CNC in the hobby workshop (part 1)

→ First part

→ Second part

→ Third part

The work of a programmer has one major drawback: as a rule, we cannot touch the result of our work. We can enjoy the beauty of the code, admire the originality of the algorithm, but, alas, we cannot touch the program. This nuance of the profession has always upset me. In order to somehow compensate for the virtuality of the result in the main field of activity, a few years ago I got myself quite a tangible hobby - carpentry. At first everything went well, but very soon the professional illnesses of any programmer began to show up - laziness and perfectionism. Especially, I finished off the fact that when it was necessary to make 10 identical parts I could not make one qualitatively and copy it 9 more times. In general, you understand, after a while, CNC appeared in the workshop. This story is about two years of experience owning this miracle of technology.

Flour choice

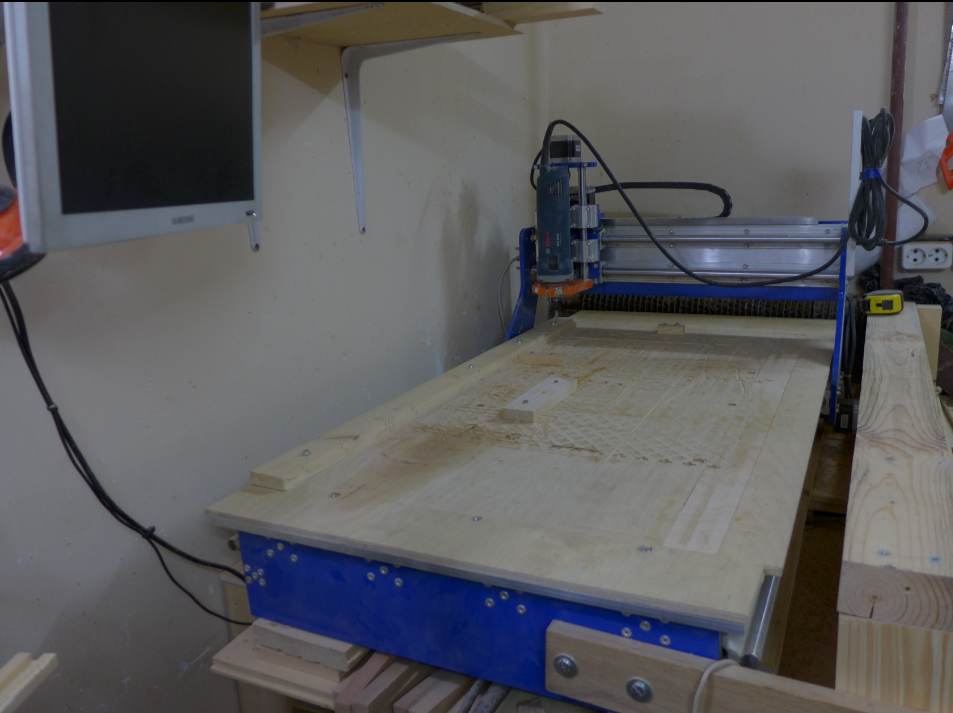

Having decided to acquire a CNC machine, I faced a dilemma: buy ready or assemble a homemade one. I needed a unit of decent size, because plans to use it in furniture matters. But, on the other hand, I was severely limited in the choice of two things: the budget and the size of the workshop (I had 9 square meters, already pretty crowded). After careful measurements, it became clear that the device is more than a meter in length to deliver will be problematic. Accordingly, you need to look for an option with a table size meter by 50 - 60 centimeters.

Here are the main parameters of the choice:

- Table size 1000x500

- Good table and portal rigidity

- Rack and pinion in X and Y axes

The last point is important: for the carpentry business you need a good speed of moving the portal. Helical gear sooo slow.

After reading the thematic forums, it became clear to me that, having no experience with metal in the foreseeable future, a normal machine could not be made, and I didn’t want to use a long-term project with an unclear result either.

It remained to buy ready. Searching for something cheap in China did not seem logical - the delivery of 80-100 kilograms of iron promised to fly a pretty penny. I monitored Avito for several months, but they either sold large industrial machines or small, not very high-quality homemade products.

