The second life of the old watch

In continuation of my acquaintance with LaunchPad mps430, I propose an article on restoring the operability of old wall pendulum clocks.

Caught in the hands of the old pendulum wall clock with a battle of 1952 release. The mechanism had traces of repair and was a disappointing sight. In watches of this class, unlike mechanical watches, the axis of the gears does not rotate in stones (rubies) but in the holes of brass plates. This, with continuous operation and the absence of regular lubrication, leads to an increase in gear backlash in the seat. The backlash accumulates in proportion to the number of gears, and the clock eventually stops walking. I don’t know how it is treated according to science, but my watch left marks from the core in the area of the seats, thus, apparently, they tried to reduce the diameter of the broken holes. In general, I did not begin to restore the fully mechanical course.

It was decided to replace the spring stroke with an electromechanical one, while maintaining the same functionality, namely, displaying time and battle, as well as adding new features.

For work, we will need: a pair of stepper motors from the printer, RTC, a controller, keys for controlling motors, an ionistor for storing parameters and counting time in the absence of external power supply, well, the little things ...

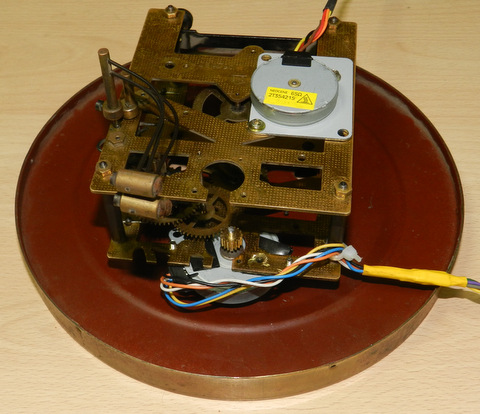

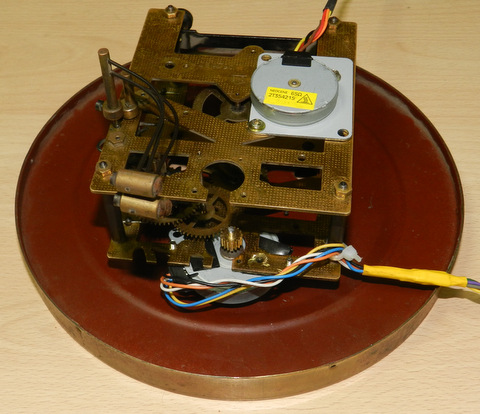

Mechanically, it looks like this:

Initially, the watch had 2 springs, one Chassis, second for battle, a pendulum that ensures accuracy and so on. Afterretrieving unnecessary partsmodernization left minute and hour gear + running step, as well as several gears, hammers and a step, controlling the battle. In the picture above, the running motor, below - the "combat". A separate dance with a tambourine was obtained when calculating the number of steps of the running motor to move the arrow for 1 minute. Since printer manufacturers do not take into account the gear ratios of old Soviet watch gears (I used gears mounted on motor shafts by printer manufacturers), it turned out that it takes 14 half steps to move the hands for a minute, and 16 half steps every 25 minutes so that time testimony did not float away. With a fight easier. For a strike, 3 engine revolutions were needed (576 half-steps).

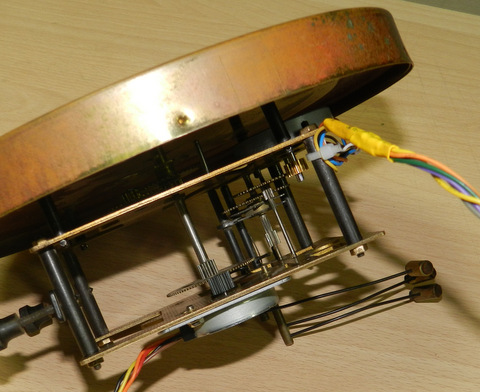

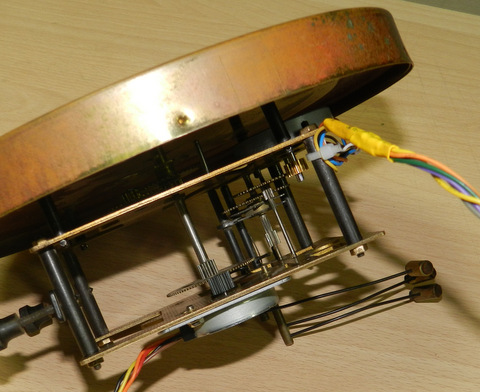

Here is another picture:

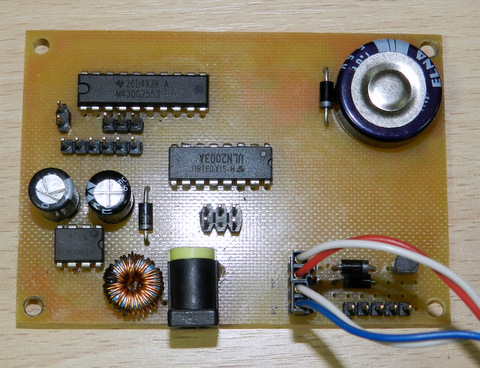

Further electronics.

