How 3D printers print bones, blood vessels, and organs

- Transfer

At the dawn of the development of rapid prototyping technology, it was widely believed that 3D printing transforms all production, stimulating the consumer revolution, with the result that the printer will appear in every home. This has not yet happened, however, as it happened with many latest technologies, rapid prototyping found its application in a completely different field - in medicine.

An article from the Gizmodo website.

Below we will talk about research and projects, which are the most interesting examples of the use of bioprinting and the use of computer-controlled machines for the assembly of biological matter, during which organic ink and ultra-strong thermoplastics are used. The range of application of bioprinting is very wide - from the reconstruction of the main parts of the human skull to the printing of scaffolds - scaffolds on which stem cells can develop into new bones. Read the details below.

Skulls

Osteofab is a product of Oxford Performance Materials . Initially, OPM entered the market by selling a highly effective polymer, often used in the manufacture of medical implants, as a thermoplastic called polyetherketone ketone (PEKK), but in the past few years the company has become the first to master the use of this material, especially in additive manufacturing . So, in February 2013, a 3D-implant of a part of the skull was installed on an American patient , the quality of which was approved by the FDA. The casting and printing were approached very carefully to match the unique geometry of the patient's skull, 75% of which is now an implant.

Leather

The main problem of creating new skin with the help of printing is the difficulty of reproducing a certain shade from the entire possible spectrum. Given that our skin is unique, thin and subject to change, it’s quite difficult to create an exact copy of it. There are many interesting studies on this subject, the essence of which cannot be put into a short story.

However, here are two of the most interesting: scientist James Yoo of Wyake Forest University, using a grant funded by the US Department of Defense, is working on a machine that can printskin directly on people who are victims of burns. Another study is conducted by scientists from the University of Liverpool, who use carefully calibrated 3D scanners to obtain skin samples containing all its smallest nuances, which will allow printing of more realistic implants in the future.

The study is still ongoing, and the team plans to create a “skin sample base” with scanned examples, which can be connected from remote hospitals where they do not have cameras necessary for scanning the skin of a particular patient. [ Gizmodo ; PhysOrg ]

Noses and ears

Creating prostheses for ears, noses, and chins is often a painful, expensive, and time-consuming process for both the patient and the doctor himself. Over the past 5 years, British industrial designer Tom Fripp, together with scientists from the University of Sheffield, has been developing a cheaper and easier to manufacture facial prosthesis, which can be obtained using 3D printing. The process of creating such a prosthesis includes a 3D scan of the patient’s face (which is much less painful than casting), modeling the replaced part and printing it using pigment, starch and medical silicone.

Such prostheses have an additional bonus: when it wears out (which ultimately will happen anyway), it can be printed again, and financially it will be very cheap. [ The Guardian ]

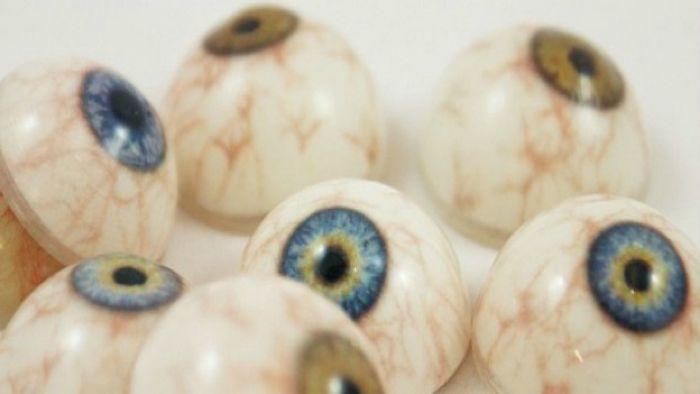

Dentures

Fripp and the team of the University of Sheffield published the results of testing a similar process for the manufacture of prostheses for the eyes. Eye prostheses are expensive, and since they are manually signed, it can take several months to make them. Fripp Designs printers can make 150 eye prostheses in an hour, and details such as the color of the iris, size and number of blood vessels can be easily changed depending on the needs of the patient. [ PhysOrg ]

