Heavy FPV quadrocopter - development, assembly and first flight

I have been practicing quadrocopters as a hobby for almost half a year. On my last device I hung a camera (GoPro HD Hero 2) and a video transmitter, and flew on it through video glasses - the coolest feeling, I want to tell you. But the technique was not perfect. The old X525 frame with aluminum beams was not stable enough for a weight of 1.8 kg, the quadcopter shook in the air, and it all looked quite collective. Therefore, it was decided to build a new quad, on a frame designed by ourselves, taking into account all needs. And the needs were as follows:

- Place under all equipment. There should be enough space on the new frame for the camera (without the propellers in the picture), the transmitter, OSD, a large battery, plus control electronics (flight controller board and GPS).

- Stability. The frame should be as rigid as possible, but at the same time provide vibration isolation of the camera from the motors.

- Appearance. I wanted to make the copter so that it was nice to look at it, and not typical for beginners, a lump of wires and ties on a standard cross-shaped frame.

- (Secondary) Weight. The X525-based copter weighed 1.8 kg with a camera and battery, I wanted to slightly reduce this figure, and at the same time raise the flight time on one battery.

Puzzling and deciding how it all looks, I installed LibreCAD and set to work.

Development

The inspiration for the overall shape of the copter was the Spidex v2 frame . I liked the location of the components on the same level - the camera in the front, then the center shifted forward, and the battery suspended from the back. Such a scheme allows you to position the camera so that the propellers do not fall into its field of view. They also came up with a good way of vibration isolation - the camera and the battery are suspended from two horizontal pipes, which in turn are mounted on the center using rubber insulators. The mass of the battery helps to reduce vibrations transmitted to the camera. Well, such a copter looks, in my opinion, very decent.

However, Spidex did not fit completely my needs. Firstly, it uses aluminum tubes, from which I have already suffered - they bend, and even without accidents, just from a constant load. Secondly, I use the GoPro Hero HD2 camera, borrowed indefinitely from a roommate - I’m not ready to mount it on a copter without a protective housing, but Spidex does not provide for this.

In short, from Spidex, I decided to use only the general layout. I decided to assemble the frame myself, using fiberglass plates and carbon pipes with clamps. A familiar house has a milling machine on which plates of the required shape can be cut. To create this very form, I sat down at LibreCAD, and here's what I got:

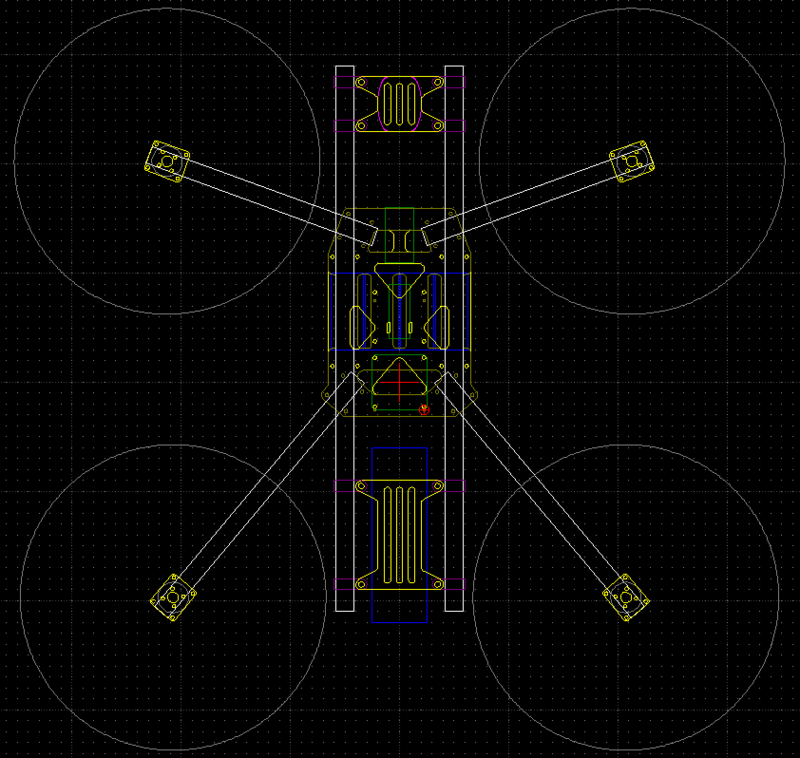

General view of the copter from above

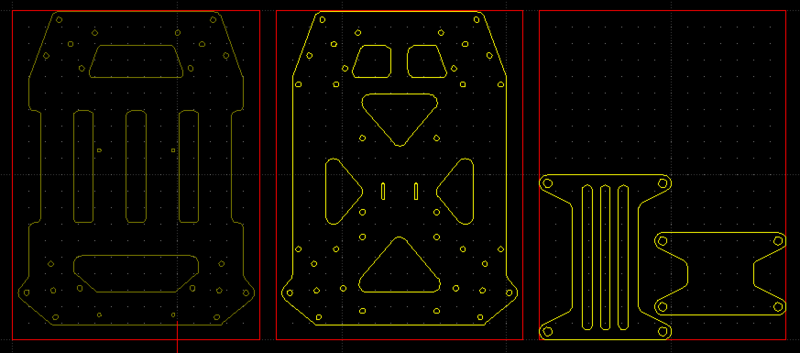

Central plates and holders of the camera and battery

Satisfied with this result, I passed the drawings to a friend, and ordered all the necessary details in local (German) online stores. In particular, carbon tubes (16x14mm, meter length, three pieces were bought - you will need two for the frame, well, in reserve), clamps for them together with suitable screws / nuts (from the FCP HL set from Flyduino), wires for laying through tubes to motors, vibration isolators (silent blocks under M3), and a bunch of small things.