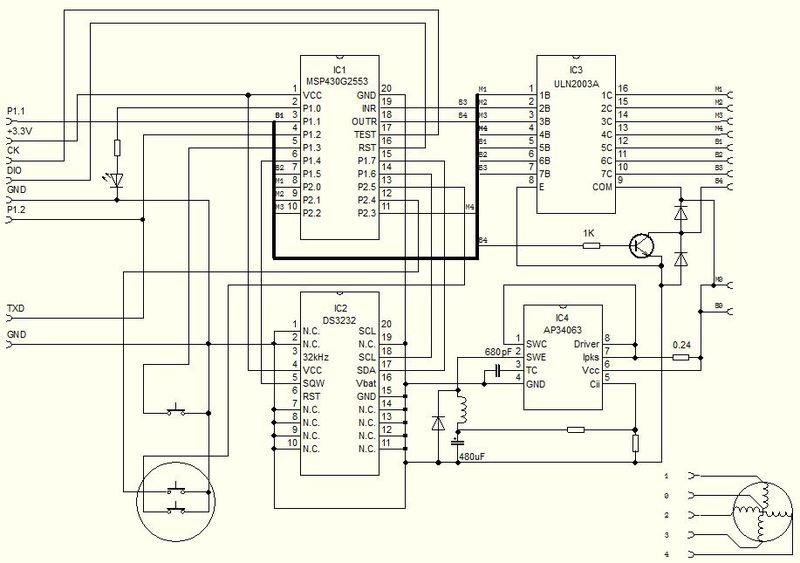

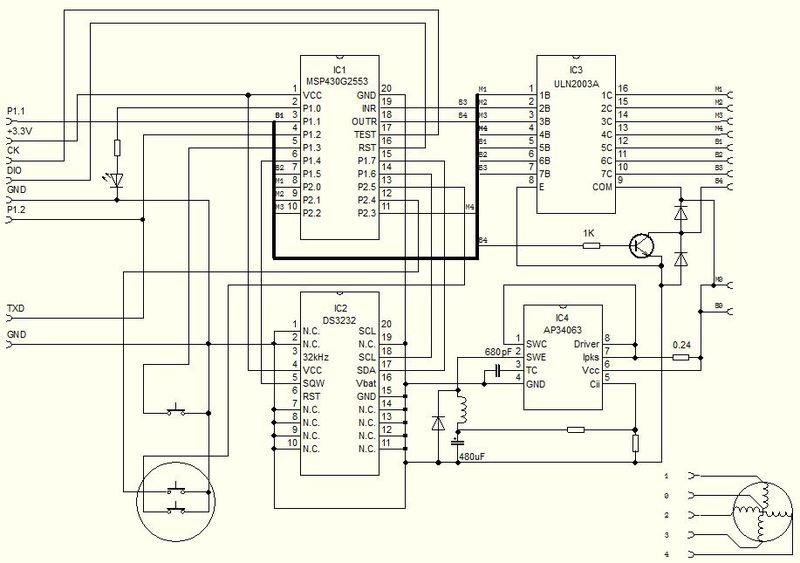

Here is the diagram:

As an RTC, I ordered Extremely Accurate I²C RTC literally on ebay , which means “terribly accurate”. The terrible accuracy of the datasheet is determined by the built-in quartz and a temperature sensor that connects / disconnects correction capacities to / from the quartz. In principle, when checking the accuracy of the course, I was pleased with the result. For a week I did not notice leaving for more than a second.

The controller is our beloved msp430g2553, the oldest from the TI launchpad set. It carries on board 2 hardware serial interfaces, one of them will communicate with RTC via I2C, the second will dump debug information to the computer via RS232.

Low-current motors (not that they are not accurate, but that they consume little current), the 7-channel transistor module ULN2003A is quite suitable for control. True, you need 8 channels, but there were no other modules in the magic chest, so the 8th channel was assembled on a BC547C transistor and a pair of Schottky diodes that protect against reverse induction. On verification, it turned out that 5V is enough to power the motors.

On 34063, a DownStep DC-DC voltage converter from 5 and above (within reasonable limits) to 3.3V is assembled for RTC and msp430.

