Automatic control of temperature, ventilation and lighting in a greenhouse in the 80s

Hi Habr!

Often I read articles about various gizmos collected by enthusiasts (and not only), which use high-tech devices based on modern microcontrollers, programmable, remote-controlled, capable of performing many different functions with the click of a button, etc. And then one day, after reading another such article, I thought - but how did people live without all this electronics before? After all, they controlled devices without it, analog circuits, relays, switches, etc. And then I remembered how my father, not being a radio electronics engineer, using only the analog devices available to him, made an almost completely autonomous climate control system in the greenhouse. Unfortunately, my father is already at an advanced age and almost lost his sight, so the article was written only with his words,

Who cares - I ask for a cat.

It was already in the distant 80s. My parents then actively engaged in the cultivation of flowers (tulips). In the days of the USSR, only the state did this. greenhouses and rare lovers. For my parents, this business was put on stream — planting bulbs in the fall in greenhouses for “distillation” on March 8, harvesting, selling, and so on every year. The volumes were about 6-7 thousand bulbs in greenhouses. And since the tulip flower is quite delicate and from the slightest temperature difference it can lose its presentation, it was necessary to monitor the growth of flowers with increased attention. The problems were thrown by the changing weather of the southern coast of Crimea, where parents live. In winter, in February, the temperature during the day can rise to +18 and the sun shines with might and main, at night it can drop to minus and “freeze” the upper layer of soil. Constant fogs from the sea on sunny days brought high humidity and condensation from which the flowers became speckled and completely lost their presentation in one day. In such conditions, maintaining a constant temperature of +18 degrees, humidity and lighting in the greenhouse became completely hellish and tedious. Parents were on duty, one could say in shifts, constantly monitoring the temperature, opening and closing the frames on the roof of the greenhouse, ventilating it, adjusting the temperature of the heating, monitoring the humidity. And since dad went to work full time, and my mother babysit me a little, there were times when everyone had the maximum strength and nerves and something had to be decided - either curl up with growing flowers, or my father quit his job either Parents were on duty, one could say in shifts, constantly monitoring the temperature, opening and closing the frames on the roof of the greenhouse, ventilating it, adjusting the temperature of the heating, monitoring the humidity. And since dad went to work full time, and my mother babysit me a little, there were times when everyone had the maximum strength and nerves and something had to be decided - either curl up with growing flowers, or my father quit his job either Parents were on duty, one could say in shifts, constantly monitoring the temperature, opening and closing the frames on the roof of the greenhouse, ventilating it, adjusting the temperature of the heating, monitoring the humidity. And since dad went to work full time, and my mother babysit me a little, there were times when everyone had the maximum strength and nerves and something had to be decided - either curl up with growing flowers, or my father quit his job eitherto put me somewhere :) automate the process. Which in the end was done. I must say that my father was not a radio electronics engineer, he worked in the organization Krylift, which was engaged in the installation and repair of elevators, and in those years the elevators worked on ordinary relays (yes, these are the same elevators that still stand in high-rise buildings and click all kinds of reels on the technical floor). No electronics there and did not smell close.

This was the easiest task that had to be solved.