After studying the Moscow market of CNC manufacturers, I found 3 companies more or less in my budget (I describe the events two years ago, now the situation may be different). In order not to upset UFOs, I will not give their names. A machine with suitable characteristics was found at one of these 3 manufacturers. On the thematic forums, reviews about this manufacturer were not the most flattering, but there were also frankly abusive ones. The main message of the feedback was “Components - China, the service is bad, but for this price there is nothing better”. By the way, "this price" of the router with the spindle was in the region of 115k forever wooden ...

Purchase

Price bite and I was not sure whether I want these victims. But a case helped: quite unexpectedly, they paid me one old project in which I had already put up a cross. The amount approximately corresponded to the cost of the machine. It was a sign from above, on the same day made an order and transferred 50% of the cost to the manufacturer.

A month later, I went to pick up my device. The company was located on the territory of a plant. It seems that the demand for CNC in Moscow is good: in addition to my machine tool, there were a dozen other smaller machines in the corridor.

The first launch and the first bummer

For the machine still need a computer. I found an old Pentium4 with an LPT port in my bins. Being in the soul of the linux user as the control software, I chose CNC Linux (http://www.linuxcnc.org/). It was quickly downloaded / installed distribution. I turn on the toggle switch with some excitement, the machine tool responded with an optimistic buzz.

Here it is the future, already near! I press Reset and try to move the carriage with the cursor keys. Then the first bummer happened: on the Y and Z axes, everything works fine, but with X there are serious problems. The fact is that in my machine on the X axis two stepper motors (one each on the right and left guides) and when I tried to move, one of them turned, and the other stood dead. Thus, the native config that came with the machine did not work in the CNC Linux environment.

The next few hours were spent in learning forums and smoking docks. But the maximum of what was achieved was that both footsteps moved in, but they did it reluctantly and at different speeds. By a non-characteristic sound and by the way the portal is jerking, at some point, I realized that at this rate I would soon break, to hell, this expensive piece of iron and with effort of will stopped the experiments with CNC Linux.

Mach3

Next weekend, continued attempts to start the machine. This time clearly followed the instructions of the manufacturer. Installed Microsoft Windows for Legacy PCs, turned off almost all services, turned off the screensaver and power saving. Put Mach3. Loaded config. And a miracle happened, the machine earned.

Second bummer

The trouble happened about a couple of weeks after the successful launch. I left the machine on in standby mode, and he walked away for a couple of minutes. Upon my return, an unpleasant surprise awaited me, the machine behaved like Schwarzenegger-Terminator when Kristanna Loken infected him with nano-robots. The portal jerked erratically in convulsions. I quickly de-energize the device. A few minutes later turned on. Everything was quiet, but after 5 minutes the nano-robots returned.

Mood slid somewhere under the plinth. I vividly imagined a trip through the whole of Moscow to a service center. Yes, and just pull a 70 pound piece of iron from a cramped basement is still a pleasure.

