Mega structures. The world's largest excavator Bagger 293

Bagger 288, the predecessor of Bagger 293, is slightly inferior in length, but has the same height of 96 m. The

Bagger 293 (TAKRAF RB293, TAKRAF SRs 8000 ) is a giant rotary excavator built in 1995 by the TAKRAF industrial company from Leipzig. In terms of its size, the Bagger 293 roughly corresponds to the Egyptian pyramid of Cheops in length / base (226 m versus 230 m), although it loses in height (96 m versus 138.8 m). But if you put next to Bagger 293 and the pyramid of Cheops, they will be very similar.

This giant holds the world record as the largest land vehicle in the world, as such it was recorded in the Guinness Book of Records. Interestingly, the Bagger 293 exceeded its legendary predecessor Bagger 288 quite a bit in length, while their height and width are about the same. It was Bagger 288 that for many years held the world record as the largest ground vehicle.

A rotary excavator is a continuous-action excavator on crawler or walking-rail running equipment that develops soil with the help of work items (buckets, scrapers or chisels) mounted on a rotary wheel.

The Bagger 293 excavator has a simple working principle. He removes the rock layer with buckets on the rotor wheel - and the rock is transferred along the transport belt to the place of loading. The process is organized in a manner similar to the illustration.

The TAKRAF

Bagger 293 rotary excavator was the next and largest in a series of similar rotary excavators, among which Bagger 281 (built in 1958), Bagger 285 (1975), Bagger 287 (1976), Bagger 288 (1978), Bagger 291 (1993) and others.

