Assembling a water-cooled computer

- Tutorial

Last year I wrote a “fundamental” article about cooling systems - the work came out in two large parts ( 1 , 2 ), but I tried to talk about everything from radiators to liquid nitrogen. Most recently, I have matured to another "feat", namely - to install a water cooling system.

If you are interested in a detailed illustrated guide to assembling / installing such a system (using the example of a productive config), then welcome to cat. Traffic!

Radiators and coolers - even writing about this is not so interesting, because all this has long been on any computer and you won’t surprise anyone. Liquid nitrogen and all sorts of systems with a phase transition are another extreme, the chances of meeting with which in the economy of an ordinary person are almost zero. But the dropsy ... in the matter of cooling the computer, it’s like a middle ground - unusual, but affordable; almost no noise, but at the same time, anything can cool. In fairness, it is more correct to call a water-cooling system (water cooling system) as a water cooling system (liquid cooling system), because, in fact, you can pour anything inside. But, looking ahead, I used plain water, so I’ll use more of the term CBO.

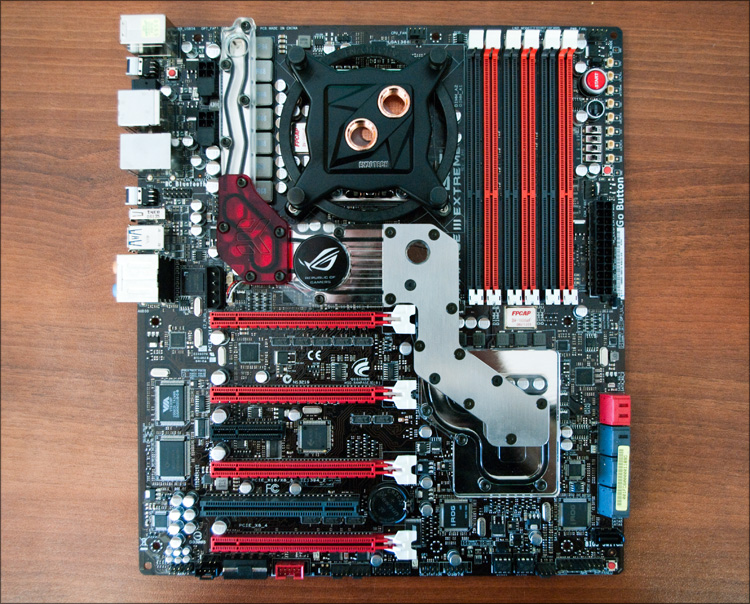

More recently, I wrote in sufficient detail about the assembly of a new system unit. The resulting stand was as follows:

- Thermaltake Level 10 chassis - Thermaltake Toughpower Grand 750W

power supply - ASUS Rampage III Extreme motherboard - Intel Core i7-930 processor - Leadtek GeForce GTX 480 graphics card - Crucial Ballistix Tracer memory - WD SiliconEdge Blue SSD hard drive A thoughtful study of the list suggests that the heat dissipation of some devices is not just high, but VERY high. And if you connect everything as it is, then inside even the most spacious case it will be at least hot; and as practice shows, it will also be very noisy.

Let me remind you that the case into which the computer is assembled is, albeit not very practical (although each time I am convinced of the opposite), but it is very presentable Thermaltake Level 10 - it has disadvantages, but you can forgive a lot for its appearance alone .

I did a reviewof this building, then a less productive stand was going into it - with the temperature regime everything was not bad, although according to the assurances of many reputable iron sites, the building is completely not intended for collecting really powerful configs. Moreover, according to the same publications, the casing is also unsuitable for installing a liquid cooling system, with which without checking I once agreed. Finally, I had the opportunity to refute both of these statements by doing some useful things - assembling a computer, installing a water cooling system in it and telling you about it. Let me tell you on the example of a rare and expensive case, but nothing prevents you from applying the acquired knowledge on any other case - it will only be easier!

And the last one. I thought for a long time about how to present all the information I received. As a result, having looked at 1000+ photos taken during the work, I wrote a universal algorithm (sequence of actions) for assembling the SVO - I got 8 points, about each of which I wrote in detail and with pictures. Someone may get fewer of these points, some may have more, but in general, this “HowTo” can be used for any system - add to favorites, you look, it will come in handy;)

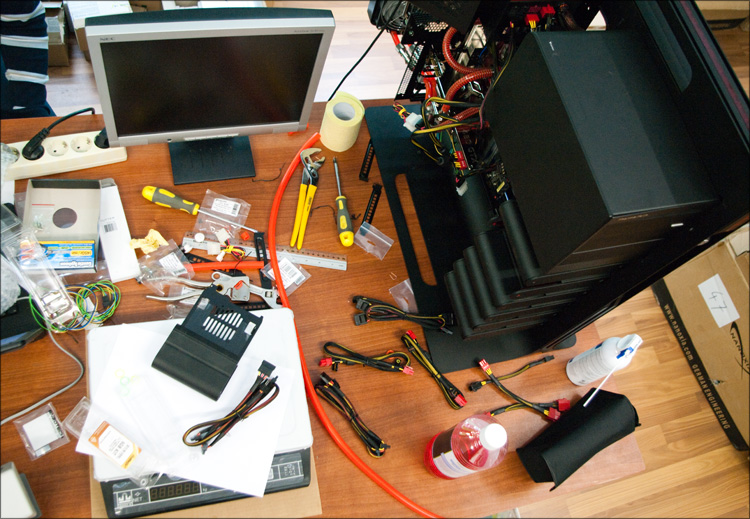

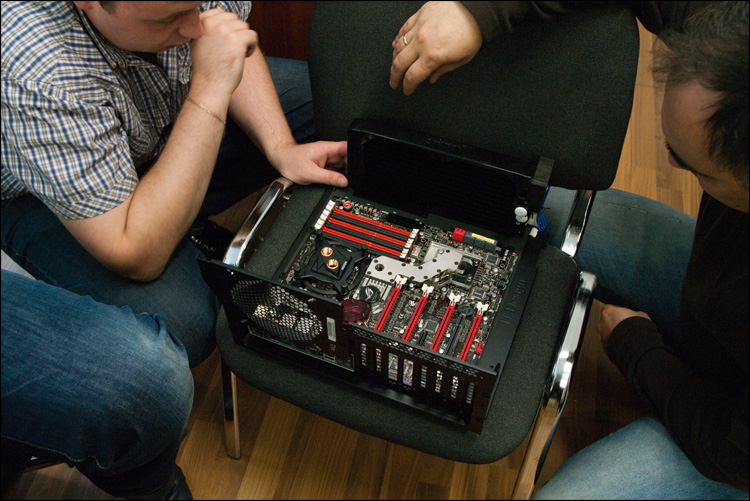

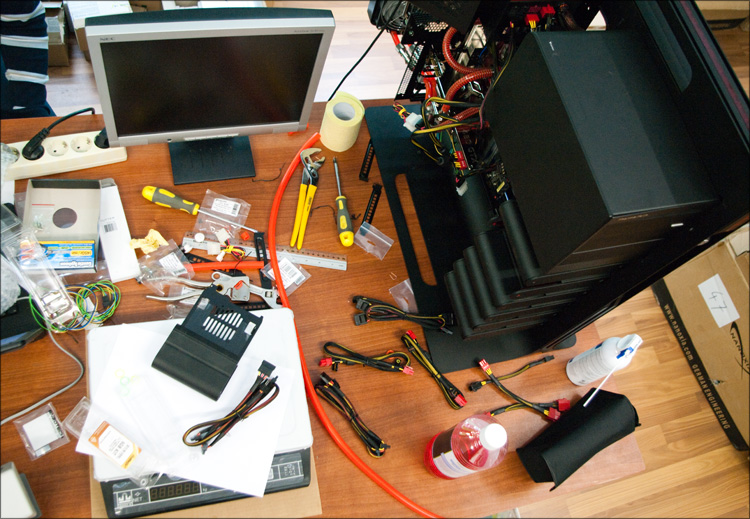

On one of the days off (on the day off), I arrived in a chock-full, clogged-up iron car in a store and we almost immediately began to solve the problem. In addition to me there were two more people (Maxim and Aleksey), the third came in the evening - to look at the result and offer us a way to solve one problem (because of which the assembly of the system was very delayed). Looking ahead - it is very good that everything happened in the store, where everything was necessary - without it I would have spent 100% more money, time and nerves.

So, the goal was set - to assemble a single-circuit water cooling system that would effectively cool the motherboard, processor and video card. As quiet as possible, ideally with the possibility of further upgrading the system .

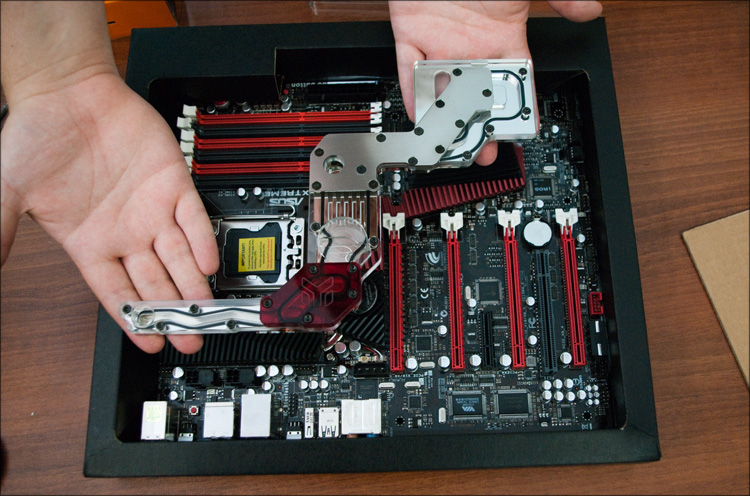

Having estimated the action plan, the necessary iron and its presence on the shelves of the store, we took up screwdrivers. Like it or not, you need to start with the motherboard - it is the most important thing in the computer.

