Industrial revolution. Part 3. 3D printer for $ 1000

In the previous parts of the translation of the article “In the Next Industrial Revolution, Atoms Are the New Bits”, you could learn about virtual mini-factories and Rally Fighter - a car created by the “crowd” . Today I will tell you about existing 3D printers and how, using www.alibaba.com , you can order and produce almost anything in China!

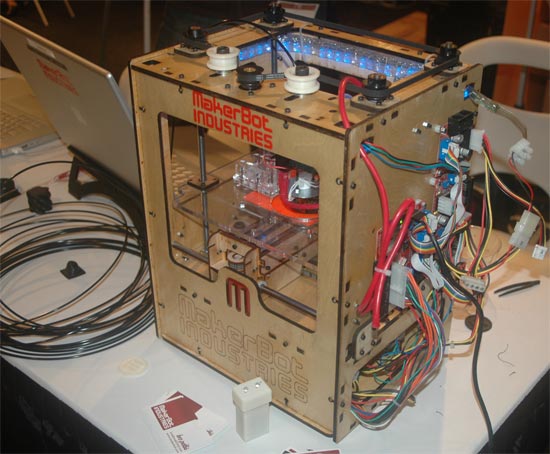

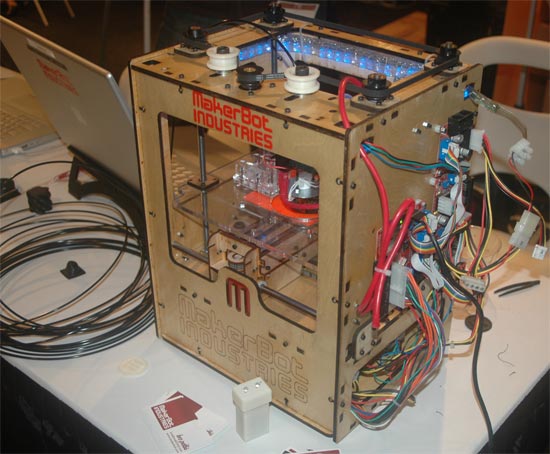

In a former Brooklyn brewery, Bre Pettis and his engineering team assemble MakerBot- The first 3D printer costing less than $ 1,000! Unlike inkjet printers, instead of ink, MakerBot builds objects by extruding a layer of molten plastic (ABS Plastic) 0.33 mm thick. Just 5 years ago, you couldn't get anything like that for less than $ 125,000.

At the production site, you can see 100 boxes of MakerBots, lined up and ready to go to their customers. To date, 500 MakerBots have already been sold and, with each instance sold, more and more new ideas are emerging regarding its possible use. For example, instead of the usual head that squeezes liquid plastic, you could create a cutting head by making a saw machine out of the printer for wood, metal, or just ice cubes for drinks!

MakerBot is designed to make plastic parts based on a three-dimensional model file. Want to create a gear? Create a gear model and print it on the printer! Want to change a product that you already have? Scan it (researchers at Cambridge University have developed a technology that allows you to create a 3D file by rotating an object in front of a web camera), correct it in a 3D designer, such as Google SketchUp , and upload it to ReplicatorG . Within minutes, you will receive a new physical object.

With other tools, you can do more! So, the ShopBot PRSalpha machinecosting $ 18,000 will allow you to create wooden products the size of the front door. Or you can buy yourself a smaller installation for $ 1,500 from buildyourcnc.com . If you work with metal, try a machine for $ 2000. Well, if you are fond of electronics, create your own circuit board using CadSoft Eagle , after which you can make it in Advanced Circuits .

The same applies to laser, plasma and water machines. Using this approach, you can create anything from a piece of jewelry to a car chassis. To be honest, tens of thousands of people do that. We have already seen the do-it-yourself boom on the example of creating T-shirts and mugs, then on the example of Etsy- a portal for trade in hand-made items (Etsy's sales turnover last year was about $ 200 million ). Now the do-it-yourself boom is moving into more complex applications, such as creating 3D models from plastic and open source electronic equipment, such as the groundbreaking Arduino project .

Using such tools, individuals can produce products previously available only to full-fledged manufacturers. In addition, over the past few years, Chinese manufacturers have learned to process small orders more efficiently, which has allowed us to produce almost anything on virtually any scale of production.

First, the maturity and web orientation of business in China led to this situation. Chinese factories accept more and more orders via the Web, communicate with customers via email, and accept payments via credit cards or PayPal, a convenient alternative to bank transfers, letters of credit, etc. In addition, the economic crisis has forced companies to seek individual orders that have higher profitability.

To plunge into the new world of opportunities offered by Chinese factories, go to Alibaba.com, which is the largest directory of Chinese manufacturers and suppliers. On it, using a regular search, you can find the providers you need and then through the Instant Messaging system find out if they can do what you need. Alibaba's instant messaging system contains an online translator from English to Chinese, so that people can communicate in their own language. Usually the answer comes within a few minutes: “we can’t do this” or “we can do it and this is how you can place an order” or “we have already done something similar and that’s how much it will cost”.

Alibaba CEO Jack Ma calls it “C to B” (consumer to business). This is a new type of trading that is ideal for do-it-yourself entrepreneurs. “If we support companies in smaller cross-border operations, profits can be large because, in this case, unique goods will be produced, not consumer goods,” says Ma. Since its founding in 1999, Alibaba has become a company with a turnover of 12 billion US dollars and 45 million registered users worldwide. The initial public offering of $ 1.7 billion in 2007 was the largest since Google. According to Ma, over 1.1 million jobs have been created in China over the past three years by companies doing business through Alibaba.

