Post-iron technology for the production of printed circuit boards

- From the sandbox

- Tutorial

The last time I made a circuit board, when there was still no Internet, laser printers and other modern nonsense, but there was an adhesive tape, a scalpel and a lot of free time. And now it's time for me to return to solving this problem.

Now, everything seems to be there, but the problem remains. After all, everyone understands the inconvenience of ordering printed circuit boards in specialized production, when you need to make only one piece, or a prototype. Therefore, they use LUT, photoresist, milling, in general, who can what. But you want to get a guaranteed and repeatable result without developing special skills. So

let 's get started ... Once I came across this article. An interesting method is proposed that provides an impeccable result, and completely changes the attitude of the home production of printed circuit boards.

Literally in two words technology

It differs from LUT in the way the toner is transferred to the board foil. Namely, it is supposed to lay a blank of foil material on a flat surface, on top, as usual, a printer print. But on top is a flexible heating element, which must be pressed firmly and evenly into the device. After that, the heating is turned on until the melting point of the toner is reached.

And about the proposed implementation

In the article, it is proposed to use food foil as a heating element, and to warm it up, a current of about 200 amperes is passed through it at a voltage of about 1 volt. Nice, isn't it?

I see some flaws:

- High currents mean increased demands on wires, contacts, and buses. This makes the construction more expensive. In addition, hard wires create inconvenience, well, in general ...

- The transformer must be fenced

- The foil is flimsy. However, it is more a matter of aesthetics.

- The whole structure is excessively bulky

However, it is possible that someone will like this particular implementation.

Obviously, the foil, or rather, the low resistance of the heating element based on it, creates problems. Indeed, the resistivity of aluminum is one of the smallest - we look at the table . And we would have something from the end of the list, for example nichrome, at worst, constantan. There is a foil or tape of similar materials in nature, but it’s unlikely to buy comfortably less than a car.

However, over time, two working options were born:

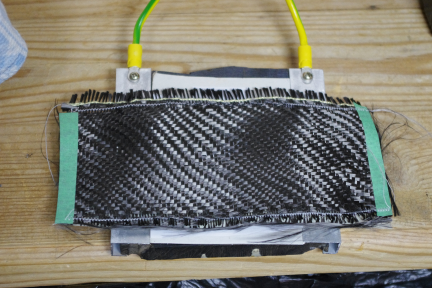

- Carbon fabric. As usual, it is sold in meters. When I managed to get a piece of reasonable size, and I twisted it in my hands, the idea slightly disliked. The threads spread easily, in addition, they are intertwined in different directions, that is, the current will not go in all directions. But it should work.

- Mask of a color picture tube, or TV. It just came up with the idea that the resistivity of the Invar, from which it is made, should be good, but I still have not found reliable data ... We must try.

Receive a printer fingerprint

So, we make a mirror print on a laser printer. I used a backing from self-adhesive labels. It had to be sanded, otherwise the toner would crumble. As a result, there were villi. Most of the villi then stuck to the board (which did not create a problem), but some of them along with the toner remained on the substrate, which is already unpleasant. Here it is, the human factor! I then tinted these places with a permanent marker. In general, this moment has not been worked out perfectly for me, but it seems that it has been globally resolved. It just seemed to be worth ordering this , but, unfortunately, I met it too late. Or maybe you should get Oracal 651 .

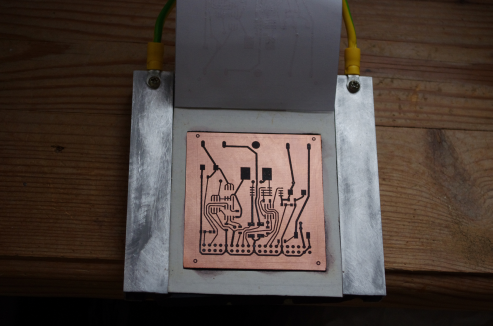

My fixture

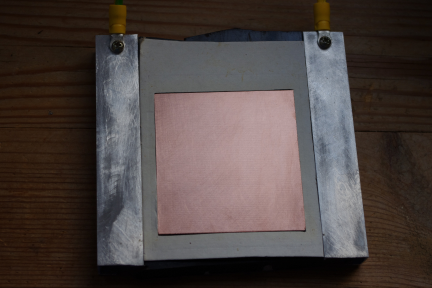

The whole structure is assembled from improvised materials, it can be seen in the photographs. The tires protrude to the height of the board, i.e. about 1.5 mm. The board is surrounded by a cardboard frame, it is not necessary, but very desirable, since it helps to keep the heating element even.

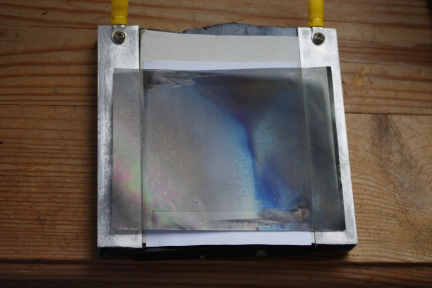

The following photo shows that the heating element cut from the mask is laid on top of the printer's print. And it is made of such a size that there is contact with aluminum tires.

