FTDI-POF Optical Transceiver

Hi, Habr, I am a student in lasers in info-communication systems and for the first time I worked with optical fiber. I was offered to participate in one project related to the transfer of data via optical fiber and I took up this work with interest.

Optical fiber is increasingly fixed in our lives. This is the Internet, connecting a variety of sensors, laser devices. It is also used in the lighting of the premises.

Optical lines have a number of advantages: no problems with grounding, high noise immunity, privacy (no electromagnetic radiation that can be overheard), lightness.

Task: to create a working prototype of the board with a serial port, the signals of which are transmitted via a plastic fiber-optic communication line. The basis is taken by the MBFTDI programmer, built on the FT2232H chip. The JTAG connector from the programmer had to be removed and in its place put the optical receiver and transmitter. What was done.

Further I will tell about what and how I did

Having heard the technical task, I immediately said that it was not possible. I can say that in high school we have repeatedly talked about optical fiber, but all the time the emphasis was placed on quartz fiber, which is now used in communication lines. To work with him you need expensive equipment. And it was necessary to find an inexpensive solution.

However, after studying the article on Habré , I was very puzzled. That's what puzzled me: with my estimates of “excellent” and almost 100% of all classes (yes, I did not miss the opportunity to praise myself) I could not assume that there is a POF (Plastic Optical Fiber). This is a plastic fiber, which is just right for our task.

- Its dimensions are 2.2 mm in diameter. For comparison: the diameter of a standard quartz fiber is 125 microns.

- Processing is almost not required. You can cut the fiber with a regular knife and not handle the butt, but it will still work.

- The receiver and transmitter together cost a little more than 1000 rubles, which is less than devices for working with quartz fiber.

- The minimum absorption is in the visible spectrum - 650 nm (red)

Naturally, the transfer performance is better with quartz fiber, but the POF is perfect for us. Its advantages make our work easier and more convenient, and the low price of components generally makes us happy.

Let's move on to the development process itself.

From start to finish in 3 steps

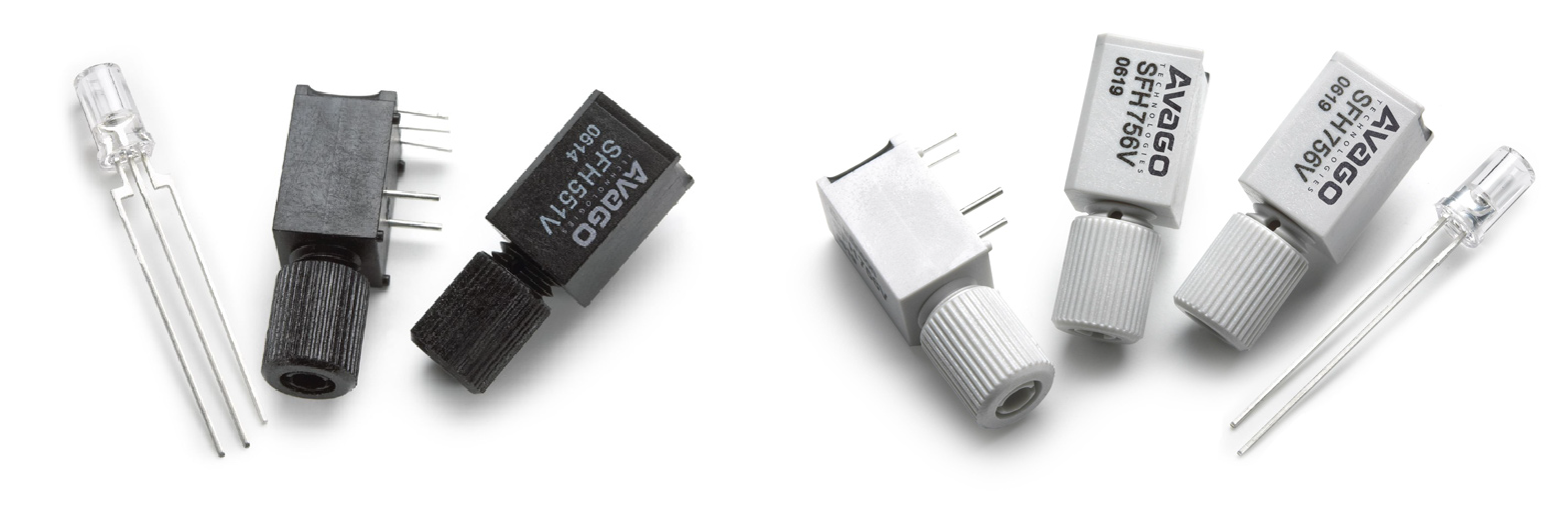

To work with this fiber, we need a receiver and a transmitter. The choice fell on SFH551 (black) and SFH756 (white), respectively.

