The main types of printing and their features

We suggest to talk about printing in general and consider the main technologies and features of printing, as you asked in the comments to the past of our reviews.

The concept of modern printing is wider than just a large-circulation printing. This includes the production of banners, promotional materials, the implementation of a full print cycle: from the source file to the finished product. The range of materials used and tasks performed is expanding. Now you can transfer smells, stereo and three-dimensional images. Nevertheless, four basic types of printing remain traditional: offset, screen, laser and inkjet. What are their main features and differences?

For printing large quantities usually used offset printing. Often it serves as a benchmark for the quality of color printing. Offset technology is the process of transferring the image to the media from the photoform through the intermediate offset shaft. The printed material successively passes through a series of photoforms, applying one color at a time. Color prints, superimposed on each other, ultimately give a full-color image of high quality.

The main advantages of offset printing is high speed with excellent quality color and monochrome prints. The performance of typographic printing equipment is several thousand ready-made A4 pages per minute. In addition, the low cost of copies provides the "omnivorous" offset printing in terms of paper used.

However, offset printing has a number of features that make it unprofitable to print small runs. Preparation takes a lot of time and requires serious expenses, which are then distributed over the entire circulation. To make a color print, it is necessary to perform color separation, create and make photoforms for each color, since only one color is applied in one pass. In addition, prepress preparation includes press preparation, color balancing and a whole range of auxiliary debugging works. Therefore, as a disadvantage of offset printing, we can note the lack of flexibility of the process and the impossibility of prompt printing within a few hours.

An alternative to offset printing for monochrome images is screen printing. It is well suited for low-budget information products, which include newspapers, letterheads, flyers, instructions.

A special case of screen printing is risography. On a special film, in accordance with the figure, the smallest holes are burned, which, when printed, will perform the function of nozzles. The film stretches on the drum with paint. During the rotation of the drum, under the action of centrifugal forces, the paint is distributed on the inner walls of the drum and is forced through the holes in the film. Then the ink is transferred to the paper.

Risography has a high print speed and very short prepress. Less than 40 seconds pass from the page layout to the first printout. However, with high print speeds and the lowest cost per print among other types of printing, risography has its drawbacks. With its help, you can not get high-quality color images, and monochrome printing is performed without semitones. Print resolution is limited by the size of the holes of the stencil. Risography is optimal for small and medium print runs of monochrome printed products.

The main advantage of digital printing is the absence of intermediate steps between the digital file and the printing process itself. Digital printing is divided into two large classes - inkjet and laser.

Laser printing

Laser printing is mainly used for printing documents and drawings. In this it is similar to a monochrome screen printing. But other principles work in laser printing. Under the action of a laser beam on the surface of the photodrum, the electrical resistance varies locally. Toner is fixed in these places, which is then transferred to paper. The toner paper passes through the fuser (heater) to make the print stick. There the toner is fused into the carrier.

At Canon, we use this technology in all of our laser printers andoffice multifunction devices . From model to model, we improve our devices, improving print quality, and also pay great attention to the protection of print data. This is implemented not only in new hardware developments, but also in specialized software. For example, in one of the previous articles, we reviewed the technologies uniFLOW and Therefore .

An analogue of laser printing is LED printing. Instead of a laser, it uses LEDs that shine through the slots. At the same time, a beam of light falls perpendicular to the drum unit, without distorting the image. When laser printing at the edges of the print, a slight blurring of the image is possible due to the large inclination of the laser beam to the surface of the drum.

Océ DirectPress technology used on our VarioPrint devices converts data into a digital image in one step. This is a 100% digital process that does not depend on the light source, temperature changes, static charge, moisture and toner composition, and is extremely stable in terms of uniformity and image quality. Also with less mechanical parts, this technology is very reliable and allows the system to be affordable and compact. It contributes to a healthier working environment, since no ozone is released during printing and no toner waste remains.

Inkjet printing

This is a promising area of printing, which allows printing high-quality multi-color images not only on paper. The principle of inkjet printing is drip ink application from the print head. There are two ways to supply ink - piezoelectric and thermal. In the first case, the role of a “piston” is performed by a curving piezoelectric plate, and in the second, a vapor bubble formed on the surface of the microheater. Depending on the method of submission is determined by the type of ink. Attempting to replace ink with others will result in failure of printing equipment. Therefore, the use of original consumables is not the whim of the manufacturer, but the features of the technologies used.