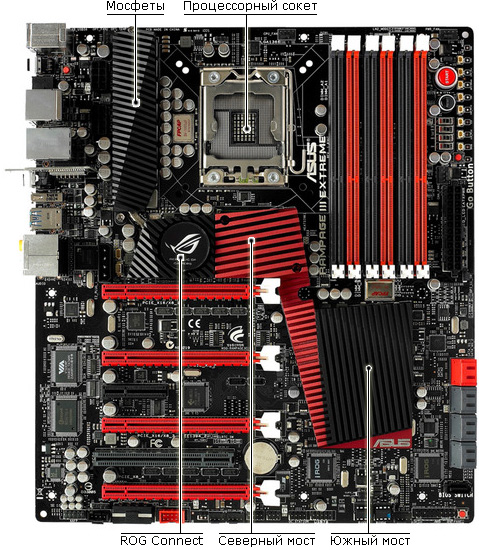

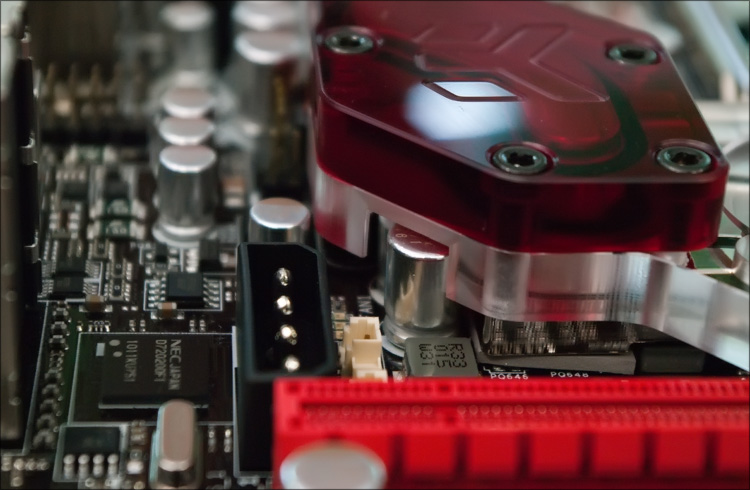

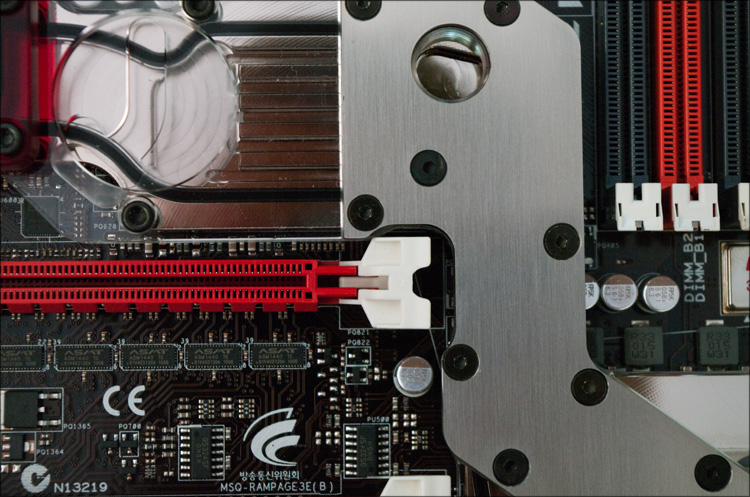

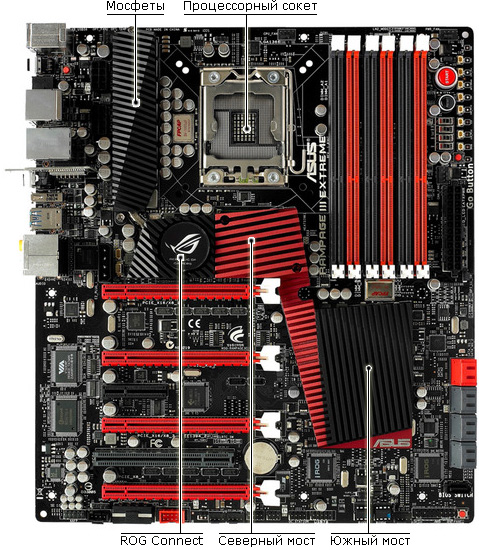

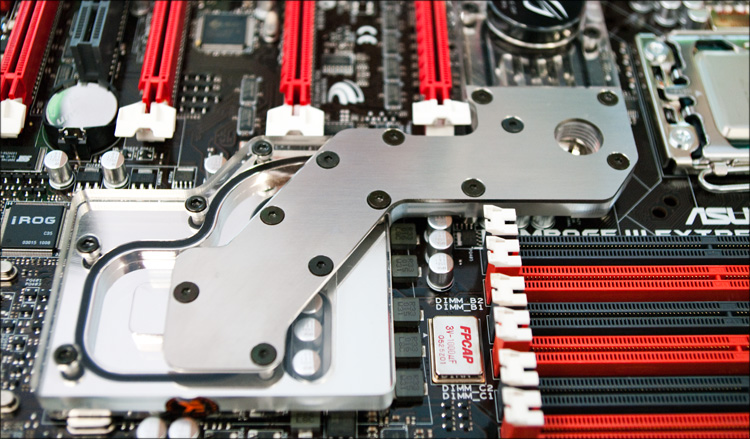

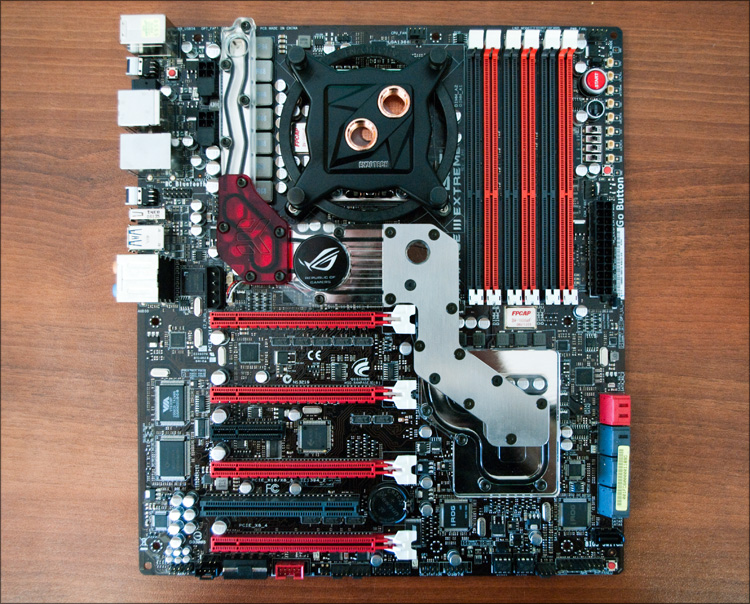

The motherboard ASUS Rampage III Extreme is very popular in the overclocking environment - if you look at world records, then in very many cases it appears. Great potential and technological prospects, the "freshness" of the model and the ASUS brand itself - all this was the result of the appearance on the market of various accessories tailored specifically for this board. In particular, I'm talking about a fullcover water block (there are already three different models on the overhard for this board ). Fullcover - means that this piece of iron covers all the necessary elements of the board (very hot, especially during overclocking), such as mosfets, north and south bridges.

For simpler motherboards (and for less common ones), there are many ordinary water blocks that cool only a particular area, but in this case it is easy to run into a “file”, and the number of tubes for liquid will in any case be larger.

We chose the nickel-plated fullcover-water block EK-FB RE3 (from EK Waterblocks) - an expensive piece of metal with various cavities, which is suitable for the device as a native, skillfully bypassing all capacitors, protrusions and other features of the relief.

When designing motherboards, the radiators of the power subsystem of the central processor are designed to blow the cooler of the central processor. When installing a CBO, mosfets lose their airflow, and even with a slight acceleration, their temperature can reach critical 100 degrees. So fullcover for ASUS Rampage III Extreme is what the doctor ordered!

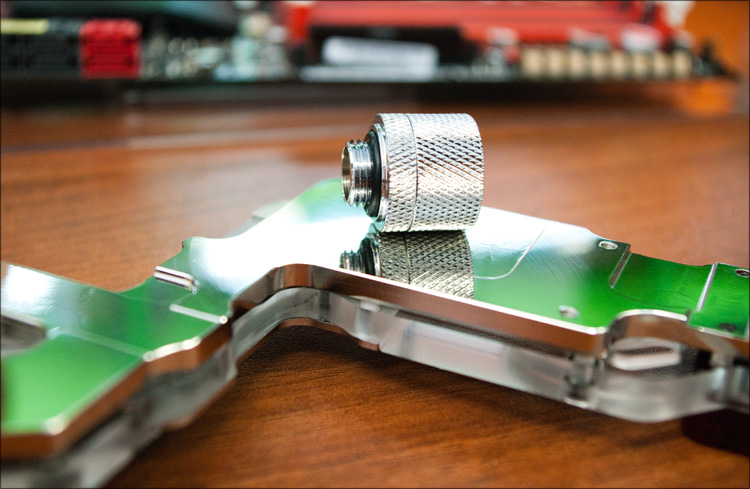

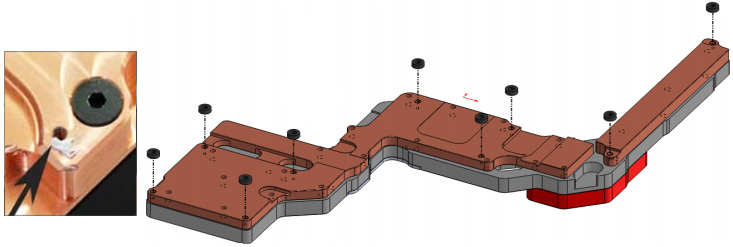

Pay attention to how complicated the design of the water block. In addition to the mirror polishing of the base, the unusual shape of the piece of iron itself and the precisely milled holes for the capacitors, there is a space inside (with no less complex geometry) along which water will flow. Horror.

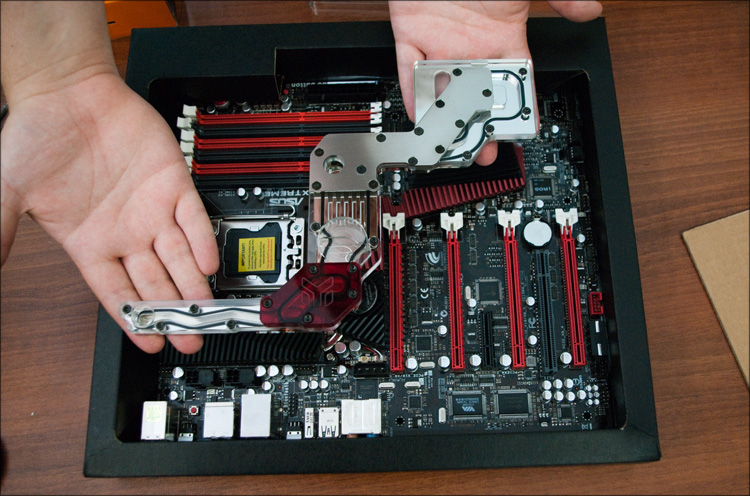

The installation process to disgrace is simple. We unscrew the 9 screws on which the stock fullcover radiator rests - it is beautiful, so we will not throw it out.

Max at work)

Along the way, we pull out the luminous washer “ROG Connect” - it will still be useful to us.

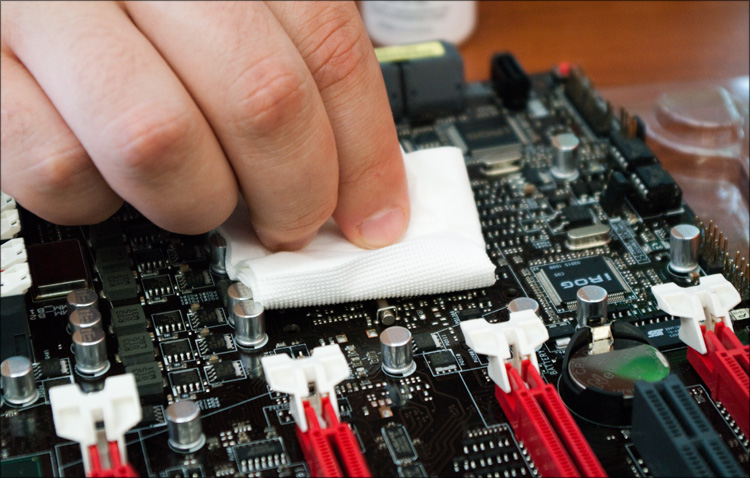

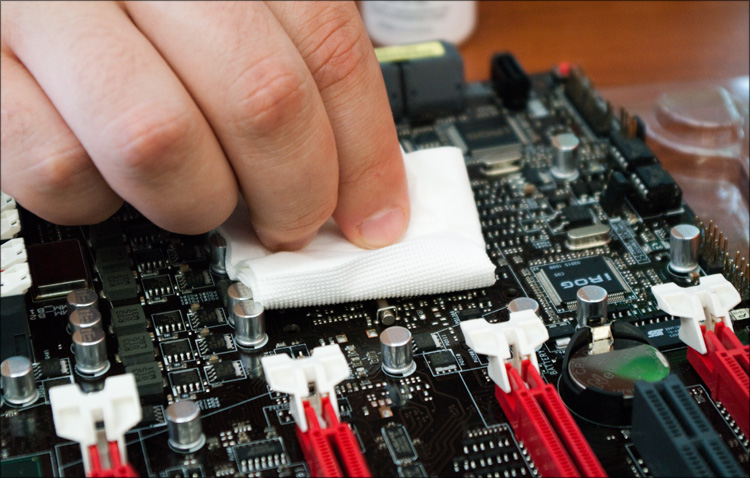

Then we take some cotton wool and remove the thermal interface that was on the microcircuits under the radiator. You can use a special liquid to remove thermal paste - it helps. Next, take a thermal pad (it comes complete with a water block) and, following the instructions, cut out the necessary pieces - paste them on the mother’s schemes.

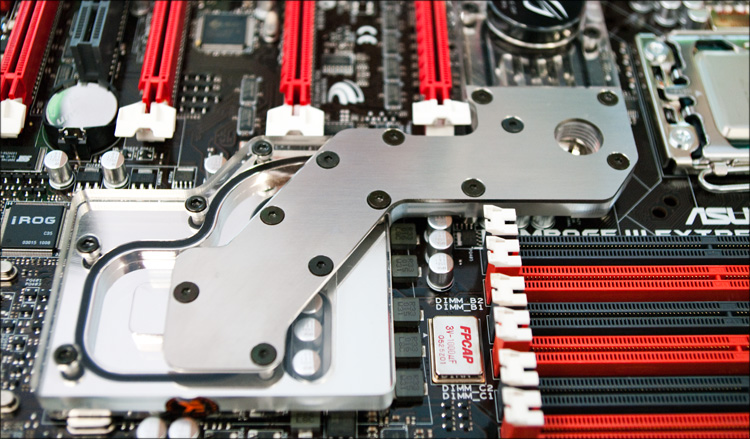

Next, we simply screw the water block, after installing “standoffs” (small plastic rings that prevent distortions and tensions of the water block) in the screw holes.

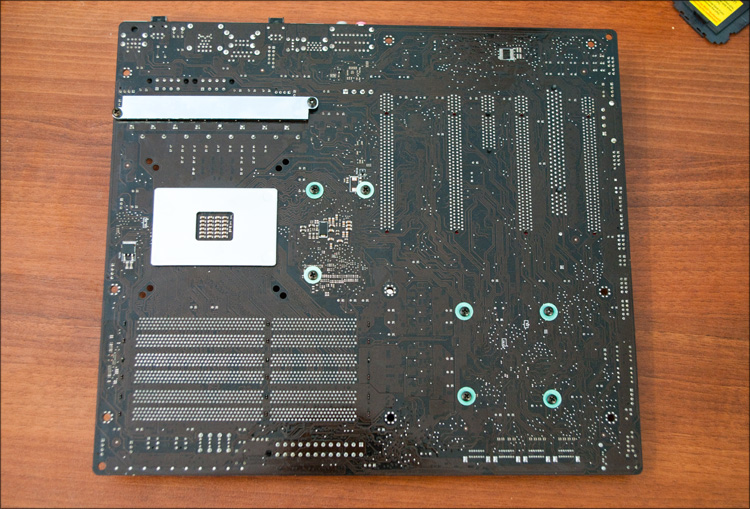

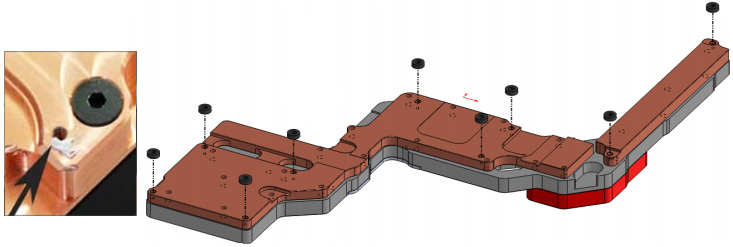

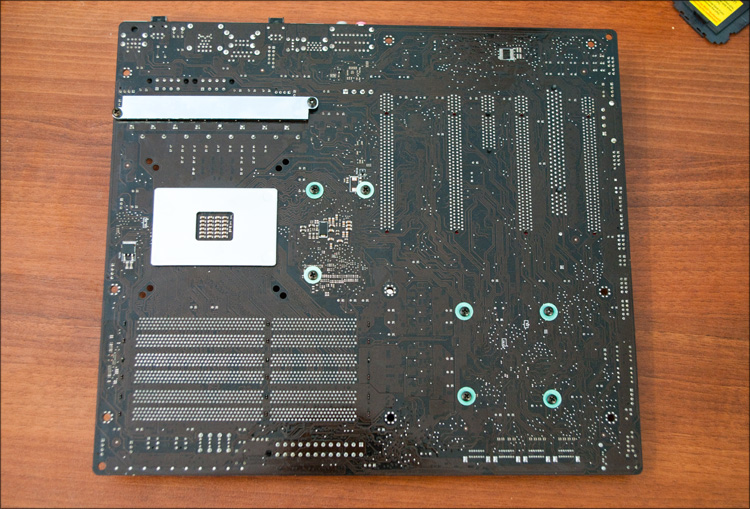

The weight of the water block is 550 grams, so for reliability on the back of the motherboard you need to install a load-balancing backplate.

