How to collect cars for passenger trains

There is such a Tver Carriage Works. Tomorrow is his birthday. So here I will tell something interesting about the plant itself.

This is the plant whose passengers passengers take for German. This is the plant where sheet metal comes in at the entrance, and the output is a car with all subsystems, including a control panel with firmware. It employs about 8 thousand people, it is the largest enterprise in the Tver region, and seagulls live here, because they are warm in some buildings.

If you think that a car is a very simple thing, then I recommend returning to the post about passenger car subsystems . Everything is there - from the local network to the electric doors. And all this must be collected.

Let's start the tour.

The plant occupies 93 hectares. These are the two Vaticans.

The first thing that you can see is how the cars from one workshop are sent to another by rail:

Or not. The first is that the railway enters the factory. In production workshops, metal is unloaded from cargo platforms and sent for further processing:

This is how it looks (this is a photo and above with a panorama of the S. Bogdanov plant, an employee of TVZ):

Full cycle - steel sheets come in, carriages come out:

The plant uses a lean production system so everything is organized so that the necessary details are always at hand. A special marking was made on the floor in the production workshops: marked pedestrian areas, storage areas for finished parts, equipment locations, etc.

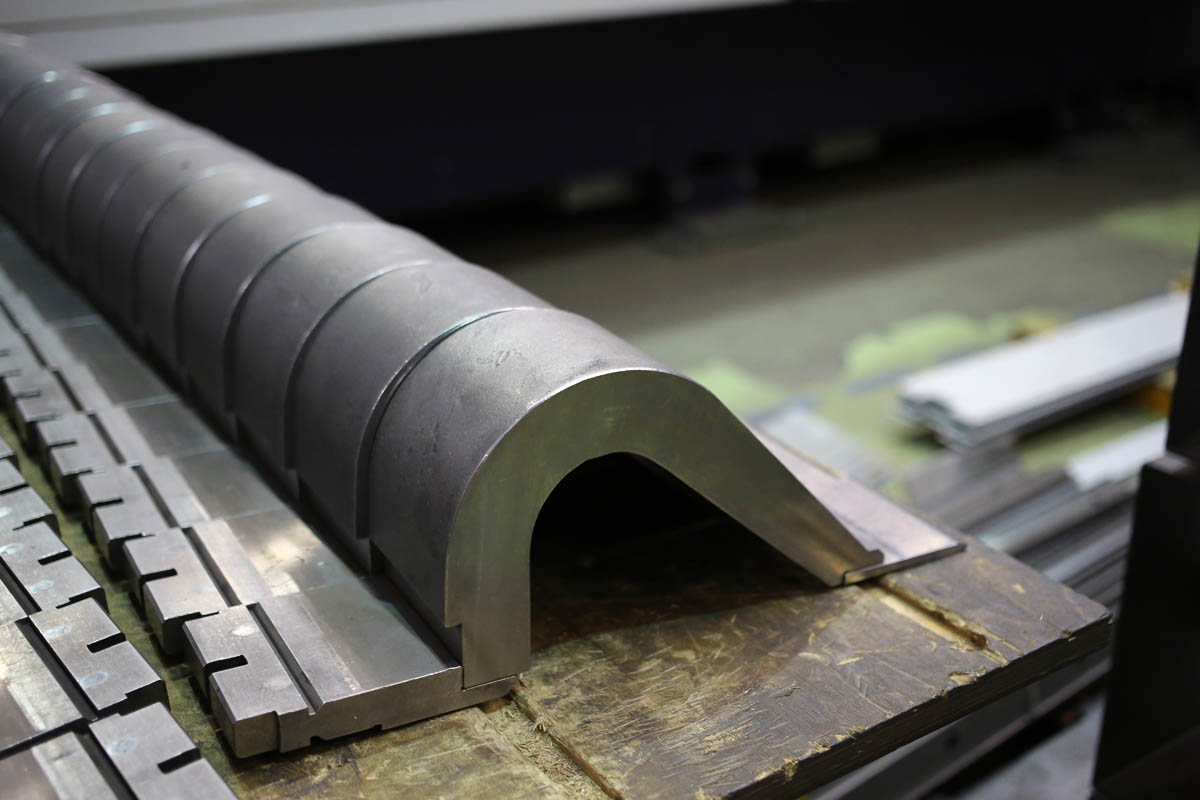

Here is a horizontal stretching machine, where the frame for the car's roof is made:

And facing the arches of the car's roof:

There is such a thing:

To make something more complicated from metal, at the initial stage of blank production, you first need to cut this very metal and bend it well:

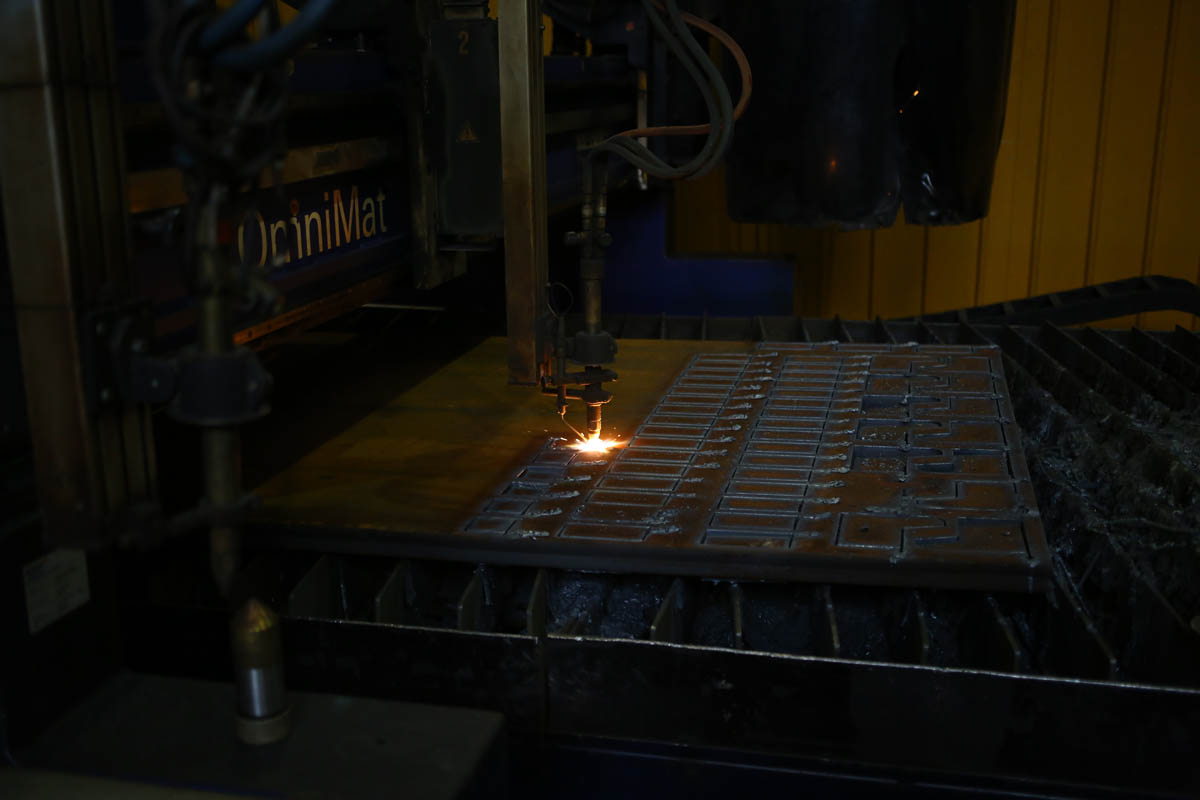

Thick the workpiece is cut in a plasma cutting machine:

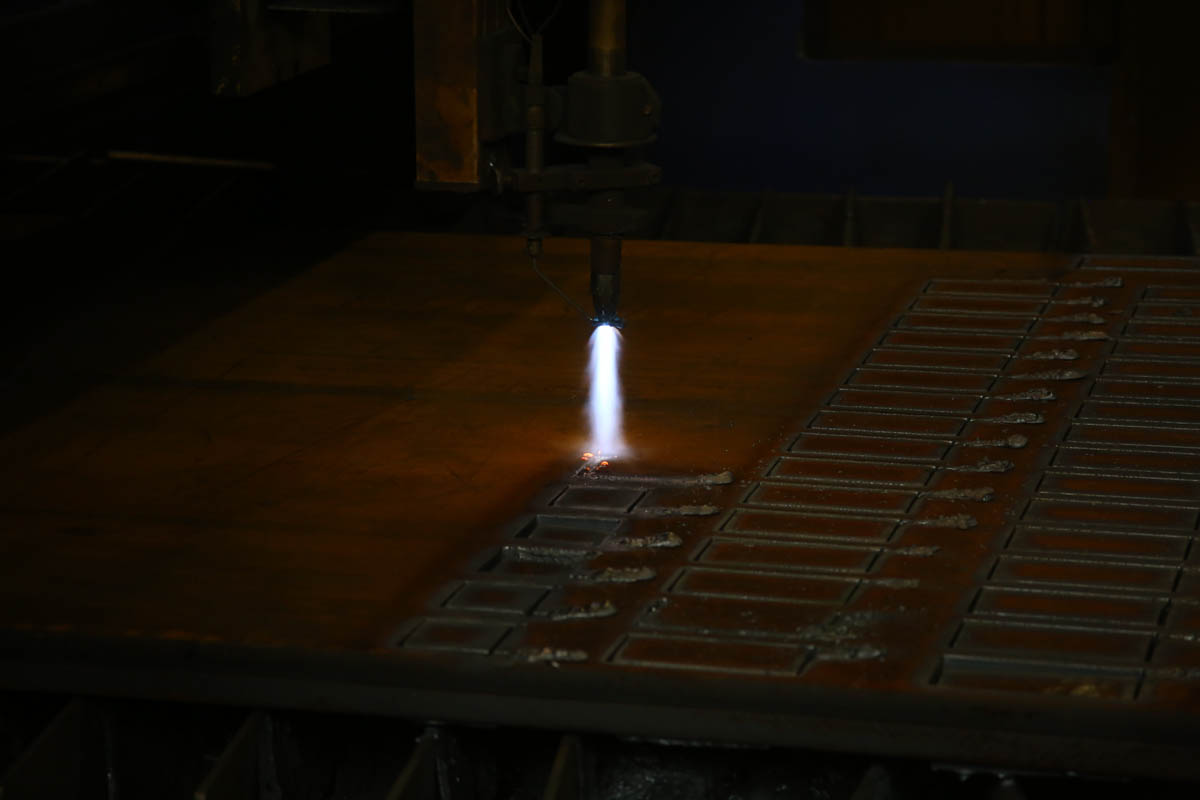

Thinner workpieces are cut with a laser:

Some need to be put in a press. Here they repair its equipment:

Here you can make a film about Fallout:

Here are the elements of the future car:

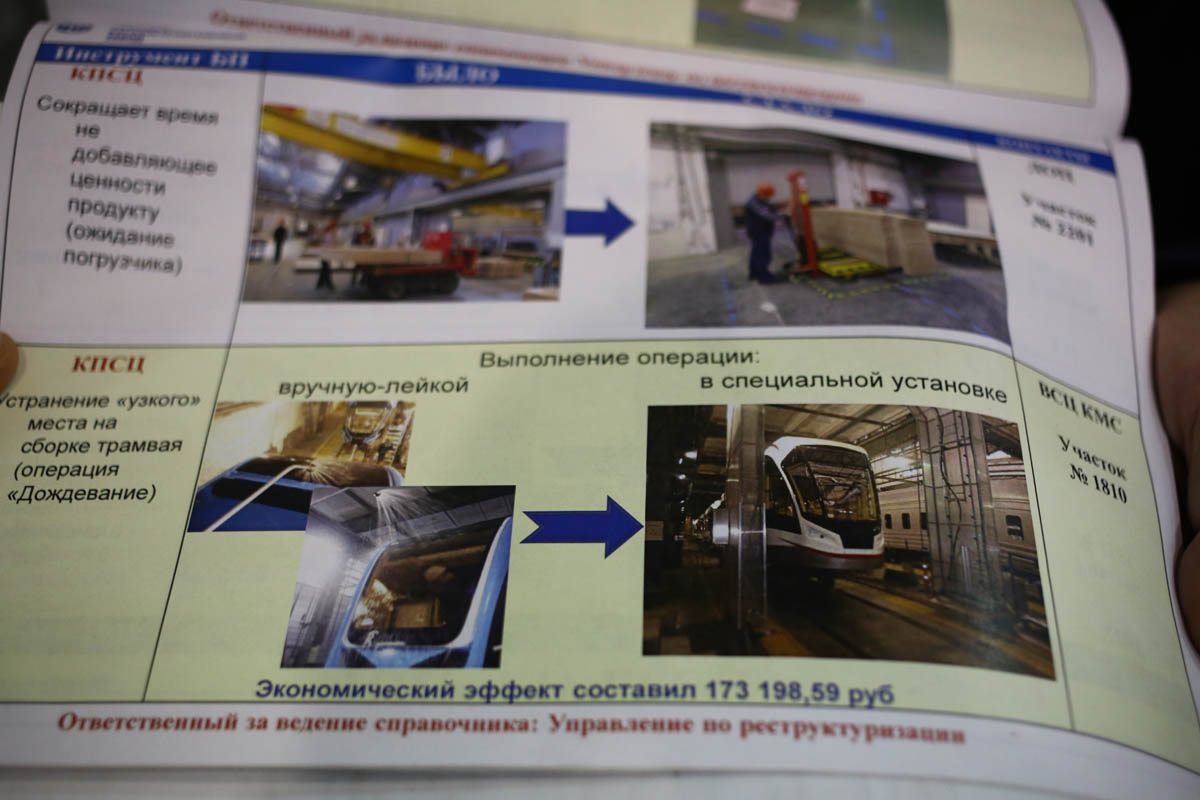

Workers receive rewards for improvements. Everywhere there are stands with information and examples:

Quote from the press release:

“In the first quarter of 2018, the inventors and rationalizers of the Tver Carriage Works saved the company almost 1.5 million rubles. From January to March, 105 proposals were submitted to the competition, 43 of them have already been introduced into production. Most of the rationalization ideas are aimed at saving material and labor resources, at improving working conditions, product quality and work performed. ”

There is a chat between shifts:

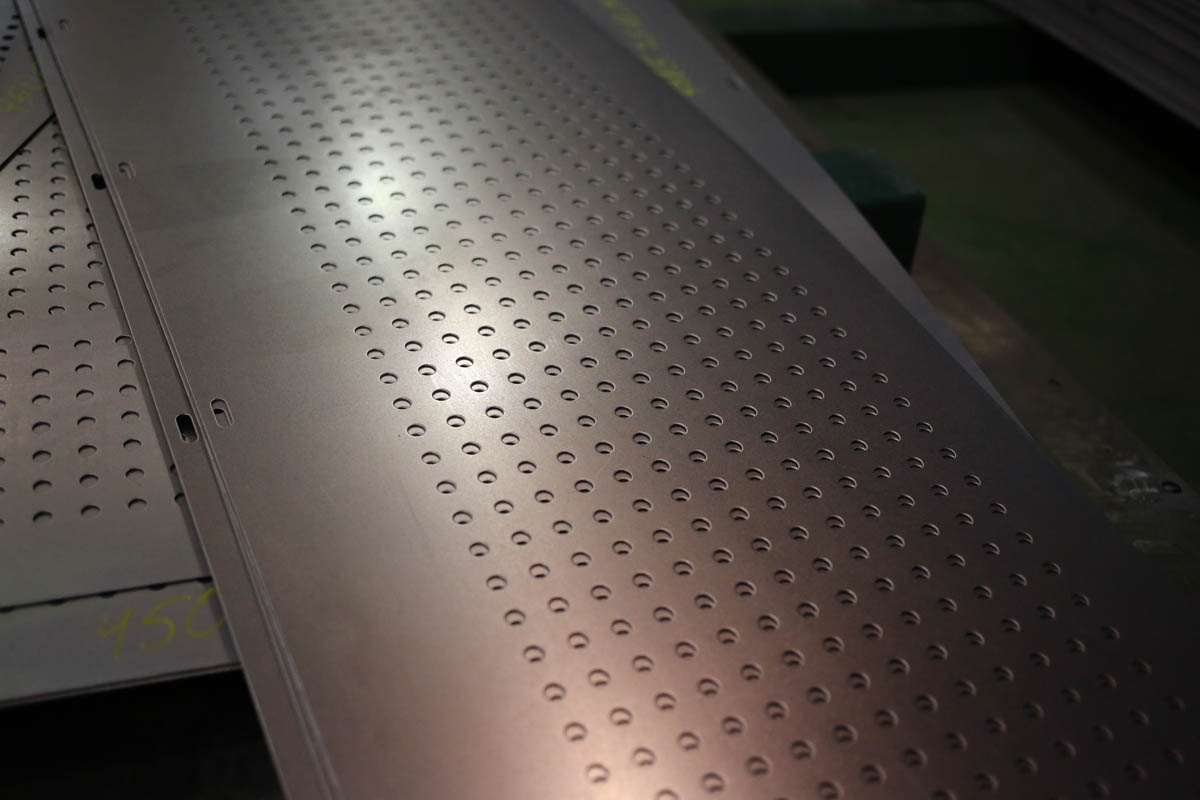

Next in the shop there is a place where special equipment (coordinate punching press) makes perforated sheets (this will be the ventilation of the car):

And right next to the installation, which in a minute can make all these holes in one piece with insane speed , one of the oldest factory machines:

Gravity then move the crane to the ceiling system:

In this workshop valves are controlled from the floor but with these remotes:

Near uhaet news and get new parts for the car of the future:

More of the things cast - has its own e foundry where iron comes, and then from it formed the necessary details. But in fact, there are still not very many cast parts in the car (photo by S. Bogdanov):

Go ahead. Now - the assembly of this designer and welding!

We take a gofrolist from the first workshop, attach large parts to it, and the frame begins to emerge:

Something is welded by hand:

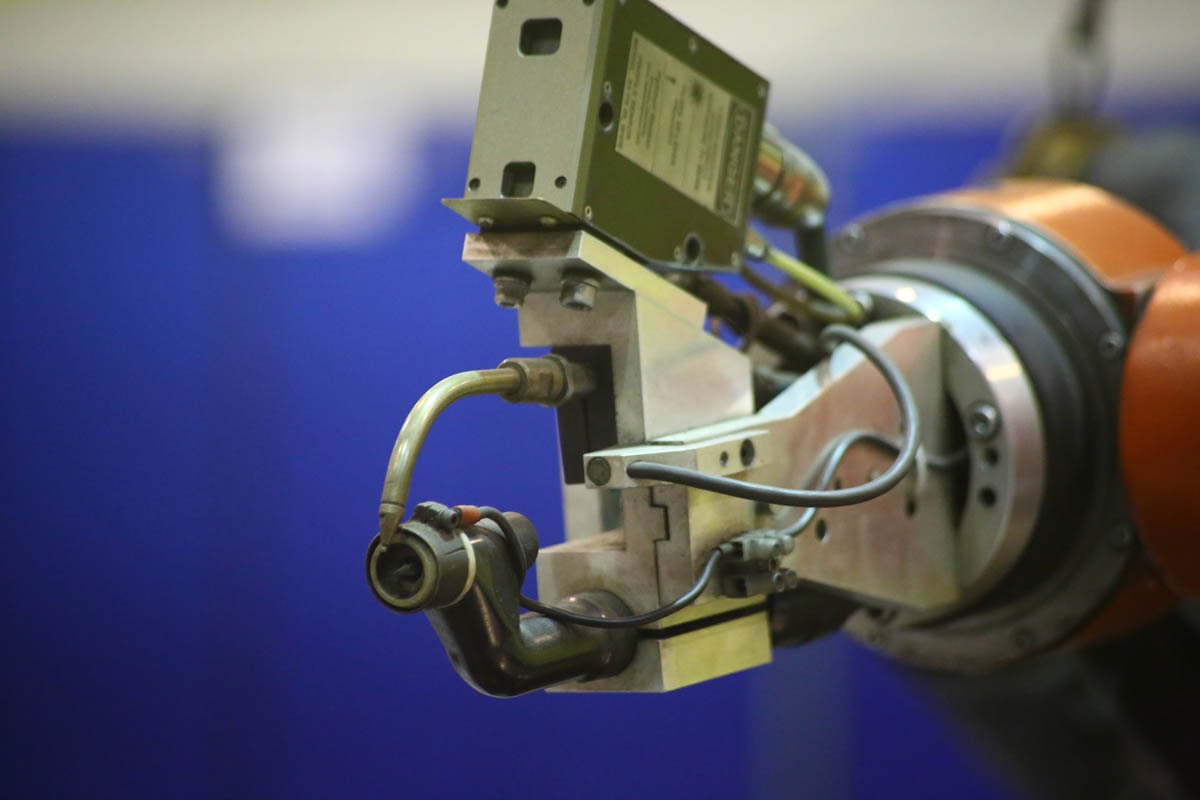

Something - with a robot:

With such a hand:

And now you can see how the car body starts to turn out:

More and more:

By the way The first series of Portal type machines was born here. Now they are applied all over the world.

The parts at different production sites are joined to it again and again. They come immediately in sets on the car:

Different cars have different roofs. But whenever possible, designers try to use elements from other cars in new ones: this is convenient for the unification of production.

Here's the big detail -heating boiler :

It is, of course, worth moving the crane:

Now you need to level the plane:

Here are the tracks, where you have to go again, the marks are applied with a marker directly on the car:

The car is put on temporary - technological - carts:

Then it is painted in a powder coating chamber. It becomes like this:

Sheathe isolation:

Add a sheathing body:

By the way, and the insulation, and the tree is disgustingly burning. Mineral insulation material, wood treated by impregnation. Modern cars burn badly, but we will get to the fire tests.

With the head cars of electric trains the assembly process becomes more complicated:

Then you need to lay the floor covering:

Mount partitions (we are now going to great jumps, a lot of small operations):