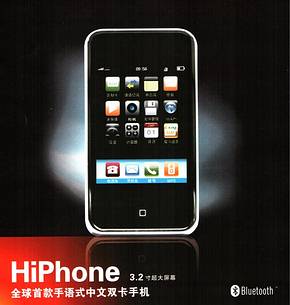

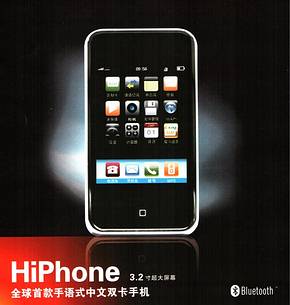

What is happening is very close to shanzhai . The term “shanzhai,” which translates from Chinese as “gangster,” usually refers to a thriving electronics counterfeit business, or, as shanzhai.com defines it , is a “supplier that conducts business without following traditional rules and regulations, which often leads to innovative and unusual products or business models. ” But interestingly, these same suppliers are the catalysts for the production side of the industrial revolution, quickly and flexibly responding to any wishes of micro-entrepreneurs. Boosting Business Practices “shanzhai” “offers a new approach to economic recovery, based on a closer connection of small companies with each other,” says Tom Igoy, a leading developer of open source computing platform Audrino. “What happens if you apply this approach in the manufacturing world?” See you soon! ”

To be continued…

In a former Brooklyn brewery, Bre Pettis and his engineering team assemble MakerBot- The first 3D printer costing less than $ 1,000! Unlike inkjet printers, instead of ink, MakerBot builds objects by extruding a layer of molten plastic (ABS Plastic) 0.33 mm thick. Just 5 years ago, you couldn't get anything like that for less than $ 125,000.

At the production site, you can see 100 boxes of MakerBots, lined up and ready to go to their customers. To date, 500 MakerBots have already been sold and, with each instance sold, more and more new ideas are emerging regarding its possible use. For example, instead of the usual head that squeezes liquid plastic, you could create a cutting head by making a saw machine out of the printer for wood, metal, or just ice cubes for drinks!

MakerBot is designed to make plastic parts based on a three-dimensional model file. Want to create a gear? Create a gear model and print it on the printer! Want to change a product that you already have? Scan it (researchers at Cambridge University have developed a technology that allows you to create a 3D file by rotating an object in front of a web camera), correct it in a 3D designer, such as Google SketchUp , and upload it to ReplicatorG . Within minutes, you will receive a new physical object.

With other tools, you can do more! So, the ShopBot PRSalpha machinecosting $ 18,000 will allow you to create wooden products the size of the front door. Or you can buy yourself a smaller installation for $ 1,500 from buildyourcnc.com . If you work with metal, try a machine for $ 2000. Well, if you are fond of electronics, create your own circuit board using CadSoft Eagle , after which you can make it in Advanced Circuits .

The same applies to laser, plasma and water machines. Using this approach, you can create anything from a piece of jewelry to a car chassis. To be honest, tens of thousands of people do that. We have already seen the do-it-yourself boom on the example of creating T-shirts and mugs, then on the example of Etsy- a portal for trade in hand-made items (Etsy's sales turnover last year was about $ 200 million ). Now the do-it-yourself boom is moving into more complex applications, such as creating 3D models from plastic and open source electronic equipment, such as the groundbreaking Arduino project .

Using such tools, individuals can produce products previously available only to full-fledged manufacturers. In addition, over the past few years, Chinese manufacturers have learned to process small orders more efficiently, which has allowed us to produce almost anything on virtually any scale of production.

First, the maturity and web orientation of business in China led to this situation. Chinese factories accept more and more orders via the Web, communicate with customers via email, and accept payments via credit cards or PayPal, a convenient alternative to bank transfers, letters of credit, etc. In addition, the economic crisis has forced companies to seek individual orders that have higher profitability.

To plunge into the new world of opportunities offered by Chinese factories, go to Alibaba.com, which is the largest directory of Chinese manufacturers and suppliers. On it, using a regular search, you can find the providers you need and then through the Instant Messaging system find out if they can do what you need. Alibaba's instant messaging system contains an online translator from English to Chinese, so that people can communicate in their own language. Usually the answer comes within a few minutes: “we can’t do this” or “we can do it and this is how you can place an order” or “we have already done something similar and that’s how much it will cost”.

Alibaba CEO Jack Ma calls it “C to B” (consumer to business). This is a new type of trading that is ideal for do-it-yourself entrepreneurs. “If we support companies in smaller cross-border operations, profits can be large because, in this case, unique goods will be produced, not consumer goods,” says Ma. Since its founding in 1999, Alibaba has become a company with a turnover of 12 billion US dollars and 45 million registered users worldwide. The initial public offering of $ 1.7 billion in 2007 was the largest since Google. According to Ma, over 1.1 million jobs have been created in China over the past three years by companies doing business through Alibaba.

What is happening is very close to shanzhai . The term “shanzhai,” which translates from Chinese as “gangster,” usually refers to a thriving electronics counterfeit business, or, as shanzhai.com defines it , is a “supplier that conducts business without following traditional rules and regulations, which often leads to innovative and unusual products or business models. ” But interestingly, these same suppliers are the catalysts for the production side of the industrial revolution, quickly and flexibly responding to any wishes of micro-entrepreneurs. Boosting Business Practices “shanzhai” “offers a new approach to economic recovery, based on a closer connection of small companies with each other,” says Tom Igoy, a leading developer of open source computing platform Audrino. “What happens if you apply this approach in the manufacturing world?” See you soon! ”

To be continued…