I decided to use all the electronics from the previous copter. Two quads are useless; everything works great - why buy new parts? List of the same electronics and other details that migrated from the previous model:

- Motors: 4x NTM 28-30 750kv

- Motor controllers: 4x HobbyKing Blue Series 30A, with SimonK firmware

- Propellers: 4x Graupner E-Prop 11x5

- Control Board: Crius MultiWii SE v0.1, with MultiWii 2.2

- Batteries: Turnigy Nanotech 4S 4500mAh 25-35C

- Camera: GoPro HD Hero2

- Video Transmitter: ImmersionRC 5.8G 25mW

- Antenna: Clowerleaf 5.8G, DIY from a craftsman in a local forum

- OSD: MinimOSD with KV Team OSD firmware for MultiWii 2.2

- GPS: Drotek I2C GPS

- Radio: Graupner HoTT GR-16, under my transmitter (MX-16)

Assembly

After a few days, all the parts were in place, and it was possible to proceed with the assembly.

Assembling a copter in 23 pictures

Details are laid out on the table, assembly begins. The order did not last long ...

To start, we saw the pipes to the desired length - 22cm and 28cm, all four are sawn from one meter pipe. A file for metal with fine teeth goes very well.

We try on the clamps to the lower center.

The center is assembled to check whether everything fits together as it should. It seems so.

Screwed all the other parts of the frame. It seems like it's almost done? No matter how.

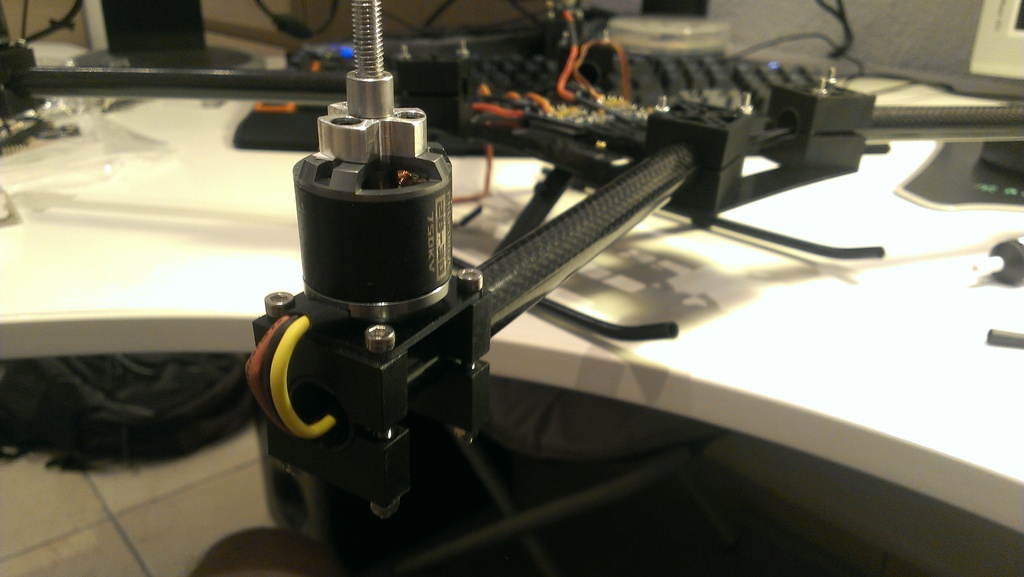

The axes of the motors need to be cut off - they protrude from the back side, and interfere with the installation on top of the tubes. We glue the motor with duct tape in order to prevent metal sawdust from getting inside ...

... and its Dremel, Dremel. Dremel cuts a 3mm axis like a butter knife. The main thing is not to forget safety glasses.

Remove heat shrink from the motor controllers to solder new wires.

The wires are cut to the desired length. Solder the motor connectors. Three phases per motor, you need to solder dofiga - and this is only a quad.

