Will 3D printing change the world?

“Technologies, potential and consequences of additive production”, an article under this heading was published by specialists of the Strategic Foresight Initiative. This organization was created to analyze the potential consequences of long-term global trends, revolutionary changes and shocks that can occur in the world. Over the past six years, the Strategic Forecasting Initiative, together with the US National Intelligence Council, has published reports predicting long-term trends through 2025–2030. This time they pay attention to 3D printing and other methods of the so-called additive production (AP, additive manufacturing).

According to researchers, AP can radically change society and the global economy. In terms of impact, this can be compared with the invention of a steam engine, light bulb, atomic energy or microchip. Moreover, right now, in their opinion, the technology is “ready for take-off”, and in the next decade a sharp increase in the use of 3D printing in industry will begin.

The report briefly discusses existing additive manufacturing technologies and their current applications. The authors note that initially AP was used for rapid prototyping, that is, the rapid production of conceptual models and prototypes. But with the improvement of materials and the technological process, AP technologies first switched to the creation of parts for functional testing, then to the creation of parts for presses and other tools of industrial production and, finally, directly to industrial production. In 2009, according to studies, 16% of the AP devices were used directly for the manufacture of parts, 21% for functional modeling and 23% for the creation of tools.

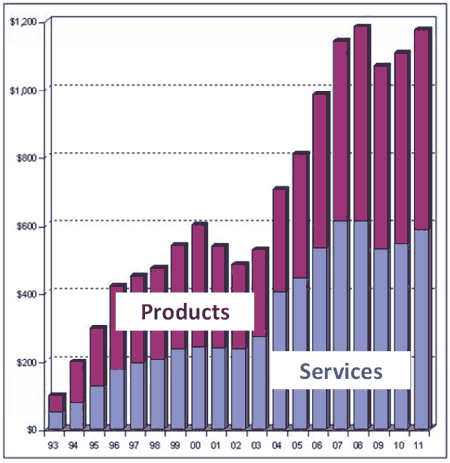

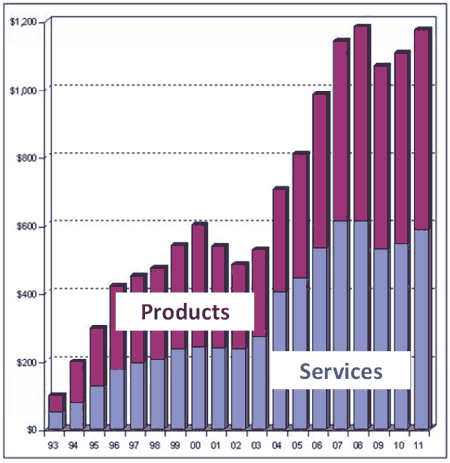

Estimation and forecast of income (in millions of US dollars) from AP products and services

Now there are several "success stories", that is, those areas where the AP is successfully used for the manufacture of parts:

Among the existing limitations, APs call the poor choice of materials used and the low speed of 3D printing (several tens of cubic centimeters per hour). According to the authors of the study, these restrictions are temporary and can be considered either insignificant or surmountable in the future.

But the potential of the technology is truly difficult to overestimate. Mass production can be transformed beyond recognition: for many products, standard conveyors can be greatly reduced or completely replaced with 3D printers, because the final product - for example, a car - will be assembled not from hundreds and thousands of individual spare parts, but within one process. This will affect many manufacturers and suppliers - many factories around the world that manufacture parts for this conveyor.

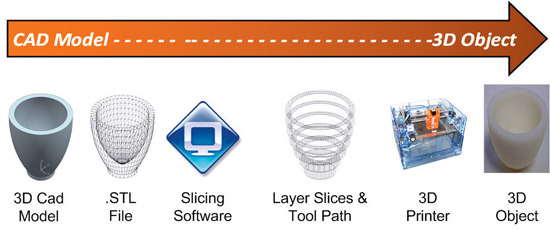

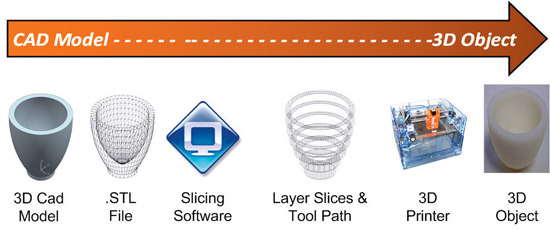

Globalization will change its face. The movement of goods will begin to occur not in the physical world (on barges, containers and freight trucks), but on the Internet - in the form of digital files and 3D models. As an email, you can forward it to the other end of the world and print it there in 2D, the file of the three-dimensional model STL can be sent and printed on a 3D printer, having received the original device. STL files will be created either by three-dimensional scanning of originals, or designed by designers in 3D modeling packages.

In some cases, printing a couple of hundreds of iPhones of the latest model for the villagers will be easier and cheaper on a local printer than producing millions of devices in China, transporting them across the ocean, and then ensuring delivery to this locality, remote from large distribution centers. Due to the localization of production, the current exporting countries may suffer in the future, in which exports exceed imports, such as Germany, Japan and China. The importing countries (USA), as well as countries with a large domestic market (USA) and countries with great potential for the export of intellectual products (again the USA) will win. In general, the researchers believe, due to the distribution of three-dimensional printing, the United States can regain its former influence in the global economy, industry, the intellectual property market, design,

Despite the improvement in the foreign trade balance due to the localization of production in some of the countries listed above that benefit from the introduction of AP, such a transformation of the economy can lead to political destabilization due to rising unemployment. But in the United States, experts say, this trend can be offset by an aging population and a natural reduction in the number of working-age people. In addition, APs themselves will create a new industry with a turnover of hundreds of billions of dollars, which will require specialists in new professions (more than 3D-designers, programmers, engineers, printer developers, printers and packaging factories).