The final touch is the installation of the ROG Connect indicator, for which there is now a corresponding recess. With a successful set of circumstances, in the load mode, such a water block is able to remove up to 40 degrees of heat.

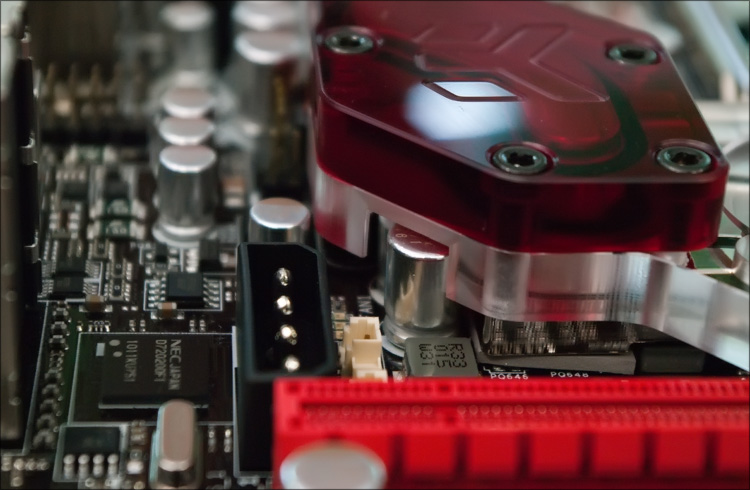

So that the motherboard could be removed for some time, we decided to install a water block on the processor - for obvious reasons, it can only be fullcover for processors :)

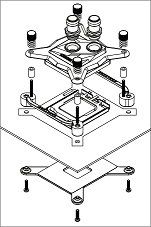

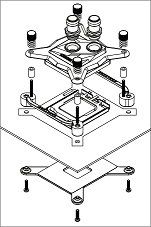

We used the cross-socket (775/1366) Enzotech Stealth - a stylish black water block made in compliance with the most high requirements (the base is polished to a mirror shine, the maximum deviation from a straight line is less than 0.0003 inches).

In addition to it, the kit included:

- Backplates for 775 and 1366 sockets

- Backplates for 775 and 1366 sockets

- One Enzotech 1366EZ mounting frame

- 4 nylon spacers

- 4 mounting screws

- 2 Christmas tree high-fittings with a diameter of 13 mm (with o-rings)

- 2 hose clamps with an internal diameter of 13 mm

- Arctic Silver Céramique thermal paste tube

The procedure is approximately the same, you don’t need to dismantle anything - first we install a protective backplate on the back of the motherboard (weight of the water block is 250 grams), and on the front side we put special frame (as is the case with air coolers).

We open the socket, put the processor in it, similarly we clean (already from the fat) the heat-distributing cover of the processor, apply a thin layer of thermal paste and install the water block on top. Just in case, you can immediately remove it to make sure (due to poor visibility) that there is the necessary contact between the processor cover and the base of the water block. Once again, we carefully clean both surfaces and, with complete confidence in a screwdriver, tighten the screws on the water block.

In order not to lose the parts, we screw both fittings from the kit - they are quite stylish by default. All.

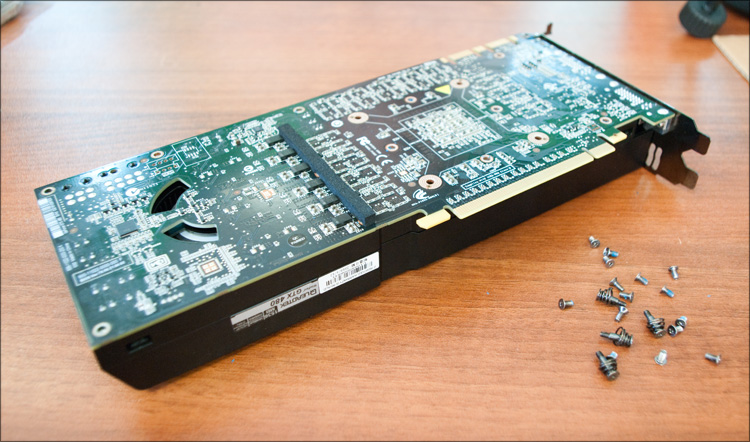

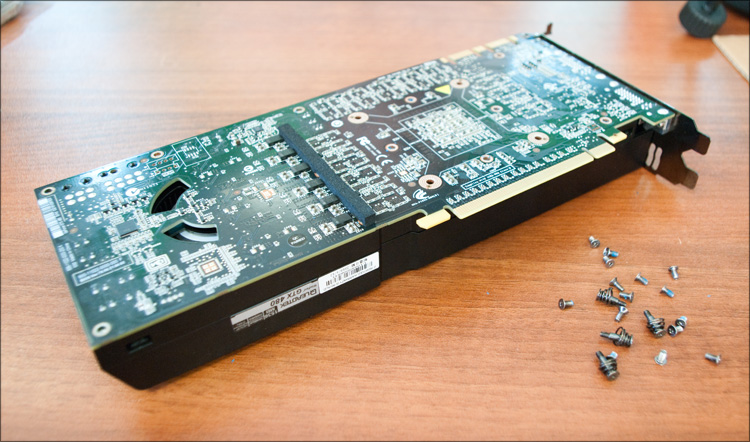

If you deprive the components of the guarantee, then all at once;) Now we come to the hottest component of the system, to the Leadtek GeForce GTX 480 video card - if you believe the tests, then this lady easily heats up to 100+ degrees in the load, which is accompanied by an equally disturbing hum stock turbine.

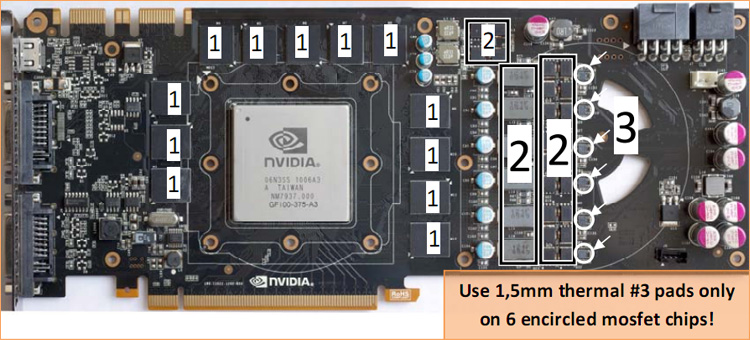

To complete the picture, it was also decided to use a fullcover-water block. For graphics cards with NVIDIA Fermi architecturethey were already used up quite a lot, and we, apparently, were lucky - the Leadtek GeForce GTX 480 had a "reference design", that is, the one that was originally designed by NVIDIA itself. Most often, the most obvious sign of a non-reference design is a non-standard cooling system - what manufacturers give out as a plus (in fact, it is). It is much worse when the wiring on the board is modified - it will be much more difficult to guess here.

In the hope that everything works, we started dismantling the factory cooling system (the loss of warranty starts from this stage). In the case of this video card, the process is somewhat tiring - 17 screws from the side of the PCB and 2 from the side of the connectors. Next, carefully remove the entire radiator, having previously disconnected the cooler wire from the board.

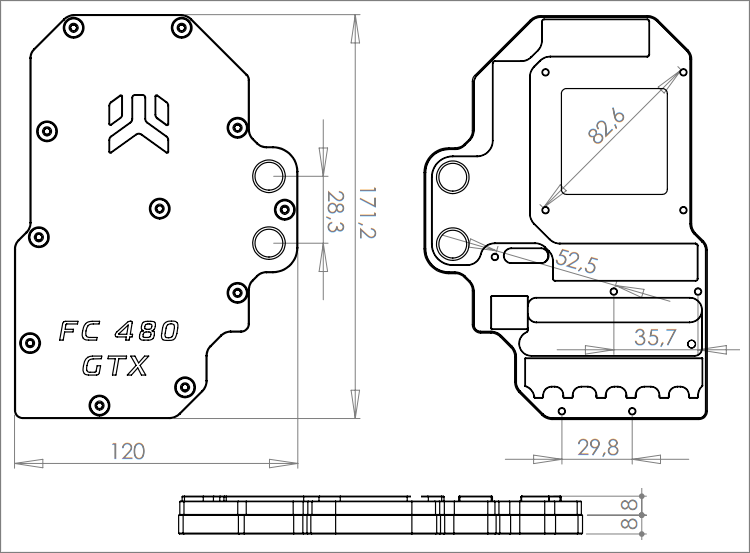

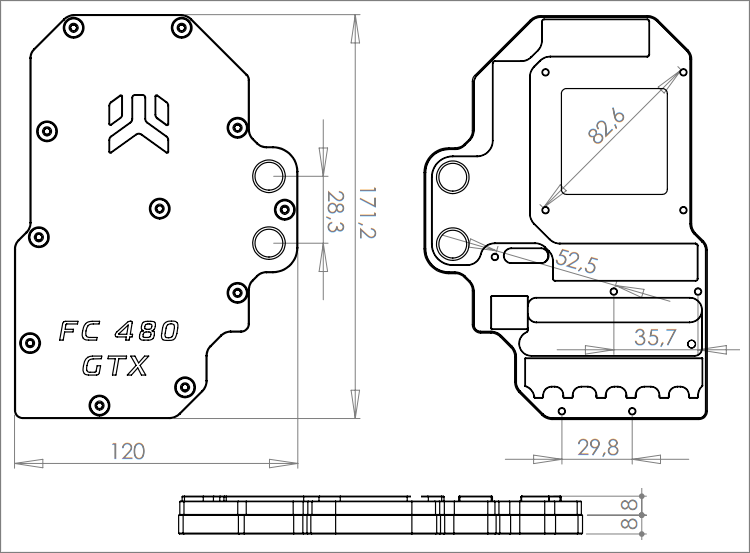

Trying a fullcover water blockEK-FC480 GTX Nickel + Plexi was a success - it fits perfectly)

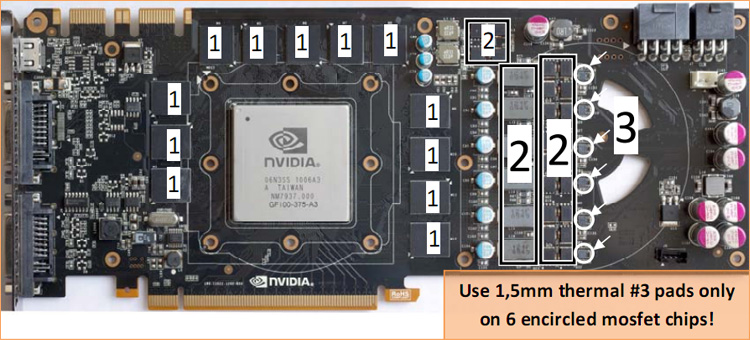

We open the instructions, start cutting thermal pads (it is best to do with scissors, which are not a pity or with an office knife).

We stick thermal pads - it is very important to stick them correctly, so read the instructions carefully!

We put the standoffs in the holes of the water block mounting, we clean the GPU cover with a special liquid, apply a thin layer of thermal paste and put on the water block.

For reliability, this high-tech sandwich lacks 9 screws - the most important thing is not to tighten them very much!

Further, the video card was tried on to the motherboard - beautifully, of course, but the textolite is completely unpresentable. Moreover, it can be accidentally touched and damaged, water can drip on top of it ... in general, it was decided to install a decorative-protective fullcover backplate, which became the EK-FC480 GTX Backplate Nickel . There were no problems with installing it at all - they installed and realized that they had not lost. Actually, that's all.

Even when I was working for the “skinny” GeForce 2 MX 400, and people were taking the 8800s with might and main - I think from that moment on, many (and mine too) had the memory that the video card is soooo big. What can I say about modern "fools" who have ceased to fit in many cases (the length of some video cards is almost 30cm!). Then it always seemed to me that under the protective casing of these various electronics were teeming, but, as it turned out, it was the cooling system radiator that occupied most of the space - the board itself was very thin.

I mean, to see such a thin top-end video card is very unusual - the height of the water block is only 8.8 millimeters, so the total video card is slightly higher than a centimeter, which is less than the height of the plug for a PCI slot! Accordingly, there will be no problems with the creation of an SLI system (for 2-3-4 video cards).

It involuntarily seems that such a system simply cannot work efficiently ... but when you take it in your hands ... By the way, the weight of a water block alone is 950 grams without fittings and plugs! The weight of the video card assembly was 1.22kg.

