NASA has developed a technology for 3D printing of spare parts for spacecraft

The dream of 3D prototyping fans is becoming a reality. NASA has developed and tested technology that allows the manufacture of metal objects of any shape right on board the spacecraft.

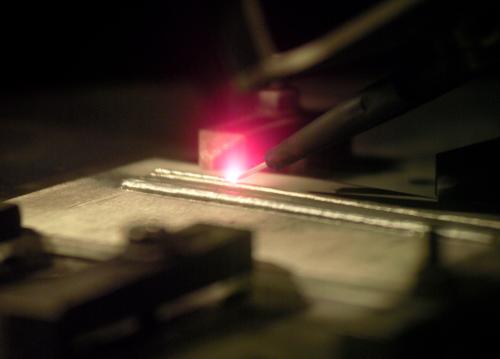

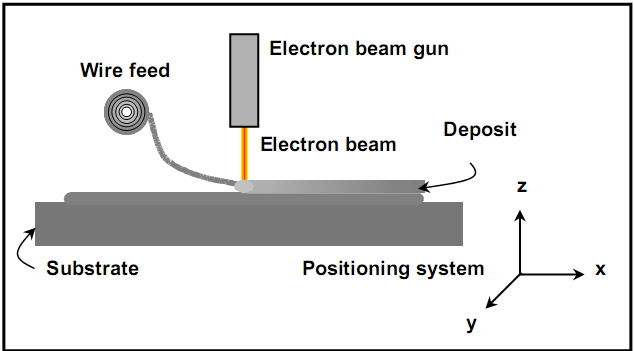

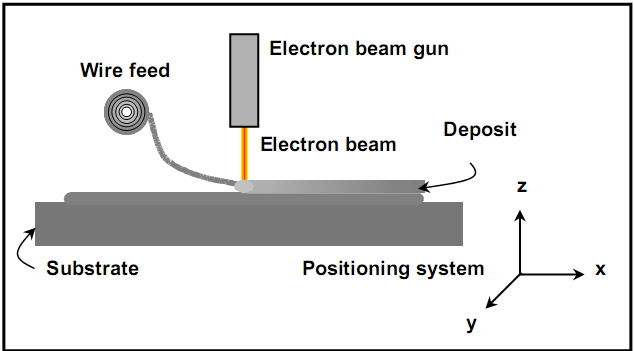

This technology is called the “Electron Beam Process for Creating Arbitrary Shape" ( Electron Beam Freeform Fabrication EBF3) and is a mixture of 3D printing and electronic welding. Using an electron beam, the metal filament is heated to its melting point and the molten material is laid layer by layer on a substrate according to a computer model.

