122 days under UV rays: comparative testing of 3D printed products made of ABS and ASA plastics

A few days ago, comparative testing of plastics for resistance to UV radiation with a duration of 122 days was completed.

Two kinds of similar plastic took part in the test - white ABS and white ASA.

If the ABS plastic is known to everyone, then the ASA plastic went on sale not so long ago, and is positioned as protected from ultraviolet radiation.

We were interested to find out how much ASA is more resistant to UV than ABS.

Introduction Goals, objectives and means of testing: the

Testing was carried out using a 30 W bactericidal lamp T8 HNS from OSRAM ( Ledvance ). This lamp emits the ultraviolet of the toughest "C" range.

In nature, this radiation is delayed by the atmosphere.

This lamp has been selected for accelerated testing.

Many polymers used in consumer goods are degraded by UV light. The problem manifests itself in the disappearance of color, fading of the surface, cracking, and sometimes complete destruction of the product itself. The rate of destruction increases with increasing exposure time and the intensity of sunlight. The described effect is known as UV aging and is one of the varieties of aging polymers.

Sensitive polymers include thermoplastics, such as polypropylene, polyethylene, polymethyl methacrylate (organic glass), as well as special fibers, for example, aramid fiber. Absorption of UV leads to the destruction of the polymer chain and loss of strength in a number of points of the structure.

The electromagnetic spectrum of UV radiation can be divided into subgroups in different ways. The ISO standard for the definition of solar radiation (ISO-DIS-21348) gives the following definitions:

The near UV range is often referred to as “black light,” since it is not recognized by the human eye, but when reflected from certain materials, the spectrum shifts to visible light due to the phenomenon of photoluminescence. But at relatively high brightness, for example, from diodes, the eye sees purple light, if the radiation captures the border of visible light 400 nm.

For the far and extreme ranges, the term “vacuum” (VUV) is often used, in view of the fact that waves in this range are strongly absorbed by the Earth’s atmosphere.

