Frost on glass: how to make heavy-duty metglass plastic

Metglass - metal glasses - is almost an ideal material: durable, solid, corrosion-resistant, like glass, while resilient, like metal. Today they are used in various fields: from magnetic materials and medical instruments, to transformer cores, micromotor gears and sports equipment.

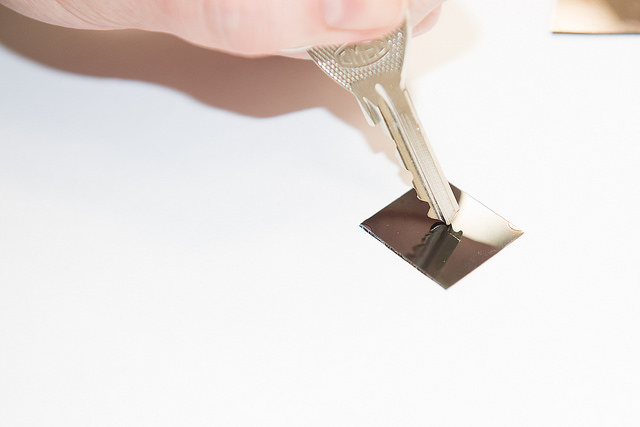

However, to ideality, the metglass still lacks plasticity. This drawback eliminates the "rejuvenation" - the transfer of material into a higher energy state, increasing its resistance to plastic deformation without loss of strength.

Scientists of NUST “MISiS” with the help of cryothermal treatment were able to freeze metal glass so that it became more “flexible” without losing its remarkable strength. For this, the method of cyclic cooling in liquid nitrogen was applied. The resulting material with optimized properties can be in demand in modern engineering and energy.

Artem Trifonov, Ph.D., engineer, Department of Non-ferrous Metals Metals, National University of Science and Technology “MISiS”: “We found that the use of cryothermal cycles can stimulate“ rejuvenation ”of some glasses and relaxation (reverse rejuvenation process) of others, depending on the composition ".Cryothermal treatment also sharply increases the ability of the material to resist stretching and compression during elastic deformation on the surface of the samples (in a thin layer of tens of nanometers). This effect, however, disappears after exposure to glass at room temperature. The volumetric effect is retained over time and can improve the ductility of the alloy.

“Cryothermal processing seems to be a universal and simple method for changing the properties, rejuvenation or relaxation of metal glasses. It’s important that it can both improve and worsen ductility - this requires a careful selection of the alloy composition, based on the structure of atomic bonds in the material, ”says Artem Trifonov.According to the authors, they will continue to study the effect of such processing on the structure and properties of different materials. The “taming” of the process will make it possible to plasticize not only bulk metal glasses, but also composites of the “metal glass-crystal” type (whose “rejuvenation” can manifest itself even more due to the greater heterogeneity of the structure). An article about the study was published in the journal NPG Asia Materials.