How we did 3D photos

A few years ago, on the site pleer.ru, I met photos of goods that could be rotated, viewed from all sides. I was very impressed. Periodically, I have seen similar services on other sites. Since I myself am a photographer, at some point I suggested to my friend to create a studio to make such videos here. A friend was very impressed with the idea and we began to think.

In this article I will try to tell how to do this technically, what difficulties may arise and what you need to pay attention to if you want to do this.

I do not pretend to be universal solution. Just tell you how we did it.

So, first of all, it was necessary to do “something” on which we could rotate our objects. It was necessary to do it taking into account that the objects can be of completely different sizes: from the phone to the motorcycle (the largest that we shot was a scooter and a person). It was decided to make a podium with a turntable. Among the friends we found kulibins who welded a 100x100cm frame from metal pipes with bolts instead of legs (so that the level could be leveled), in the center there was a steel pin, 2 cm in diameter, which rotated on bearings, and on this pin a platform was installed on which objects were already installed . Depending on the object, there could be a circle made of white plastic, glass or white painted wood (as if something heavy) as a platform.

The podium itself was laid out in 36 parts - so that the rotation of the site was 10 degrees. An arrow was attached to the pin to accurately measure degrees.

It is very important that the entire structure is heavy and does not move / stagger from the slightest impact. The podium was painted white, and a translucent black cloak could be placed on top if deep shadows were needed (translucent - to see the markings in degrees).

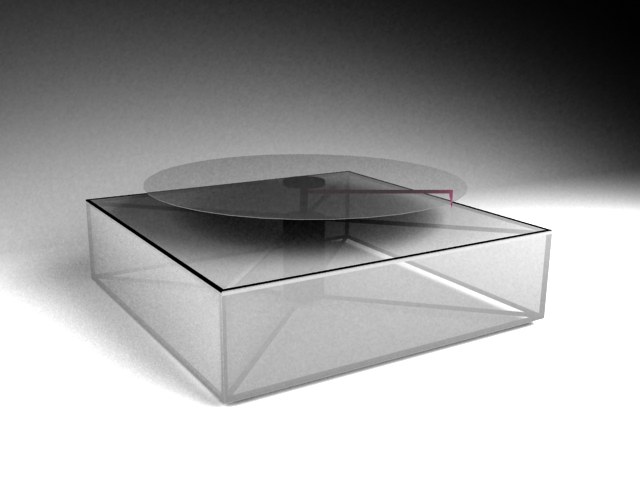

Unfortunately, I didn’t have any photos of the “live” design. I spread the render, which will allow us to imagine how it all looked:

with translucent walls, so that it was more understandable

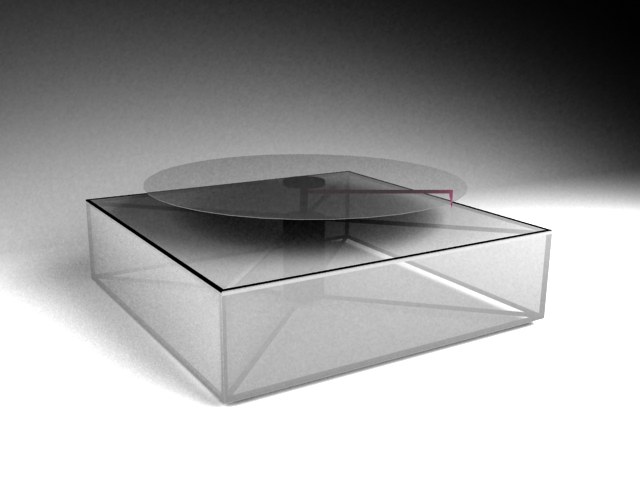

without walls, so that the frame was visible

The whole structure was stationary, because it is important to set everything as accurately as possible. Exhibited, having drawn a grid on the floor. Camera on a powerful tripod. The position of the legs of the tripod was marked on the floor. It is impossible to install the camera “once and for all”, because the subject can be very different in size, and, accordingly, you need a different distance from the camera to the object, different heights of the location of the camera, etc. Simply put, for each object (more precisely, a group of similar objects) anyway I had to adjust the entire system.