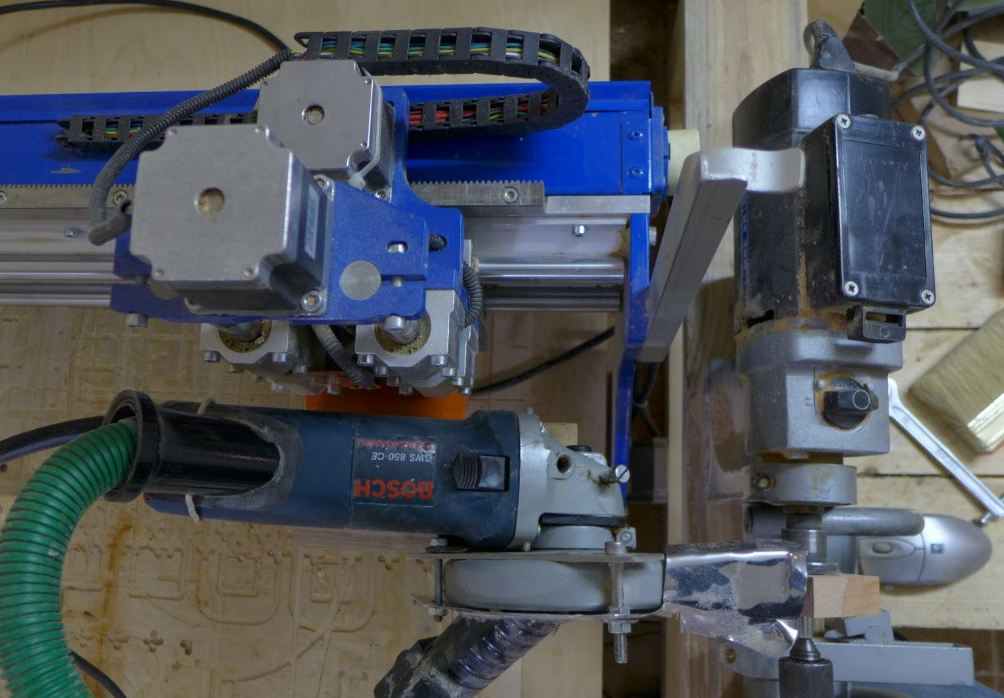

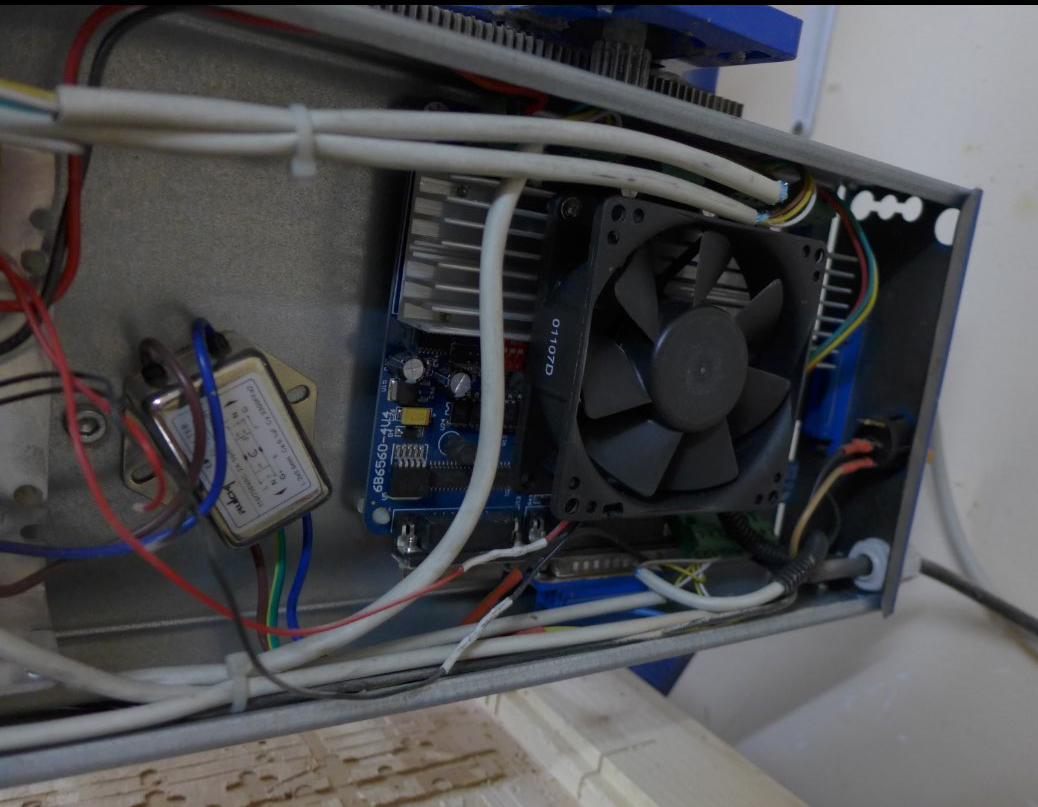

To clear my conscience, I decided to take a look at the Chinese guts. In my CNC, all the electronics are mounted on the back of the portal. Open the box was not difficult. Under the lid there are 2 blocks - the power unit and the control unit. The latter immediately aroused suspicion. More precisely, not the block itself, but what was on it. It had 2 very suspicious fans. None of them turned on when power was applied! Opening one of them shocked me a little. The impression is that the Chinese have cast him in one piece

Both fans were sent to the trash (unfortunately, I did not take a picture then) their place was taken by one large cooler from a computer power supply.