To begin with, a test model was assembled on a printed circuit board, everything worked on a 15-20 cm long cable, but when the entire coil was connected (about 100 m), the radiation was scattered in the fiber and did not reach the end. It seems the LED in the transmitter shines too weakly. Having understood the documentation, it became clear that the transmitter needs more current. The FTDI chip at the output can not give more than 12mA, but you need at least 50mA. This problem is solved by adding a transistor to the transmitter circuit.

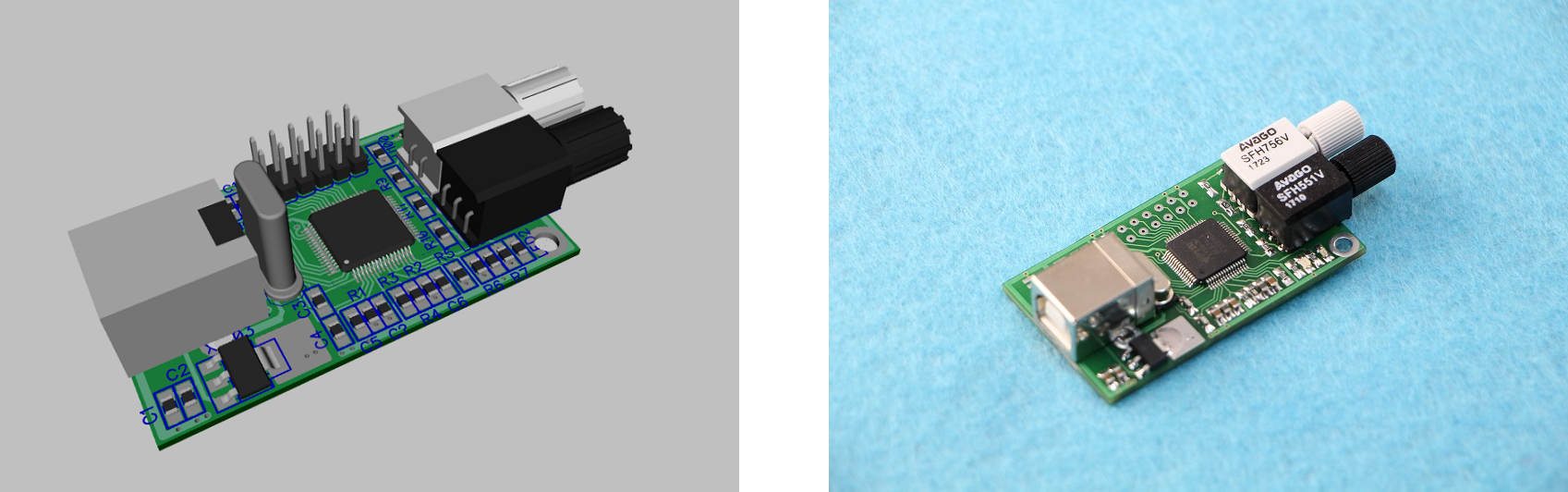

Having obtained a working optical isolation circuit, we proceeded to the PCB layout. The basis, of course, was taken MBFTDI programmer circuit. Further work was carried out in the program DipTrace. I did not find libraries for it with our elements and made them myself. To be honest, I used this program for the first time, but its clear interface helped me quickly get comfortable. Also in DipTrace there is an interesting feature 3D Preview, which shows the board with all the elements in 3D. It was fascinating for me in my own way, since you can also assign a 3D model to your element. And, of course, I made them. The work was carried out in the 3D Compass. The created models can be converted to a format suitable for DipTrace - STEP.

Here, what model turned out at the end, near the finished board:

Having working devices on hands, there came a phase of researches. First we checked if our prototype works. Yes, everything worked perfectly: at a speed of 921600 bps at a distance of 100 meters, data was successfully transmitted and received. For receiving and transmitting programs were used PUTTY and TeraTerm.

Now the question has arisen - is it possible to transmit information through a single cable? And if so, how?

