Diet for the server processor

There was a server on Supermicro X5DAL with 2 physical Intel Xeon 2.8 GHz processors in 604 sockets. It came to me in 2008, being a little used. Worked under 2003 Server, but here's the trouble: it buzzed strongly (like an airplane). Hummed and warmed up (about 400 watts). It is impossible to slow down the fans (2 on the processors and 2 in the power supply) - it overheated.

As time went on, productivity began to be missed. Replaced it with "self-assembly" on i7. But throwing such a piece of iron was a pity. Why not lower the CPU voltage? It is known that processor consumption is proportional to the clock frequency and the square of the supply voltage.

Regular Upit = 1.5V (it is written on the processor). It would be necessary to lower it. The BIOS does not have such an option, which means that you need to take on a soldering iron.

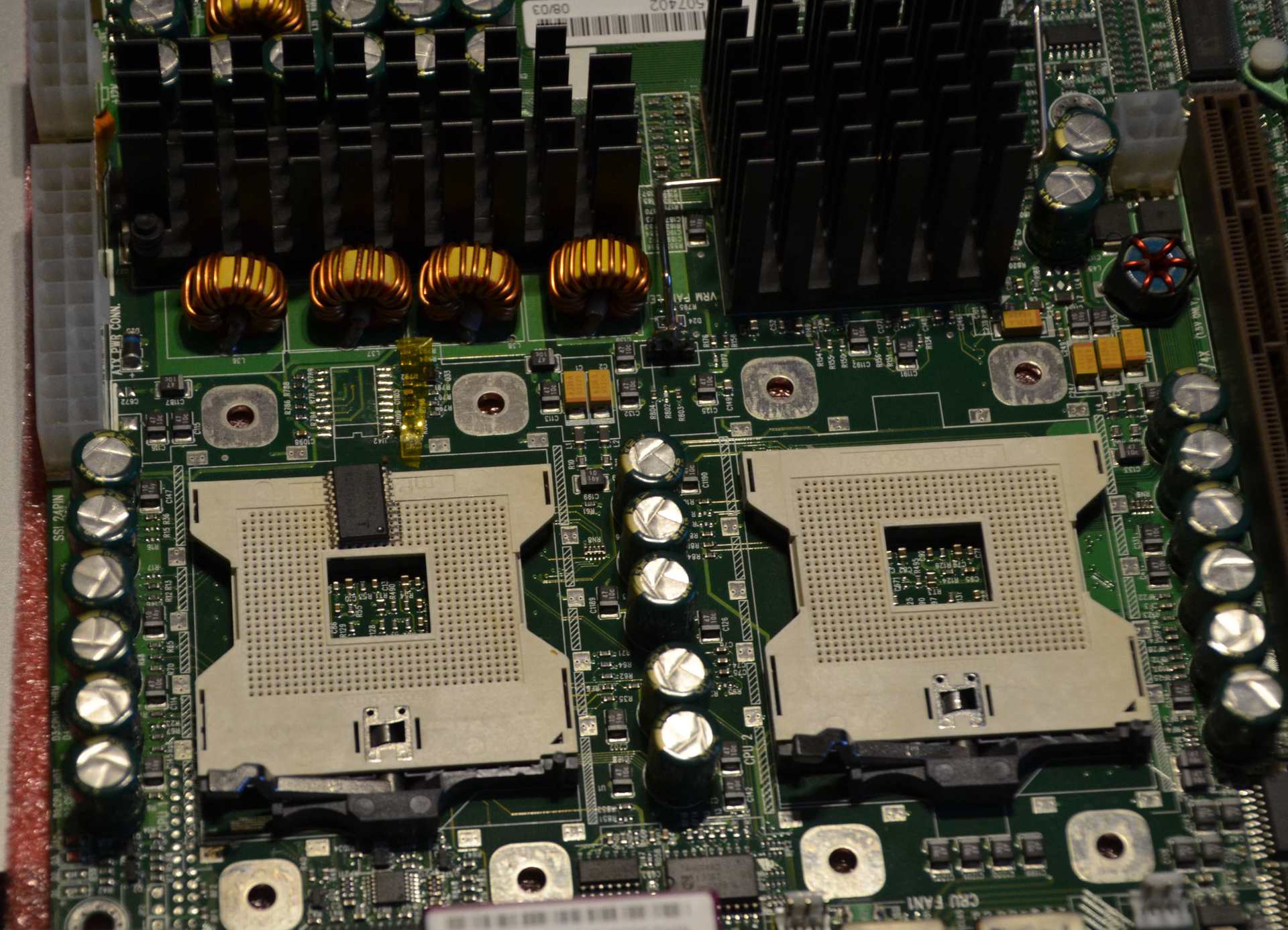

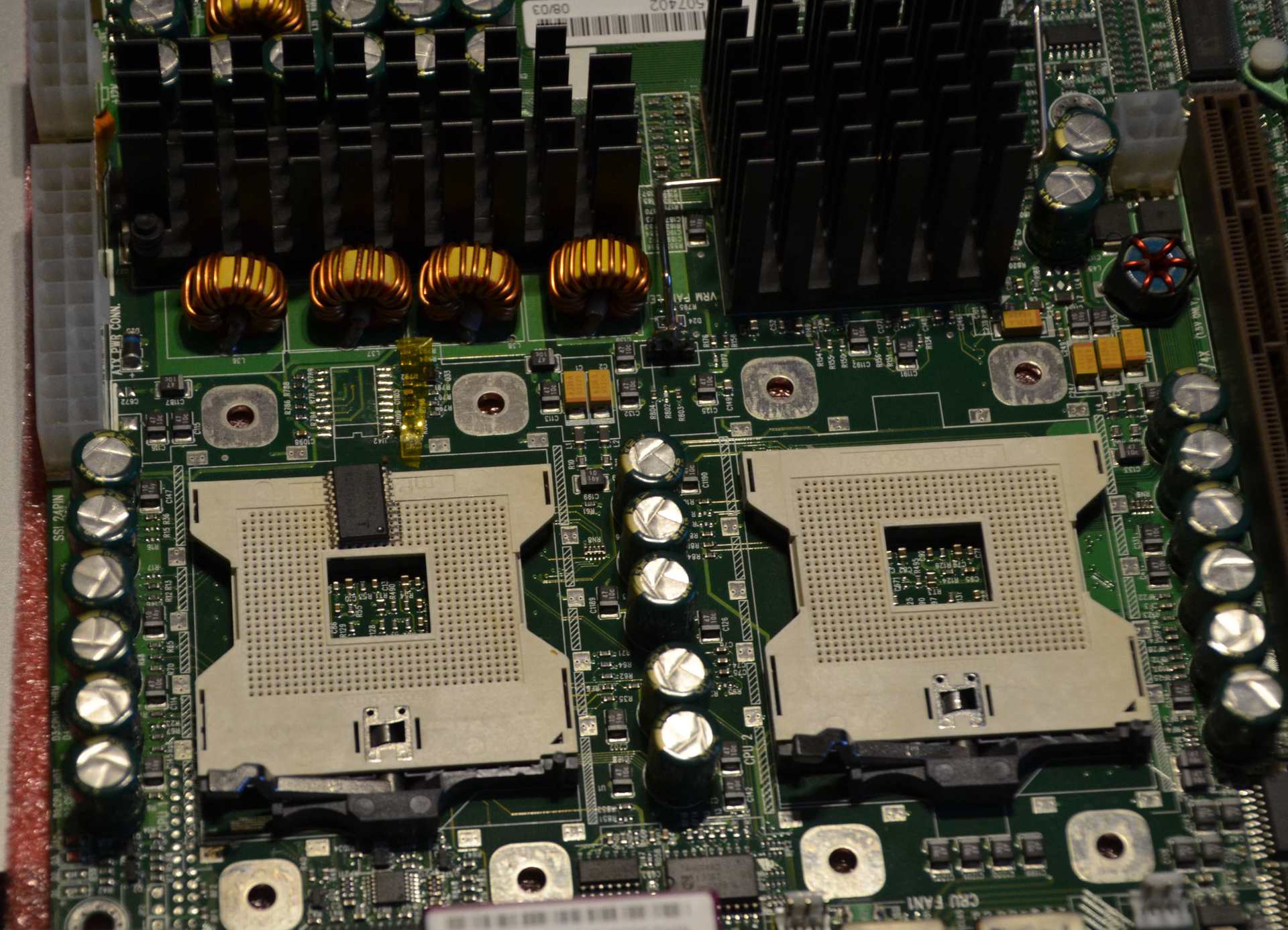

The power controller for both processors is single, 4-phase (4 chokes are visible in the photo), HIP6311. The processor has 5 special pins with the names VID0-VID5, some are shorted to ground (GND) (correspond to log.0), some are hanging in the air (correspond to log.1). This code is fed by five separate wiring from one of the processors to the HIP6311 pins of the same name, and the latter stabilizes the desired supply voltage at the output of the circuit. There is a correspondence table in the datasheet.

The table goes on and on, but this part is enough for now.