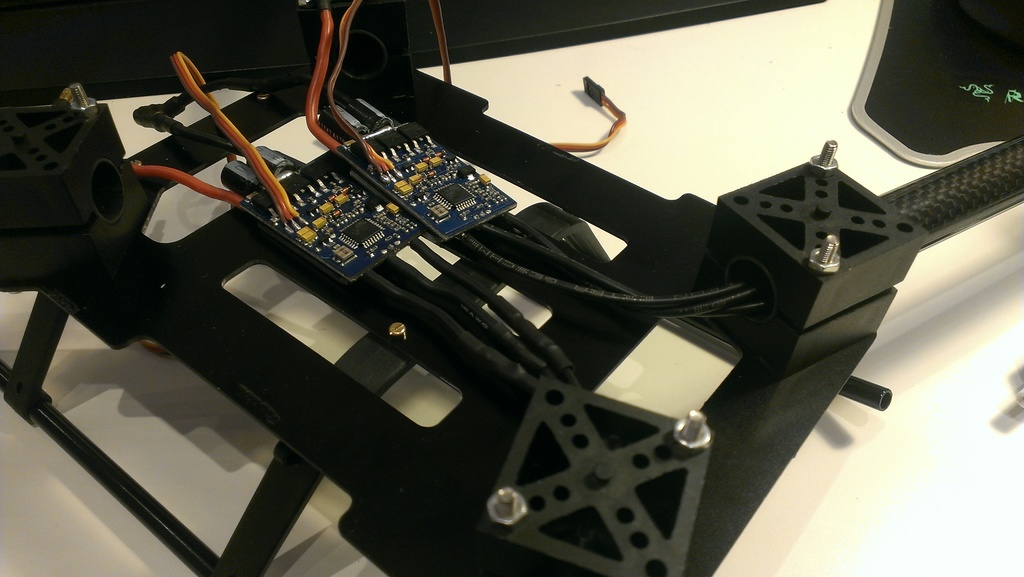

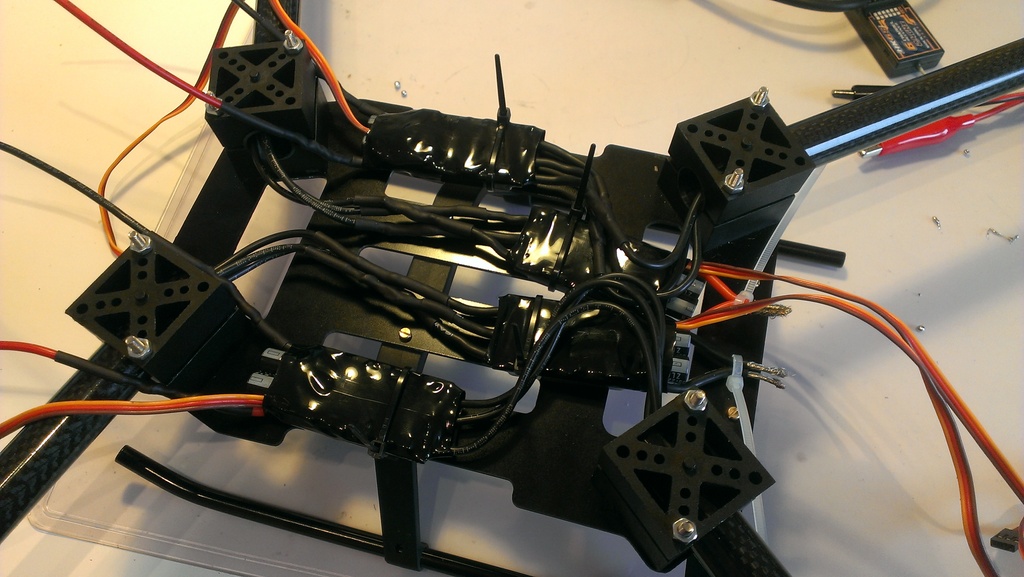

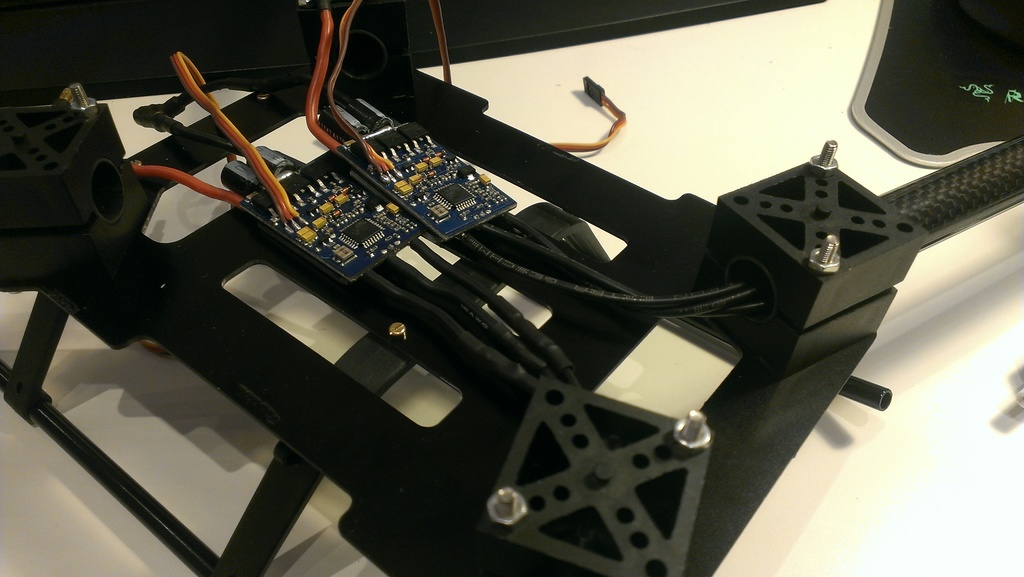

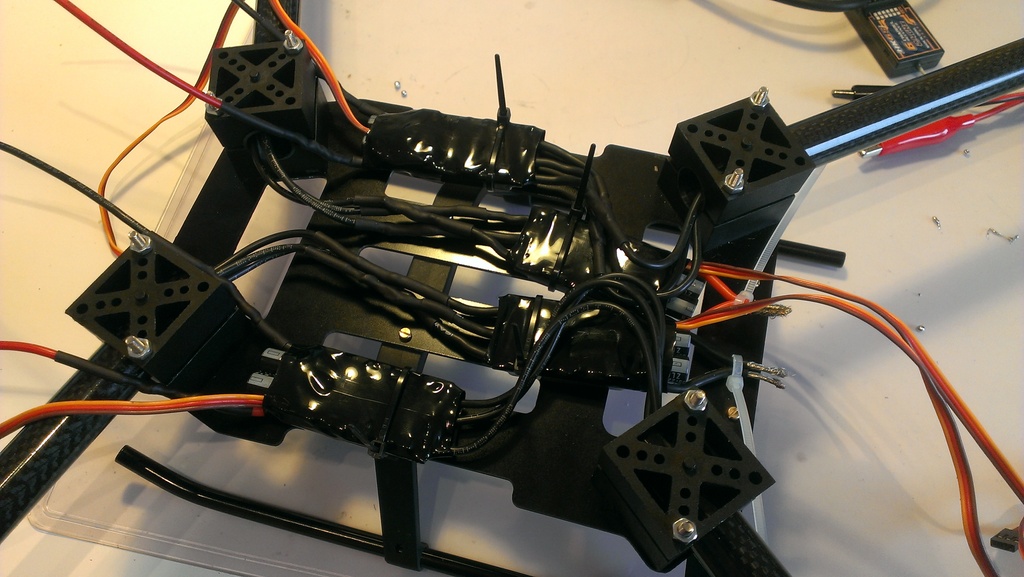

We place the controllers on the lower half frame.