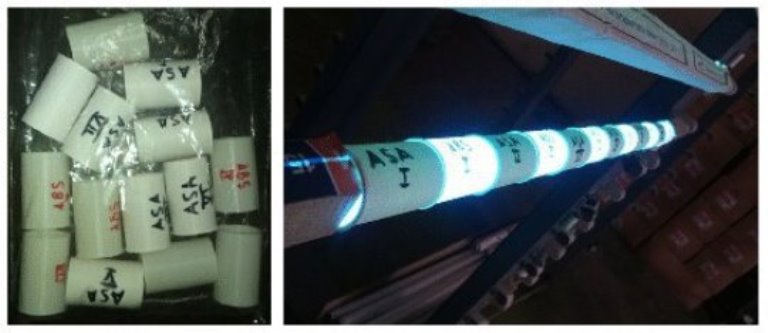

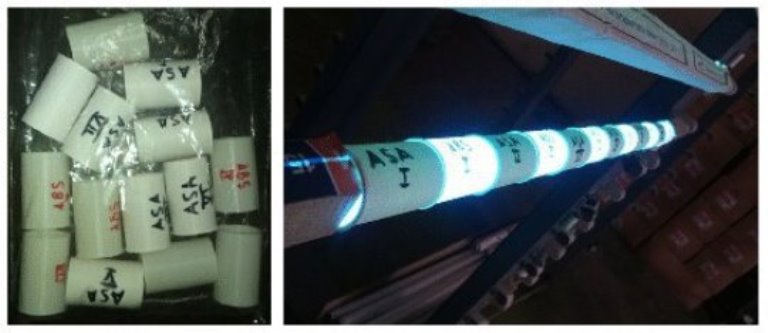

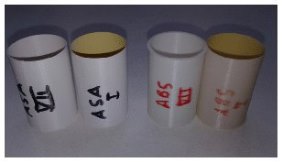

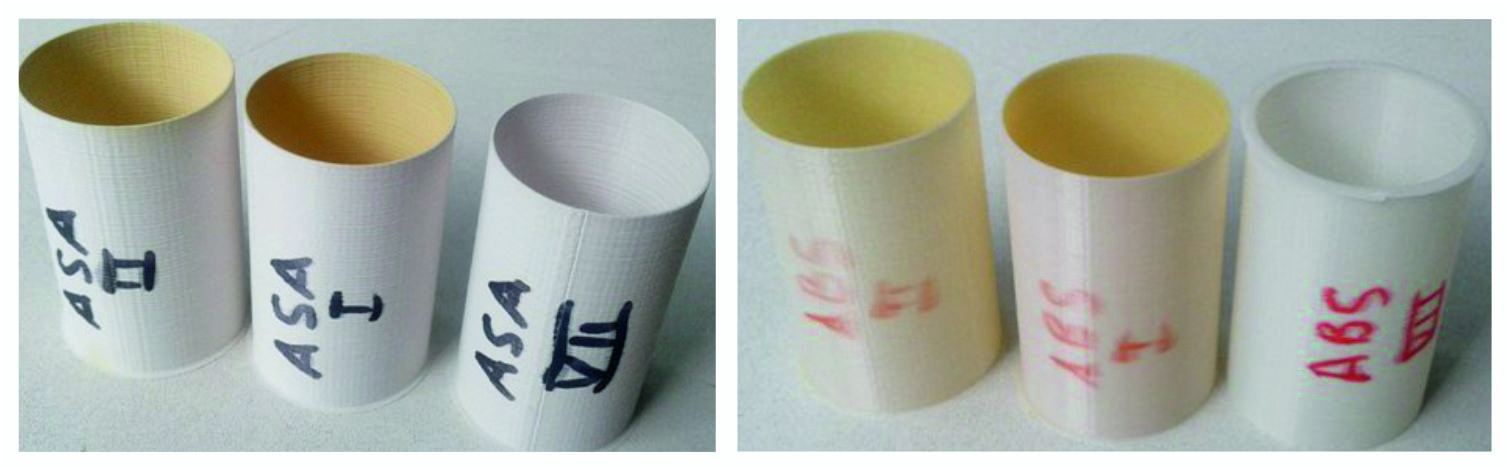

For the test of both plastics, tubes with a diameter of 30 and a length of 50 mm were printed. 7 tubes of each type of plastic. Used plastic ASA and ABS white color from one manufacturer ( BestFilament ). Printed in one run nozzle of 0.5 mm with a layer thickness of 0.2 mm. Model wall thickness 0.5 mm. All tubes were numbered from I to VII. The first six test samples were worn on the lamp, and we left the samples with the number VII as a reference for comparative analysis. Samples were continuously irradiated with a UV “C” range for a varying amount of time, i.e. we shot one pair of tubes approximately every 20 days. All samples taken were stored in a plastic ZIP bag in a dark place until the end of the test.

Photos of all samples in the package and on the HNS lamp.

So, we started testing. The photo shows that UV is visible through ABS.

This means that the degradation of this plastic should occur throughout the volume.

ASA, by contrast, bravely held back hard radiation.

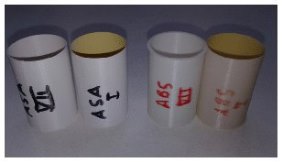

We removed the first pair after 18 days (432 hours) of UV exposure. It immediately became noticeable that the label on the ABS plastic had burnt out, but on the ASA there were apparently no changes. The inner surface of the tubes turned yellow and became dull. Visually, ABS has turned yellow more, even outside. Samples are smelt of flower pollen and burnt sugar.

We removed the second pair after 36 days (864 hours) of UV exposure. Compared with the first pair of significant changes are not noticed.