Functional Implants

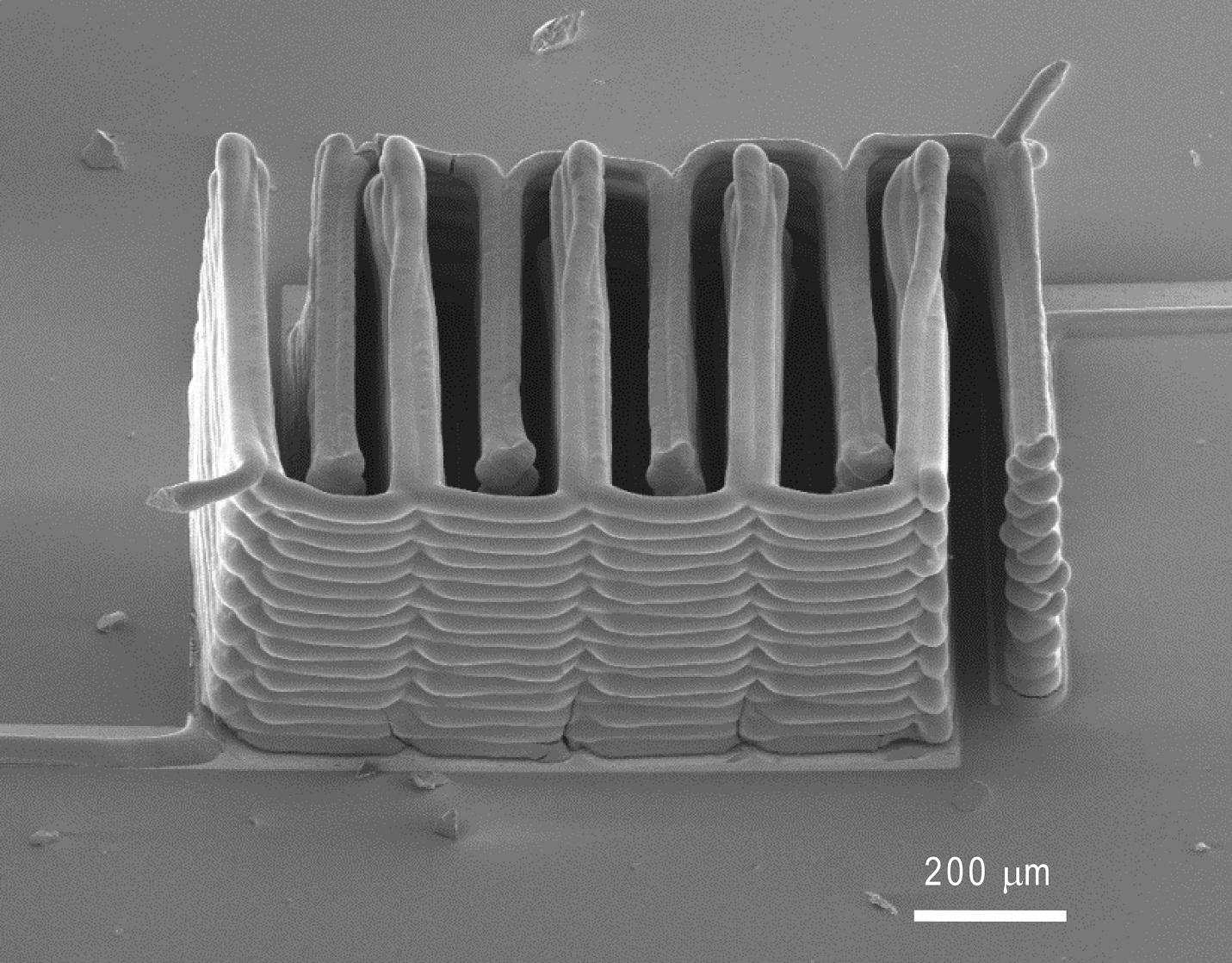

As electronic devices - from drones to medical implants - get smaller, scientists are struggling to create batteries for them that are small enough, but at the same time can provide the necessary charge. However, a team of engineers from Harvard University using a 3D printer is already printing microbatteries the size of a grain of sand. Here is what the press release says:

“... the researchers created ink for the anode using nanoparticles of one lithium oxide compound, as well as ink for the cathode from nanoparticles of another type of this compound. The printer applied ink to the teeth of two gold crests, thus creating a tightly bound structure of anodes and cathodes. Then the scientists placed the electrodes in a tiny container and filled it with an electrolyte solution to get a battery. ”

Over time, they will be able to charge medical implants, the use of which is constrained by the existing problems of their charging. [ Harvard ]

Bones

3D-printed implants, such as the jaw, have been around for several years. However, a small group of researchers is conducting an experiment whose purpose is to print real bones. For example, the scientist Kevin Shakeshuff from the University of Nottingham invented a bioprinter that creates matrices from polylactic acid and gelatin alginate, which are then coated with stem cells.

The implanted matrices will gradually dissolve and be replaced by a new growing bone: it will take about three months to completely transform the bone. [ Forbes ]

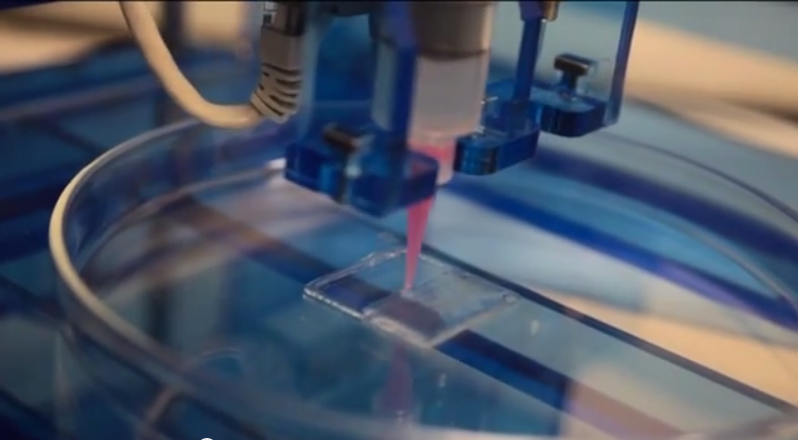

Blood vessels and cells

We can already print organs , but there is a serious problem associated with the creation of a functioning circulatory system.

German scientist Gunter Tovar, head of the Fraunhofer Institute for Interphase Engineering and Biotechnology, is engaged in a project called BioRap. Its task is to use a 3D printer for printing blood vessels, during which a mixture of synthetic polymers and biomolecules is used. Printed circulatory systems are tested on animals - they are not yet ready for introduction into the human body. Ultimately, however, they will make possible the transplantation of print media. [ Fraunhofer Institute ]

How do you imagine the prospects of 3D printing with living and substitute artificial materials for use in the human body? Will we soon be able to grow and replace full organs, such as the liver? Share your opinion in the comments.