After the design was exposed, light was installed. As illuminators, we used impulse monoblocks Falcon Eyes. In my opinion, for such purposes, constant light is better. It will allow to achieve the most uniform illumination on all frames, since pulsed sources (especially budget ones) can give a small power plug. But, having estimated how much power we need permanent light sources and how much we will spend on electricity, it was decided to use pulsed sources. Monoblocks were placed on standard racks and soft boxes 50x50cm were bought for them. In total, 2 monoblocks with soft boxes for fill light and 2 monoblocks for background illumination were used.

Two backgrounds were made: black from non-woven material, because it absorbs light well and gives a very deep black color, and white - paper.

The walls of the studio, of course, turned black to avoid stray flashes.

A bunch of cameras (Canon 30D) was made with a laptop via Bluetooth and a phone. I already wrote about this . The camera is placed on manual focus, with a sufficiently large depth of field so as not to think about the accuracy and speed of focusing. The whole process was like this: put the object exactly in the center, focus, switch to manual focus. Click, frame is done. The platform rotates until the next division. And so 36 frames.

When we shot several objects in a row to determine where one ends and the second begins, I just did one shot with the lens closed. The working lenses were the Canon 17-40 f / 4 L USM and the Canon 70-200 f / 4 L IS USM.

Next came the most important point - you need to collect a single movie from a bunch of frames. We ordered from a freelancer to implement everything that we needed on a flash. Namely:

At first we inserted frames with our hands, but it was very dreary. Therefore, later it was made so that the flash drive was single, and picked up links to pictures from the XML file. This significantly accelerated the preparation of the final clips.

We tested our design on improvised things - telephones, televisions, toys. Then the first and very serious problem appeared. It was not possible to make a frame that could be inserted into the final movie without processing. To get into the exposition, remove traces of the site and fix all sorts of little things, the frames had to be edited. Separately, it is worth highlighting the problem of combating shadows. Now imagine how long it takes to edit everything. You can easily drive off. And if the order is for several hundred objects?

Here are examples of what happened “directly from the camera”, without processing: The

second serious problem was the question “how to fix this or that object”.

If a TV or a toy car can be delivered without problems, then with telephones, for example, such a trick will no longer pass.

You need to clearly understand the simple thing: it is one thing to make a single movie, another thing is the flow. Absolutely everything can be done. Spend a lot of effort on this, a lot of time, but do it. But putting this on the stream is much more difficult.

Example:A person selling Parker pens turned to us. He said that he was interested in this technology and he was ready to order rollers from us for all products (about 500 rollers). At the same time, the man wanted the handles to rotate in 2 planes. We thought for a very long time. We tried a huge number of solutions, how to fix the handle, how to rotate, but, alas, they could not find a universal solution. Making one video is easy. Tinkering, editing, it would be possible. But to make several hundred videos ... Either it would require a tremendous investment of time and effort (read - it would not pay off in any way), or nothing would have worked at all. We had to refuse the order.

After more or less everything was tested, tested and had an idea of what and how to do, we began to look for customers. They sent out offers, called shops that this offer might interest.

Quite a few were wondering if there was the possibility of offsite shooting. Yes, there was an opportunity, but for this it was necessary to allocate certain parameters for us. Customers could not find (or allocate) such a room and refused.

Quickly enough, we found a customer in the face of an online store selling toys. They gave us lots of robots, we calmly shot them. Everyone was satisfied.

After some time, we contacted a store selling samovars. They already had such videos on the site, but they were not satisfied with the previous artists and they decided to contact us. Working conditions with them were very difficult. They could give samples only at the weekend. On Saturday morning, we took 20-30 boxes of samovars and about 20 sets of tea sets, and on Sunday afternoon we took them back. Fortunately, my partner still had business and had the opportunity to connect a GAZelle for transportation.

To say that it was hard was to say nothing. Imagine, to make a storyboard, we needed to: open the box, unpack the samovar, wipe it, install, take off, pack, close the box. The vast majority of the time was occupied by this unpacking package. Plus mirror samovars. The slightest touch to it - and the imprint remains. I had to work with gloves.

Then it was necessary to process and prepare everything that was shot. At the same time, the distribution of offers and calls to potential customers continued. But if someone was interested, he was ready to make 2-3 videos. For many, the price of 500r per roller seemed very high. As a result, after working for about six months, we decided that this undertaking did not justify itself at all. We have not received any money from this. Therefore, it was decided to complete all current orders and close.