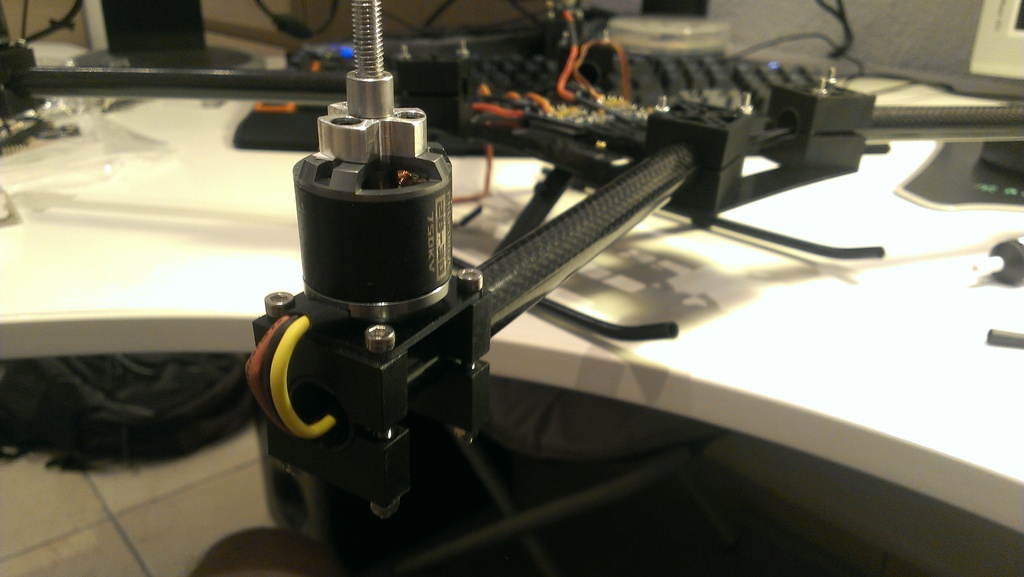

We fasten the motor and run the cable through the tube. Everything is going as planned!

We isolate the controllers with new heat shrink when all the cables are in place.

We install motor controllers in their final position. There are too many wires, but quite clean.