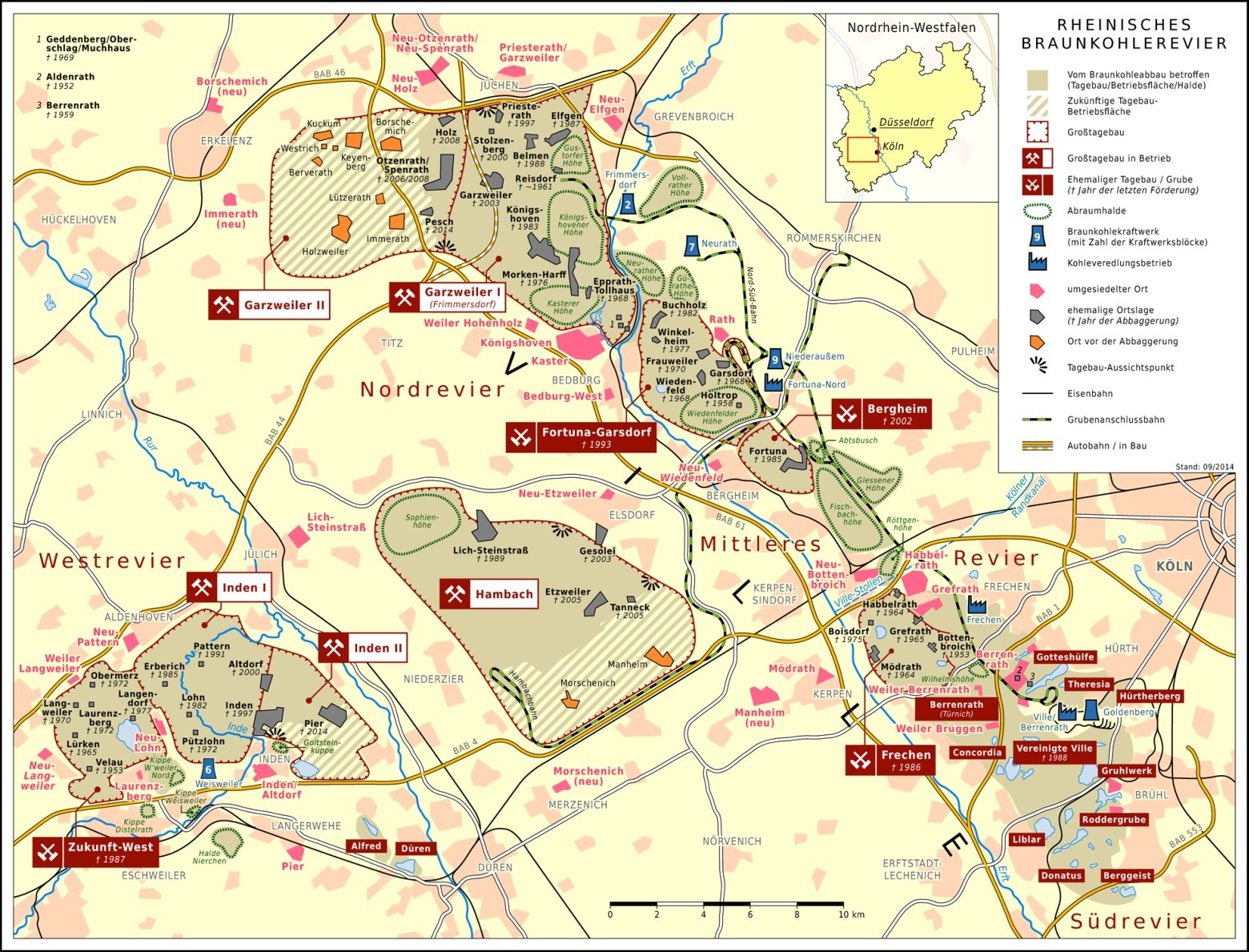

Now a giant machine is digging lignite in a large open pit (cut)Tagebau Hambach near the Tagebau Garzweiler quarry near the cities of Elsdorf, Grevenbroich and other cities in North Rhine-Westphalia (Germany) - it is difficult to accurately link careers to cities, because they are expanding towards one city or another, depending on whether what place of a cut excavators work more actively. But this area of coal mining is located south of Düsseldorf and west of Cologne.

The section Tagebau Garzweiler is named after the village that used to be located at this place. The neighboring Tagebau Hambach open- pit mine opened in 1978 and is also a record holder - it is one of the largest and deepest cuts in the world, its depth is about 370 m, and its area is 33.89 km 2. According to the original plans, the section was planned to be expanded to an area of 85 km 2 . Plans may not be realized if Germany follows the example of other countries in accordance with an international agreement to abandon coal-fired power plants, reduce carbon dioxide emissions into the atmosphere and commission new renewable energy power plants.

Quarry Tagebau Hambach

Bagger 293 is a complete vehicle. It moves on tracks with a speed of about 0.6 km / h. This is not to say that this is a very high speed, but in a few weeks the excavator can move from one pit to another. For example, in 2001, the engineers decided to transport the Bagger 288 to the next section - and in three weeks he did get there. But the larger Bagger 293, apparently, did not go anywhere at all after he got from the factory where he was assembled to the quarry where he had to work.

Bagger 293 while working in the Tagebau Hambach section, March 30, 2008

Technical Specifications of TAKRAF SRs 8000 Mining Rotary Excavators

Performance per day : 240,000 m 3

Height : 96 m

Length : 226 m

Maximum extension of the rotor wheel : 72.2 m

Distance to the center of the excavator : 138.75 m

Diameter of the rotor wheel : 21.6 m

Volume of each bucket : 6.6 m 3 The

number of buckets on the rotor wheel : 18

Weight : 14200 t

Bagger 293 is still working where it was sent after production. The site of the excavator can be seen on satellite photos : 50 ° 55 ′ 17 ″ N, 6 ° 30 ′ 30 ″ E; 50.921389, 6.508333, link to Google Maps and OpenStreetMaps .

Rotary excavators that mine brown coal in the Tagebau Garzweiler quarry, a satellite photo of Google Maps.

Each such excavator extracts coal per day to load approximately 2,400 train cars. The crew of the excavator consists of five people.

Similar TAKRAF bucket wheel excavators work worldwide. The company began production of these giants almost a hundred years ago. Interestingly, the very first copy of the TAKRAF rotary excavator was sent in 1926 to work in Namibia for the Consolidated Diamond Mines company. Since then, hundreds of these machines have spread across different continents. Now the company is proud that more than 50% of all the ore in the world is mined using its equipment.

Giants like Bagger 288 and Bagger 293 are not just very effective. They also demonstrate the brutal beauty of industrial design - the power of modern technology.