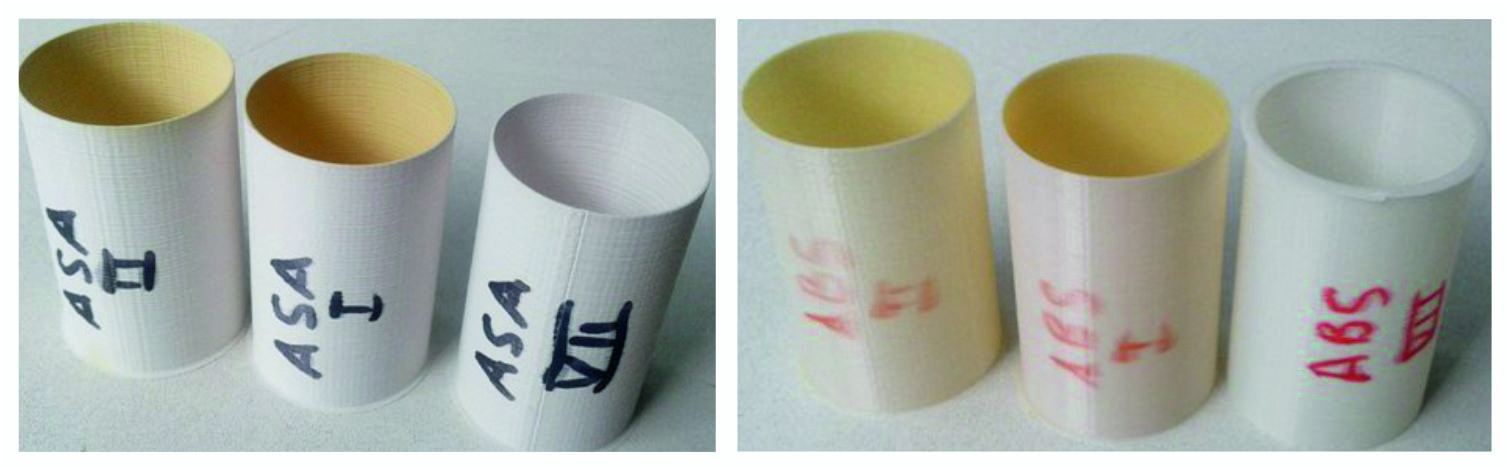

The third pair was removed after 57 days (1368 hours) of exposure to UV. ABS has become a bit more transparent. ASA unchanged compared to the first removal.

The fourth pair was removed after 75 days (1800 hours) of exposure to UV. ABS has become even more yellow. It feels like it is fading. Also, changes began to occur with the paper, which covered the edges of the lamp. The paper began to crunch.

The fifth pair was removed after 97 days (2328 hours) of exposure to UV. There are no strong differences from the previous sample.

The sixth pair decided to hold longer. In the end, she hung 122 days (almost 3000 hours) under continuous hard UV ... For comparison, we took a few photos, hanging the standard with samples VI. Glow from standards more transparent.

It is a pity that the camera does not transmit these shades. During this time, in the paper packaging appeared holes from the ultraviolet.

It's time to do some mechanical tests.

Yes, they all crushed and torn on special equipment. For this used two stands.

The first stand dynamometer SHIMPO FGV-10XY determines the maximum pressure force acting on the object. The second Regmed PU-2 stand defined the maximum tensile force, the amount of deformation before the break.

At first we crushed the tubes, putting them into a cradle of similar shape. After that, strips 5 mm wide were made of the samples and were torn at the second stand. All results are captured on video and tabulated.