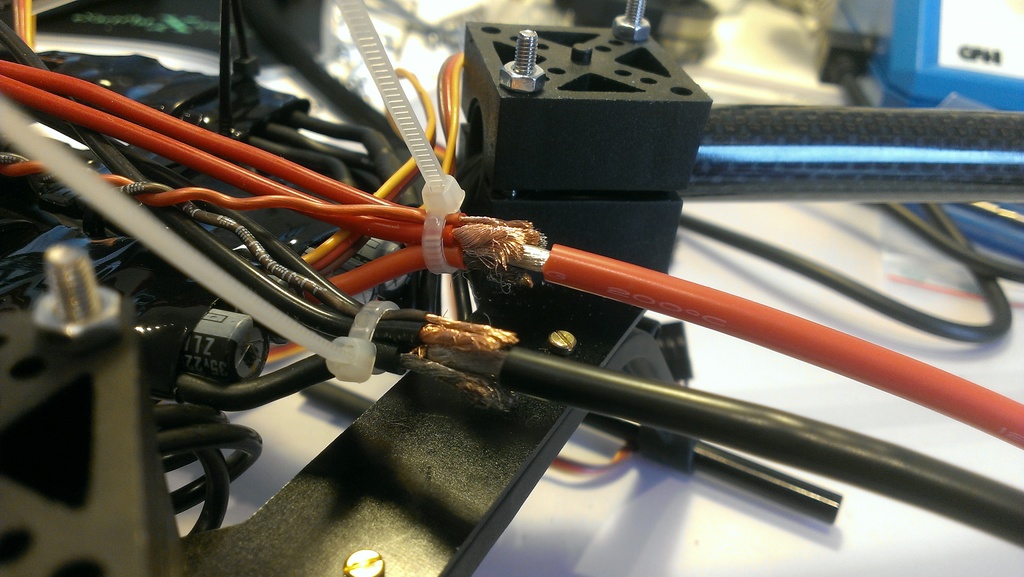

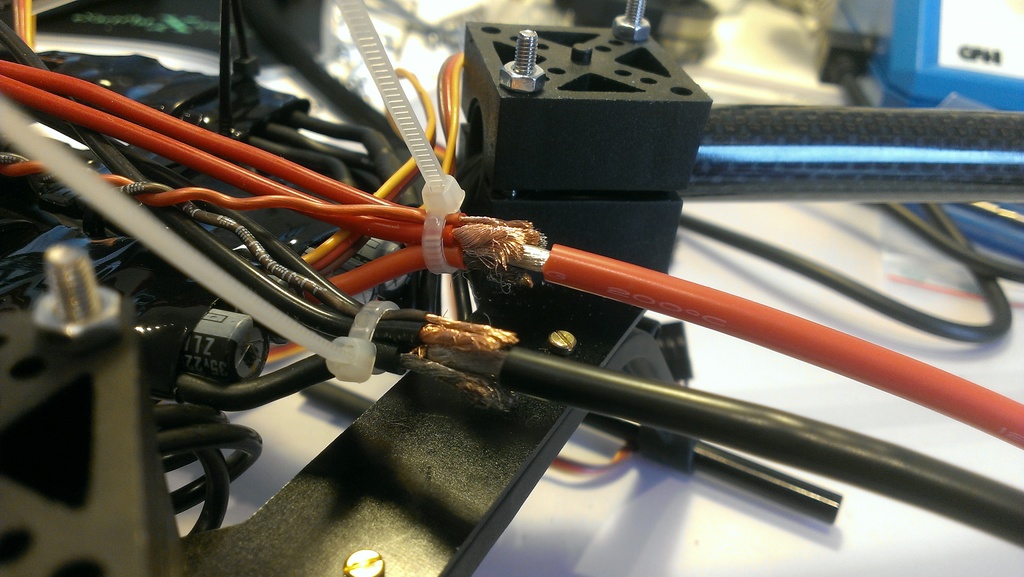

Battery wiring, RCExplorer method. First, we collect the wires from the controllers with a bundle ...

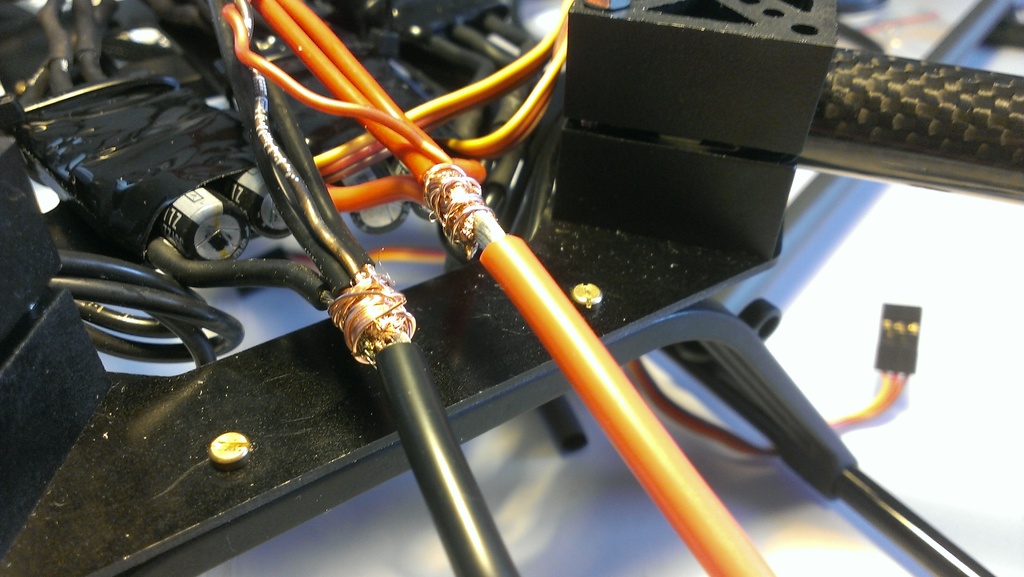

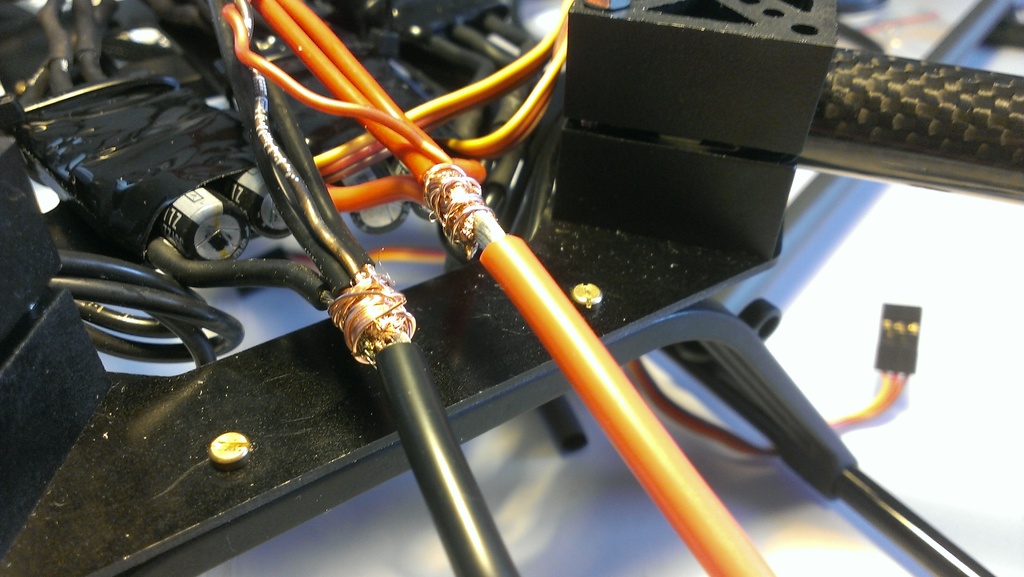

... we pull together with a thin copper wire ...