In the future, AP devices will be able to work with a wide variety of materials without complex reconfiguration. But the key technologies that will ensure a breakthrough in the next few years will be two:

Thus, the revolution of 3D printing goes both on the upper level and on the lower level, which promises convergence in the middle.

Another important value of AP is the stimulation of the process that many have been talking about lately: this is the convergence of technical disciplines, especially the four NBICs (nanotechnology, biotechnology, information technology, cognitive science).

via Bruce Sterling

According to researchers, AP can radically change society and the global economy. In terms of impact, this can be compared with the invention of a steam engine, light bulb, atomic energy or microchip. Moreover, right now, in their opinion, the technology is “ready for take-off”, and in the next decade a sharp increase in the use of 3D printing in industry will begin.

The report briefly discusses existing additive manufacturing technologies and their current applications. The authors note that initially AP was used for rapid prototyping, that is, the rapid production of conceptual models and prototypes. But with the improvement of materials and the technological process, AP technologies first switched to the creation of parts for functional testing, then to the creation of parts for presses and other tools of industrial production and, finally, directly to industrial production. In 2009, according to studies, 16% of the AP devices were used directly for the manufacture of parts, 21% for functional modeling and 23% for the creation of tools.

Estimation and forecast of income (in millions of US dollars) from AP products and services

Now there are several "success stories", that is, those areas where the AP is successfully used for the manufacture of parts:

- automotive parts , for example, some parts of the engines of Formula 1 cars are made by direct laser firing for metal;

- aircraft parts , for example, a tube for the F-18 fighter / attack aircraft environmental control system;

- individual orthodontics : Align Technology uses AP to create accurate individual dental staples for hundreds of thousands of patients around the world using stereolithography using 3D scans of the oral cavity, a polymer approved by the FDA is used as the material for staples production;

- individual hearing aids : manufactured by Siemens and Phonak on the basis of a 3D scan of the ear canal, so that the device is ideal for the user and almost imperceptible.

Among the existing limitations, APs call the poor choice of materials used and the low speed of 3D printing (several tens of cubic centimeters per hour). According to the authors of the study, these restrictions are temporary and can be considered either insignificant or surmountable in the future.

But the potential of the technology is truly difficult to overestimate. Mass production can be transformed beyond recognition: for many products, standard conveyors can be greatly reduced or completely replaced with 3D printers, because the final product - for example, a car - will be assembled not from hundreds and thousands of individual spare parts, but within one process. This will affect many manufacturers and suppliers - many factories around the world that manufacture parts for this conveyor.

Globalization will change its face. The movement of goods will begin to occur not in the physical world (on barges, containers and freight trucks), but on the Internet - in the form of digital files and 3D models. As an email, you can forward it to the other end of the world and print it there in 2D, the file of the three-dimensional model STL can be sent and printed on a 3D printer, having received the original device. STL files will be created either by three-dimensional scanning of originals, or designed by designers in 3D modeling packages.

In some cases, printing a couple of hundreds of iPhones of the latest model for the villagers will be easier and cheaper on a local printer than producing millions of devices in China, transporting them across the ocean, and then ensuring delivery to this locality, remote from large distribution centers. Due to the localization of production, the current exporting countries may suffer in the future, in which exports exceed imports, such as Germany, Japan and China. The importing countries (USA), as well as countries with a large domestic market (USA) and countries with great potential for the export of intellectual products (again the USA) will win. In general, the researchers believe, due to the distribution of three-dimensional printing, the United States can regain its former influence in the global economy, industry, the intellectual property market, design,

Despite the improvement in the foreign trade balance due to the localization of production in some of the countries listed above that benefit from the introduction of AP, such a transformation of the economy can lead to political destabilization due to rising unemployment. But in the United States, experts say, this trend can be offset by an aging population and a natural reduction in the number of working-age people. In addition, APs themselves will create a new industry with a turnover of hundreds of billions of dollars, which will require specialists in new professions (more than 3D-designers, programmers, engineers, printer developers, printers and packaging factories).

In the future, AP devices will be able to work with a wide variety of materials without complex reconfiguration. But the key technologies that will ensure a breakthrough in the next few years will be two:

- Direct AP metal components . Significant progress has been made in this area over the past five years. Engineers can now produce components from titanium and some metal alloys based on 3D models as part of the AP manufacturing process, and these parts are not inferior in many respects to their analogues made in the traditional way. As this technology improves, we will see more and more introduction of AP in industry.

- Desktop 3D printers . While direct AP of metal parts will revolutionize the industry, desktop 3D printers lower the price barrier for this technology and make it affordable for every user. Thanks to expired patents and technologies that have come into the public domain, as well as open source projects, today you can buy an AP device for only $ 1000. Thanks to such a low starting price, interest in 3D printing has grown sharply in recent years, as more and more fans join the new hobby. In this sense, 3D printing is now at about the same stage as the first Apple I computers, after which the mass market for personal computers appeared.

Thus, the revolution of 3D printing goes both on the upper level and on the lower level, which promises convergence in the middle.

Another important value of AP is the stimulation of the process that many have been talking about lately: this is the convergence of technical disciplines, especially the four NBICs (nanotechnology, biotechnology, information technology, cognitive science).

via Bruce Sterling