Video tests: part 1

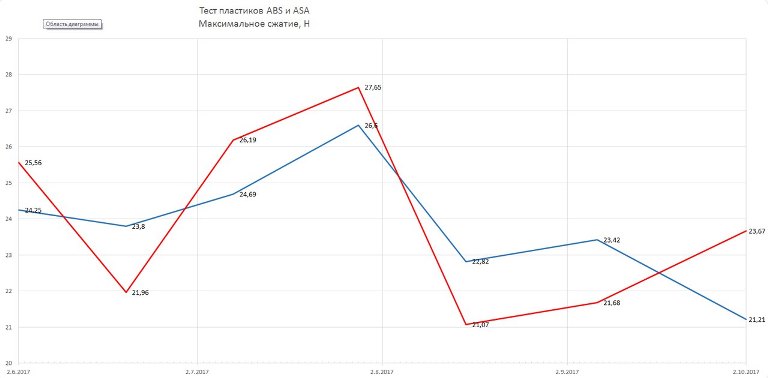

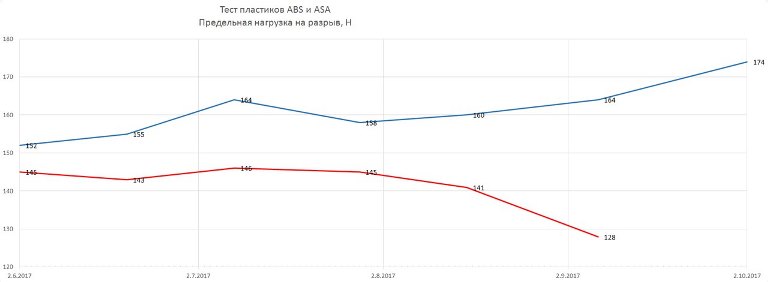

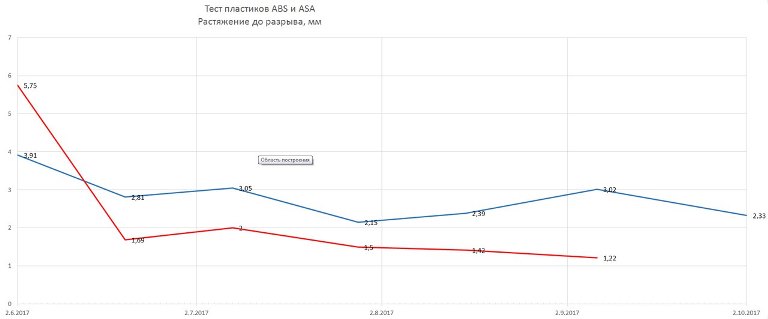

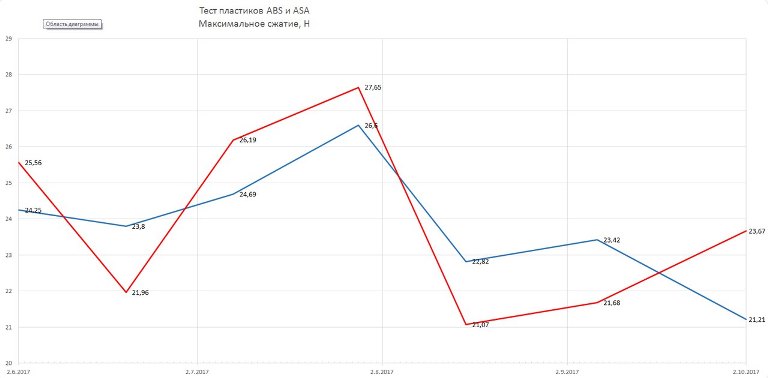

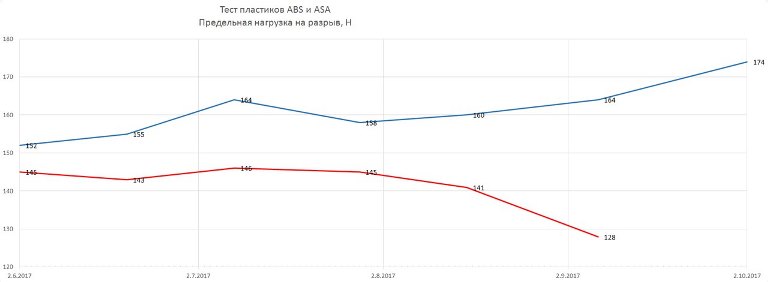

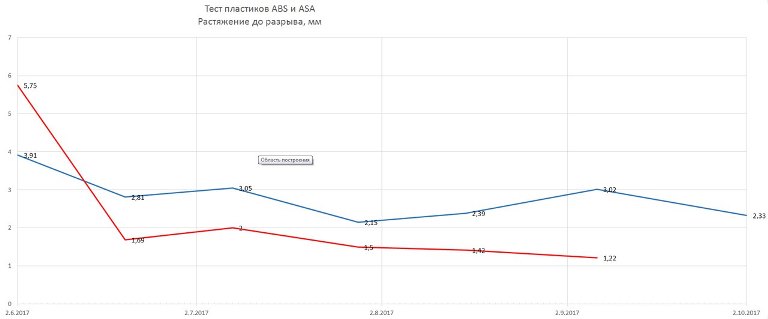

According to the obtained data, diagrams were constructed.

Testing has shown that ASA plastic fairly calmly endures long-term exposure to hard UV radiation without serious loss of physical properties. For 122 days of continuous irradiation, a slight decrease in the sample elasticity occurred with an increase in the tensile strength characteristic.

As for ABS plastic, it dramatically reduced the elasticity almost at the beginning of the test. Under the influence of hard UV radiation degradation of the material structure occurred, and the plastic became fragile. Test sample, sagging 122 days in the UV, failed. He broke when trying to clamp the ring in the installation.

Results and conclusions of testing.

The use of precisely the hard version of the C-band radiation made it possible to speed up the process and get results more quickly.

It is worth making the assumption that under the influence of sunlight the processes proceed in a similar way, only plastic degradation takes more time, since the UV “C” range is absorbed by the atmosphere, and in everyday life it is found only in water disinfection installations or in medical institutions in antibacterial air treatment devices .

Obviously, both of these plastics can be used in everyday printing. But if you decide to print parts for use under sunlight (signs, machine parts) it is better to use ASA.

Especially, if you plan to launch your satellite, or give to a friend doctor a plafond for a quartz lamp in the office.

Testing conducted: Silin Roman Smolensk

Two kinds of similar plastic took part in the test - white ABS and white ASA.

If the ABS plastic is known to everyone, then the ASA plastic went on sale not so long ago, and is positioned as protected from ultraviolet radiation.

