Printing on a 3D printer. 3Dtool's Secret Experiences

Good day! 3Dtool is

with you . Today we’ll talk about the “fill” parameter aka “ infill ” in the slicer settings. In the arsenal, we still have the same Hercules Strong on the hardware side and Slic3r on the software side. Task: it is necessary to find out reasonably and objectively which of the filling types is the most optimal (the most durable and fast). Go…

We print one simple model with all possible types of filling.

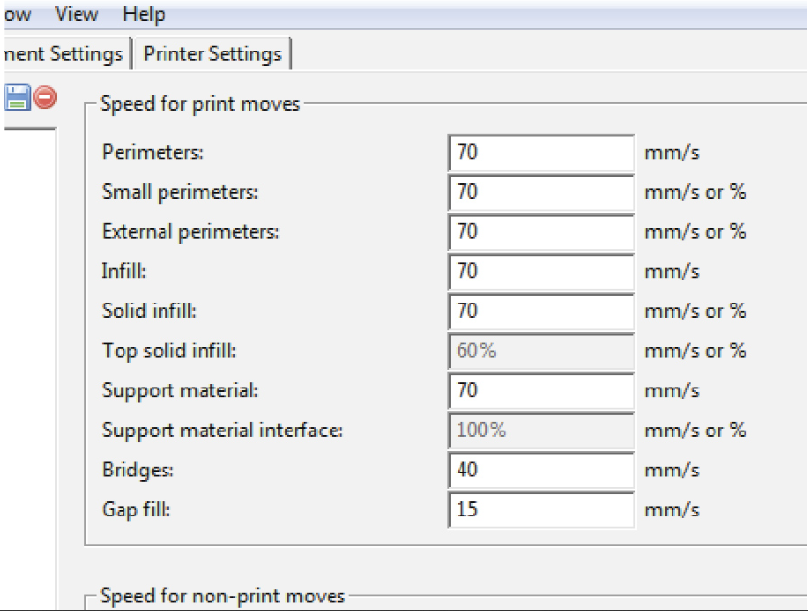

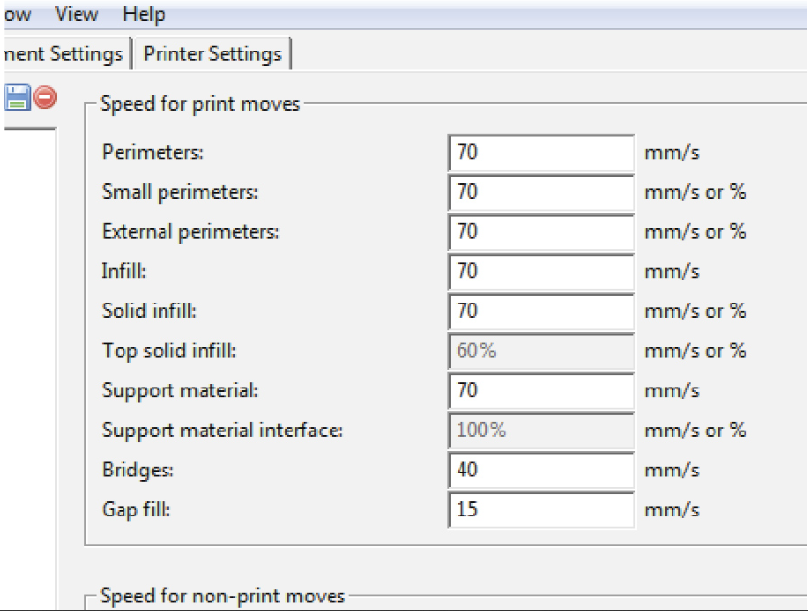

PLA, nozzle diameter 0.5 mm, layer height 0.2 mm, filling everywhere 10%, speed 70 mm / s (!)

Part size: 69mm * 63mm * 4 mm

Next, we took three different parts for comparison: a simple model: a 60 x 60 x 60 mm cube, our printed simple part and a complex large part, and we compared the printing time.

PLA material, nozzle diameter 0.5 mm, layer height 0.2 mm, filling density everywhere 10%.

On fillings such as Line and Rectilinear , where the filaments are printed perpendicular to each other, extrusion at a speed of 70 mm / s breaks. The thread hooks onto the thread of the previous layer and breaks, resulting in holes, which can adversely affect the strength of the part. Therefore, it is better not to use these types of filling at high speeds, or to reduce the print speed to approximately 40 mm / s.

Filling Hilbert is the Curve , Archimedean Chords , Octagram Spiral and Concentricprint quickly, but we could not figure out their purpose. It may be possible to print puzzles and roll balls from bearings in the maze. It is also possible that these types will be useful for printing layouts where strength characteristics are not so important. Maybe someone else has ideas?

Parts with Honeycomb , 3D Honeycomb , Cubic , Stars, and Triangles fillings turned out to be the most durable, but the density of the Cubic , Stars and Triangles fillings is visually lower than that of Honeycomb and 3D Honeycombdespite a single value of 10%. If we need to get a denser grid (15-20%), the print time will also increase accordingly. 3D Honeycomb

wins in print quality at a speed of 70 mm / s, in print time and in strength . Here is the result. We hope this experience will be useful to you. Catalog of 3D printers 3D printer Hercules Strong 17 Do not forget to subscribe to our social networks: INSTAGRAM VKontakte Facebook Our Youtube channel

with you . Today we’ll talk about the “fill” parameter aka “ infill ” in the slicer settings. In the arsenal, we still have the same Hercules Strong on the hardware side and Slic3r on the software side. Task: it is necessary to find out reasonably and objectively which of the filling types is the most optimal (the most durable and fast). Go…

First stage

We print one simple model with all possible types of filling.

PLA, nozzle diameter 0.5 mm, layer height 0.2 mm, filling everywhere 10%, speed 70 mm / s (!)

Part size: 69mm * 63mm * 4 mm

Types of filling:

Next, we took three different parts for comparison: a simple model: a 60 x 60 x 60 mm cube, our printed simple part and a complex large part, and we compared the printing time.

PLA material, nozzle diameter 0.5 mm, layer height 0.2 mm, filling density everywhere 10%.

Comparison table

On fillings such as Line and Rectilinear , where the filaments are printed perpendicular to each other, extrusion at a speed of 70 mm / s breaks. The thread hooks onto the thread of the previous layer and breaks, resulting in holes, which can adversely affect the strength of the part. Therefore, it is better not to use these types of filling at high speeds, or to reduce the print speed to approximately 40 mm / s.

Filling Hilbert is the Curve , Archimedean Chords , Octagram Spiral and Concentricprint quickly, but we could not figure out their purpose. It may be possible to print puzzles and roll balls from bearings in the maze. It is also possible that these types will be useful for printing layouts where strength characteristics are not so important. Maybe someone else has ideas?

Parts with Honeycomb , 3D Honeycomb , Cubic , Stars, and Triangles fillings turned out to be the most durable, but the density of the Cubic , Stars and Triangles fillings is visually lower than that of Honeycomb and 3D Honeycombdespite a single value of 10%. If we need to get a denser grid (15-20%), the print time will also increase accordingly. 3D Honeycomb

wins in print quality at a speed of 70 mm / s, in print time and in strength . Here is the result. We hope this experience will be useful to you. Catalog of 3D printers 3D printer Hercules Strong 17 Do not forget to subscribe to our social networks: INSTAGRAM VKontakte Facebook Our Youtube channel