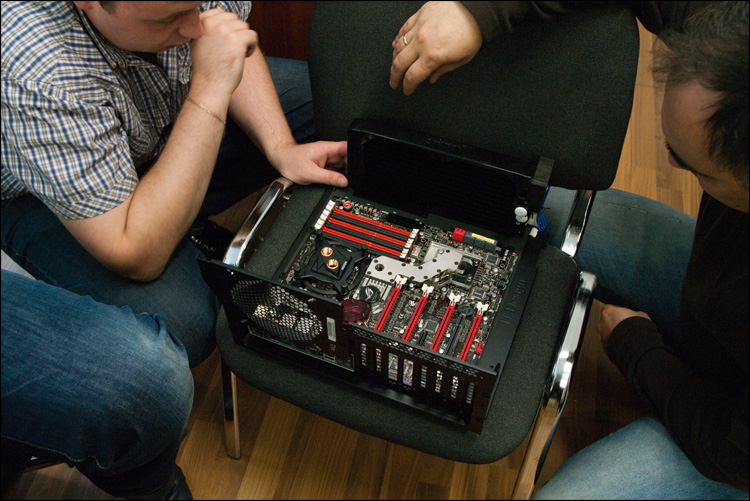

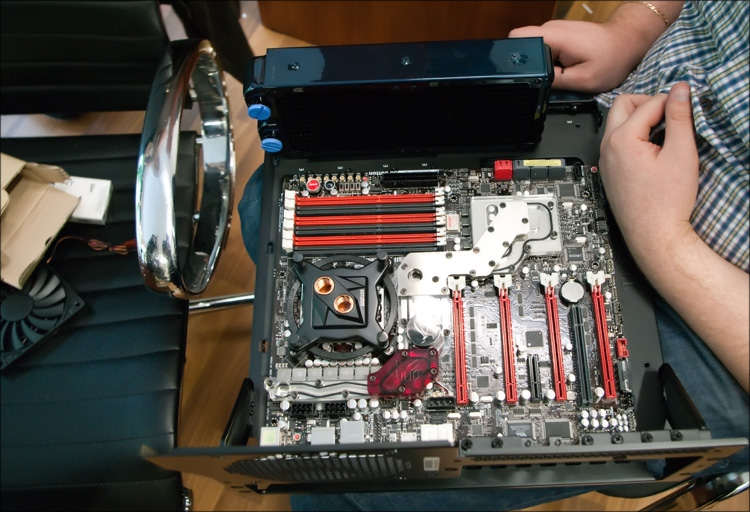

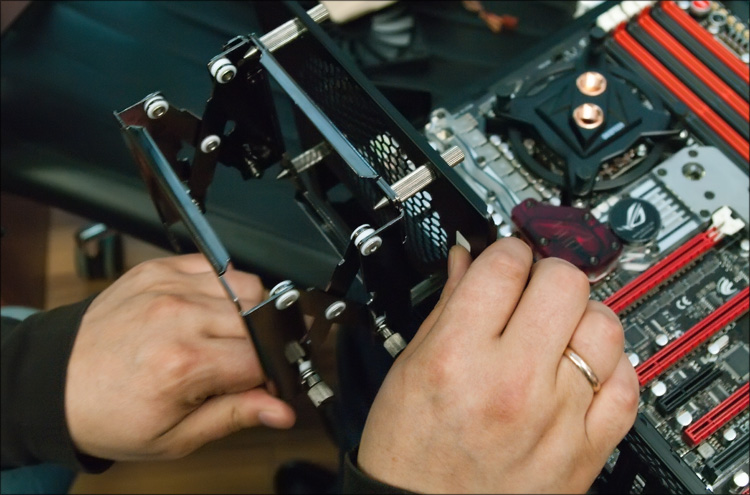

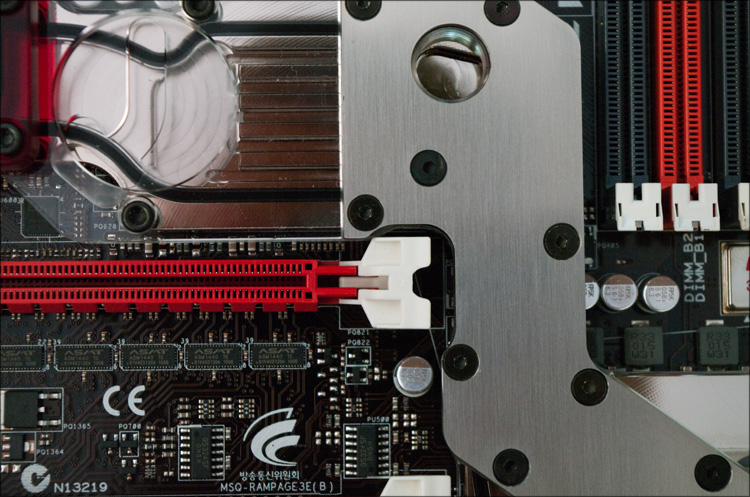

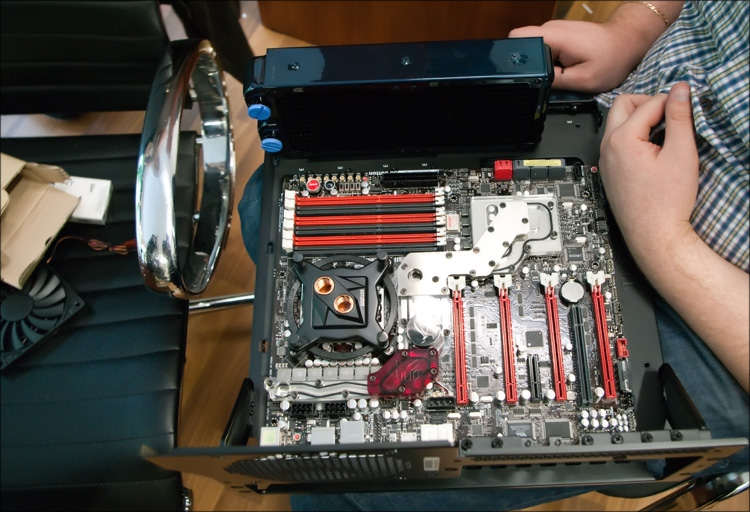

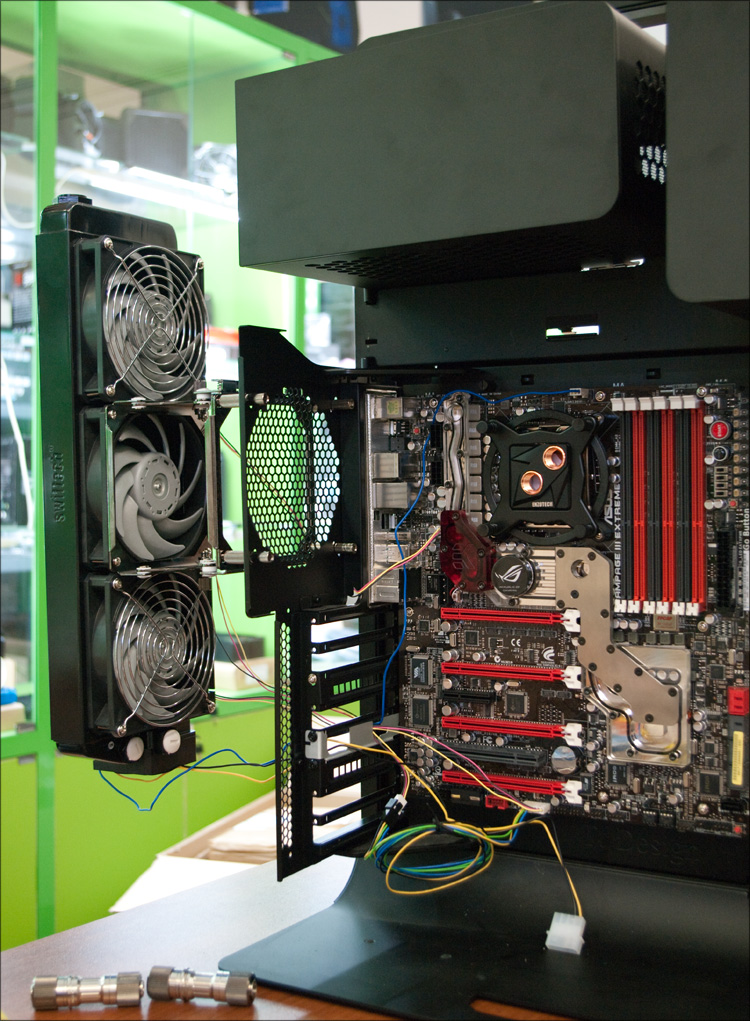

At this stage, the motherboard was installed in the case, a video card was installed in it - previously in the highest PCI-slot.

One of the most interesting stages of work, which took us the most time (if we immediately went the easy way, we would have managed in half an hour, but first we tried all the difficult options, because of which all the work stretched for 2 days in total (Of course, far from incomplete.)

The water cooling system is very similar to that used in cars, just a little more - there is also a radiator (most often not one), a cooler, coolant, etc. But the car has one advantage - solid counter flow of cold water spirit, which plays a key role in the cooling system while driving.

In the case of a computer, heat must be removed by the air that is in the room. Accordingly, the larger the size of the radiator and the number of coolers, the better. And since you want a minimum of noise, effective cooling will be achieved mainly due to the surface of the radiator.

And the essence of the problem was as follows. On Skype, we previously agreed that “we will hang 2-3 sections behind the radiator — it will be more than enough!”, But as soon as we looked at the case, it turned out that everything was not so simple. Firstly, there was really not enough space for a three-section radiator (if you fasten the radiator to the hole where you would install the blowing cooler of the case), and secondly, even if it were enough, you couldn’t open the case itself - it would interfere "Door" of the system compartment :)

In general, we counted at least four options for installing a radiator in the Thermaltake Level 10 case - all of them are possible, each would require a different amount of time and each would have its own pros and cons. I will start with those that we considered, but which did not suit us:

1. Installing a radiator on the back (from the user) side, that is, on a removable door.

Pros:

+ The possibility of horizontal and vertical installation of any radiator, at least 3-4 coolers

+ The dimensions of the case would not particularly increase

Minuses:

- I would have to drill from 4 to 6-8 holes in the door

- It would be very inconvenient to remove the door

- With a horizontal arrangement would require a radiator with a non-standard arrangement of the hole for the fluid inlet

- With a vertical arrangement, the hoses would be very long and with a large bend

- The body would be on my left (on the windowsill), and I do not need warm air from the coolers in my face :)

2. Installing the radiator on top, on the "casing" of the power supply compartment . The pros and cons are identical

3. Installing a two-section radiator inside the system compartment

Pros:

+ Easy to solve

+ Outwardly there would be no changes

+ The door of the system compartment would open without problems

Cons:

- Only a 2-section radiator would fit (this is not enough for the config iron)

- In this case, cold air would not come from, and I did not want to drive warm air back and forth.

- There would be difficulties in “arranging” the pump and tank

- Even if we used ultra-thin coolers, all SATA connectors would overlap (if they were displayed to the user, and not to the side, this problem would not exist)

In general, we would have all these options to one degree or another they tried it - they spent a lot of time searching for the necessary components, trying them on, etc.

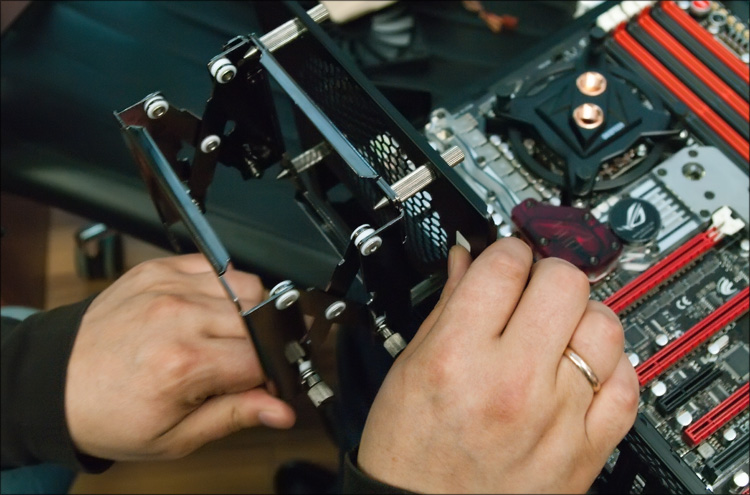

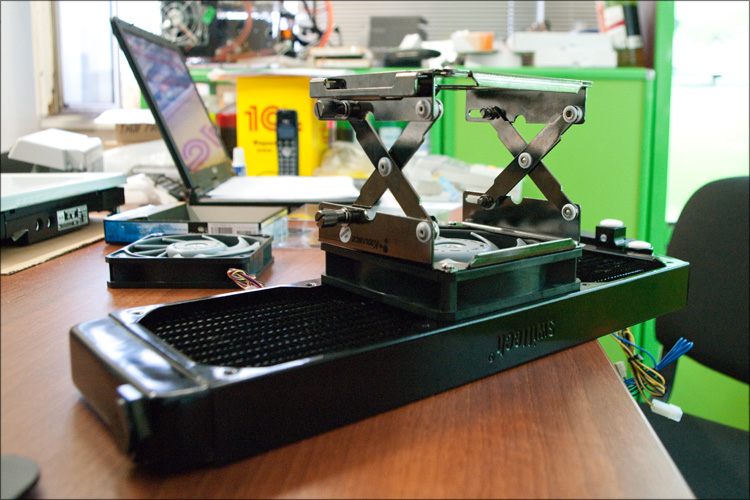

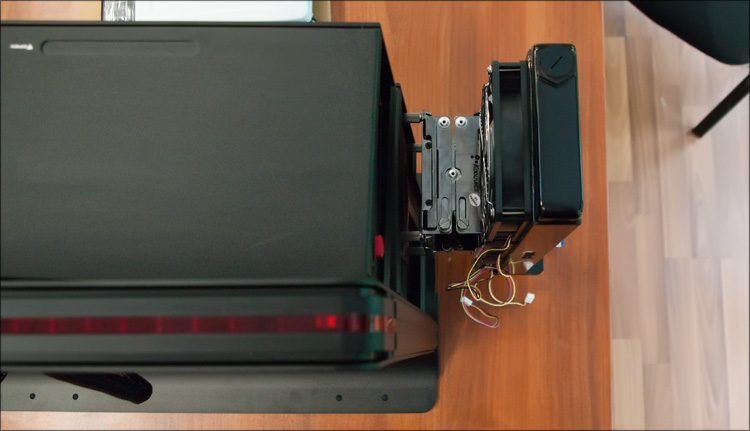

The most recent solution turned out to be a rather unusual solution - it may not be the most beautiful at first glance, but really practical. This is the installation of a radiator on the back of the case through a special adjustable adapter with a mechanism of the “scissors” type .