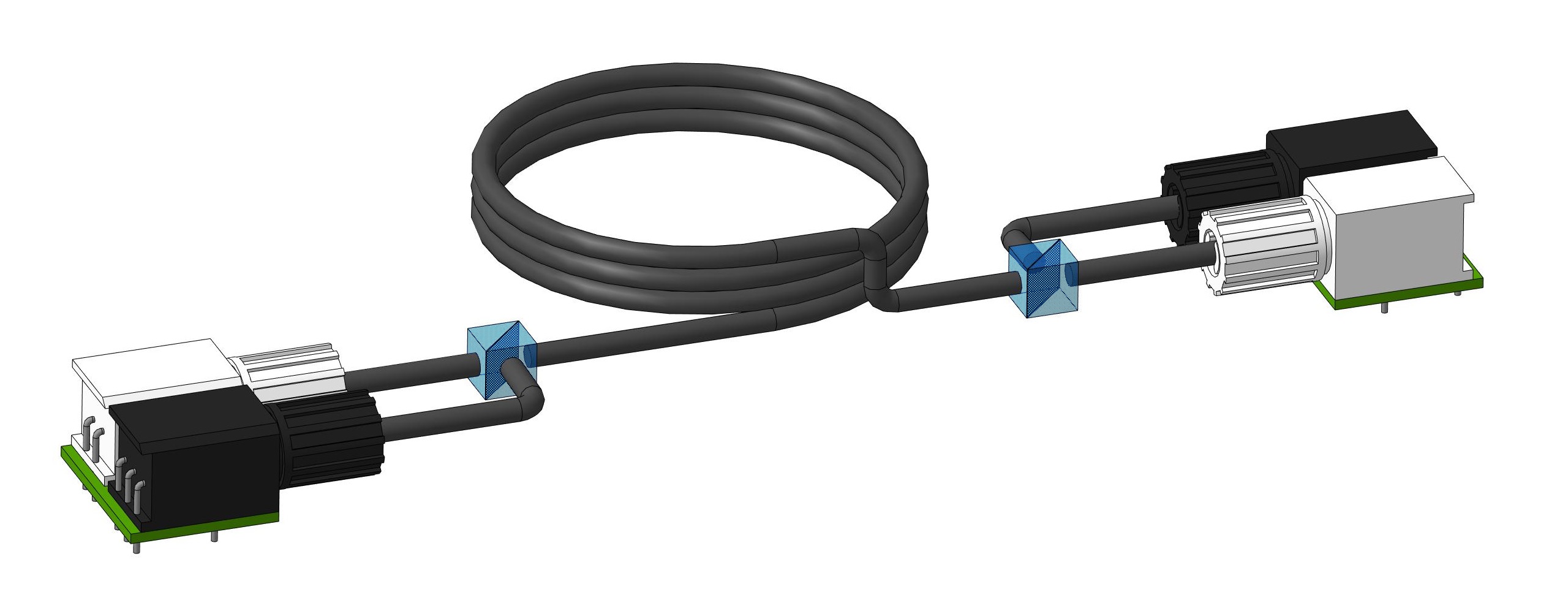

For example, you can assemble a circuit with light-dividing cubes.

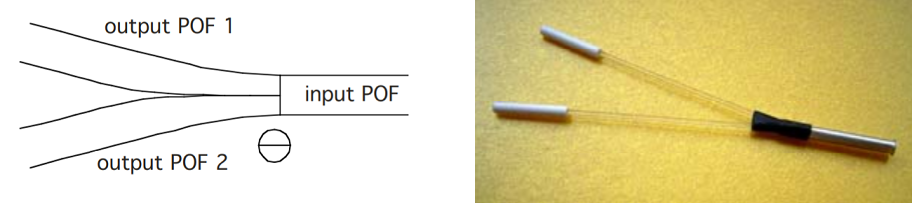

Here we are thinking about the price of the cubes, and this option immediately disappears. Well, okay, we will look for something else. And we will find! We remembered the optical splitters.

I looked on the Internet, but for some reason no one offered them for sale (or I was looking bad), although there were several articles on this topic.

Well, in any case, the idea for us is understandable, you can try yourself. We make on each cable along the bevel, approximately to the middle. Combining them, we get something like X - divider.

Notches made stationery knife, no calculation of the division of power is not worth doing, the loss at the junction is too high. But as a small experiment, it suits us, even something turned out.

You also need to remember that when adding dividers to the circuit, the power that has reached the receiver decreases: with cubes we get 25%, with dividers 50% of the initial power. This is also not very good for us.

Short conclusion

Pleasant acquaintance with DipTrace. An unexpected acquaintance POF and work with him. Getting experience (somewhere without him) and just joy for the work done. Unfortunately, the question remains about using a single cable for transmission in both directions.

A library of two AVAGO elements can be found on GitHub .

I hope that you liked the article, if there are tips, I will be glad to read them.