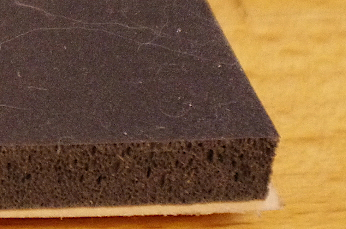

To evenly distribute the pressure, I used a plate of porous silicone with a thickness of 8 mm. Stacked on top of the heating element, it tightly presses it simultaneously to the board and aluminum tires, providing good electrical contact with them. This made the device very simple and convenient. I was afraid that the plate was too soft and thick, but it turned out - just right. This is what porous silicone looks like:

“3M” on the reverse side is a kind of substrate, because I got the self-adhesive plate. Of course, you won’t find one in a nearby store, but maybe several layers of ordinary silicone cut out of a baking dish will do. You can take any soft rubber, but it will have to be insulated with the same silicone.

Porous rubber is pressed on top of a metal plate. If the rubber is soft enough, I think you can press it with thick plywood.

This sandwich in my case is compressed by a clamp. For a small experimental setup, this is enough, and so you can figure out something quick-clamping. When tightening the clamp, I did not make significant efforts, it turned out 2.5 turns, but it all depends on the hardness of the rubber used.

Now you can measure the resistance of the heating element. Roughly it amounted to 0.05 Ohms with a heating zone of 80 x 80 mm. By the way, the resistance of the carbon fabric element was about 0.35 Ohms.

Heating lasted one minute, power consumption was approximately 350 watts. Perhaps these are not optimal modes, and should be kept for several minutes with less power, but for now I decided to stop there. Here is the finished result:

What to add

Since the mask is spherical, it may not be pressed completely against the surface of a large board. But on the latest models of extinct picture tubes, it is quite flat. By the way, I got it from a 15 '' monitor. Using carbon fabric, or carbon fiber, is also tempting, especially if you can fix it on a suitable basis. This is what carbon fabric looks like in my experiment:

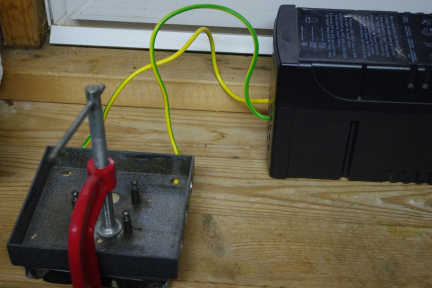

And what is in the black box?

Heating requires a relatively large current and the ability to adjust it. Here you can apply different solutions, and perhaps you already have something ready. I did not find anything suitable, so I had to invent it myself. As a result, such a construction was built from improvised means:

only the housing and the transformer were left from the UPS, the voltage from the power regulator from the vacuum cleaner is supplied to the primary winding of the transformer. As a regulator, you can use the simplest dimmer of sufficient power, or you can solder a homemade one. The heating element is connected directly to half of the secondary winding of the transformer.

The heating power (we are interested in specific power, i.e., power per unit area of heating) can vary widely. So, in the original article it turns out, it was 0.9 W / cm 2 , and my experiment was carried out at 5.5 W / cm 2 .

What about etching?

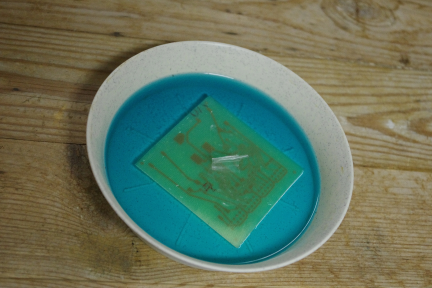

For etching applied a method based on hydrogen peroxide . About it already wrote on a habr . But the method deserves additional mention, at least for replenishment of statistics.

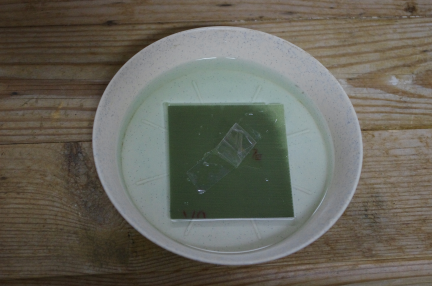

So, the dimensions of my board are 65 x 68 mm. Etching took place under the following conditions.

I dissolved in 50 ml of 3% hydrogen peroxide 16 g of citric acid (2 bags of 8 g) and a spoon (per eye) of salt.

The scarf swam for 45 minutes, periodically I took it out to look, and at the same time slightly mixed the solution.

The final result:

UPD: I slightly corrected the description to make it clearer.