The source is quite powerful: each processor consumes about 90 W, respectively, the source provides ~ 200 W, and at 1.5 V it is a current of 133 A.

A single processor is sufficient for testing. The radiator simply lay on top of the thermal grease (the original fasteners are reliable and strong, but it is time-consuming to wear and remove it every time).

Soldering the legs of the HIP6311 chip, I closed some of them on GND, choosing a supply voltage less than the specified one, but minimizing the number of rations. Naturally, all switching and soldering were performed on a switched off system.

Soldering another leg, I hear: sparks. It turns out that the soldering iron was grounded, but the power supply was turned on through a makeshift power meter, then without a grounding contact. 110VAC from the capacitors of the power supply sparked to the soldering iron through the HIP6311 leg. Clearly, the microcircuit could not stand the electric shock. The processor before soldering removed - good.

Again, throwing a pity. Thought, thought ... Ebay! I ordered, it came, re-soldered. He bent his legs, lengthened with wires - everything became easier. You could attach a dip-switch, but it happened. As a result, the CPU earned 1.15V.

I used a 3-digit mini-voltmeter for indication. In the standard configuration, he measured 0.0-33.0V, 0.1V accuracy is not enough. He removed the lower resistor of the divider from him (by sketching the circuit and figuring out the divider coefficient) - a voltmeter of 0.00-3.30V turned out, however, the point cannot be changed without flashing. 1.15V displayed as 11.5, but it's not so scary. (It was possible, of course, to solder the tester, but then I also used a voltmeter to repair AGP video cards).

The processors started up, they worked stably and they warmed up really less. Withdrew + power supply of fans from the power supply, connected to + power supply of processor fans.

I thought of making a separate adjustable switching regulator for them on the LM2596, but it turned out to be enough just to apply + 5V to them. Control of heating during continuous operation - blowing +40 degrees. Excellent! The noise became quiet (and with a pleasant timbre, but this, of course, is not for everybody).

Disappointment 2:

1) processors do not support hardware virtualization. But I wanted to make a server for virtual machines ...

2) Windows XP Home, whose sticker was on the case, supports only 1 physical processor. Found out after activation.

The video card was supplied by the GF5500 (the stabilizer burned out in it, replaced it with the KIS-3R33S with a voltage change of up to 1.2V). Not very new toys coming.

For meaningful work, I installed CentOS 6.5.

It is clear that you should think for a while before starting such a server in production, but you don’t see any special problems at first glance (except for the need to test reliability and the very fact of interference with the soldering iron on the motherboard): most importantly, the thermal and electrical load on all components has decreased. The voltage is reduced in an almost regular way. In modern motherboards, the processor voltage can be adjusted from the BIOS, increasing for overclocking, for example, and decreasing to save energy and reduce noise.