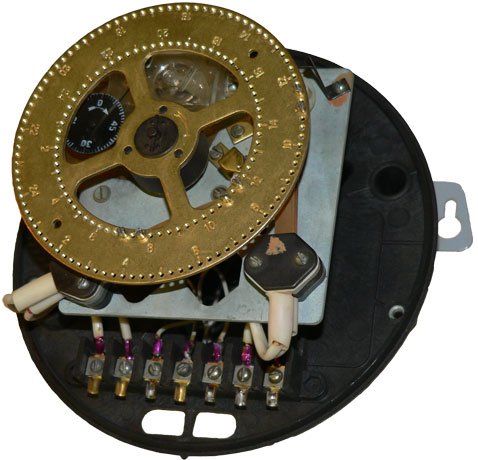

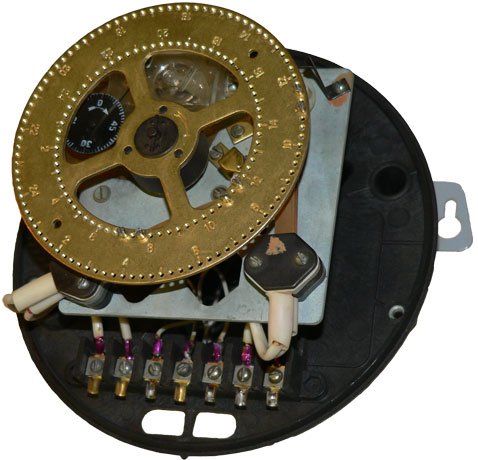

Due to the fact that the winter day is short, the flowers need extra. light so that they grow faster and are not pale. For this, several different types of lamps were used - ordinary Ilyich bulbs of 150-200 watts, infrared lamps and fluorescent lamps. All this was hung at a certain height, turned on early in the morning and turned off in the evening. Turning on and off was monitored by a timer of the PBM2 type.

More details can be read here.

Simple as doors, but at the same time it allowed to “program” the on and off times of two (and in some versions more) contacts. It works like this: on the disk there are 2 tracks from the holes into which the pins are screwed. Each hole corresponds to a time stamp at intervals, for example, every 15 minutes. The disk rotates slowly by an electric motor. At a certain point, the pin reaches the contact and starts to turn it, turning it 90 degrees, the contact either closes or opens. Having twisted the pins into the desired holes, we get a timer for ourselves that can cope with the task. And since there are 2 contacts, the IR lamps turn on and off several times a day, when the general lighting is on for about 12 hours a day.

Draining the greenhouse and removing condensation from all internal surfaces during high humidity from the outside seemed to be not an easy task at first. Despite the fact that the soil should be sufficiently moistened, moisture evaporates from its surface and from the flowers very intensively while also condensing intensively on the film with which the greenhouse is covered. The solution turned out to be quite simple and effective - what is now called heat guns (large hairdryer). A fan was inserted into the large-diameter pipe, which drove air through heated spirals. The air was dry and less condensate was deposited. But the problem was different - such guns had to be turned on somehow, depending on humidity and temperature, since they not only dried the air, but also heated it. Another analog device came to the rescue - an air humidity sensor (photo unfortunately could not be found). This sensor was a box through which the air flow passed and, depending on its humidity, miraculously closed the contacts. This sensor could be adjusted to the required humidity and at the same time it worked with an allowable error. The sensor closed the magnetic starter, which in turn already included guns. For greater accuracy, the sensor was placed in the range of one of the guns in such a way that dry air blew onto it, and the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit! This sensor was a box through which the air flow passed and, depending on its humidity, miraculously closed the contacts. This sensor could be adjusted to the required humidity and at the same time it worked with an allowable error. The sensor closed the magnetic starter, which in turn already included guns. For greater accuracy, the sensor was placed in the range of one of the guns in such a way that dry air blew onto it, and the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit! This sensor was a box through which the air flow passed and, depending on its humidity, miraculously closed the contacts. This sensor could be adjusted to the required humidity and at the same time it worked with an allowable error. The sensor closed the magnetic starter, which in turn already included guns. For greater accuracy, the sensor was placed in the range of one of the guns in such a way that dry air blew onto it, and the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit! This sensor could be adjusted to the required humidity and at the same time it worked with an allowable error. The sensor closed the magnetic starter, which in turn already included guns. For greater accuracy, the sensor was placed in the range of one of the guns in such a way that dry air blew onto it, and the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit! This sensor could be adjusted to the required humidity and at the same time it worked with an allowable error. The sensor closed the magnetic starter, which in turn already included guns. For greater accuracy, the sensor was placed in the range of one of the guns in such a way that dry air blew onto it, and the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit! the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit! the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit!

It turned out to be more difficult to ensure a stable temperature inside. And there were 2 ways of development: simple - to make electric heating (air heaters) and a temperature sensor. And the way that my dad went is to modernize water heating by controlling a liquid fuel boiler, depending on temperature. Soviet people are not looking for easy ways :)