To date, inkjet poly-color printing has, perhaps, most of all different types of implementation. This can be seen in our equipment. Océ ProStream large-format printers with a piezo-electric printhead use solvent-based inks. This type of equipment has a number of innovative features. For example, ColorGrip, which allows to make high-quality prints on low quality paper. This is achieved by spraying when printing a special composition that creates an adhesive film on the surface of the carrier. The printhead has also undergone a serious modernization. It recycles ink while idle and maintains a stable temperature to prevent ink from drying out. Océ Colorado 1640

PrinterWorks with UV printing technology. Due to the curing of ink with ultraviolet radiation, this technology allows printing on heat-sensitive materials. When printing, the printer maintains a stable carrier temperature at +28 ° C.

We also developed our own textured print technology for transmitting with high accuracy not only color, but also surface texture. This method opens up a full-fledged access to the printing industry for people with limited vision, for whom the main channel for obtaining information is tactile sensations. We talked about this technology in our post “ Elevated printing: a new look at print ”.

The use of the latest developments in digital printing has allowed her to significantly strengthen and expand her position in modern printing. However, it would be incorrect to consider it from the standpoint of an alternative to offset printing, since these types of printing services have different technologies and objectives. But it is recommended to compare the profitability depending on the size of the circulation.

If for digital printing the cost of a copy is almost independent of the size of the circulation, for offset printing, where the main costs are in the preparatory stages of work, an increase in circulation leads to a decrease in the cost of the copy. In the form of graphs, this can be represented as a straight horizontal line for the “digit” and a hyperbole for offset. The point of intersection of these graphs will give the boundary size of the circulation, separating the scope of application of these printing methods. The emergence of new developments and technologies in digital printing is constantly shifting the point of circulation size upwards. Earlier, the profitability of the “figures” was in the hundreds of copies, but now the bill goes to thousands. Nice to know that this is our merit. We give only a few examples.

Earlier, expensive high-quality paper was used for inkjet printing due to the fact that the ink was heavily absorbed on more porous, cheaper paper, and color quality and image clarity were disturbed. Offset printing in this regard was in a much more advantageous position. Many types of paper were suitable for it, including from the budget segment. This means that the cost of the copy can be significantly reduced only at the expense of the media, while not taking into account the cost of the print itself. Switching to cheaper media would open up new perspectives for digital printing. The possibility of such a transition, we have implemented in several ways.

A versatile way to print on a wide range of media was the new ColorGrip technology, which is optional on wide-format inkjet printers. Its essence lies in the fact that before the ink a special composition is applied to the paper. It has a dual function. First, the film formed on the surface of the carrier limits the absorption of ink into the paper. Secondly, the composition of ColorGrip plays the role of soil, providing better adhesion. Accurate positioning of the composition drops optimizes its flow rate. ColorGrip is used exactly as much as necessary for each ink drop, leaving an unprinted surface clean.

Another way is the creation of pigment inks. This was implemented on imagePROGRAF wide format printers. New pigment inks LUCIA EX have greater saturation, with less absorbed into the media. Because of this, they can be used on different types of paper.

To reduce the cost of the printing process itself due to the economical consumption of ink, we have made a number of developments, from the variable size of the ink drop to the recycling of ink in the print head. All this provided a better color reproduction without unnecessary ink consumption for auxiliary operations.