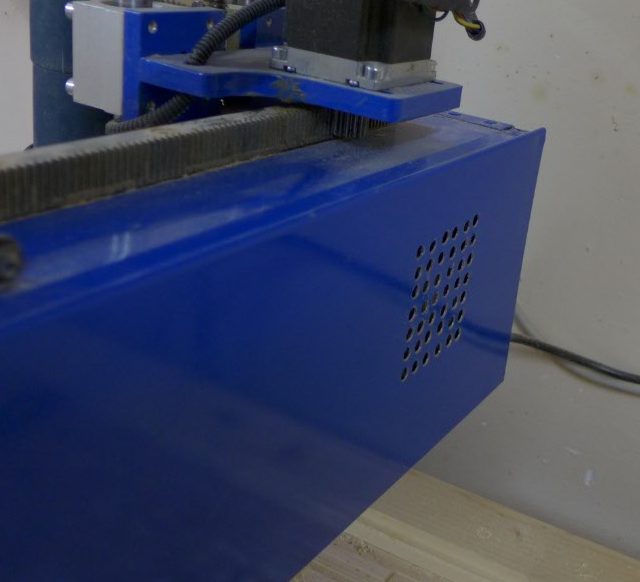

For better cooling in the back cover, I drilled holes:

Since then, for more than two years now, the machine electronics has not caused any problems. The rhetorical question: why it could not be taken into account in production? Issue price - 100 rubles. I do not think that I am the only one who has encountered such a problem ...

Computer

Separately, I want to talk about the control computer. As I wrote above, initially, I connected the machine to an old Pentium4. Now I don’t remember what chipset it was on,

for its time it was a good machine. From the very first days small problems began to be observed. As a rule, they consisted in single passes of steps. It was also very annoying that the “0” along the Z axis was slowly but surely “floating away”. This was especially noticeable with a large number of repetitions. For example, when I made screens on batteries, I needed to make several hundred shaped holes in a plywood sheet. Somewhere in the middle of the work "0" in Z, I "went" down a centimeter, drilling through the sacrificial table.

At that moment, I sinned on the machine controller, after all, until I changed my own coolers, it seriously overheated for me a couple of times. But after a while, I paid attention to the pattern. Sometimes, when the computer was turned on, the following effect was observed: when launching any application in Windows, first the screen went out for a couple of seconds, then the application was started. If such an effect took place, then the machine worked as he wanted - he missed steps, lost “0”. To remedy the situation, it was enough to reboot the computer. If after the restart this effect was not observed, everything worked as it should.

To deal with this there was neither the time nor the desire. I just overloaded the computer if the screen blinked when starting Mach3. This went on for a long time. But from a certain moment I began to understand that something was happening with the computer. In the beginning, one reboot at the start was enough. But over time, to start the system in normal mode, I had to do 5-6 restarts. Well, to top it all off, the keyboard began to “fly off”. It was treated by removing / inserting a usb-connector. In general, it is understood that the computer should go to the dump.

I decided not to experiment anymore and buy what the manufacturer recommends. A manufacturer strongly advised to find something on the old Intel Atom. The task seemed to me elementary. The bold plan was to go to the humpback and in 20 minutes buy for 2 kopeks what I needed. Enthusiasm quickly vanished in the face of harsh reality. I climbed the whole Gorbushkin yard, all the commissions found there, I couldn't find the atom with lpt.

Next was Avito. I called around a dozen vendors who had an intel atom in the ad, the result is the same: as soon as they found out that I needed an atom with lpt, the conversation ended. But whoever seeks will find, after long ordeals, I finally found a benefactor who had a new (!) Fee on the Atom D2700 with LPT, and even for ridiculous 2500r.

After replacing the computer, a holiday finally came: the machine started working like a clock, the steps are not skipped, “0” stands as nailed. Since then, my CNC began to bring extremely positive emotions.

At the end of the first part. The second will be entirely devoted to mechanics. About how I managed to adapt an ordinary CNC router to solve problems that are not typical for him. I promise it will be interesting.

The second part of