But the first option had only one plus - ease of installation and configuration, there were more minuses - it dries the air, is not safe (tena needed to be hung all over the greenhouse), expensive (finding and buying was not so easy in a small town). Water heating has already been done, plus it was also laid under the beds to warm the ground to achieve faster shoots of bulbs, and burying heaters under the ground was an ungrateful thing, plus the load on the meter would lead to its obvious loss. Solved - upgrade the old system! To do this, you need: to have a temperature sensor inside the greenhouse, somehow regulate the fuel supply to the burner, and provide an emergency shutdown. Now all this would be decided by ordering the necessary parts on the Internet or going to the nearest radio goods store with subsequent installation and refinement, a week maximum. Then it took about 2 years ... To adjust the supply of diesel fuel (yes, she was drowned then at 70 rubles per 1000 liters :)) a lot of things were tried, but the most optimal at that time was a system of 4 electro valves that were connected in parallel and opened opened depending on the air temperature thereby increasing the fuel supply to the burner. Four of these thermometers served as sensors:

each connected to its valve. More details here . This thermometer was really cool, at least then it seemed to me like that. Probably because it contained wiring, silver mercury (a lot), contacts, 2 scales, etc. The principle of its operation is this: a wiring was soldered near the mercury bubble, which applied voltage to the mercury itself. On the other side of the tube where this mercury moved, a thin wiring was placed, which set the temperature. It was possible to move it with the help of a twist in the upper part of the thermometer, which rotated the rod with a thread and a nut to which this wiring was attached. Probably very confusedly written, but there are more details on the link, I hope its principle will be clear.

In general, when the mercury rose to the desired temperature, it closed the conductors through itself (touching the wiring in the tube) and so the low-power relay worked, which in turn closed the valve and "reduced the heat." As soon as the temperature dropped, the circuit opened, the valve opened and more fuel flowed into the boiler. The temperature rose. You ask - why four such systems - for smooth adjustment. Thermometers were set at intervals of 2 degrees. Those. a temperature range of almost 10 degrees was provided, which was quite enough to smooth out daily temperature jumps. At night, all the valves were usually open depending on the temperature and the boiler burned at full power. Such a seemingly simple system, I threw up one problem - due to the inertness of the coolant and its slow circulation inside the heating circuit, the air overheated, which once almost led to the spoilage of the whole “crop”. The circulation pump did not make the situation much better. 500+ liters of water in the system will not cool quickly. And with the sudden illumination of the greenhouse with the sun, the temperature inside could rise in a matter of minutes above normal. And after much torment, it was decided to make a ventilation system. But she was not at all trivial. And after much torment, it was decided to make a ventilation system. But she was not at all trivial. And after much torment, it was decided to make a ventilation system. But she was not at all trivial.

The simplest thing is to embed the fan into the wall of the greenhouse. But such a father did not do even before the automation of the process. The reason is simple - when it is not used, the hole must be closed so that warm air does not come out. Also, the fan is not very useful for blowing. Hm. Well, what else should he do? And therein it is a minus - it catches up the condensate on the flowers and they, you understand, are not in a salable condition and there is a cover for everything. To prevent this from happening in the greenhouses, the opening upper frames were made, roughly speaking - the roof was rising! It was the craziest thing to do! But it was so effective that it raised the quality of the crop to almost 100%!

The system was made on the basis of a drive for opening elevator doors. I didn’t find the photo, but the principle is that the block consisted of the engine itself, the gearbox and the linkage. He worked on the principle of windshield wipers in a car - the motor rotates and through the gearbox turns the lever in one direction or another. Further, the whole system was adapted inside the greenhouse under the movable roof frame. The frame itself was fixed with one edge in the center of the roof (on the ridge) and the other edge freely lay on the wall of the greenhouse. He was lifted from below by a lever. There was enough power to lift the frame to a height of 40 cm. But by the method of scientific poking, the rise was set to 10 cm. With this rise, good ventilation was provided, not a sharp drop in temperature and a smooth flow of fresh air over a large area. It all worked quite simply - another control thermometer, which was set to 20 degrees (critical temperature). When the circuit was closed, the frame rose and the air cooled, the thermometer opened the circuit and the frame fell. The whole cycle of opening / closing the frame took no more than 10 minutes, then the air slowly warmed up again and if a critical temperature came, ventilation worked.

After airing, guns were usually triggered to dry fresh air, which was sometimes more humid.

At first glance, the system may seem unnecessarily complicated for such a seemingly trivial task, but it really has proven itself well. For all the artisanal assembly of critical damage did not happen. The maximum was poorly connected contacts that did not lead to anything serious. During the operation of the system, the yield was at the highest level with minimal interventions in the process.