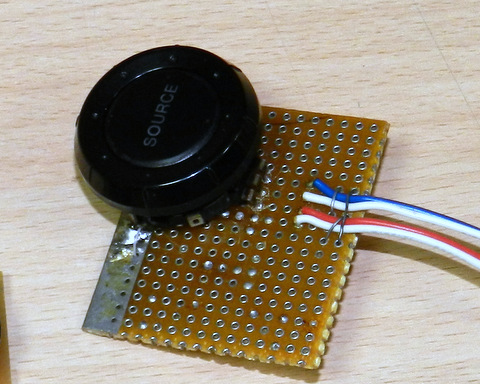

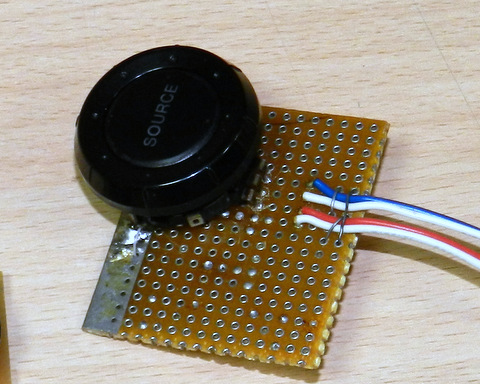

A mechanical encoder from the body of an old, deceased radio was amputated as a control element. In the diagram it is shown as 2 buttons in a circle (encoder itself). Its central button is also involved. To tighten its outputs to power, we will use the internal resistors msp430.

For feedback (reaction to control) we add an LED.

Here it is time to describe the conceived feature. RTC has built-in memory stored on batteries and accessible like other registers via I2C. The idea is as follows. Since we have a stepping motor, we can, knowing the reference point, understand the position of the arrows at the moment and store this position in the RTC memory. When the external power is turned off, RTC continues to count the time and store data on the last position of the hands. When the power returns, we take the old position from the memory, the current time, consider the difference, and bring the arrows to the current time. Those. it turns out a watch with an automatic drive.

The reference point is set by setting the arrows at 12:00 and long pressing the central button of the encoder.

Next, the encoder sets the current time and at the beginning of the sixth signal, briefly pressing the central button synchronizes (the clock connects the current position of the hands and the internal time RTC).

Here is a video of the half-hour battle and the operation of the encoder:

After this procedure, we have every right to provide sound accompaniment to the move, namely the battle. Every hour we will beat the corresponding number of times, every half hour 1 time, but at a higher speed. Actually, 1 blow is actually a blow of one hammer and the subsequent blow of two more. In the video you can hear.

To carry out a quality battle, we also need to know the relative position of the main gear that controls the hammers. To do this, when you turn on the power, we carry out "parking". We twist the battle motor in the opposite direction until it stops. Fortunately, the motor is weak, and when this stop is reached, it just starts to hum. After that, using the empirically obtained number of steps, we bring the “combat” gear to the desired position.

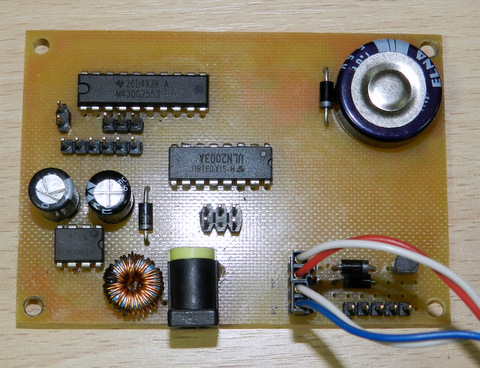

The fee is made in part by LUT. If it weren’t for the SOIC RTC case, I would do it as usual on the installation. And so, I left a place under the loose, that's what happened: the

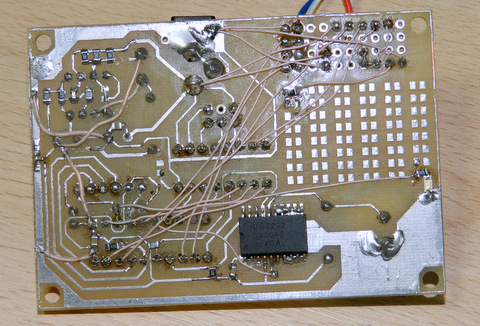

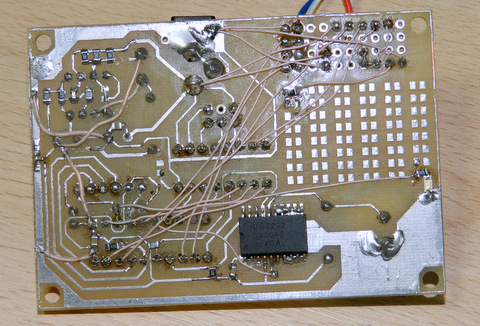

reverse side:

The program is written in C under CCS5

Here are the sources: The

picture must be opened by winrar.

