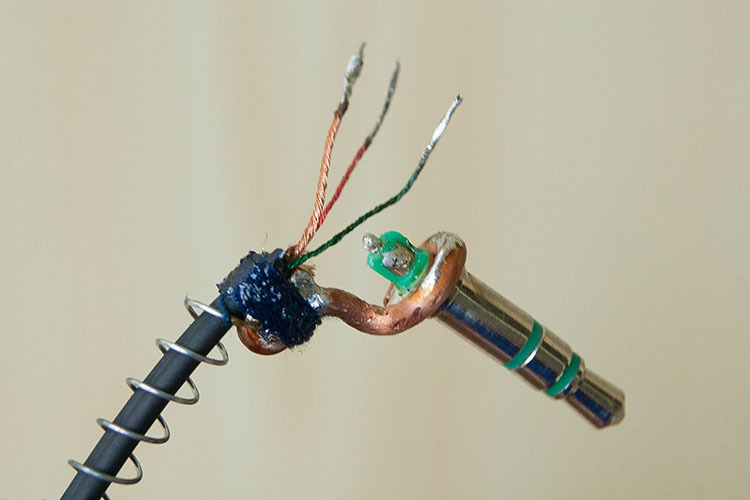

As you can see, "land to earth." We pass the finished wire through the spring, and we wind it to the base with threads, which are then impregnated with superglue:

Solder the wires into place. The red wire (right channel) corresponds to the end contact. Green, it is left, solder to the middle. We solder the earth to a pre-prepared patch on the basis of.

It’s also kung fu, the wires spring and do not want to stay in place. It's time to check the performance of the headphones. If everything is OK, we make the case.

I used to sculpt it from a piece of cold welding. A very simple way that does not even require a description. The only negative is that in small quantities it is rather difficult to maintain mixing proportions, and hardened welding can be very loose and fragile. This time I decided to try the “home composite” - superglue and baking soda. The technology is quite well-known: pour a bunch of soda in the right place, gently drop it with superglue. Soda is impregnated in a couple of seconds, the glue instantly sets, and we get a solid and durable plastic. Layer by layer, we build up the object, in some places you can lay together the clumping soda lumps instead of powder.

For example, in the gap between the base and the wires in this photo:

I assumed that it is more difficult than cold welding. But the reality was even worse than expected. This process took a good half an hour! However, the result is very good. After file processing, I got this connector:

After painting in black, it will look pretty good.

As you can see, the process is for the diligent. But once purchased 3.5 mm plugs, except for Chinese, can not find what to do? The players of one fruit company have a reliable, but very finicky socket, in which the curve of the Chinese plug simply does not touch the contacts. Somehow I was lucky to buy several direct mini-jacks from Neutric, which turned out to be too large and therefore dangerous for the nest, but I could not find the corner ones on sale. Therefore, my instruction will help someone, I'm sure.

New dress

Finally painted. The paint on the body went down fine, although it took a little longer to work with a file.

Well and the hanging test. In my opinion, not bad)

So, pick up the tool, and let's go. Under the cut photo at 800 kB.

Using this technology, I have already repaired several pairs of headphones. The life time after such a repair still depends on the quality of the wire itself, but it is noticeably longer than from the factory. Old monitor headphones have been living with such a connector for five years, and some Japanese have lived only 3 weeks (one and a half worked before the repair).

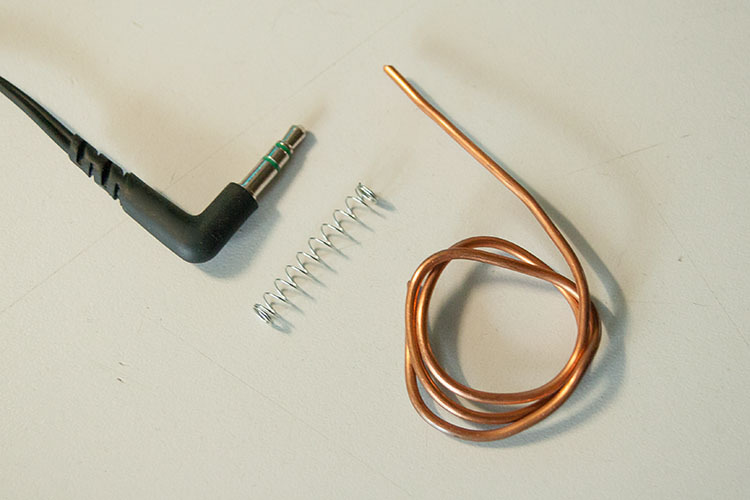

From the materials we need:

- thick copper wire;

- fountain pen spring;

- liquid superglue + soda, or cold welding;

- threads.

Of the tools we need, first of all, a soldering iron and pliers for delicate work.

So, the patient in the first photo. First you need to release the plug itself from the rubber casing. To do this, we make such an incision:

Usually the wires soldered to the plug are filled with plastic, from which a small barrel is formed. This design is then inserted into a pre-molded rubber casing. At the same headphones, the casing was cast, apparently right on this barrel, and tightly stuck to it. It’s impossible to disassemble step-by-step accurately, therefore, having made an incision, we break out the necessary part from plastic. The wires are thin enough to come off almost imperceptibly. Result:

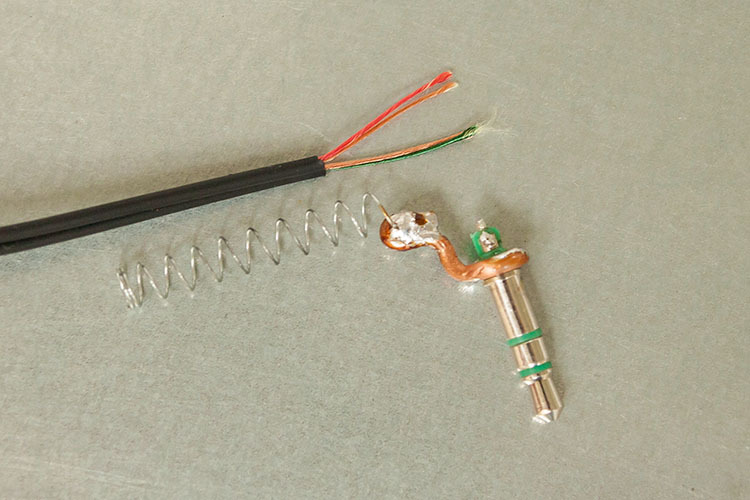

Now we need to make the basis of the design of copper wire. Before that, it is worth cleaning it with sandpaper. First, we bend this loop:

It should be tightly worn on the part from the side of the solder contacts. Next, we give the base the following form:

The base is ready. The resulting hook will serve to secure the spring, which will serve as protection against excessive bending of the wire. Now we take a spring, and unwind a few turns: We

straighten the straightened part of the spring again. This time, the diameter of the turns should be slightly less than the diameter of the copper wire. We put the spring on the hook and clamp it with pliers like this:

Solder the plug and spring to the base. On the basis of it, we immediately trickle a small area to which the common wire is soldered. Despite the fact that the spring is made of steel, it is soldered remarkably with a simple rosin flux:

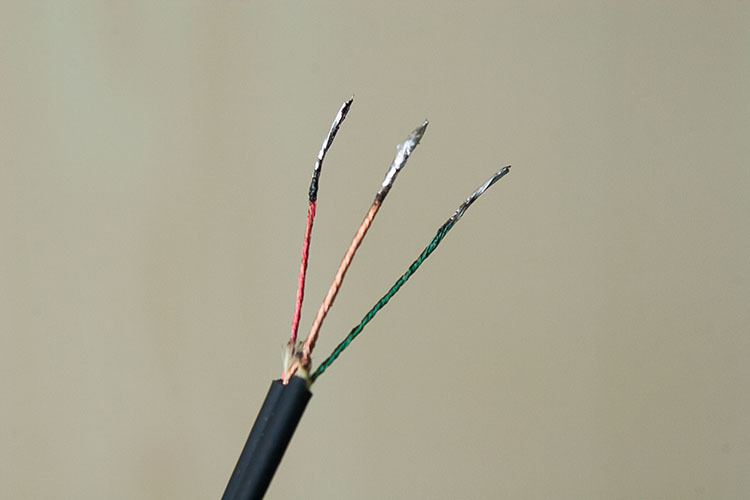

Now we take up the wires. We clean a small section from insulation:

The most disgusting thing is to get rid of the fiber onto which the wires are wound. To do this, I clamp the wire between the thumbnail and the index pad, and with a movement similar to stripping the wire, I disintegrate the wires. I collect the veins in a bunch of tweezers and twist them together, and burn the fiber. I used to burn immediately, but after that the wires became brittle, the varnish burned over a long length.

For tinning, I used an aspirin tablet as a flux. Acetylsalicylic acid perfectly removes varnish. Important: her fumes are very caustic, do not allow them to inhale or get in eyes !

This is how the result should be:

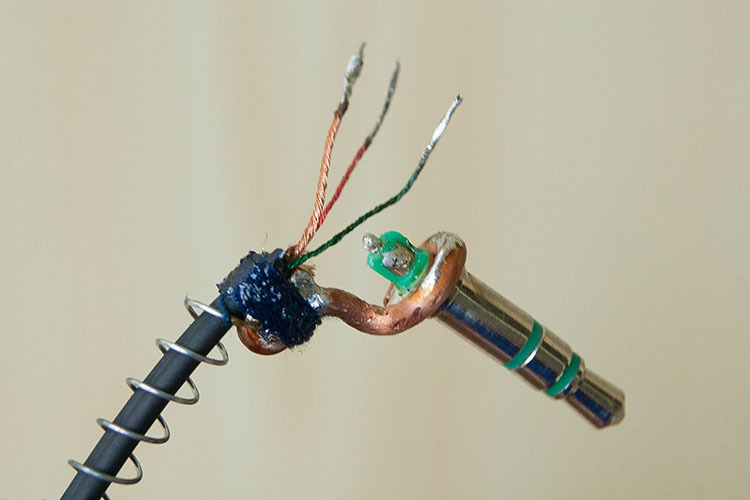

As you can see, "land to earth." We pass the finished wire through the spring, and we wind it to the base with threads, which are then impregnated with superglue:

Solder the wires into place. The red wire (right channel) corresponds to the end contact. Green, it is left, solder to the middle. We solder the earth to a pre-prepared patch on the basis of.

It’s also kung fu, the wires spring and do not want to stay in place. It's time to check the performance of the headphones. If everything is OK, we make the case.

I used to sculpt it from a piece of cold welding. A very simple way that does not even require a description. The only negative is that in small quantities it is rather difficult to maintain mixing proportions, and hardened welding can be very loose and fragile. This time I decided to try the “home composite” - superglue and baking soda. The technology is quite well-known: pour a bunch of soda in the right place, gently drop it with superglue. Soda is impregnated in a couple of seconds, the glue instantly sets, and we get a solid and durable plastic. Layer by layer, we build up the object, in some places you can lay together the clumping soda lumps instead of powder.

For example, in the gap between the base and the wires in this photo:

I assumed that it is more difficult than cold welding. But the reality was even worse than expected. This process took a good half an hour! However, the result is very good. After file processing, I got this connector:

After painting in black, it will look pretty good.

As you can see, the process is for the diligent. But once purchased 3.5 mm plugs, except for Chinese, can not find what to do? The players of one fruit company have a reliable, but very finicky socket, in which the curve of the Chinese plug simply does not touch the contacts. Somehow I was lucky to buy several direct mini-jacks from Neutric, which turned out to be too large and therefore dangerous for the nest, but I could not find the corner ones on sale. Therefore, my instruction will help someone, I'm sure.

New dress

Finally painted. The paint on the body went down fine, although it took a little longer to work with a file.

Well and the hanging test. In my opinion, not bad)