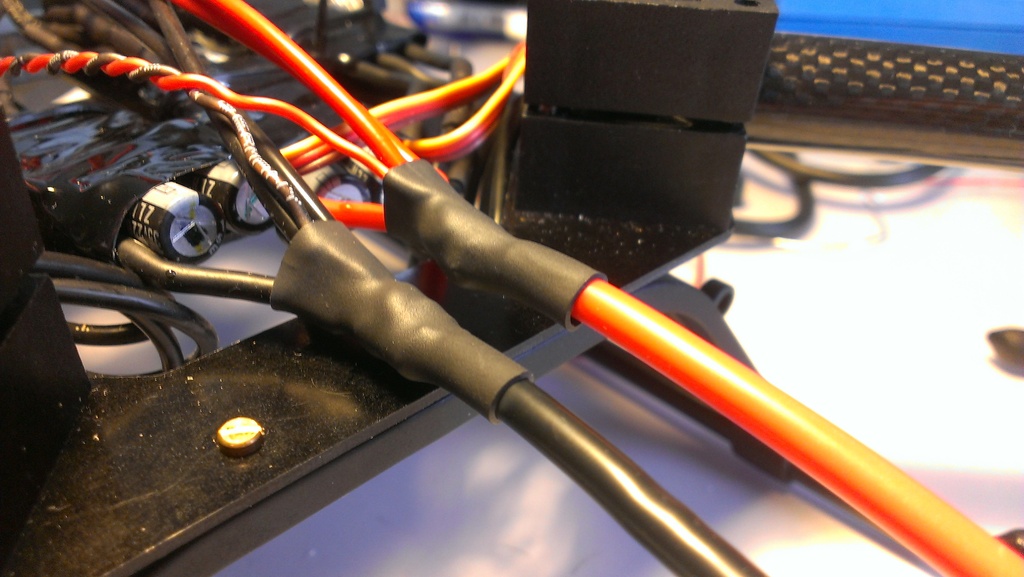

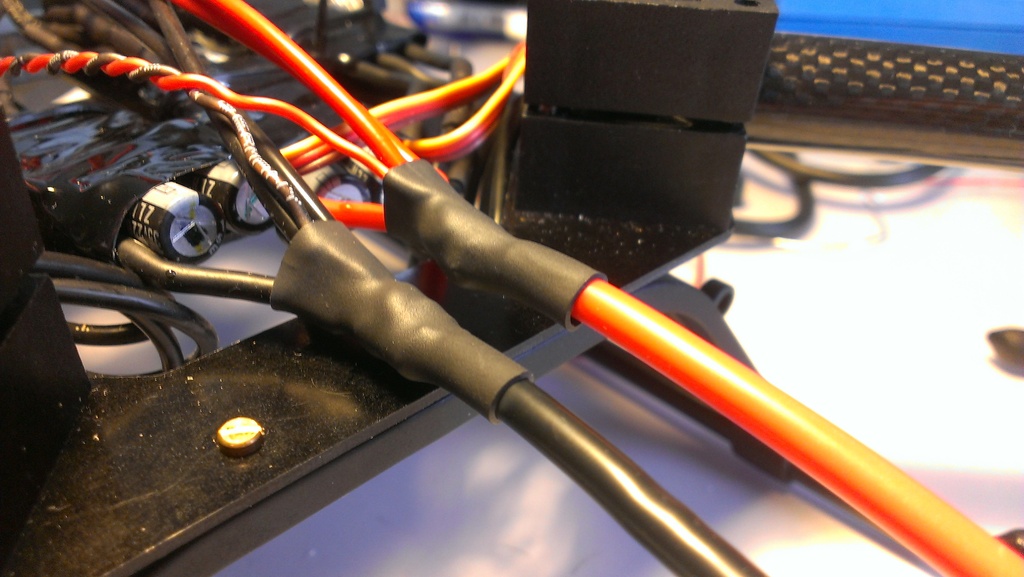

... solder, and insulate with heat shrink. The compound is mechanically strong and well conductive.

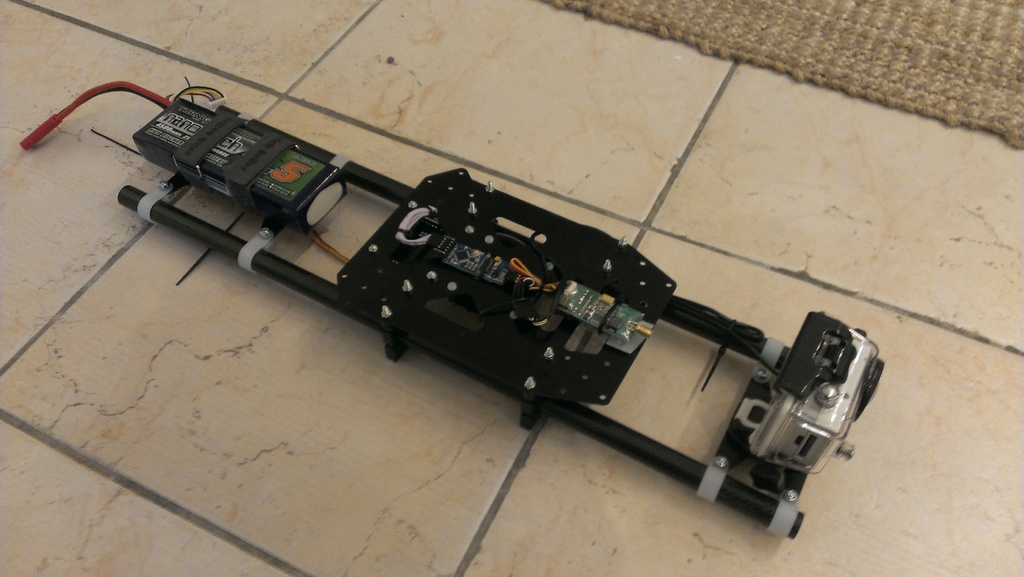

We try on the final assembly: everything matches! The upper frame is not yet screwed, just lies on top.