Pros:

+ I did not have to drill anything

+ The ability to hang ANY radiator

+ Excellent blowing

+ The access to the connectors of the motherboard did not overlap

+ The minimum length of hoses, the minimum of bends

+ The design is removable and

portable Cons:

- Not the most presentable appearance :)

- Opening the system compartment door is now not so easy

- Quite an expensive adapter

Why did we come to this option in last turn? Because during the searches for the previous three options, we accidentally found an adapter that everyone forgot about, but it wasn’t in the online store) Looking at the only (last) instance of the Koolance Radiator Mounting Bracket, I thought, "And why not come up with!". The bottom line is that in the holes for attaching to the rear blower cooler body 4 "conical nails" are inserted, on which a special frame is hung.

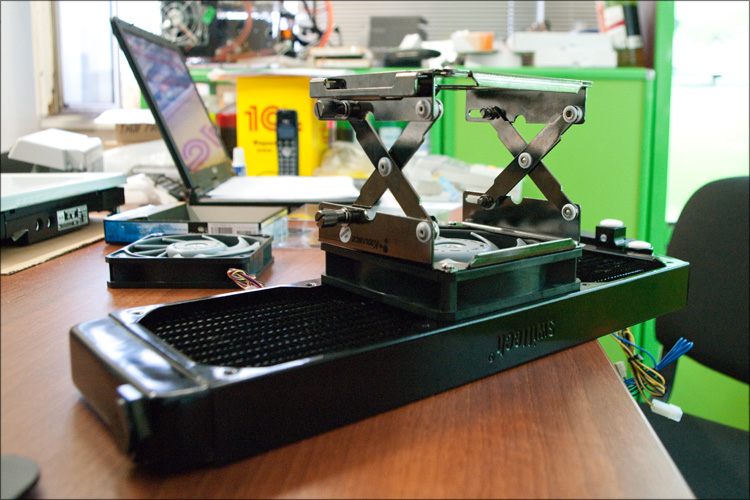

The design of this frame is such that its length can be changed by tightening the locks, and it is removed by mixing the two parts of its body (so that the holes open and it can be removed from the “studs”) - so I turned down! ) It is much easier to understand everything from the photo.

The frame is metal and very durable - I was convinced of this when we hung a 3-section (3 coolers) radiator for testing. Nothing dangles and does not swing, everything hangs tightly, but in the “open” case the door completely opened to itself - this option completely suited me!

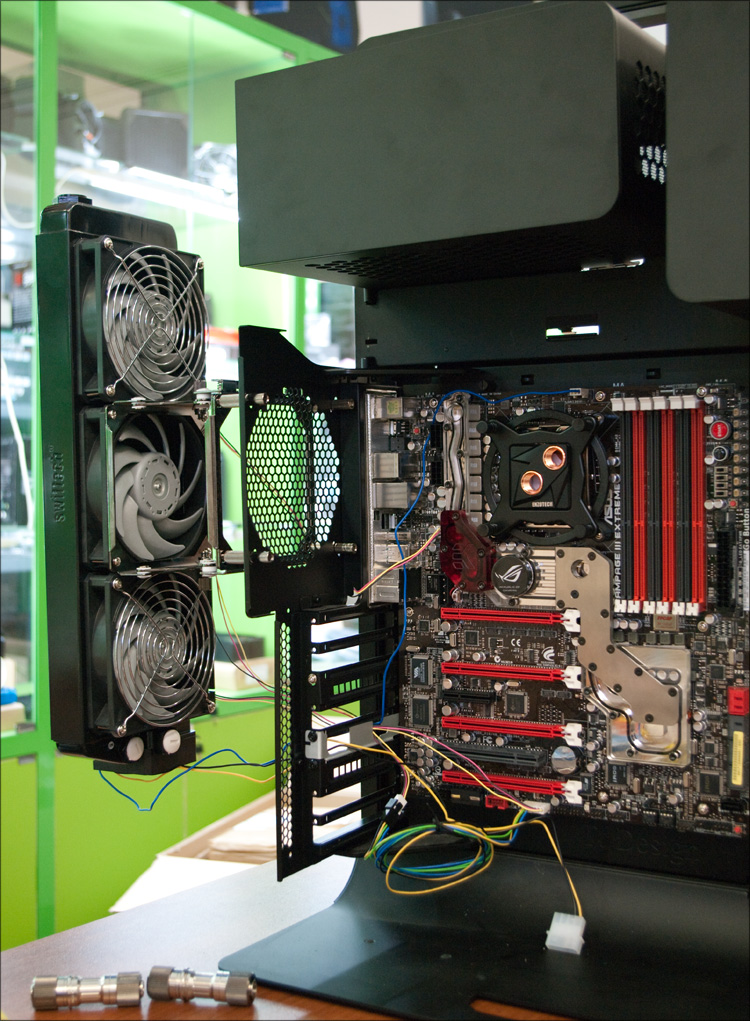

There were a huge number of radiators to choose from - black, white, red ... In this matter, I was most surprised by the 4-section TFC Monsta , which is able to dissipate up to 2600W of heat (this, apparently, is an SLI out of four 480s)! But we people are much simpler, so we decided to stay on the radiator that we tried on - Swiftech MCR320-DRIVE . Its advantage is that it combines three components at once - a radiator (MCR320 QP Radiator for three 120mm coolers), a liquid tank and a high-pressure pump ( MCP350 Pump , a complete analogue of the “ordinary” Laing DDC pump) In fact, with such a piece of iron for NWO it will be necessary to buy only water blocks, hoses and other little things that we already had. The pump runs from 12V (8 to 13.2), making a noise of 24 ~ 26 dBA. The maximum pressure created is 1.5 bar, which is approximately equal to 1.5 "atmospheres".

There were three candidate coolers for the radiator - Noctua , Be Quiet and Scythe . As a result, settled on Indonesian (with Japanese roots) Scythe Gentle Typhoon(120mm, 1450 rpm, 21 dBA) - these turntables are not the first day in great demand among many users. They are very quiet, and the quality of balancing the bearings is simply surprising - the cooler will turn unnaturally for a long time even from the lightest touch. The service life is 100,000 hours at 30 ° C (or 60,000 hours at 60 ° C), which is enough for the obsolescence of this system unit.

A review of these "typhoons" was at the Center - I advise you to read . Protective grilles were placed on top of the coolers so that the child would not put anything vital in the fans.

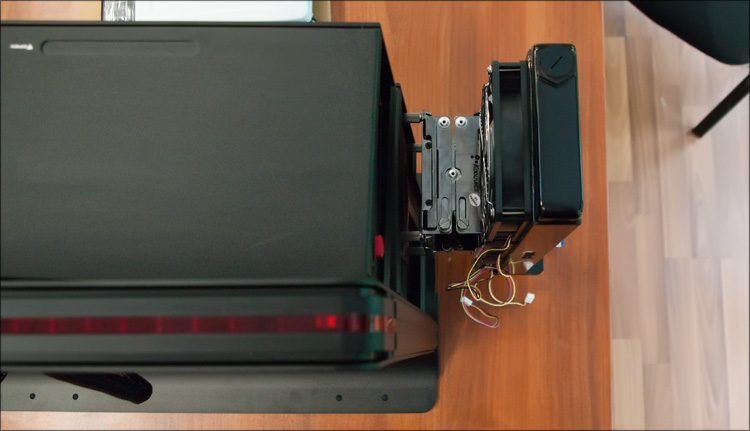

We try on the resulting design for the system unit - it looks very unusual) But look, how convenient it is - to get inside the case (or remove the cooling system), just press one “button” and the whole structure is, in fact, already disconnected. We squeeze the mounting frame and have full access to the insides - it is more than spacious there, because we did not pile anything up there. Maybe I described not the most convenient option, but ... if you take into account that after assembling the computer you practically don’t have to climb inside, and good cooling is much more important, then I think our solution is right.

The assembly assembly weighs 2.25 kilograms, and with liquid and fittings, probably all 3 are looking ahead, even such a weight from the Koolance frame was enough, for which she respects and respects :)

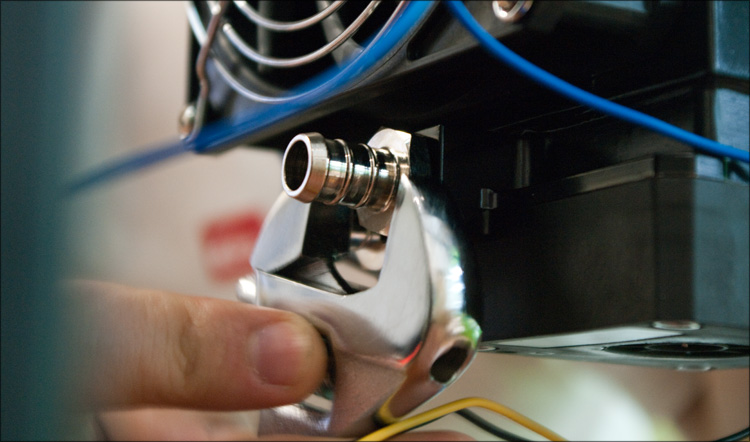

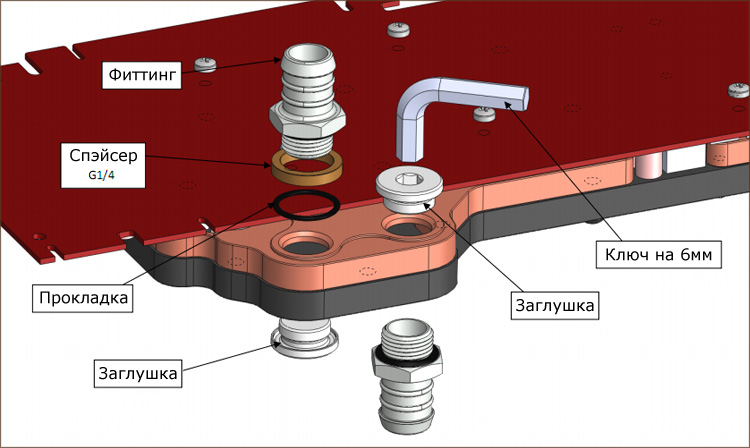

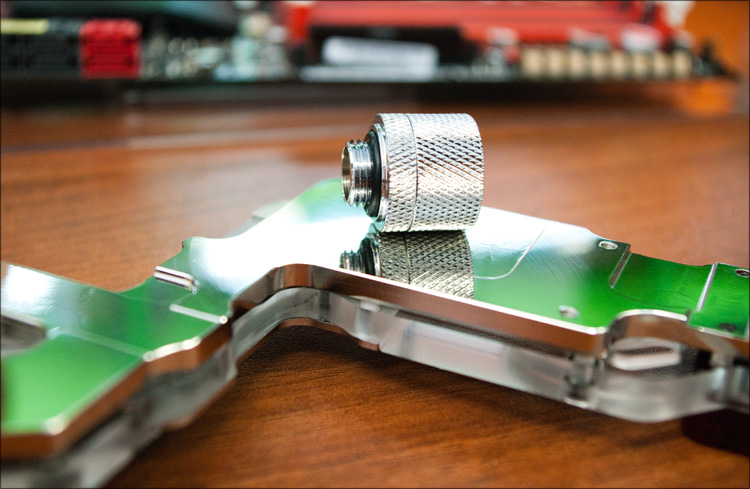

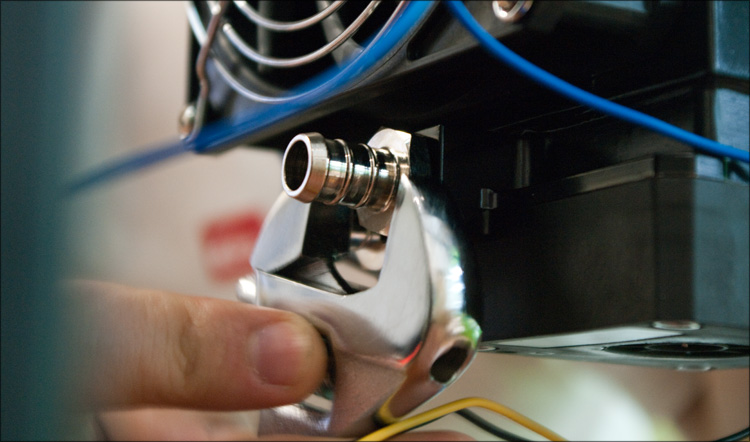

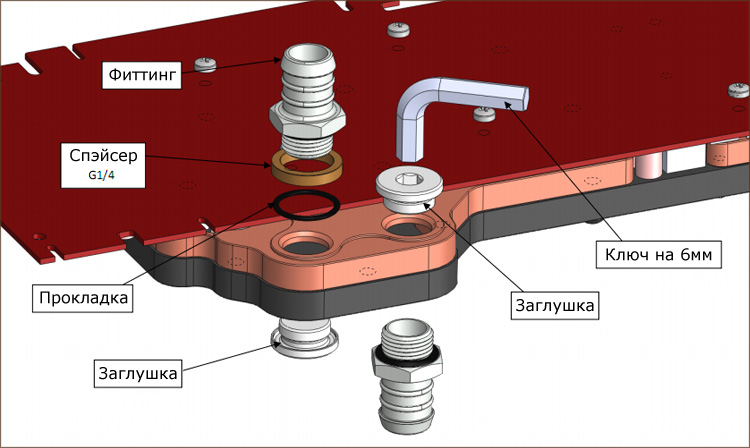

The only thing left is to install all the components, “tie up with water” and test the resulting computer. It all started with the installation of fittings - such beautiful pieces of iron (in the form of "fir-trees") that are installed through special gaskets (and sometimes when the thread of the fitting is very long, through special spacers) into the corresponding hole of the water block or tank - we used a small adjustable wrench to tighten , but it’s also important not to overdo it.