We were interested to find out how much ASA is more resistant to UV than ABS.

Introduction Goals, objectives and means of testing: the

degradation of ABS and ASA polymers under the influence of UV radiation.

Testing was carried out using a 30 W bactericidal lamp T8 HNS from OSRAM ( Ledvance ). This lamp emits the ultraviolet of the toughest "C" range.

In nature, this radiation is delayed by the atmosphere.

This lamp has been selected for accelerated testing.

Many polymers used in consumer goods are degraded by UV light. The problem manifests itself in the disappearance of color, fading of the surface, cracking, and sometimes complete destruction of the product itself. The rate of destruction increases with increasing exposure time and the intensity of sunlight. The described effect is known as UV aging and is one of the varieties of aging polymers.

Sensitive polymers include thermoplastics, such as polypropylene, polyethylene, polymethyl methacrylate (organic glass), as well as special fibers, for example, aramid fiber. Absorption of UV leads to the destruction of the polymer chain and loss of strength in a number of points of the structure.

The electromagnetic spectrum of UV radiation can be divided into subgroups in different ways. The ISO standard for the definition of solar radiation (ISO-DIS-21348) gives the following definitions:

The near UV range is often referred to as “black light,” since it is not recognized by the human eye, but when reflected from certain materials, the spectrum shifts to visible light due to the phenomenon of photoluminescence. But at relatively high brightness, for example, from diodes, the eye sees purple light, if the radiation captures the border of visible light 400 nm.

For the far and extreme ranges, the term “vacuum” (VUV) is often used, in view of the fact that waves in this range are strongly absorbed by the Earth’s atmosphere.

Preparing the experiment.