All this business existed until the beginning of the 90s and became unprofitable when they began to carry flowers from Holland. It became difficult to compete with outbid on the spot, if before the father loaded boxes with flowers, loaded onto a plane and flew the day to sell flowers somewhere there beyond the horizon of our vast country then, then after the collapse of the union this was no longer possible. And the age of the parents was not the same.

But the design just did not go down in history. According to his father, an amateur gardener came to him from somewhere in the center of Ukraine, where he was also engaged (and probably is now engaged in) growing flowers and wrote down, sketched, memorized how everything works. After that he did something similar at home. And according to his modernized system, there was an article in some magazine, either "Gardener", or "Home Garden Floriculture" or something like that. If someone knows something about what kind of magazine it was, I will be grateful to you.

Thanks for attention!

Often I read articles about various gizmos collected by enthusiasts (and not only), which use high-tech devices based on modern microcontrollers, programmable, remote-controlled, capable of performing many different functions with the click of a button, etc. And then one day, after reading another such article, I thought - but how did people live without all this electronics before? After all, they controlled devices without it, analog circuits, relays, switches, etc. And then I remembered how my father, not being a radio electronics engineer, using only the analog devices available to him, made an almost completely autonomous climate control system in the greenhouse. Unfortunately, my father is already at an advanced age and almost lost his sight, so the article was written only with his words,

Who cares - I ask for a cat.

A bit of history

It was already in the distant 80s. My parents then actively engaged in the cultivation of flowers (tulips). In the days of the USSR, only the state did this. greenhouses and rare lovers. For my parents, this business was put on stream — planting bulbs in the fall in greenhouses for “distillation” on March 8, harvesting, selling, and so on every year. The volumes were about 6-7 thousand bulbs in greenhouses. And since the tulip flower is quite delicate and from the slightest temperature difference it can lose its presentation, it was necessary to monitor the growth of flowers with increased attention. The problems were thrown by the changing weather of the southern coast of Crimea, where parents live. In winter, in February, the temperature during the day can rise to +18 and the sun shines with might and main, at night it can drop to minus and “freeze” the upper layer of soil. Constant fogs from the sea on sunny days brought high humidity and condensation from which the flowers became speckled and completely lost their presentation in one day. In such conditions, maintaining a constant temperature of +18 degrees, humidity and lighting in the greenhouse became completely hellish and tedious. Parents were on duty, one could say in shifts, constantly monitoring the temperature, opening and closing the frames on the roof of the greenhouse, ventilating it, adjusting the temperature of the heating, monitoring the humidity. And since dad went to work full time, and my mother babysit me a little, there were times when everyone had the maximum strength and nerves and something had to be decided - either curl up with growing flowers, or my father quit his job either Parents were on duty, one could say in shifts, constantly monitoring the temperature, opening and closing the frames on the roof of the greenhouse, ventilating it, adjusting the temperature of the heating, monitoring the humidity. And since dad went to work full time, and my mother babysit me a little, there were times when everyone had the maximum strength and nerves and something had to be decided - either curl up with growing flowers, or my father quit his job either Parents were on duty, one could say in shifts, constantly monitoring the temperature, opening and closing the frames on the roof of the greenhouse, ventilating it, adjusting the temperature of the heating, monitoring the humidity. And since dad went to work full time, and my mother babysit me a little, there were times when everyone had the maximum strength and nerves and something had to be decided - either curl up with growing flowers, or my father quit his job either

Additional lighting

This was the easiest task that had to be solved.

Due to the fact that the winter day is short, the flowers need extra. light so that they grow faster and are not pale. For this, several different types of lamps were used - ordinary Ilyich bulbs of 150-200 watts, infrared lamps and fluorescent lamps. All this was hung at a certain height, turned on early in the morning and turned off in the evening. Turning on and off was monitored by a timer of the PBM2 type.

More details can be read here.