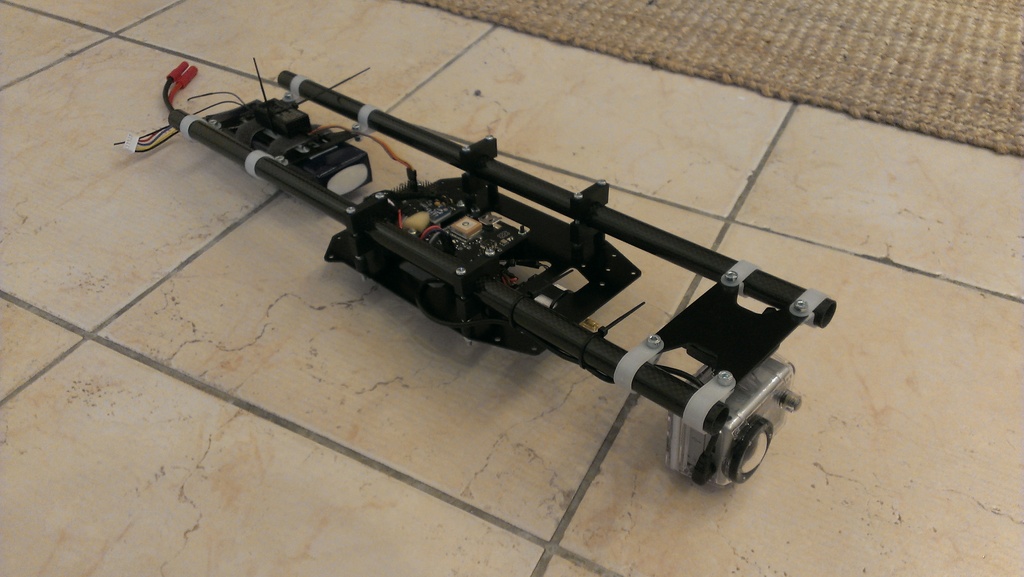

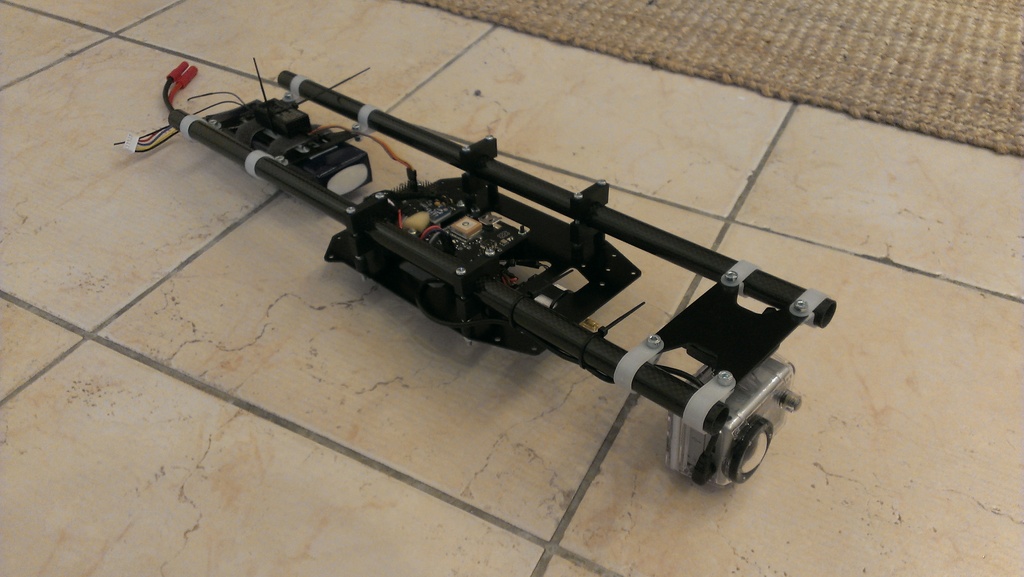

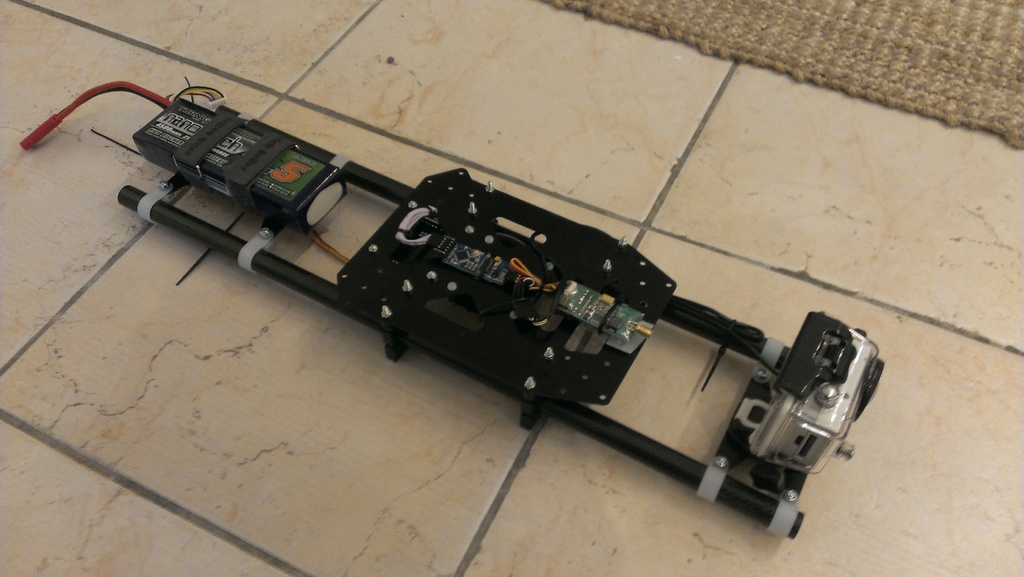

Upper frame with control electronics in the center (controller and GPS) and vibration-insulated tubes with a camera and battery.