For the test of both plastics, tubes with a diameter of 30 and a length of 50 mm were printed. 7 tubes of each type of plastic. Used plastic ASA and ABS white color from one manufacturer ( BestFilament ). Printed in one run nozzle of 0.5 mm with a layer thickness of 0.2 mm. Model wall thickness 0.5 mm. All tubes were numbered from I to VII. The first six test samples were worn on the lamp, and we left the samples with the number VII as a reference for comparative analysis. Samples were continuously irradiated with a UV “C” range for a varying amount of time, i.e. we shot one pair of tubes approximately every 20 days. All samples taken were stored in a plastic ZIP bag in a dark place until the end of the test.

Photos of all samples in the package and on the HNS lamp.

The course of irradiation of polymers.

So, we started testing. The photo shows that UV is visible through ABS.

This means that the degradation of this plastic should occur throughout the volume.

ASA, by contrast, bravely held back hard radiation.

We removed the first pair after 18 days (432 hours) of UV exposure. It immediately became noticeable that the label on the ABS plastic had burnt out, but on the ASA there were apparently no changes. The inner surface of the tubes turned yellow and became dull. Visually, ABS has turned yellow more, even outside. Samples are smelt of flower pollen and burnt sugar.

We removed the second pair after 36 days (864 hours) of UV exposure. Compared with the first pair of significant changes are not noticed.

The third pair was removed after 57 days (1368 hours) of exposure to UV. ABS has become a bit more transparent. ASA unchanged compared to the first removal.

The fourth pair was removed after 75 days (1800 hours) of exposure to UV. ABS has become even more yellow. It feels like it is fading. Also, changes began to occur with the paper, which covered the edges of the lamp. The paper began to crunch.

The fifth pair was removed after 97 days (2328 hours) of exposure to UV. There are no strong differences from the previous sample.

The sixth pair decided to hold longer. In the end, she hung 122 days (almost 3000 hours) under continuous hard UV ... For comparison, we took a few photos, hanging the standard with samples VI. Glow from standards more transparent.

It is a pity that the camera does not transmit these shades. During this time, in the paper packaging appeared holes from the ultraviolet.

Testing of prepared samples.

It's time to do some mechanical tests.

Yes, they all crushed and torn on special equipment. For this used two stands.

The first stand dynamometer SHIMPO FGV-10XY determines the maximum pressure force acting on the object. The second Regmed PU-2 stand defined the maximum tensile force, the amount of deformation before the break.

At first we crushed the tubes, putting them into a cradle of similar shape. After that, strips 5 mm wide were made of the samples and were torn at the second stand. All results are captured on video and tabulated.

Video tests: part 1

According to the obtained data, diagrams were constructed.

The results of comparative testing of polymers ABS and ASA.

Testing has shown that ASA plastic fairly calmly endures long-term exposure to hard UV radiation without serious loss of physical properties. For 122 days of continuous irradiation, a slight decrease in the sample elasticity occurred with an increase in the tensile strength characteristic.

As for ABS plastic, it dramatically reduced the elasticity almost at the beginning of the test. Under the influence of hard UV radiation degradation of the material structure occurred, and the plastic became fragile. Test sample, sagging 122 days in the UV, failed. He broke when trying to clamp the ring in the installation.

Results and conclusions of testing.

The use of precisely the hard version of the C-band radiation made it possible to speed up the process and get results more quickly.

It is worth making the assumption that under the influence of sunlight the processes proceed in a similar way, only plastic degradation takes more time, since the UV “C” range is absorbed by the atmosphere, and in everyday life it is found only in water disinfection installations or in medical institutions in antibacterial air treatment devices .

Obviously, both of these plastics can be used in everyday printing. But if you decide to print parts for use under sunlight (signs, machine parts) it is better to use ASA.

Especially, if you plan to launch your satellite, or give to a friend doctor a plafond for a quartz lamp in the office.

Testing conducted: Silin Roman Smolensk