Simple as doors, but at the same time it allowed to “program” the on and off times of two (and in some versions more) contacts. It works like this: on the disk there are 2 tracks from the holes into which the pins are screwed. Each hole corresponds to a time stamp at intervals, for example, every 15 minutes. The disk rotates slowly by an electric motor. At a certain point, the pin reaches the contact and starts to turn it, turning it 90 degrees, the contact either closes or opens. Having twisted the pins into the desired holes, we get a timer for ourselves that can cope with the task. And since there are 2 contacts, the IR lamps turn on and off several times a day, when the general lighting is on for about 12 hours a day.

Humidity

Draining the greenhouse and removing condensation from all internal surfaces during high humidity from the outside seemed to be not an easy task at first. Despite the fact that the soil should be sufficiently moistened, moisture evaporates from its surface and from the flowers very intensively while also condensing intensively on the film with which the greenhouse is covered. The solution turned out to be quite simple and effective - what is now called heat guns (large hairdryer). A fan was inserted into the large-diameter pipe, which drove air through heated spirals. The air was dry and less condensate was deposited. But the problem was different - such guns had to be turned on somehow, depending on humidity and temperature, since they not only dried the air, but also heated it. Another analog device came to the rescue - an air humidity sensor (photo unfortunately could not be found). This sensor was a box through which the air flow passed and, depending on its humidity, miraculously closed the contacts. This sensor could be adjusted to the required humidity and at the same time it worked with an allowable error. The sensor closed the magnetic starter, which in turn already included guns. For greater accuracy, the sensor was placed in the range of one of the guns in such a way that dry air blew onto it, and the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit! This sensor was a box through which the air flow passed and, depending on its humidity, miraculously closed the contacts. This sensor could be adjusted to the required humidity and at the same time it worked with an allowable error. The sensor closed the magnetic starter, which in turn already included guns. For greater accuracy, the sensor was placed in the range of one of the guns in such a way that dry air blew onto it, and the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit! This sensor was a box through which the air flow passed and, depending on its humidity, miraculously closed the contacts. This sensor could be adjusted to the required humidity and at the same time it worked with an allowable error. The sensor closed the magnetic starter, which in turn already included guns. For greater accuracy, the sensor was placed in the range of one of the guns in such a way that dry air blew onto it, and the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit! This sensor could be adjusted to the required humidity and at the same time it worked with an allowable error. The sensor closed the magnetic starter, which in turn already included guns. For greater accuracy, the sensor was placed in the range of one of the guns in such a way that dry air blew onto it, and the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit! This sensor could be adjusted to the required humidity and at the same time it worked with an allowable error. The sensor closed the magnetic starter, which in turn already included guns. For greater accuracy, the sensor was placed in the range of one of the guns in such a way that dry air blew onto it, and the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit! the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit! the system often turned on for short periods of time without overheating the air. Due to the high inertness of the room, the humidity was kept fairly even. Condensate did not accumulate in large volumes and no precipitation fell in the greenhouse :) Profit!

Heating

It turned out to be more difficult to ensure a stable temperature inside. And there were 2 ways of development: simple - to make electric heating (air heaters) and a temperature sensor. And the way that my dad went is to modernize water heating by controlling a liquid fuel boiler, depending on temperature. Soviet people are not looking for easy ways :)

But the first option had only one plus - ease of installation and configuration, there were more minuses - it dries the air, is not safe (tena needed to be hung all over the greenhouse), expensive (finding and buying was not so easy in a small town). Water heating has already been done, plus it was also laid under the beds to warm the ground to achieve faster shoots of bulbs, and burying heaters under the ground was an ungrateful thing, plus the load on the meter would lead to its obvious loss. Solved - upgrade the old system! To do this, you need: to have a temperature sensor inside the greenhouse, somehow regulate the fuel supply to the burner, and provide an emergency shutdown. Now all this would be decided by ordering the necessary parts on the Internet or going to the nearest radio goods store with subsequent installation and refinement, a week maximum. Then it took about 2 years ... To adjust the supply of diesel fuel (yes, she was drowned then at 70 rubles per 1000 liters :)) a lot of things were tried, but the most optimal at that time was a system of 4 electro valves that were connected in parallel and opened opened depending on the air temperature thereby increasing the fuel supply to the burner. Four of these thermometers served as sensors:

each connected to its valve. More details here . This thermometer was really cool, at least then it seemed to me like that. Probably because it contained wiring, silver mercury (a lot), contacts, 2 scales, etc. The principle of its operation is this: a wiring was soldered near the mercury bubble, which applied voltage to the mercury itself. On the other side of the tube where this mercury moved, a thin wiring was placed, which set the temperature. It was possible to move it with the help of a twist in the upper part of the thermometer, which rotated the rod with a thread and a nut to which this wiring was attached. Probably very confusedly written, but there are more details on the link, I hope its principle will be clear.