The style of the watch, with the exception of the amputation of the pendulum, is preserved.

Total:

1. Revived the old watch

2. Added new features

3. Pumped mechanics, electronics and coding.

Caught in the hands of the old pendulum wall clock with a battle of 1952 release. The mechanism had traces of repair and was a disappointing sight. In watches of this class, unlike mechanical watches, the axis of the gears does not rotate in stones (rubies) but in the holes of brass plates. This, with continuous operation and the absence of regular lubrication, leads to an increase in gear backlash in the seat. The backlash accumulates in proportion to the number of gears, and the clock eventually stops walking. I don’t know how it is treated according to science, but my watch left marks from the core in the area of the seats, thus, apparently, they tried to reduce the diameter of the broken holes. In general, I did not begin to restore the fully mechanical course.

It was decided to replace the spring stroke with an electromechanical one, while maintaining the same functionality, namely, displaying time and battle, as well as adding new features.

For work, we will need: a pair of stepper motors from the printer, RTC, a controller, keys for controlling motors, an ionistor for storing parameters and counting time in the absence of external power supply, well, the little things ...

Mechanically, it looks like this:

Initially, the watch had 2 springs, one Chassis, second for battle, a pendulum that ensures accuracy and so on. After

Here is another picture:

Further electronics.

Here is the diagram:

As an RTC, I ordered Extremely Accurate I²C RTC literally on ebay , which means “terribly accurate”. The terrible accuracy of the datasheet is determined by the built-in quartz and a temperature sensor that connects / disconnects correction capacities to / from the quartz. In principle, when checking the accuracy of the course, I was pleased with the result. For a week I did not notice leaving for more than a second.

The controller is our beloved msp430g2553, the oldest from the TI launchpad set. It carries on board 2 hardware serial interfaces, one of them will communicate with RTC via I2C, the second will dump debug information to the computer via RS232.

Low-current motors (not that they are not accurate, but that they consume little current), the 7-channel transistor module ULN2003A is quite suitable for control. True, you need 8 channels, but there were no other modules in the magic chest, so the 8th channel was assembled on a BC547C transistor and a pair of Schottky diodes that protect against reverse induction. On verification, it turned out that 5V is enough to power the motors.

On 34063, a DownStep DC-DC voltage converter from 5 and above (within reasonable limits) to 3.3V is assembled for RTC and msp430.

A mechanical encoder from the body of an old, deceased radio was amputated as a control element. In the diagram it is shown as 2 buttons in a circle (encoder itself). Its central button is also involved. To tighten its outputs to power, we will use the internal resistors msp430.

For feedback (reaction to control) we add an LED.

Here it is time to describe the conceived feature. RTC has built-in memory stored on batteries and accessible like other registers via I2C. The idea is as follows. Since we have a stepping motor, we can, knowing the reference point, understand the position of the arrows at the moment and store this position in the RTC memory. When the external power is turned off, RTC continues to count the time and store data on the last position of the hands. When the power returns, we take the old position from the memory, the current time, consider the difference, and bring the arrows to the current time. Those. it turns out a watch with an automatic drive.

The reference point is set by setting the arrows at 12:00 and long pressing the central button of the encoder.

Next, the encoder sets the current time and at the beginning of the sixth signal, briefly pressing the central button synchronizes (the clock connects the current position of the hands and the internal time RTC).

Here is a video of the half-hour battle and the operation of the encoder:

After this procedure, we have every right to provide sound accompaniment to the move, namely the battle. Every hour we will beat the corresponding number of times, every half hour 1 time, but at a higher speed. Actually, 1 blow is actually a blow of one hammer and the subsequent blow of two more. In the video you can hear.

To carry out a quality battle, we also need to know the relative position of the main gear that controls the hammers. To do this, when you turn on the power, we carry out "parking". We twist the battle motor in the opposite direction until it stops. Fortunately, the motor is weak, and when this stop is reached, it just starts to hum. After that, using the empirically obtained number of steps, we bring the “combat” gear to the desired position.

The fee is made in part by LUT. If it weren’t for the SOIC RTC case, I would do it as usual on the installation. And so, I left a place under the loose, that's what happened: the

reverse side:

The program is written in C under CCS5

Here are the sources: The

picture must be opened by winrar.

The style of the watch, with the exception of the amputation of the pendulum, is preserved.

Total:

1. Revived the old watch

2. Added new features

3. Pumped mechanics, electronics and coding.