3D printer prints regolith lunar base

Project of the European Space Agency

In 2011, NASA published its project for the construction of a lunar base with the participation of a large number of robots (excavators, bulldozers, shredders, etc.). Now the European Space Agency has proposed an alternative project for 3D printing of the lunar base , using local soil as a building material.

The ESA project was created with the help of architects from Foster + Partners . For printing, a D-Shape printer from the British company Monolite is used. On the moon, the printer will be able to use local soil as regolith.

Regolith is a loose, different-grained debris-dust layer several meters deep. It consists of fragments of igneous rocks, minerals, glass, meteorites, contains a lot of aluminum, iron and titanium. Particles are very small and have high adhesion due to the absence of an oxide film on their surface and high electrification. All in all, pretty good for construction.

True, one regolith is not enough: periclase must be added to the mixture. This is magnesium oxide, burnt magnesia, used, for example, by weight lifters to wipe hands before trying. Probably, the powder for the printer will have to be delivered from Earth.

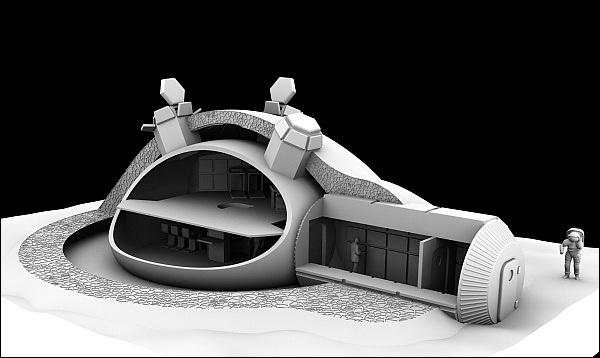

Pictured is a one and a half ton building block made by the D-Shape printer as a demonstration. For printing, we used 99.8% material similar to regolith obtained from the basaltic rocks of one of the volcanoes in central Italy. The print head of a 3D printer walks along a six-meter frame. The robot prints at a speed of 2 cubic meters per hour, the final version will print 3.5 cubic meters per hour. The construction of one small building will take about a week. On the render below ( larger version)

) can be considered in the details of the project of the European Space Agency. The base consists of four residential modules, of which the central and upper left modules are already completed, and two more are in the final stages of construction. Residential modules are connected by tunnels; each of them has four portholes. The approximate size of the base can be estimated in comparison with the astronaut, who stands next to the central module. It will be rather sad if the technology of 3D printing of buildings using computer models first starts on the Moon, and only then reaches the Earth. However, the D-Shape printer recently appeared on the news when a building design in the shape of a Mobius ring won the architectural competition.

. They promise to build this house in 2015, it can become the first residential building on the planet, fully printed on a 3D printer.

Mobius ring-shaped building