In addition to the fittings, special plugs were installed in the two holes of the water block of the video card:

After that, we thought out the route along which water will go. The rule is simple - from less heated to more. Accordingly, the “output” of the radiator is connected first with the water block of the motherboard, from it the output to the processor, then to the video card and then back to the radiator input, cool down. Since there is one water at all, the temperature of all components as a result will be approximately the same - it is from these considerations that multi-circuit systems are made and for this reason it does not make sense to connect all kinds of hard drives, RAM, etc. to the same circuit.

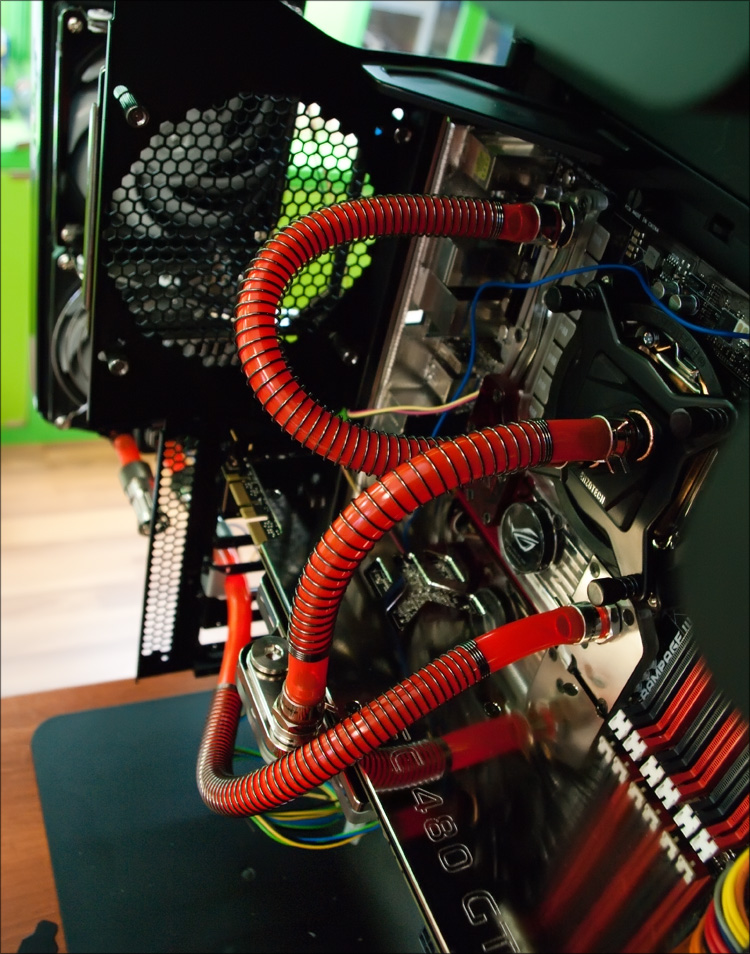

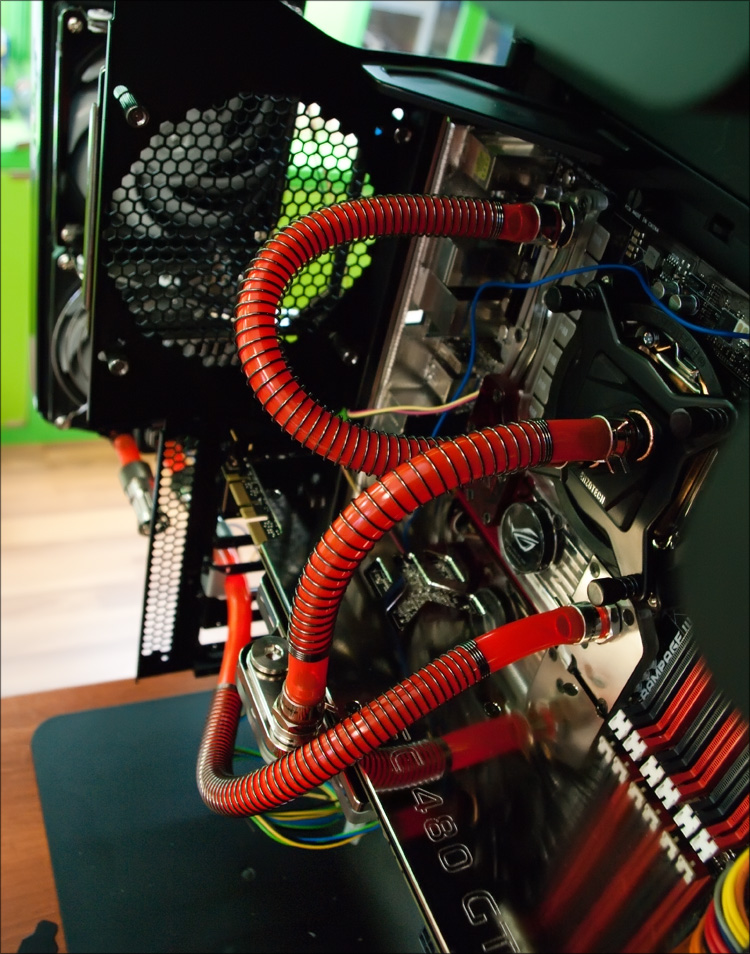

The role of the hose went to the red Feser Tube (PVC, operating temperature from -30 to + 70 ° C, tensile pressure 10 MPa), for cutting which a special predatory tool was used.

Cutting off the hose exactly - it may not be so difficult, but it is very important! Almost all hoses were equipped with special springs against bends and kinks of the hose (the minimum radius of the hose loop becomes ~ 3.5 cm).

For each hose (on both sides) in the fitting area, you need to install a “clamp” - we used the beautiful Koolance Hose Clamp . They are installed using ordinary pliers (with brute masculine force), so you need to act carefully so as not to accidentally hurt anything.

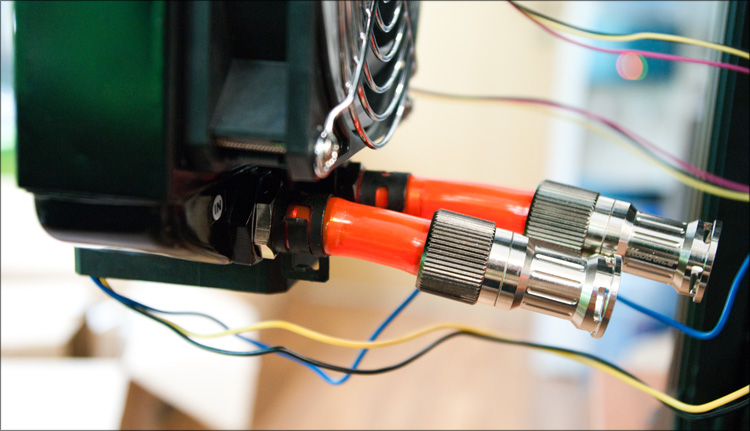

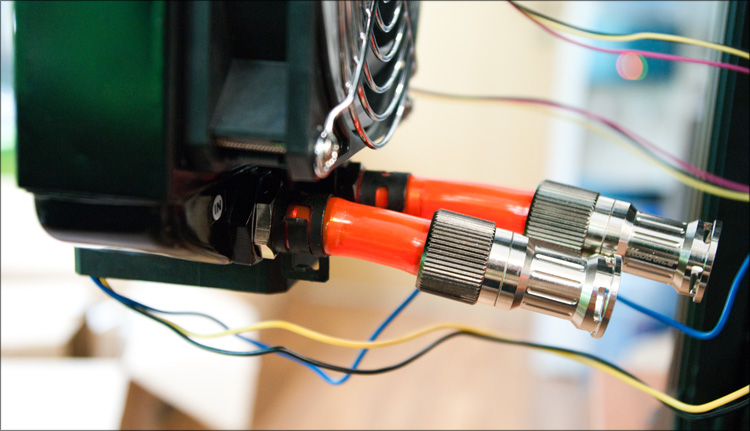

The time has come to work on connecting the “inner world” with the “outer”. In order to be able to remove the radiator-tank-pump (for example, to open the case or for transportation), we put on the tube the so-called “quick couplers” (quick-release valves), the principle of operation of which is outrageously simple.

The time has come to work on connecting the “inner world” with the “outer”. In order to be able to remove the radiator-tank-pump (for example, to open the case or for transportation), we put on the tube the so-called “quick couplers” (quick-release valves), the principle of operation of which is outrageously simple.

When we rotate the connection (as with BNC connectors), the hole in the tube closes and opens, so you can dismantle the dropsy in less than a minute, without any puddles and other consequences. A couple more expensive, but beautiful looking piece of iron:

5110 - EK FB RE3 Nickel water block on the

3660 motherboard - EK-FC480 GTX Nickel + Plexi water block on the video card

1065 - EK-FC480 GTX backplate Nickel on the video card

2999 - Enzotech Stealth water block on the

9430 processor - Swiftech MC3 pump / radiator / tank DRIVE

2610 - Two Quick Release Valves Release Coupling

4000 - Koolance Radiator Mounting Bracket

1325 Adapter - Three Scythe Gentle Typhoon Coolers (120mm) for Radiator

290 - Four EK-10mm High Flow Fitting

430 Fittings - Arctic-Cooling-MX-3

400 Thermal Grease - Nine hose clamps Koolance Hose Clamp

365 - Nanoxia HyperZero

355 Fluid - Feser Tube Hose

Such a high price in this case is due to the fact that fullcover-water blocks were used for VERY hot pieces of iron, all the heat from which must be dissipated by an appropriate radiator. For simpler systems, such solutions simply will not be needed, you can also do without decorative pads and any quick-release valves - in such cases, you can easily meet half the cost. The price of the average dropsy is 12-15 thousand rubles, which is 4-5 times higher than the cost of a really good processor cooler.

After all the components of the system were connected, the time came for a “leak test” (leak test) - coolant was poured into the radiator (twice distilled Nanoxia HyperZero water of red color, with anticorrosion and antibiological additives) - the order entered the circuit 500 ml

The guy runs in habramayke radiator)

Because it is impossible to exclude the possibility that something was connected to the computer components incorrectly, it was decided to separately check the operation of the water cooling system itself. To do this, all wires (from coolers and from the pump) were connected, and a paper clip was inserted into the 24-pin connector of the power supply for idling. Just in case, we put napkins downstairs to make the smallest leak easier to detect.

Pressing a button and ... everything as intended) Honestly, before that I had to see dropsy (besides the Internet) only at various exhibitions and competitions, where it was very noisy; therefore, I unconsciously prepared for the “murmur of a stream”, but the noise level was pleasantly surprised - for the most part, only the operation of the pump was audible. Initially, there were “hissing” sounds - due to air bubbles inside the circuit (they were visible in some places of the hoses). To solve this problem, the plug of the radiator tank was opened - from the circulation of the flow, the air gradually came out and the system began to work even quieter. After adding fluid, the plug was closed and the computer worked for another 10 minutes. No noise was heard from the cooler of the power supply and from three on the radiator at all, although their air currents made themselves felt.

After making sure that the system is fully operational, we decided to finally assemble the test bench. Connecting the wires took no more than a minute - they looked much longer for the monitor and the wire for connecting it, because everyone worked on laptops;) The phrase “Reboot and select proper boot device or insert boot media in selected boot device and press a key” became a balm for the soul - we inserted one of the “working” SSDs (with Windows 7 on board) - it is good that the new comp has accepted such an option. For complete happiness, we just updated the drivers for the chipset and installed the drivers for the video card.

Run the diagnostic monster Everest, where on one of the tabs we find the readings of temperature sensors: 30 ° C were valid for all components of the system - CPU, GPU and motherboard - well, very nice numbers. The equality of numbers led to the assumption that cooling in idle mode is limited by room temperature, because there can be no temperature below it in ordinary dropsy. In any case, it is much more interesting to see what the situation will be under load.

15 minutes of “office work” and the temperature of the video card rose to 35 ° C.