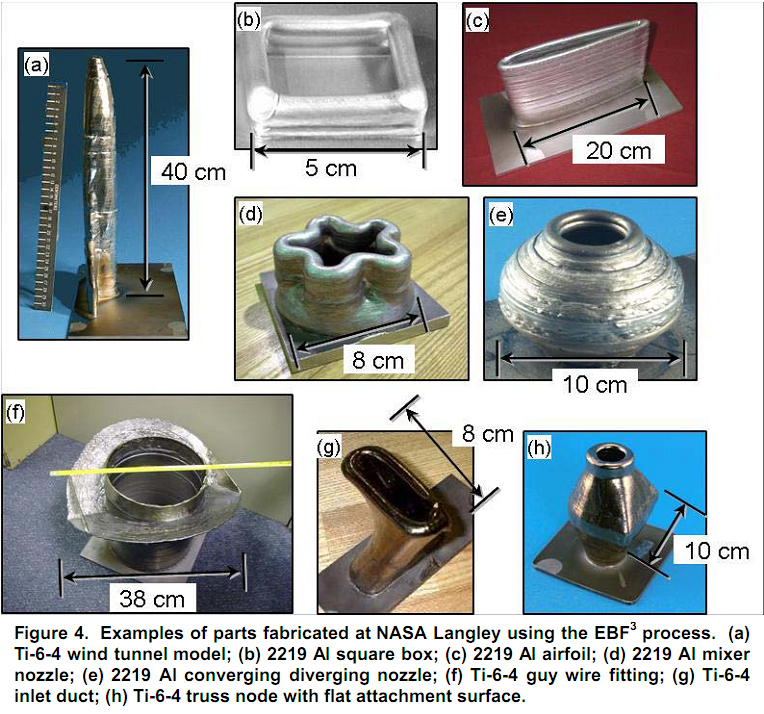

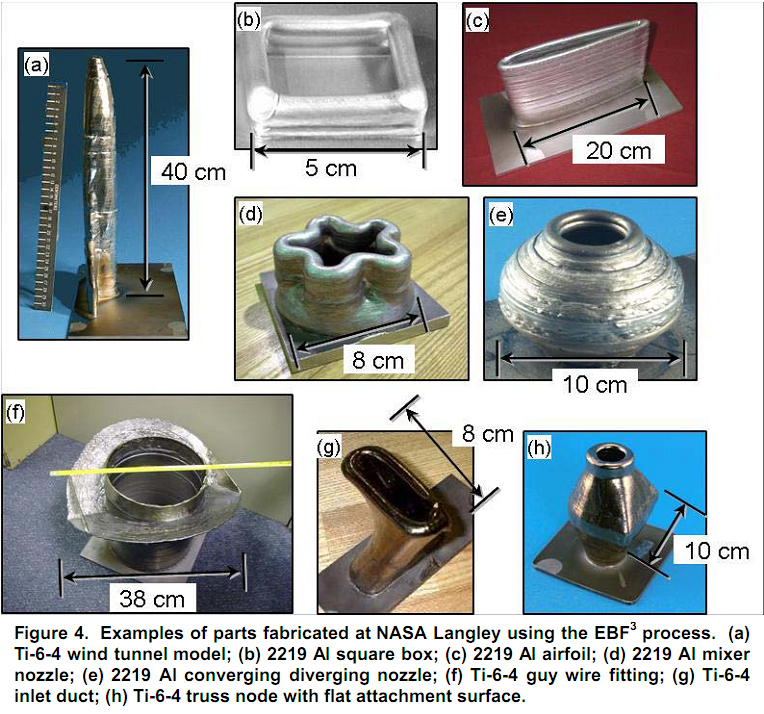

For printingspaceshipsmetal parts developers used alloys based on aluminum, titanium and nickel, as the most commonly used in the aerospace industry. In particular, wires with a thickness of 1.6 mm (an alloy based on aluminum) and 2.4 mm (an alloy based on titanium) were used. What they did can be seen in the following figure.

As you can see here, the spatial resolution of this technology leaves much to be desired. Indeed, what can be expected from a titanium wire with a diameter of 2.4 mm, because when melted, the metal also spreads. But let's hope that this process will still scale to acceptable values in industry (especially aerospace). After all, the test sample of the installation, on which experiments were carried out under microgravity conditions (for which it was loaded onto an airplane and forced to swirl at high altitude) is not so compact.

In any case, the next team plans to create a facility that can be delivered to the ISS and already conduct an experiment on its board. And for this, its weight and dimensions will have to be significantly reduced, since each kilogram of cargo launched into orbit costs considerable funds.

The developers create their own printing machine in order to eliminate the need to deliver spare parts for it to the station, because why are they needed if each can be printed on site, there would only be source material. You can still dream up and imagine in the distant (or not so) future plants, for example, in the asteroid belt, which will build spaceships from the extracted material.

We will hope that this technology will enter the open market as soon as possible, because the demand for it is already very large. And everyone will have the opportunity to print a bicycle, a car or an army of killer robots ...

Prepared from Phys.Org

This technology is called the “Electron Beam Process for Creating Arbitrary Shape" ( Electron Beam Freeform Fabrication EBF3) and is a mixture of 3D printing and electronic welding. Using an electron beam, the metal filament is heated to its melting point and the molten material is laid layer by layer on a substrate according to a computer model.

For printing

As you can see here, the spatial resolution of this technology leaves much to be desired. Indeed, what can be expected from a titanium wire with a diameter of 2.4 mm, because when melted, the metal also spreads. But let's hope that this process will still scale to acceptable values in industry (especially aerospace). After all, the test sample of the installation, on which experiments were carried out under microgravity conditions (for which it was loaded onto an airplane and forced to swirl at high altitude) is not so compact.

In any case, the next team plans to create a facility that can be delivered to the ISS and already conduct an experiment on its board. And for this, its weight and dimensions will have to be significantly reduced, since each kilogram of cargo launched into orbit costs considerable funds.

The developers create their own printing machine in order to eliminate the need to deliver spare parts for it to the station, because why are they needed if each can be printed on site, there would only be source material. You can still dream up and imagine in the distant (or not so) future plants, for example, in the asteroid belt, which will build spaceships from the extracted material.

We will hope that this technology will enter the open market as soon as possible, because the demand for it is already very large. And everyone will have the opportunity to print a bicycle, a car or an army of killer robots ...

Prepared from Phys.Org