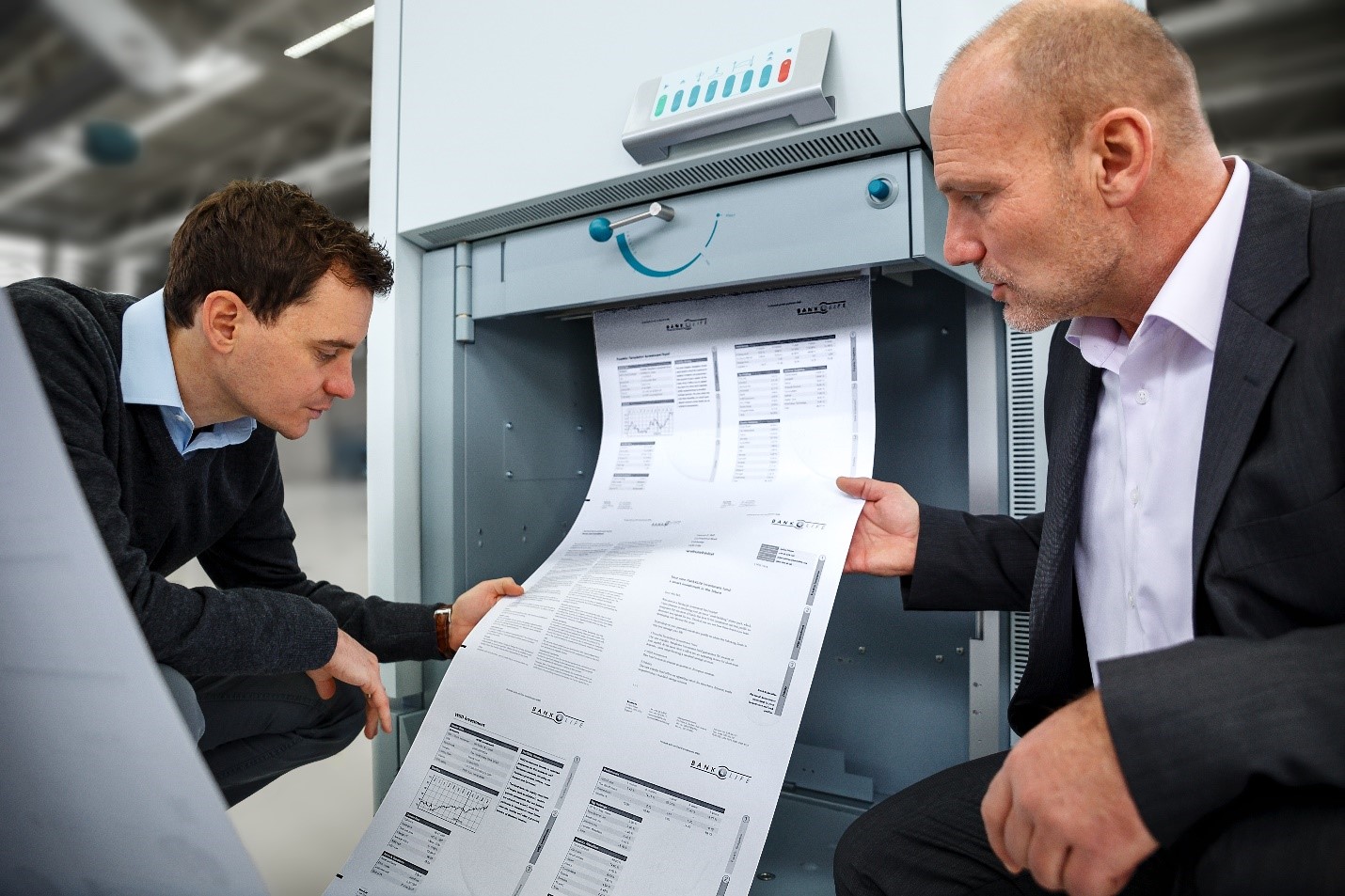

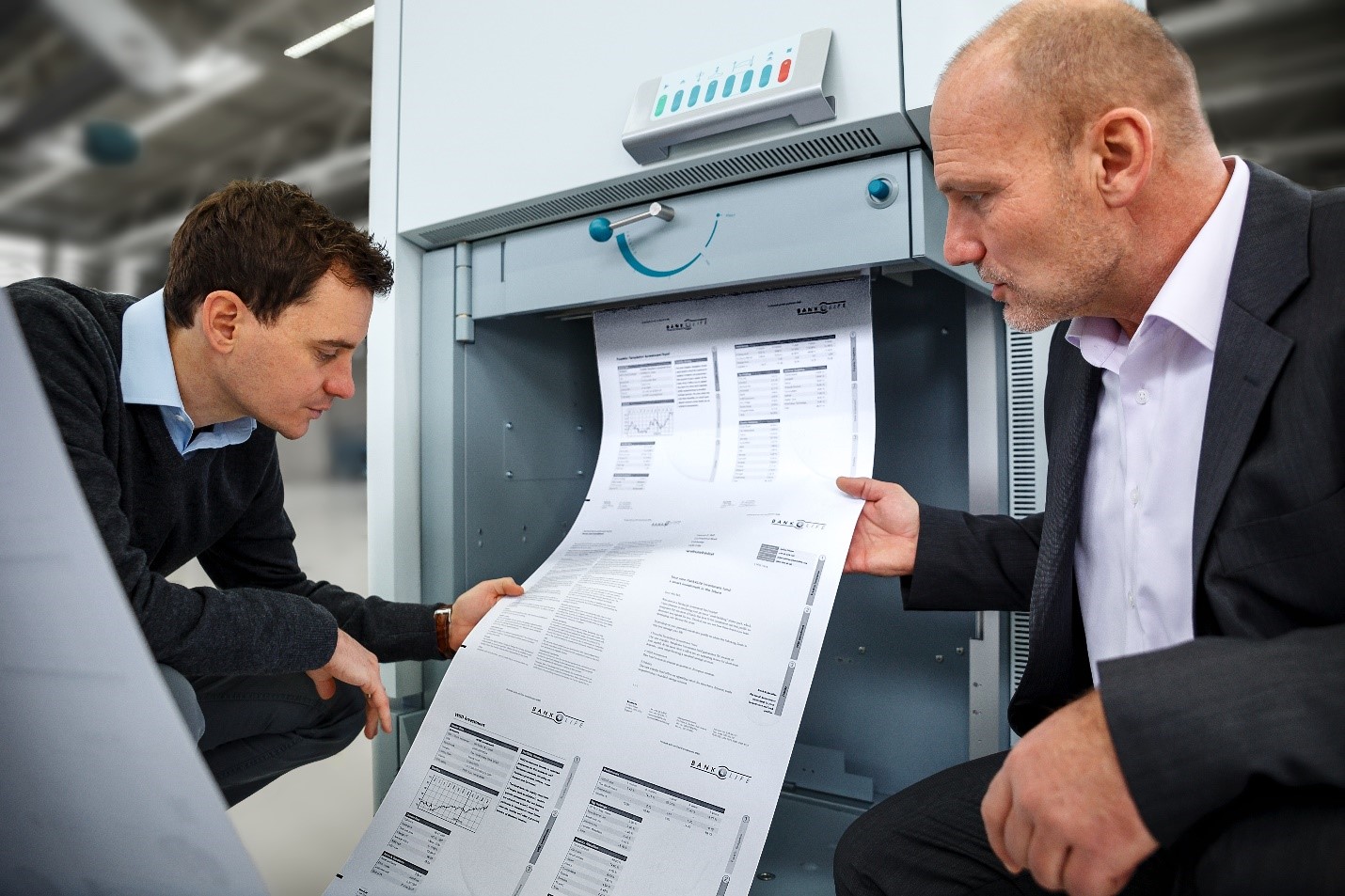

It should be noted another important point. In offset printing presses, finished printed sheets arrive at the binding area, where they are folded, stitched, cut, and undergo further processing steps that turn them into a finished product. This requires additional equipment, production space, staff. It takes costs that are included in the cost of the instance. In digital printing, we managed to reduce these costs. Optionally, various post-printing modules can be connected to our wide-format inkjet printers. Thus, digital printing equipment is transformed into a fully automated production line of a full cycle.

We continue our developments in the field of digital printing. Of course, it is difficult to imagine that the “figure” will ever completely replace the “offset”, but the printing market is changing in the direction of customized printing, when each copy will be printed according to the individual needs of the buyer. And for this, digital printing with its flexibility and versatility of technology is best suited.

In subsequent articles we will tell you about new trends in the industry, innovative developments, applied technologies, and prepare reviews of the most interesting models.

Write to us if this article was useful to you, and what materials you would like to see on this blog, what questions should be covered and what to pay attention to.

The concept of modern printing is wider than just a large-circulation printing. This includes the production of banners, promotional materials, the implementation of a full print cycle: from the source file to the finished product. The range of materials used and tasks performed is expanding. Now you can transfer smells, stereo and three-dimensional images. Nevertheless, four basic types of printing remain traditional: offset, screen, laser and inkjet. What are their main features and differences?