We start by checking the CPU, for which we use the OCCT 3.1.0 program - after a fairly long time in 100% load mode, the maximum processor temperature was38 ° C, and core temperatures 49-55 ° C, respectively. The temperature of the motherboard was 31 ° C, the north bridge - 38 ° C, the south - 39 ° C. By the way, it is very remarkable that all four cores of the processor had almost the same temperature - apparently, it was the merit of the water block, which removes heat evenly from the entire surface of the processor lid. 50+ degrees for a 4-core Intel Core i7-930 with a TDP of 130W - at least one stock air cooler is hardly capable of such a result. And even if it is capable, it is unlikely that anyone will like the noise from its operation (the Internet says about the temperature of this processor at 65-70 degrees with the cooler Cooler Master V10 - the one with the Peltier element).

The video card was heated out of habit with the FurMark 1.8.2 program(in common people, “bagel”) - it was unlikely to whip up something more resource-intensive and informative.

In addition to Everest, EVGA Precision 2.0 was also installed . At the maximum available resolution (with maximum smoothing), a stress test was launched with temperature logging - after about 3 minutes, the temperature of the video card was settled at 52 degrees! 52 degrees in load for the top-end (at the moment) NVIDIA GTX 480 video card based on Fermi architecture - it's not just great, it's great! )

For comparison, the temperature of a video card in a load with a standard cooler can reach up to 100 degrees, and with a good non-reference one - up to 70-80.

In general, the temperature regime is in perfect order - in the load, coolers blow almost cold air out of the radiator, and the radiator itself is barely warm. In this article I will not talk about overclocking potential, I will only say that it is. But much more pleasant is quite another - the system works almost silently!

You can talk for a long time about the result, but I liked it, like all those who have already seen it. Say what you like, but in the Thermaltake Level 10 case I managed to assemble a more than productive config that will be relevant for a long time. Moreover, almost without problems, a full-fledged water cooling system "stood up", which in addition to good cooling of the filling gives +5 to the appearance. Speaking about the temperature regime, we can safely speak of a solid potential for overclocking - now even in a load, the cooling system is far from the limit of possibilities.

I forgot to write about another important plus - interesting. Perhaps this is the most interesting thing that I had to do with the glands - not a single computer assembly brought so much pleasure! It’s one thing when you collect the usual “soulless” compics, it’s a completely different thing when you understand all the responsibility and approach the matter with all your heart. Such work takes far from 5 minutes - all this time you feel like a child playing an adult constructor. And also an engineer-technologist-designer-plumber-designer, and just a geek ... in general, the interest is greatly increased!

Good luck and frosty freshness!

Radiators and coolers - even writing about this is not so interesting, because all this has long been on any computer and you won’t surprise anyone. Liquid nitrogen and all sorts of systems with a phase transition are another extreme, the chances of meeting with which in the economy of an ordinary person are almost zero. But the dropsy ... in the matter of cooling the computer, it’s like a middle ground - unusual, but affordable; almost no noise, but at the same time, anything can cool. In fairness, it is more correct to call a water-cooling system (water cooling system) as a water cooling system (liquid cooling system), because, in fact, you can pour anything inside. But, looking ahead, I used plain water, so I’ll use more of the term CBO.

More recently, I wrote in sufficient detail about the assembly of a new system unit. The resulting stand was as follows:

- Thermaltake Level 10 chassis - Thermaltake Toughpower Grand 750W

power supply - ASUS Rampage III Extreme motherboard - Intel Core i7-930 processor - Leadtek GeForce GTX 480 graphics card - Crucial Ballistix Tracer memory - WD SiliconEdge Blue SSD hard drive A thoughtful study of the list suggests that the heat dissipation of some devices is not just high, but VERY high. And if you connect everything as it is, then inside even the most spacious case it will be at least hot; and as practice shows, it will also be very noisy.

Let me remind you that the case into which the computer is assembled is, albeit not very practical (although each time I am convinced of the opposite), but it is very presentable Thermaltake Level 10 - it has disadvantages, but you can forgive a lot for its appearance alone .

I did a reviewof this building, then a less productive stand was going into it - with the temperature regime everything was not bad, although according to the assurances of many reputable iron sites, the building is completely not intended for collecting really powerful configs. Moreover, according to the same publications, the casing is also unsuitable for installing a liquid cooling system, with which without checking I once agreed. Finally, I had the opportunity to refute both of these statements by doing some useful things - assembling a computer, installing a water cooling system in it and telling you about it. Let me tell you on the example of a rare and expensive case, but nothing prevents you from applying the acquired knowledge on any other case - it will only be easier!

And the last one. I thought for a long time about how to present all the information I received. As a result, having looked at 1000+ photos taken during the work, I wrote a universal algorithm (sequence of actions) for assembling the SVO - I got 8 points, about each of which I wrote in detail and with pictures. Someone may get fewer of these points, some may have more, but in general, this “HowTo” can be used for any system - add to favorites, you look, it will come in handy;)

Go-go-go!

On one of the days off (on the day off), I arrived in a chock-full, clogged-up iron car in a store and we almost immediately began to solve the problem. In addition to me there were two more people (Maxim and Aleksey), the third came in the evening - to look at the result and offer us a way to solve one problem (because of which the assembly of the system was very delayed). Looking ahead - it is very good that everything happened in the store, where everything was necessary - without it I would have spent 100% more money, time and nerves.

So, the goal was set - to assemble a single-circuit water cooling system that would effectively cool the motherboard, processor and video card. As quiet as possible, ideally with the possibility of further upgrading the system .

Having estimated the action plan, the necessary iron and its presence on the shelves of the store, we took up screwdrivers. Like it or not, you need to start with the motherboard - it is the most important thing in the computer.

Installing a fullcover water block on the motherboard

The motherboard ASUS Rampage III Extreme is very popular in the overclocking environment - if you look at world records, then in very many cases it appears. Great potential and technological prospects, the "freshness" of the model and the ASUS brand itself - all this was the result of the appearance on the market of various accessories tailored specifically for this board. In particular, I'm talking about a fullcover water block (there are already three different models on the overhard for this board ). Fullcover - means that this piece of iron covers all the necessary elements of the board (very hot, especially during overclocking), such as mosfets, north and south bridges.

For simpler motherboards (and for less common ones), there are many ordinary water blocks that cool only a particular area, but in this case it is easy to run into a “file”, and the number of tubes for liquid will in any case be larger.

We chose the nickel-plated fullcover-water block EK-FB RE3 (from EK Waterblocks) - an expensive piece of metal with various cavities, which is suitable for the device as a native, skillfully bypassing all capacitors, protrusions and other features of the relief.

When designing motherboards, the radiators of the power subsystem of the central processor are designed to blow the cooler of the central processor. When installing a CBO, mosfets lose their airflow, and even with a slight acceleration, their temperature can reach critical 100 degrees. So fullcover for ASUS Rampage III Extreme is what the doctor ordered!

Pay attention to how complicated the design of the water block. In addition to the mirror polishing of the base, the unusual shape of the piece of iron itself and the precisely milled holes for the capacitors, there is a space inside (with no less complex geometry) along which water will flow. Horror.

The installation process to disgrace is simple. We unscrew the 9 screws on which the stock fullcover radiator rests - it is beautiful, so we will not throw it out.

Max at work)

Along the way, we pull out the luminous washer “ROG Connect” - it will still be useful to us.

Then we take some cotton wool and remove the thermal interface that was on the microcircuits under the radiator. You can use a special liquid to remove thermal paste - it helps. Next, take a thermal pad (it comes complete with a water block) and, following the instructions, cut out the necessary pieces - paste them on the mother’s schemes.

Next, we simply screw the water block, after installing “standoffs” (small plastic rings that prevent distortions and tensions of the water block) in the screw holes.

The weight of the water block is 550 grams, so for reliability on the back of the motherboard you need to install a load-balancing backplate.

The final touch is the installation of the ROG Connect indicator, for which there is now a corresponding recess. With a successful set of circumstances, in the load mode, such a water block is able to remove up to 40 degrees of heat.

Installing a water block on the processor

So that the motherboard could be removed for some time, we decided to install a water block on the processor - for obvious reasons, it can only be fullcover for processors :)

We used the cross-socket (775/1366) Enzotech Stealth - a stylish black water block made in compliance with the most high requirements (the base is polished to a mirror shine, the maximum deviation from a straight line is less than 0.0003 inches).

In addition to it, the kit included:

- Backplates for 775 and 1366 sockets

- Backplates for 775 and 1366 sockets - One Enzotech 1366EZ mounting frame

- 4 nylon spacers

- 4 mounting screws

- 2 Christmas tree high-fittings with a diameter of 13 mm (with o-rings)

- 2 hose clamps with an internal diameter of 13 mm

- Arctic Silver Céramique thermal paste tube

The procedure is approximately the same, you don’t need to dismantle anything - first we install a protective backplate on the back of the motherboard (weight of the water block is 250 grams), and on the front side we put special frame (as is the case with air coolers).

We open the socket, put the processor in it, similarly we clean (already from the fat) the heat-distributing cover of the processor, apply a thin layer of thermal paste and install the water block on top. Just in case, you can immediately remove it to make sure (due to poor visibility) that there is the necessary contact between the processor cover and the base of the water block. Once again, we carefully clean both surfaces and, with complete confidence in a screwdriver, tighten the screws on the water block.

In order not to lose the parts, we screw both fittings from the kit - they are quite stylish by default. All.

Installing a fullcover water block on a video card

If you deprive the components of the guarantee, then all at once;) Now we come to the hottest component of the system, to the Leadtek GeForce GTX 480 video card - if you believe the tests, then this lady easily heats up to 100+ degrees in the load, which is accompanied by an equally disturbing hum stock turbine.

To complete the picture, it was also decided to use a fullcover-water block. For graphics cards with NVIDIA Fermi architecturethey were already used up quite a lot, and we, apparently, were lucky - the Leadtek GeForce GTX 480 had a "reference design", that is, the one that was originally designed by NVIDIA itself. Most often, the most obvious sign of a non-reference design is a non-standard cooling system - what manufacturers give out as a plus (in fact, it is). It is much worse when the wiring on the board is modified - it will be much more difficult to guess here.

In the hope that everything works, we started dismantling the factory cooling system (the loss of warranty starts from this stage). In the case of this video card, the process is somewhat tiring - 17 screws from the side of the PCB and 2 from the side of the connectors. Next, carefully remove the entire radiator, having previously disconnected the cooler wire from the board.

Trying a fullcover water blockEK-FC480 GTX Nickel + Plexi was a success - it fits perfectly)

We open the instructions, start cutting thermal pads (it is best to do with scissors, which are not a pity or with an office knife).

We stick thermal pads - it is very important to stick them correctly, so read the instructions carefully!

We put the standoffs in the holes of the water block mounting, we clean the GPU cover with a special liquid, apply a thin layer of thermal paste and put on the water block.

For reliability, this high-tech sandwich lacks 9 screws - the most important thing is not to tighten them very much!

Further, the video card was tried on to the motherboard - beautifully, of course, but the textolite is completely unpresentable. Moreover, it can be accidentally touched and damaged, water can drip on top of it ... in general, it was decided to install a decorative-protective fullcover backplate, which became the EK-FC480 GTX Backplate Nickel . There were no problems with installing it at all - they installed and realized that they had not lost. Actually, that's all.

Even when I was working for the “skinny” GeForce 2 MX 400, and people were taking the 8800s with might and main - I think from that moment on, many (and mine too) had the memory that the video card is soooo big. What can I say about modern "fools" who have ceased to fit in many cases (the length of some video cards is almost 30cm!). Then it always seemed to me that under the protective casing of these various electronics were teeming, but, as it turned out, it was the cooling system radiator that occupied most of the space - the board itself was very thin.

I mean, to see such a thin top-end video card is very unusual - the height of the water block is only 8.8 millimeters, so the total video card is slightly higher than a centimeter, which is less than the height of the plug for a PCI slot! Accordingly, there will be no problems with the creation of an SLI system (for 2-3-4 video cards).

It involuntarily seems that such a system simply cannot work efficiently ... but when you take it in your hands ... By the way, the weight of a water block alone is 950 grams without fittings and plugs! The weight of the video card assembly was 1.22kg.

At this stage, the motherboard was installed in the case, a video card was installed in it - previously in the highest PCI-slot.

Installing a radiator / pump / tank

One of the most interesting stages of work, which took us the most time (if we immediately went the easy way, we would have managed in half an hour, but first we tried all the difficult options, because of which all the work stretched for 2 days in total (Of course, far from incomplete.)

The water cooling system is very similar to that used in cars, just a little more - there is also a radiator (most often not one), a cooler, coolant, etc. But the car has one advantage - solid counter flow of cold water spirit, which plays a key role in the cooling system while driving.

In the case of a computer, heat must be removed by the air that is in the room. Accordingly, the larger the size of the radiator and the number of coolers, the better. And since you want a minimum of noise, effective cooling will be achieved mainly due to the surface of the radiator.

And the essence of the problem was as follows. On Skype, we previously agreed that “we will hang 2-3 sections behind the radiator — it will be more than enough!”, But as soon as we looked at the case, it turned out that everything was not so simple. Firstly, there was really not enough space for a three-section radiator (if you fasten the radiator to the hole where you would install the blowing cooler of the case), and secondly, even if it were enough, you couldn’t open the case itself - it would interfere "Door" of the system compartment :)

In general, we counted at least four options for installing a radiator in the Thermaltake Level 10 case - all of them are possible, each would require a different amount of time and each would have its own pros and cons. I will start with those that we considered, but which did not suit us:

1. Installing a radiator on the back (from the user) side, that is, on a removable door.

Pros:

+ The possibility of horizontal and vertical installation of any radiator, at least 3-4 coolers

+ The dimensions of the case would not particularly increase

Minuses:

- I would have to drill from 4 to 6-8 holes in the door

- It would be very inconvenient to remove the door

- With a horizontal arrangement would require a radiator with a non-standard arrangement of the hole for the fluid inlet

- With a vertical arrangement, the hoses would be very long and with a large bend

- The body would be on my left (on the windowsill), and I do not need warm air from the coolers in my face :)

2. Installing the radiator on top, on the "casing" of the power supply compartment . The pros and cons are identical

3. Installing a two-section radiator inside the system compartment

Pros:

+ Easy to solve

+ Outwardly there would be no changes

+ The door of the system compartment would open without problems

Cons:

- Only a 2-section radiator would fit (this is not enough for the config iron)

- In this case, cold air would not come from, and I did not want to drive warm air back and forth.