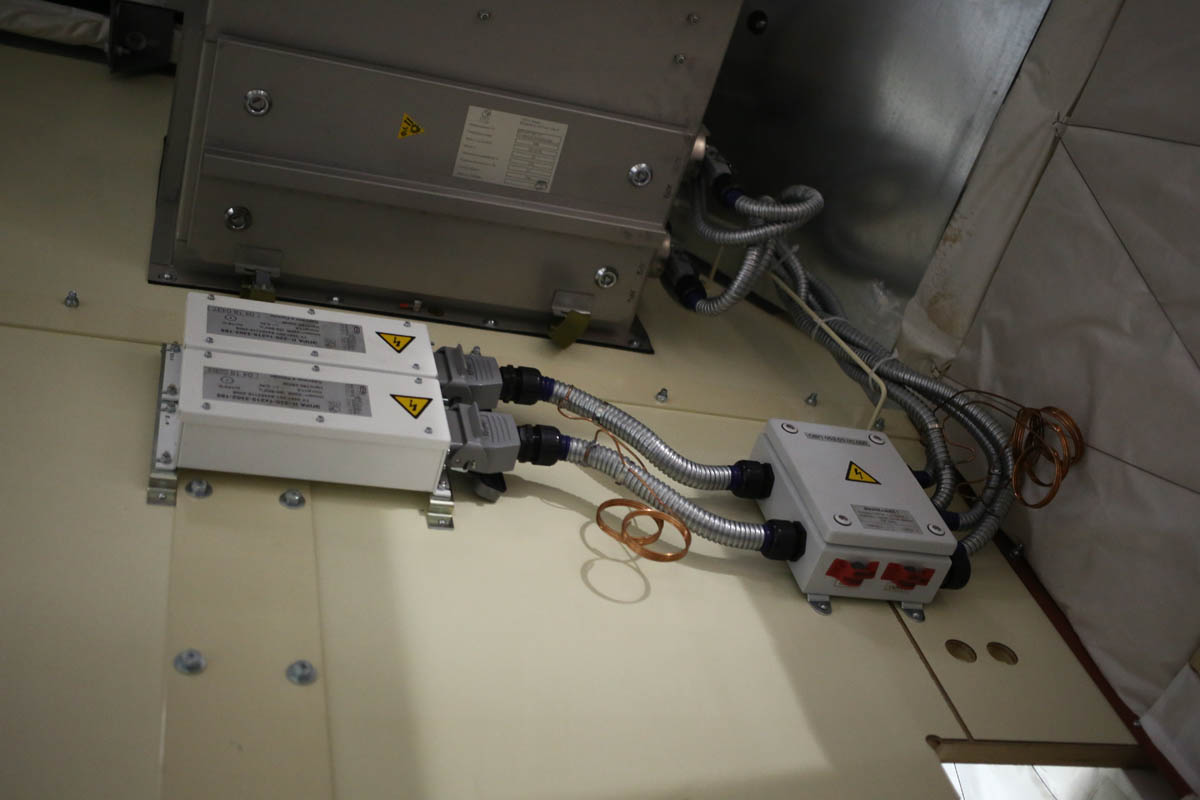

Add engineering subsystems:

Put furniture:

And put equipment at the end:

Where did all this come from? Most often - produced in another place of the plant. Here, for example, they work with plastic:

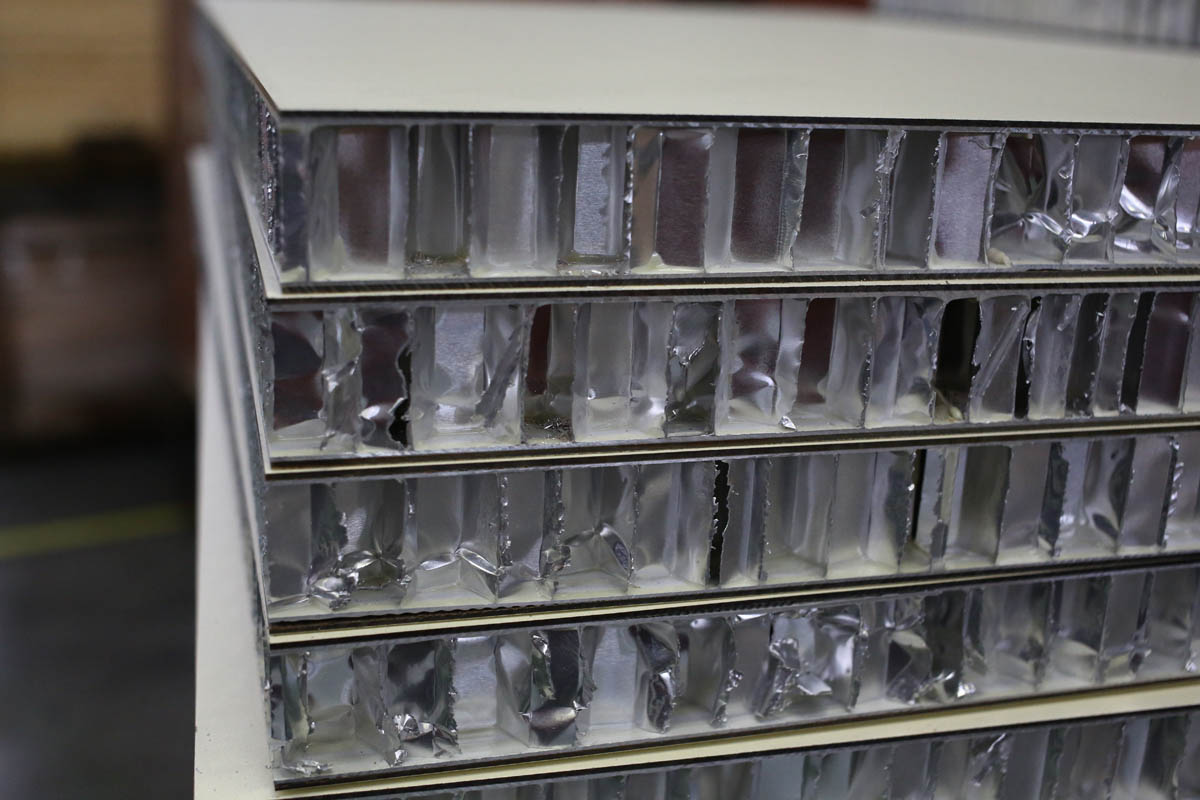

Modern structural material of a cellular structure, light and durable. But still, there is a lot of wood where it is still indispensable for the combination of "price - effect":

Do you make coupe furniture nearby:

Wheelsets? Here they are still rolling out of one workshop: You

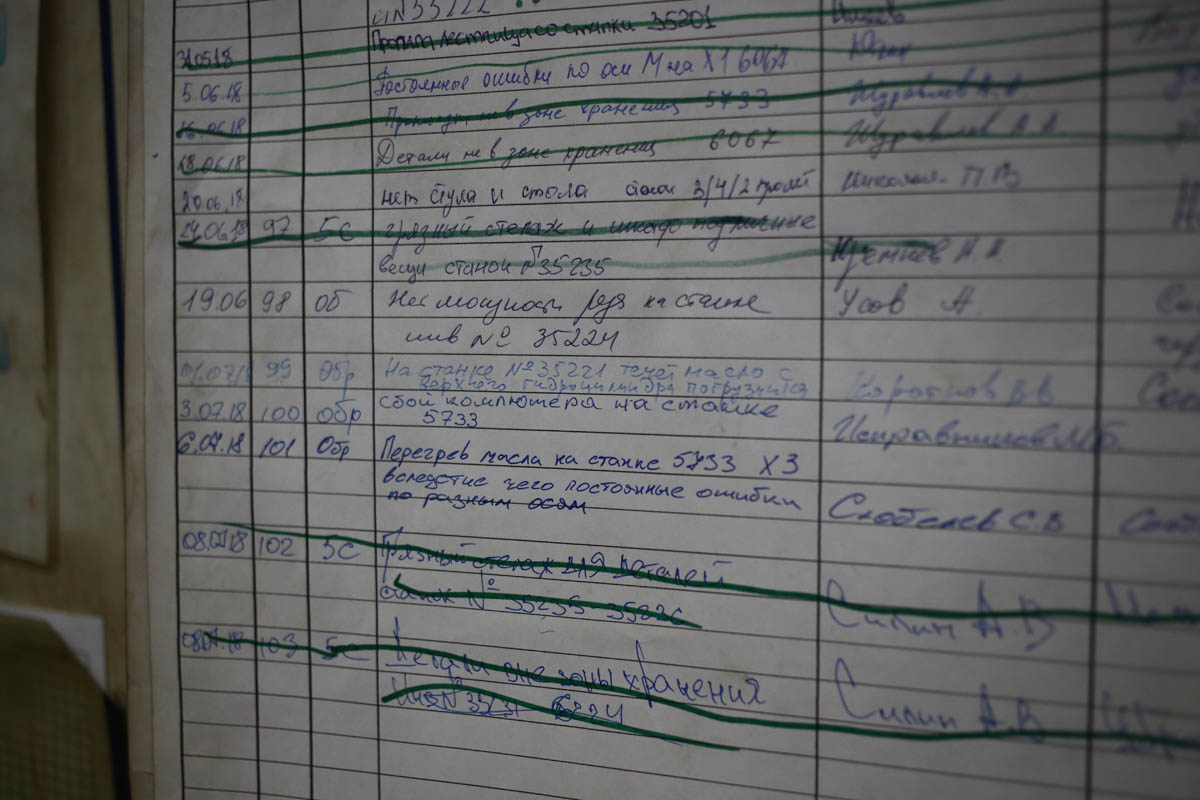

can read the documentation about everything, everything:

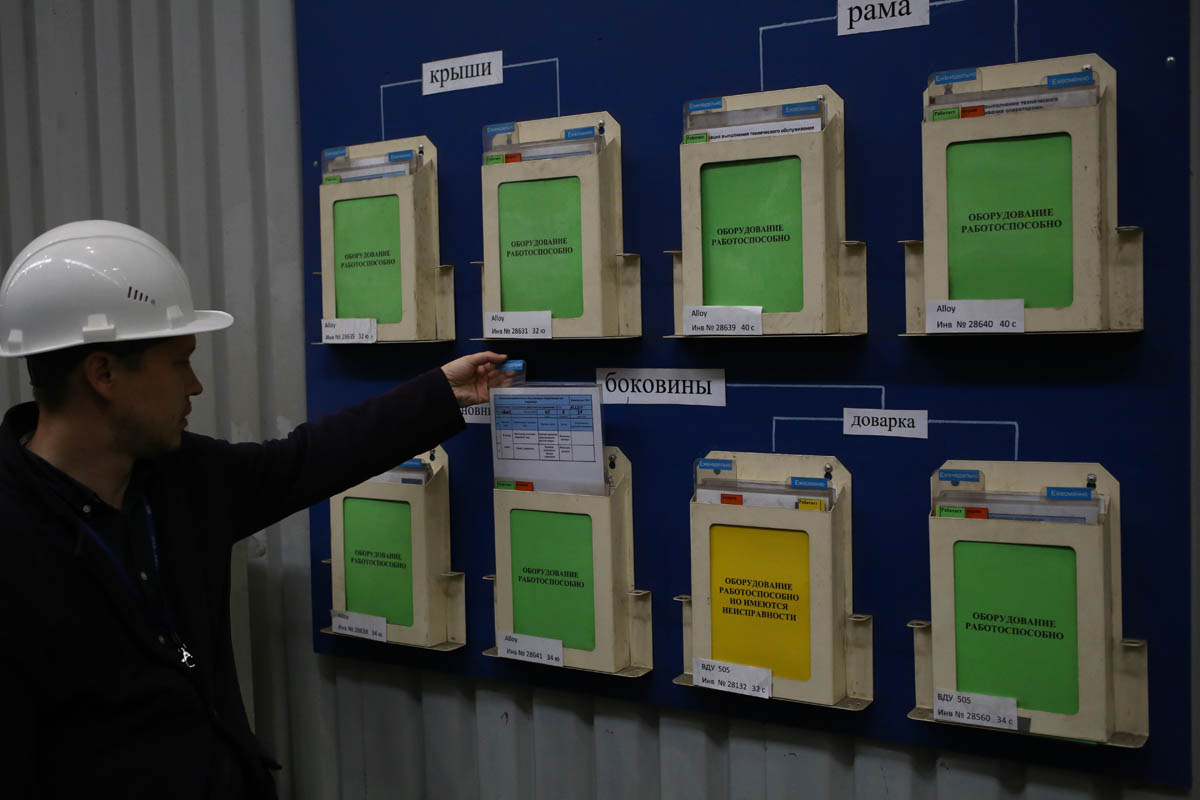

You can see where, with which car and what they do:

At the end of the assembly, the car is waiting for acceptance tests, since for cars there is a GOST and many more standards. What they do:

- Electrical testing. This is the dielectric strength of the insulation and the performance check of the devices. Insulation resistance - test breakdown is checked. More subsystems are powered from all current sources - the generator, the converter and the main.

- Climatics. First, the ventilation is measured for compliance with the modes, then heating and cooling. Next, the conditioning mode is set and the car is driven into the heat chamber. This is a sealed place where the upper limit of the operating temperature is +50 degrees. The task of the car - to cope and hold the set point (22 or 24 degrees) inside.

- Brake tests are done on the stand stationary and in the process of running. Air tightness and actuation of electropneumatics are permanently checked.

- Running tests - full range. A train of at least 6 cars is driving, road performance is measured by grinding the carts with the body, coupling devices, electrical equipment. Efficiency is confirmed.

- Fire tests are not carried out with each car (it would be expensive to burn them upon acceptance). A mockup is being made that is being tried to burn. End walls must comply with GOST, partitions. Chairs and shelves should not emit toxic combustion products and so on. Among other things, an accredited test center is sure to burn every new chair in the camera with mice. The task of the mice is to survive. The task of the chair is to burn so that they survive.

In general, this is part of the certification tests to confirm the safety requirements for 184-FZ. Each process is confirmed by a certificate, and then the cars go into a series of these agreed processes.

There are evacuation tests: for a certain time, it is necessary to evacuate - break the glass, clean the opening, throw a blanket, get out of the car. Determine the time of evacuation. There are explosive tests: the battery box must be explosion-proof. Explosives are called, they set a charge similar to the maximum destructive force from a battery explosion. Boxing is deformed, but remains intact, the front panel flips out, the blast wave goes sideways from the car, and battery fragments fly there. The car passes many tests - for example, even for a collision.

Sometimes during testing with cars something happens. If something is wrong, return for revision. But on the trials themselves, this happens extremely rarely, since more often the car is returned from commissioning (this is something like alpha testing).

After testing, the car gets on the way around the plant and it remains to wait for the conductor. His future owner arrives, settles inside the car and tries to check everything as accurately as possible. Then he leaves right on this car in a big life. The car is rented as ready as possible - with a showcase for cookies, a microwave and everything.

In the same way you can make a tram:

Only the tram will not have a conductor.

About factory

August 25, the company celebrates 120 years. A long time ago it was a private enterprise of the French who made cars for the king. Then they sold it to the guys who transferred the business from Riga, then the plant was nationalized and began to produce what worked. In wartime, it turned out basically this:

At the beginning of the war it was completely destroyed (the territory was seized by the Germans, a few hours before their onset, everything that could not be evacuated was destroyed). Then, after the liberation of the city, the plant was restored, and in the 90s he almost went bankrupt again - there were no orders. Nowadays TVZ is a world-class machine-building enterprise and makes passenger cars for customers from all over the CIS.

There are customers. Now, in 2018, the plant again feels stable. This is evidenced by the fact that before the whole team vacation was given in August. Now for the first time in 9 years, when it is impossible to take and stop production. Orders are scheduled for next year.

Wandering around the plant, we did not touch on the engineering histories of development and design (about them a little later); we ran very little through the life of the workers (for example, there are 4 canteens).

Not discussed the legacy of the USSR:

And much more. It is worth saying that hearing impaired people (about 40 people) work in the noisy workshops: they are quite comfortable there. There is a separate children's camp for the employees' children, there is a sanatorium, there are sports clubs, there is a lot of things. There is a radio inside the plant and a newspaper with a circulation of 4 thousand copies (more circulation than the largest regional edition).

But, I think, so far it has been possible to show the main thing - how a car is made out of nothing.