Offset printing

For printing large quantities usually used offset printing. Often it serves as a benchmark for the quality of color printing. Offset technology is the process of transferring the image to the media from the photoform through the intermediate offset shaft. The printed material successively passes through a series of photoforms, applying one color at a time. Color prints, superimposed on each other, ultimately give a full-color image of high quality.

The main advantages of offset printing is high speed with excellent quality color and monochrome prints. The performance of typographic printing equipment is several thousand ready-made A4 pages per minute. In addition, the low cost of copies provides the "omnivorous" offset printing in terms of paper used.

However, offset printing has a number of features that make it unprofitable to print small runs. Preparation takes a lot of time and requires serious expenses, which are then distributed over the entire circulation. To make a color print, it is necessary to perform color separation, create and make photoforms for each color, since only one color is applied in one pass. In addition, prepress preparation includes press preparation, color balancing and a whole range of auxiliary debugging works. Therefore, as a disadvantage of offset printing, we can note the lack of flexibility of the process and the impossibility of prompt printing within a few hours.

Screen printing

An alternative to offset printing for monochrome images is screen printing. It is well suited for low-budget information products, which include newspapers, letterheads, flyers, instructions.

A special case of screen printing is risography. On a special film, in accordance with the figure, the smallest holes are burned, which, when printed, will perform the function of nozzles. The film stretches on the drum with paint. During the rotation of the drum, under the action of centrifugal forces, the paint is distributed on the inner walls of the drum and is forced through the holes in the film. Then the ink is transferred to the paper.

Risography has a high print speed and very short prepress. Less than 40 seconds pass from the page layout to the first printout. However, with high print speeds and the lowest cost per print among other types of printing, risography has its drawbacks. With its help, you can not get high-quality color images, and monochrome printing is performed without semitones. Print resolution is limited by the size of the holes of the stencil. Risography is optimal for small and medium print runs of monochrome printed products.

Digital printing

The main advantage of digital printing is the absence of intermediate steps between the digital file and the printing process itself. Digital printing is divided into two large classes - inkjet and laser.

Laser printing

Laser printing is mainly used for printing documents and drawings. In this it is similar to a monochrome screen printing. But other principles work in laser printing. Under the action of a laser beam on the surface of the photodrum, the electrical resistance varies locally. Toner is fixed in these places, which is then transferred to paper. The toner paper passes through the fuser (heater) to make the print stick. There the toner is fused into the carrier.

At Canon, we use this technology in all of our laser printers andoffice multifunction devices . From model to model, we improve our devices, improving print quality, and also pay great attention to the protection of print data. This is implemented not only in new hardware developments, but also in specialized software. For example, in one of the previous articles, we reviewed the technologies uniFLOW and Therefore .

An analogue of laser printing is LED printing. Instead of a laser, it uses LEDs that shine through the slots. At the same time, a beam of light falls perpendicular to the drum unit, without distorting the image. When laser printing at the edges of the print, a slight blurring of the image is possible due to the large inclination of the laser beam to the surface of the drum.

Océ DirectPress technology used on our VarioPrint devices converts data into a digital image in one step. This is a 100% digital process that does not depend on the light source, temperature changes, static charge, moisture and toner composition, and is extremely stable in terms of uniformity and image quality. Also with less mechanical parts, this technology is very reliable and allows the system to be affordable and compact. It contributes to a healthier working environment, since no ozone is released during printing and no toner waste remains.

Inkjet printing

This is a promising area of printing, which allows printing high-quality multi-color images not only on paper. The principle of inkjet printing is drip ink application from the print head. There are two ways to supply ink - piezoelectric and thermal. In the first case, the role of a “piston” is performed by a curving piezoelectric plate, and in the second, a vapor bubble formed on the surface of the microheater. Depending on the method of submission is determined by the type of ink. Attempting to replace ink with others will result in failure of printing equipment. Therefore, the use of original consumables is not the whim of the manufacturer, but the features of the technologies used.