In general, when the mercury rose to the desired temperature, it closed the conductors through itself (touching the wiring in the tube) and so the low-power relay worked, which in turn closed the valve and "reduced the heat." As soon as the temperature dropped, the circuit opened, the valve opened and more fuel flowed into the boiler. The temperature rose. You ask - why four such systems - for smooth adjustment. Thermometers were set at intervals of 2 degrees. Those. a temperature range of almost 10 degrees was provided, which was quite enough to smooth out daily temperature jumps. At night, all the valves were usually open depending on the temperature and the boiler burned at full power. Such a seemingly simple system, I threw up one problem - due to the inertness of the coolant and its slow circulation inside the heating circuit, the air overheated, which once almost led to the spoilage of the whole “crop”. The circulation pump did not make the situation much better. 500+ liters of water in the system will not cool quickly. And with the sudden illumination of the greenhouse with the sun, the temperature inside could rise in a matter of minutes above normal. And after much torment, it was decided to make a ventilation system. But she was not at all trivial. And after much torment, it was decided to make a ventilation system. But she was not at all trivial. And after much torment, it was decided to make a ventilation system. But she was not at all trivial.

Ventilation system

The simplest thing is to embed the fan into the wall of the greenhouse. But such a father did not do even before the automation of the process. The reason is simple - when it is not used, the hole must be closed so that warm air does not come out. Also, the fan is not very useful for blowing. Hm. Well, what else should he do? And therein it is a minus - it catches up the condensate on the flowers and they, you understand, are not in a salable condition and there is a cover for everything. To prevent this from happening in the greenhouses, the opening upper frames were made, roughly speaking - the roof was rising! It was the craziest thing to do! But it was so effective that it raised the quality of the crop to almost 100%!

The system was made on the basis of a drive for opening elevator doors. I didn’t find the photo, but the principle is that the block consisted of the engine itself, the gearbox and the linkage. He worked on the principle of windshield wipers in a car - the motor rotates and through the gearbox turns the lever in one direction or another. Further, the whole system was adapted inside the greenhouse under the movable roof frame. The frame itself was fixed with one edge in the center of the roof (on the ridge) and the other edge freely lay on the wall of the greenhouse. He was lifted from below by a lever. There was enough power to lift the frame to a height of 40 cm. But by the method of scientific poking, the rise was set to 10 cm. With this rise, good ventilation was provided, not a sharp drop in temperature and a smooth flow of fresh air over a large area. It all worked quite simply - another control thermometer, which was set to 20 degrees (critical temperature). When the circuit was closed, the frame rose and the air cooled, the thermometer opened the circuit and the frame fell. The whole cycle of opening / closing the frame took no more than 10 minutes, then the air slowly warmed up again and if a critical temperature came, ventilation worked.

After airing, guns were usually triggered to dry fresh air, which was sometimes more humid.

At first glance, the system may seem unnecessarily complicated for such a seemingly trivial task, but it really has proven itself well. For all the artisanal assembly of critical damage did not happen. The maximum was poorly connected contacts that did not lead to anything serious. During the operation of the system, the yield was at the highest level with minimal interventions in the process.

All this business existed until the beginning of the 90s and became unprofitable when they began to carry flowers from Holland. It became difficult to compete with outbid on the spot, if before the father loaded boxes with flowers, loaded onto a plane and flew the day to sell flowers somewhere there beyond the horizon of our vast country then, then after the collapse of the union this was no longer possible. And the age of the parents was not the same.

But the design just did not go down in history. According to his father, an amateur gardener came to him from somewhere in the center of Ukraine, where he was also engaged (and probably is now engaged in) growing flowers and wrote down, sketched, memorized how everything works. After that he did something similar at home. And according to his modernized system, there was an article in some magazine, either "Gardener", or "Home Garden Floriculture" or something like that. If someone knows something about what kind of magazine it was, I will be grateful to you.

Thanks for attention!