- There would be difficulties in “arranging” the pump and tank

- Even if we used ultra-thin coolers, all SATA connectors would overlap (if they were displayed to the user, and not to the side, this problem would not exist)

In general, we would have all these options to one degree or another they tried it - they spent a lot of time searching for the necessary components, trying them on, etc.

The most recent solution turned out to be a rather unusual solution - it may not be the most beautiful at first glance, but really practical. This is the installation of a radiator on the back of the case through a special adjustable adapter with a mechanism of the “scissors” type .

Pros:

+ I did not have to drill anything

+ The ability to hang ANY radiator

+ Excellent blowing

+ The access to the connectors of the motherboard did not overlap

+ The minimum length of hoses, the minimum of bends

+ The design is removable and

portable Cons:

- Not the most presentable appearance :)

- Opening the system compartment door is now not so easy

- Quite an expensive adapter

Why did we come to this option in last turn? Because during the searches for the previous three options, we accidentally found an adapter that everyone forgot about, but it wasn’t in the online store) Looking at the only (last) instance of the Koolance Radiator Mounting Bracket, I thought, "And why not come up with!". The bottom line is that in the holes for attaching to the rear blower cooler body 4 "conical nails" are inserted, on which a special frame is hung.

The design of this frame is such that its length can be changed by tightening the locks, and it is removed by mixing the two parts of its body (so that the holes open and it can be removed from the “studs”) - so I turned down! ) It is much easier to understand everything from the photo.

The frame is metal and very durable - I was convinced of this when we hung a 3-section (3 coolers) radiator for testing. Nothing dangles and does not swing, everything hangs tightly, but in the “open” case the door completely opened to itself - this option completely suited me!

There were a huge number of radiators to choose from - black, white, red ... In this matter, I was most surprised by the 4-section TFC Monsta , which is able to dissipate up to 2600W of heat (this, apparently, is an SLI out of four 480s)! But we people are much simpler, so we decided to stay on the radiator that we tried on - Swiftech MCR320-DRIVE . Its advantage is that it combines three components at once - a radiator (MCR320 QP Radiator for three 120mm coolers), a liquid tank and a high-pressure pump ( MCP350 Pump , a complete analogue of the “ordinary” Laing DDC pump) In fact, with such a piece of iron for NWO it will be necessary to buy only water blocks, hoses and other little things that we already had. The pump runs from 12V (8 to 13.2), making a noise of 24 ~ 26 dBA. The maximum pressure created is 1.5 bar, which is approximately equal to 1.5 "atmospheres".

There were three candidate coolers for the radiator - Noctua , Be Quiet and Scythe . As a result, settled on Indonesian (with Japanese roots) Scythe Gentle Typhoon(120mm, 1450 rpm, 21 dBA) - these turntables are not the first day in great demand among many users. They are very quiet, and the quality of balancing the bearings is simply surprising - the cooler will turn unnaturally for a long time even from the lightest touch. The service life is 100,000 hours at 30 ° C (or 60,000 hours at 60 ° C), which is enough for the obsolescence of this system unit.

A review of these "typhoons" was at the Center - I advise you to read . Protective grilles were placed on top of the coolers so that the child would not put anything vital in the fans.

We try on the resulting design for the system unit - it looks very unusual) But look, how convenient it is - to get inside the case (or remove the cooling system), just press one “button” and the whole structure is, in fact, already disconnected. We squeeze the mounting frame and have full access to the insides - it is more than spacious there, because we did not pile anything up there. Maybe I described not the most convenient option, but ... if you take into account that after assembling the computer you practically don’t have to climb inside, and good cooling is much more important, then I think our solution is right.

The assembly assembly weighs 2.25 kilograms, and with liquid and fittings, probably all 3 are looking ahead, even such a weight from the Koolance frame was enough, for which she respects and respects :)

Finish line

Finish line

The only thing left is to install all the components, “tie up with water” and test the resulting computer. It all started with the installation of fittings - such beautiful pieces of iron (in the form of "fir-trees") that are installed through special gaskets (and sometimes when the thread of the fitting is very long, through special spacers) into the corresponding hole of the water block or tank - we used a small adjustable wrench to tighten , but it’s also important not to overdo it.

In addition to the fittings, special plugs were installed in the two holes of the water block of the video card:

After that, we thought out the route along which water will go. The rule is simple - from less heated to more. Accordingly, the “output” of the radiator is connected first with the water block of the motherboard, from it the output to the processor, then to the video card and then back to the radiator input, cool down. Since there is one water at all, the temperature of all components as a result will be approximately the same - it is from these considerations that multi-circuit systems are made and for this reason it does not make sense to connect all kinds of hard drives, RAM, etc. to the same circuit.

The role of the hose went to the red Feser Tube (PVC, operating temperature from -30 to + 70 ° C, tensile pressure 10 MPa), for cutting which a special predatory tool was used.

Cutting off the hose exactly - it may not be so difficult, but it is very important! Almost all hoses were equipped with special springs against bends and kinks of the hose (the minimum radius of the hose loop becomes ~ 3.5 cm).

For each hose (on both sides) in the fitting area, you need to install a “clamp” - we used the beautiful Koolance Hose Clamp . They are installed using ordinary pliers (with brute masculine force), so you need to act carefully so as not to accidentally hurt anything.

The time has come to work on connecting the “inner world” with the “outer”. In order to be able to remove the radiator-tank-pump (for example, to open the case or for transportation), we put on the tube the so-called “quick couplers” (quick-release valves), the principle of operation of which is outrageously simple.

The time has come to work on connecting the “inner world” with the “outer”. In order to be able to remove the radiator-tank-pump (for example, to open the case or for transportation), we put on the tube the so-called “quick couplers” (quick-release valves), the principle of operation of which is outrageously simple. When we rotate the connection (as with BNC connectors), the hole in the tube closes and opens, so you can dismantle the dropsy in less than a minute, without any puddles and other consequences. A couple more expensive, but beautiful looking piece of iron:

Costs

5110 - EK FB RE3 Nickel water block on the

3660 motherboard - EK-FC480 GTX Nickel + Plexi water block on the video card

1065 - EK-FC480 GTX backplate Nickel on the video card

2999 - Enzotech Stealth water block on the

9430 processor - Swiftech MC3 pump / radiator / tank DRIVE

2610 - Two Quick Release Valves Release Coupling

4000 - Koolance Radiator Mounting Bracket

1325 Adapter - Three Scythe Gentle Typhoon Coolers (120mm) for Radiator

290 - Four EK-10mm High Flow Fitting

430 Fittings - Arctic-Cooling-MX-3

400 Thermal Grease - Nine hose clamps Koolance Hose Clamp

365 - Nanoxia HyperZero

355 Fluid - Feser Tube Hose

Such a high price in this case is due to the fact that fullcover-water blocks were used for VERY hot pieces of iron, all the heat from which must be dissipated by an appropriate radiator. For simpler systems, such solutions simply will not be needed, you can also do without decorative pads and any quick-release valves - in such cases, you can easily meet half the cost. The price of the average dropsy is 12-15 thousand rubles, which is 4-5 times higher than the cost of a really good processor cooler.

Inclusion and work

After all the components of the system were connected, the time came for a “leak test” (leak test) - coolant was poured into the radiator (twice distilled Nanoxia HyperZero water of red color, with anticorrosion and antibiological additives) - the order entered the circuit 500 ml

The guy runs in habramayke radiator)

Because it is impossible to exclude the possibility that something was connected to the computer components incorrectly, it was decided to separately check the operation of the water cooling system itself. To do this, all wires (from coolers and from the pump) were connected, and a paper clip was inserted into the 24-pin connector of the power supply for idling. Just in case, we put napkins downstairs to make the smallest leak easier to detect.

Pressing a button and ... everything as intended) Honestly, before that I had to see dropsy (besides the Internet) only at various exhibitions and competitions, where it was very noisy; therefore, I unconsciously prepared for the “murmur of a stream”, but the noise level was pleasantly surprised - for the most part, only the operation of the pump was audible. Initially, there were “hissing” sounds - due to air bubbles inside the circuit (they were visible in some places of the hoses). To solve this problem, the plug of the radiator tank was opened - from the circulation of the flow, the air gradually came out and the system began to work even quieter. After adding fluid, the plug was closed and the computer worked for another 10 minutes. No noise was heard from the cooler of the power supply and from three on the radiator at all, although their air currents made themselves felt.

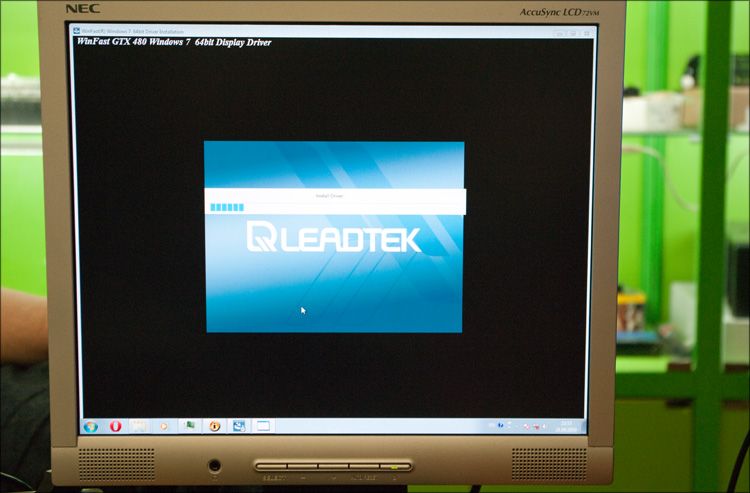

After making sure that the system is fully operational, we decided to finally assemble the test bench. Connecting the wires took no more than a minute - they looked much longer for the monitor and the wire for connecting it, because everyone worked on laptops;) The phrase “Reboot and select proper boot device or insert boot media in selected boot device and press a key” became a balm for the soul - we inserted one of the “working” SSDs (with Windows 7 on board) - it is good that the new comp has accepted such an option. For complete happiness, we just updated the drivers for the chipset and installed the drivers for the video card.

Run the diagnostic monster Everest, where on one of the tabs we find the readings of temperature sensors: 30 ° C were valid for all components of the system - CPU, GPU and motherboard - well, very nice numbers. The equality of numbers led to the assumption that cooling in idle mode is limited by room temperature, because there can be no temperature below it in ordinary dropsy. In any case, it is much more interesting to see what the situation will be under load.

15 minutes of “office work” and the temperature of the video card rose to 35 ° C.

We start by checking the CPU, for which we use the OCCT 3.1.0 program - after a fairly long time in 100% load mode, the maximum processor temperature was38 ° C, and core temperatures 49-55 ° C, respectively. The temperature of the motherboard was 31 ° C, the north bridge - 38 ° C, the south - 39 ° C. By the way, it is very remarkable that all four cores of the processor had almost the same temperature - apparently, it was the merit of the water block, which removes heat evenly from the entire surface of the processor lid. 50+ degrees for a 4-core Intel Core i7-930 with a TDP of 130W - at least one stock air cooler is hardly capable of such a result. And even if it is capable, it is unlikely that anyone will like the noise from its operation (the Internet says about the temperature of this processor at 65-70 degrees with the cooler Cooler Master V10 - the one with the Peltier element).

The video card was heated out of habit with the FurMark 1.8.2 program(in common people, “bagel”) - it was unlikely to whip up something more resource-intensive and informative.

In addition to Everest, EVGA Precision 2.0 was also installed . At the maximum available resolution (with maximum smoothing), a stress test was launched with temperature logging - after about 3 minutes, the temperature of the video card was settled at 52 degrees! 52 degrees in load for the top-end (at the moment) NVIDIA GTX 480 video card based on Fermi architecture - it's not just great, it's great! )

For comparison, the temperature of a video card in a load with a standard cooler can reach up to 100 degrees, and with a good non-reference one - up to 70-80.

In general, the temperature regime is in perfect order - in the load, coolers blow almost cold air out of the radiator, and the radiator itself is barely warm. In this article I will not talk about overclocking potential, I will only say that it is. But much more pleasant is quite another - the system works almost silently!

The end

You can talk for a long time about the result, but I liked it, like all those who have already seen it. Say what you like, but in the Thermaltake Level 10 case I managed to assemble a more than productive config that will be relevant for a long time. Moreover, almost without problems, a full-fledged water cooling system "stood up", which in addition to good cooling of the filling gives +5 to the appearance. Speaking about the temperature regime, we can safely speak of a solid potential for overclocking - now even in a load, the cooling system is far from the limit of possibilities.

I forgot to write about another important plus - interesting. Perhaps this is the most interesting thing that I had to do with the glands - not a single computer assembly brought so much pleasure! It’s one thing when you collect the usual “soulless” compics, it’s a completely different thing when you understand all the responsibility and approach the matter with all your heart. Such work takes far from 5 minutes - all this time you feel like a child playing an adult constructor. And also an engineer-technologist-designer-plumber-designer, and just a geek ... in general, the interest is greatly increased!

Good luck and frosty freshness!