Video equipment on the lower side of the upper center: the video cable from the camera goes to MinimOSD, where information from the flight controller is superimposed on it, and then to the video transmitter.

The lower frame is ready to install the upper. The motors are raised so that the clamps in the center do not fall apart when the temporary nuts are loosened.

We install and fasten the upper half frame. Tighten the nuts, connect all the wires ...

... done!

To start, we saw the pipes to the desired length - 22cm and 28cm, all four are sawn from one meter pipe. A file for metal with fine teeth goes very well.

We try on the clamps to the lower center.

The center is assembled to check whether everything fits together as it should. It seems so.

Screwed all the other parts of the frame. It seems like it's almost done? No matter how.

The axes of the motors need to be cut off - they protrude from the back side, and interfere with the installation on top of the tubes. We glue the motor with duct tape in order to prevent metal sawdust from getting inside ...

... and its Dremel, Dremel. Dremel cuts a 3mm axis like a butter knife. The main thing is not to forget safety glasses.

Remove heat shrink from the motor controllers to solder new wires.

The wires are cut to the desired length. Solder the motor connectors. Three phases per motor, you need to solder dofiga - and this is only a quad.

We place the controllers on the lower half frame.

We fasten the motor and run the cable through the tube. Everything is going as planned!

We isolate the controllers with new heat shrink when all the cables are in place.

We install motor controllers in their final position. There are too many wires, but quite clean.

Battery wiring, RCExplorer method. First, we collect the wires from the controllers with a bundle ...

... we pull together with a thin copper wire ...

... solder, and insulate with heat shrink. The compound is mechanically strong and well conductive.

We try on the final assembly: everything matches! The upper frame is not yet screwed, just lies on top.

Upper frame with control electronics in the center (controller and GPS) and vibration-insulated tubes with a camera and battery.

Video equipment on the lower side of the upper center: the video cable from the camera goes to MinimOSD, where information from the flight controller is superimposed on it, and then to the video transmitter.

The lower frame is ready to install the upper. The motors are raised so that the clamps in the center do not fall apart when the temporary nuts are loosened.

We install and fasten the upper half frame. Tighten the nuts, connect all the wires ...

... done!

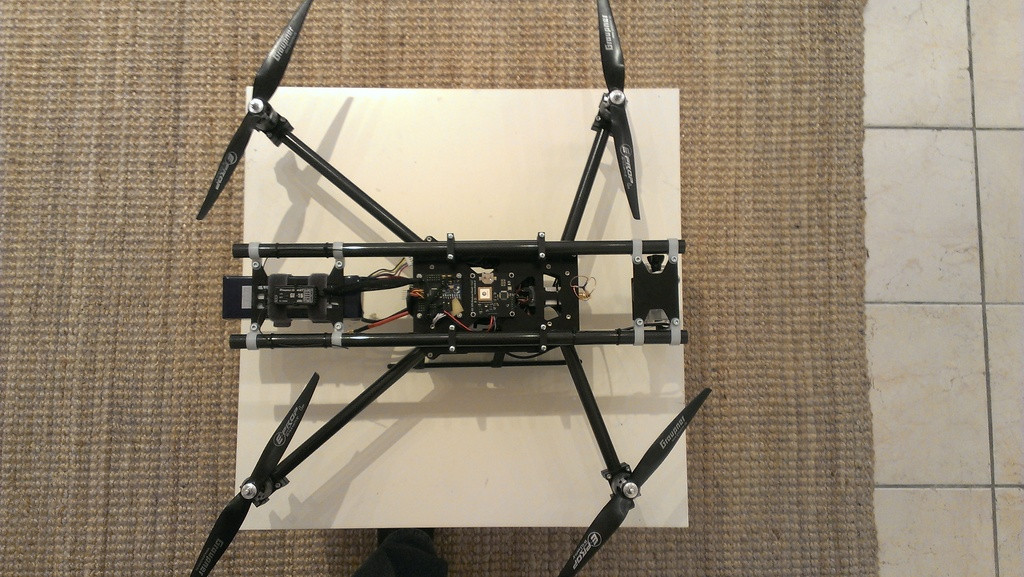

The result of the assembly:

Here is such a copter. The only thing I'm not happy with is weight. It was not possible to facilitate the design, due to the clamps for tubes and a huge number of screws with nuts, the total weight rose to 1950 grams. However, this is still entirely within the power of the drive - my doubts were completely dispelled during the first flight.

First flight

Sensations from the first flight: fantastic! The copter stands rooted in the air, perfectly controlled both visually and through FPV. Flight time on a single charge is 14 minutes, and the power reserve is more than enough for a completely comfortable flight and maneuvering. I’m still digging slightly with the controller settings - GPS does not work well (practically does not hold the position, return-to-home does not work), and PID parameters need to be adjusted (decrease P along the roll axis to get rid of light transverse vibrations visible in the video) .

In general, the project was a success. I will actively use the copter for flights and filming in the coming weeks.

Any questions, comments, etc. welcome.