Like an epilogue.

In conclusion, I would like to touch on the topic of competition and share my thoughts on all this.

There were several studios that actively promoted their services of this kind. Among them was a terrible dumping. Some claimed that they were able to make 200-300 clips per day. In fact, they did an order of magnitude longer and worse (these are not my thoughts, but the reviews of their real customers). Others set the price at 150r per video, which did not fit our minds at all. On the topic of competitors now, I think you should not ask me questions. I am talking about the situation a year ago. What is happening now - I have no idea.

The following problems were with customers:

Personally, my opinion is that potential customers simply did not understand the advantages of this technology. Yes, we can assume that we did not work well and could not explain to them. But this technology has not received its distribution in principle. Unfortunately.

Here are examples of what we did (these are not the final videos, but rather the workers. The final ones are located at the customers.):

Robot

D-Rex

Samovar

And a bonus :)

18+

In this article I will try to tell how to do this technically, what difficulties may arise and what you need to pay attention to if you want to do this.

I do not pretend to be universal solution. Just tell you how we did it.

So, first of all, it was necessary to do “something” on which we could rotate our objects. It was necessary to do it taking into account that the objects can be of completely different sizes: from the phone to the motorcycle (the largest that we shot was a scooter and a person). It was decided to make a podium with a turntable. Among the friends we found kulibins who welded a 100x100cm frame from metal pipes with bolts instead of legs (so that the level could be leveled), in the center there was a steel pin, 2 cm in diameter, which rotated on bearings, and on this pin a platform was installed on which objects were already installed . Depending on the object, there could be a circle made of white plastic, glass or white painted wood (as if something heavy) as a platform.

The podium itself was laid out in 36 parts - so that the rotation of the site was 10 degrees. An arrow was attached to the pin to accurately measure degrees.

It is very important that the entire structure is heavy and does not move / stagger from the slightest impact. The podium was painted white, and a translucent black cloak could be placed on top if deep shadows were needed (translucent - to see the markings in degrees).

Unfortunately, I didn’t have any photos of the “live” design. I spread the render, which will allow us to imagine how it all looked:

with translucent walls, so that it was more understandable

without walls, so that the frame was visible

The whole structure was stationary, because it is important to set everything as accurately as possible. Exhibited, having drawn a grid on the floor. Camera on a powerful tripod. The position of the legs of the tripod was marked on the floor. It is impossible to install the camera “once and for all”, because the subject can be very different in size, and, accordingly, you need a different distance from the camera to the object, different heights of the location of the camera, etc. Simply put, for each object (more precisely, a group of similar objects) anyway I had to adjust the entire system.

After the design was exposed, light was installed. As illuminators, we used impulse monoblocks Falcon Eyes. In my opinion, for such purposes, constant light is better. It will allow to achieve the most uniform illumination on all frames, since pulsed sources (especially budget ones) can give a small power plug. But, having estimated how much power we need permanent light sources and how much we will spend on electricity, it was decided to use pulsed sources. Monoblocks were placed on standard racks and soft boxes 50x50cm were bought for them. In total, 2 monoblocks with soft boxes for fill light and 2 monoblocks for background illumination were used.

Two backgrounds were made: black from non-woven material, because it absorbs light well and gives a very deep black color, and white - paper.

The walls of the studio, of course, turned black to avoid stray flashes.

A bunch of cameras (Canon 30D) was made with a laptop via Bluetooth and a phone. I already wrote about this . The camera is placed on manual focus, with a sufficiently large depth of field so as not to think about the accuracy and speed of focusing. The whole process was like this: put the object exactly in the center, focus, switch to manual focus. Click, frame is done. The platform rotates until the next division. And so 36 frames.

When we shot several objects in a row to determine where one ends and the second begins, I just did one shot with the lens closed. The working lenses were the Canon 17-40 f / 4 L USM and the Canon 70-200 f / 4 L IS USM.

Next came the most important point - you need to collect a single movie from a bunch of frames. We ordered from a freelancer to implement everything that we needed on a flash. Namely:

- A flash drive into which frames were inserted alternately.