There are not enough figures for power consumption, but I'm redoing the meter now (I connect a USB interface and analog sensors for datalogging).

www.intersil.com/content/dam/Intersil/documents/hip6/hip6311.pdf

As time went on, productivity began to be missed. Replaced it with "self-assembly" on i7. But throwing such a piece of iron was a pity. Why not lower the CPU voltage? It is known that processor consumption is proportional to the clock frequency and the square of the supply voltage.

Regular Upit = 1.5V (it is written on the processor). It would be necessary to lower it. The BIOS does not have such an option, which means that you need to take on a soldering iron.

The power controller for both processors is single, 4-phase (4 chokes are visible in the photo), HIP6311. The processor has 5 special pins with the names VID0-VID5, some are shorted to ground (GND) (correspond to log.0), some are hanging in the air (correspond to log.1). This code is fed by five separate wiring from one of the processors to the HIP6311 pins of the same name, and the latter stabilizes the desired supply voltage at the output of the circuit. There is a correspondence table in the datasheet.

The table goes on and on, but this part is enough for now.

The source is quite powerful: each processor consumes about 90 W, respectively, the source provides ~ 200 W, and at 1.5 V it is a current of 133 A.

A single processor is sufficient for testing. The radiator simply lay on top of the thermal grease (the original fasteners are reliable and strong, but it is time-consuming to wear and remove it every time).

Soldering the legs of the HIP6311 chip, I closed some of them on GND, choosing a supply voltage less than the specified one, but minimizing the number of rations. Naturally, all switching and soldering were performed on a switched off system.

Soldering another leg, I hear: sparks. It turns out that the soldering iron was grounded, but the power supply was turned on through a makeshift power meter, then without a grounding contact. 110VAC from the capacitors of the power supply sparked to the soldering iron through the HIP6311 leg. Clearly, the microcircuit could not stand the electric shock. The processor before soldering removed - good.

Again, throwing a pity. Thought, thought ... Ebay! I ordered, it came, re-soldered. He bent his legs, lengthened with wires - everything became easier. You could attach a dip-switch, but it happened. As a result, the CPU earned 1.15V.

I used a 3-digit mini-voltmeter for indication. In the standard configuration, he measured 0.0-33.0V, 0.1V accuracy is not enough. He removed the lower resistor of the divider from him (by sketching the circuit and figuring out the divider coefficient) - a voltmeter of 0.00-3.30V turned out, however, the point cannot be changed without flashing. 1.15V displayed as 11.5, but it's not so scary. (It was possible, of course, to solder the tester, but then I also used a voltmeter to repair AGP video cards).

The processors started up, they worked stably and they warmed up really less. Withdrew + power supply of fans from the power supply, connected to + power supply of processor fans.

I thought of making a separate adjustable switching regulator for them on the LM2596, but it turned out to be enough just to apply + 5V to them. Control of heating during continuous operation - blowing +40 degrees. Excellent! The noise became quiet (and with a pleasant timbre, but this, of course, is not for everybody).

Disappointment 2:

1) processors do not support hardware virtualization. But I wanted to make a server for virtual machines ...

2) Windows XP Home, whose sticker was on the case, supports only 1 physical processor. Found out after activation.

The video card was supplied by the GF5500 (the stabilizer burned out in it, replaced it with the KIS-3R33S with a voltage change of up to 1.2V). Not very new toys coming.

For meaningful work, I installed CentOS 6.5.

It is clear that you should think for a while before starting such a server in production, but you don’t see any special problems at first glance (except for the need to test reliability and the very fact of interference with the soldering iron on the motherboard): most importantly, the thermal and electrical load on all components has decreased. The voltage is reduced in an almost regular way. In modern motherboards, the processor voltage can be adjusted from the BIOS, increasing for overclocking, for example, and decreasing to save energy and reduce noise.

There are not enough figures for power consumption, but I'm redoing the meter now (I connect a USB interface and analog sensors for datalogging).

www.intersil.com/content/dam/Intersil/documents/hip6/hip6311.pdf