To date, inkjet poly-color printing has, perhaps, most of all different types of implementation. This can be seen in our equipment. Océ ProStream large-format printers with a piezo-electric printhead use solvent-based inks. This type of equipment has a number of innovative features. For example, ColorGrip, which allows to make high-quality prints on low quality paper. This is achieved by spraying when printing a special composition that creates an adhesive film on the surface of the carrier. The printhead has also undergone a serious modernization. It recycles ink while idle and maintains a stable temperature to prevent ink from drying out. Océ Colorado 1640

PrinterWorks with UV printing technology. Due to the curing of ink with ultraviolet radiation, this technology allows printing on heat-sensitive materials. When printing, the printer maintains a stable carrier temperature at +28 ° C.

We also developed our own textured print technology for transmitting with high accuracy not only color, but also surface texture. This method opens up a full-fledged access to the printing industry for people with limited vision, for whom the main channel for obtaining information is tactile sensations. We talked about this technology in our post “ Elevated printing: a new look at print ”.

The use of the latest developments in digital printing has allowed her to significantly strengthen and expand her position in modern printing. However, it would be incorrect to consider it from the standpoint of an alternative to offset printing, since these types of printing services have different technologies and objectives. But it is recommended to compare the profitability depending on the size of the circulation.

If for digital printing the cost of a copy is almost independent of the size of the circulation, for offset printing, where the main costs are in the preparatory stages of work, an increase in circulation leads to a decrease in the cost of the copy. In the form of graphs, this can be represented as a straight horizontal line for the “digit” and a hyperbole for offset. The point of intersection of these graphs will give the boundary size of the circulation, separating the scope of application of these printing methods. The emergence of new developments and technologies in digital printing is constantly shifting the point of circulation size upwards. Earlier, the profitability of the “figures” was in the hundreds of copies, but now the bill goes to thousands. Nice to know that this is our merit. We give only a few examples.

Earlier, expensive high-quality paper was used for inkjet printing due to the fact that the ink was heavily absorbed on more porous, cheaper paper, and color quality and image clarity were disturbed. Offset printing in this regard was in a much more advantageous position. Many types of paper were suitable for it, including from the budget segment. This means that the cost of the copy can be significantly reduced only at the expense of the media, while not taking into account the cost of the print itself. Switching to cheaper media would open up new perspectives for digital printing. The possibility of such a transition, we have implemented in several ways.

A versatile way to print on a wide range of media was the new ColorGrip technology, which is optional on wide-format inkjet printers. Its essence lies in the fact that before the ink a special composition is applied to the paper. It has a dual function. First, the film formed on the surface of the carrier limits the absorption of ink into the paper. Secondly, the composition of ColorGrip plays the role of soil, providing better adhesion. Accurate positioning of the composition drops optimizes its flow rate. ColorGrip is used exactly as much as necessary for each ink drop, leaving an unprinted surface clean.

Another way is the creation of pigment inks. This was implemented on imagePROGRAF wide format printers. New pigment inks LUCIA EX have greater saturation, with less absorbed into the media. Because of this, they can be used on different types of paper.

To reduce the cost of the printing process itself due to the economical consumption of ink, we have made a number of developments, from the variable size of the ink drop to the recycling of ink in the print head. All this provided a better color reproduction without unnecessary ink consumption for auxiliary operations.

It should be noted another important point. In offset printing presses, finished printed sheets arrive at the binding area, where they are folded, stitched, cut, and undergo further processing steps that turn them into a finished product. This requires additional equipment, production space, staff. It takes costs that are included in the cost of the instance. In digital printing, we managed to reduce these costs. Optionally, various post-printing modules can be connected to our wide-format inkjet printers. Thus, digital printing equipment is transformed into a fully automated production line of a full cycle.

We continue our developments in the field of digital printing. Of course, it is difficult to imagine that the “figure” will ever completely replace the “offset”, but the printing market is changing in the direction of customized printing, when each copy will be printed according to the individual needs of the buyer. And for this, digital printing with its flexibility and versatility of technology is best suited.

In subsequent articles we will tell you about new trends in the industry, innovative developments, applied technologies, and prepare reviews of the most interesting models.

Write to us if this article was useful to you, and what materials you would like to see on this blog, what questions should be covered and what to pay attention to.