- Animation control buttons: start “rotation”, stop “rotation”, frame forward, frame back, slider for controlling the speed of “rotation”

- 1x, 2x zoom buttons.

At first we inserted frames with our hands, but it was very dreary. Therefore, later it was made so that the flash drive was single, and picked up links to pictures from the XML file. This significantly accelerated the preparation of the final clips.

We tested our design on improvised things - telephones, televisions, toys. Then the first and very serious problem appeared. It was not possible to make a frame that could be inserted into the final movie without processing. To get into the exposition, remove traces of the site and fix all sorts of little things, the frames had to be edited. Separately, it is worth highlighting the problem of combating shadows. Now imagine how long it takes to edit everything. You can easily drive off. And if the order is for several hundred objects?

Here are examples of what happened “directly from the camera”, without processing: The

second serious problem was the question “how to fix this or that object”.

If a TV or a toy car can be delivered without problems, then with telephones, for example, such a trick will no longer pass.

You need to clearly understand the simple thing: it is one thing to make a single movie, another thing is the flow. Absolutely everything can be done. Spend a lot of effort on this, a lot of time, but do it. But putting this on the stream is much more difficult.

Example:A person selling Parker pens turned to us. He said that he was interested in this technology and he was ready to order rollers from us for all products (about 500 rollers). At the same time, the man wanted the handles to rotate in 2 planes. We thought for a very long time. We tried a huge number of solutions, how to fix the handle, how to rotate, but, alas, they could not find a universal solution. Making one video is easy. Tinkering, editing, it would be possible. But to make several hundred videos ... Either it would require a tremendous investment of time and effort (read - it would not pay off in any way), or nothing would have worked at all. We had to refuse the order.

After more or less everything was tested, tested and had an idea of what and how to do, we began to look for customers. They sent out offers, called shops that this offer might interest.

Quite a few were wondering if there was the possibility of offsite shooting. Yes, there was an opportunity, but for this it was necessary to allocate certain parameters for us. Customers could not find (or allocate) such a room and refused.

Quickly enough, we found a customer in the face of an online store selling toys. They gave us lots of robots, we calmly shot them. Everyone was satisfied.

After some time, we contacted a store selling samovars. They already had such videos on the site, but they were not satisfied with the previous artists and they decided to contact us. Working conditions with them were very difficult. They could give samples only at the weekend. On Saturday morning, we took 20-30 boxes of samovars and about 20 sets of tea sets, and on Sunday afternoon we took them back. Fortunately, my partner still had business and had the opportunity to connect a GAZelle for transportation.

To say that it was hard was to say nothing. Imagine, to make a storyboard, we needed to: open the box, unpack the samovar, wipe it, install, take off, pack, close the box. The vast majority of the time was occupied by this unpacking package. Plus mirror samovars. The slightest touch to it - and the imprint remains. I had to work with gloves.

Then it was necessary to process and prepare everything that was shot. At the same time, the distribution of offers and calls to potential customers continued. But if someone was interested, he was ready to make 2-3 videos. For many, the price of 500r per roller seemed very high. As a result, after working for about six months, we decided that this undertaking did not justify itself at all. We have not received any money from this. Therefore, it was decided to complete all current orders and close.

Like an epilogue.

In conclusion, I would like to touch on the topic of competition and share my thoughts on all this.

There were several studios that actively promoted their services of this kind. Among them was a terrible dumping. Some claimed that they were able to make 200-300 clips per day. In fact, they did an order of magnitude longer and worse (these are not my thoughts, but the reviews of their real customers). Others set the price at 150r per video, which did not fit our minds at all. On the topic of competitors now, I think you should not ask me questions. I am talking about the situation a year ago. What is happening now - I have no idea.

The following problems were with customers:

- did not understand the advantages of this technology

- didn’t want to spend money (it was easier for them to rip photos to goods from the neighbors' website)

- could not give samples for filming

Personally, my opinion is that potential customers simply did not understand the advantages of this technology. Yes, we can assume that we did not work well and could not explain to them. But this technology has not received its distribution in principle. Unfortunately.

Here are examples of what we did (these are not the final videos, but rather the workers. The final ones are located at the customers.):

Robot

D-Rex

Samovar

And a bonus :)

18+