Photo-polymer 3D printer from a home video projector creates objects without layers

A fundamentally different approach to photopolymer 3D printing, developed at the University of California at Berkeley, allows you to create 3D prints in a few minutes and complement existing objects with 3D printed parts.

Based on an article by Kara Manke from the University of California, Berkeley, Berkeley News. Translated and adapted by Top 3D Shop .

Most 3D printing methods involve adding material layer by layer. This sets some restrictions on the use of 3D-printed objects, for example - printing new objects in combination with existing ones is extremely difficult, usually you cannot install a damaged part in a 3D printer and print a broken fragment.

The same technique allows for such operations.

A metal micro screwdriver with a pen printed on it.

Authors: Brett E. Kelly, Indrasen Bhattacharya, Hossein Heidari;

Co-authors: Maxim Shusteff, Christopher M. Spadacchini;

Head of Laboratory and Corresponding Author: Hayden K. Taylor.

Scientific publication in Science 3'2019.

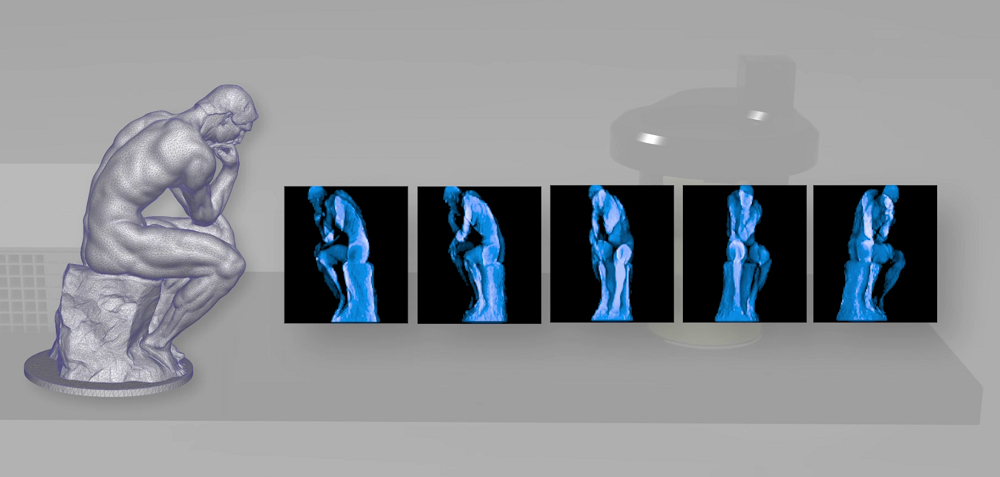

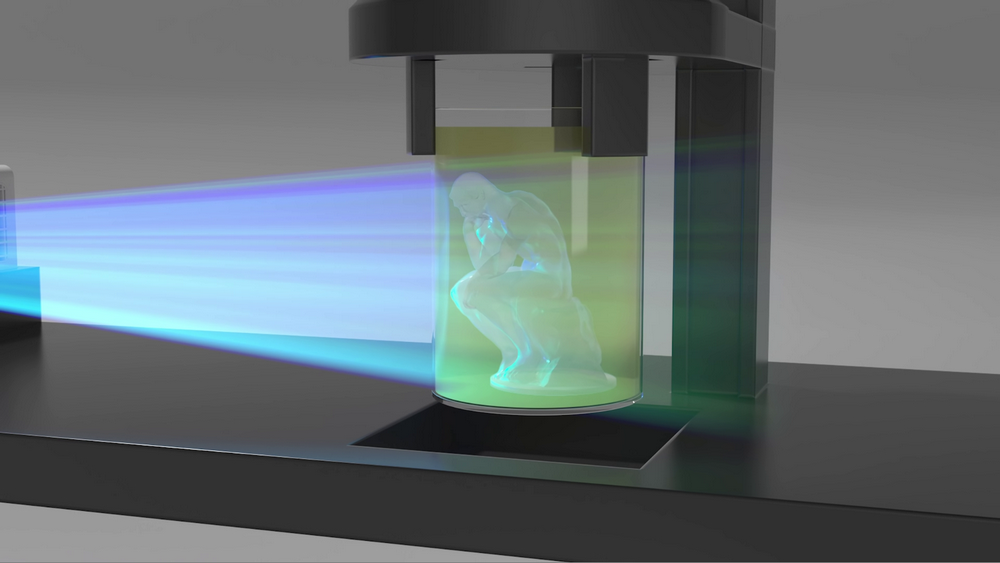

Kelly et al. Presented another manufacturing method - 3D printing by rotating a photopolymer in a dynamically developing light field. This allowed them to print entire complex objects in one full revolution of the vessel with photopolymer, bypassing the need for layer-by-layer construction.

Additive manufacturing by the new method promises geometric freedom and the ability to combine materials to produce a combination of different properties in one part.

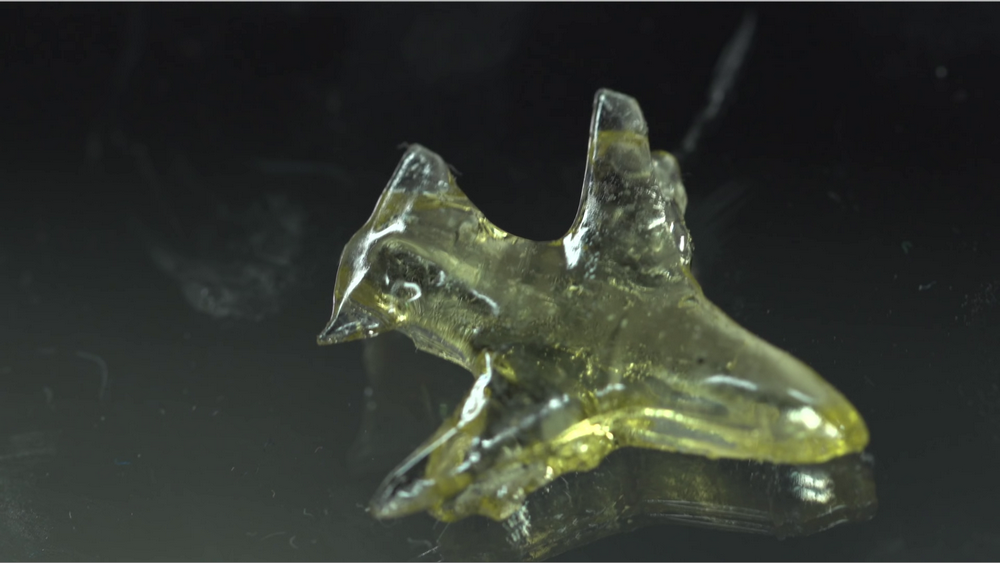

The developers demonstrated the simultaneous printing of all points in a three-dimensional object by illuminating a rotating volume of photosensitive material with a dynamically developing light pattern. During the tests, elements of only 0.3 mm in size were obtained in engineering acrylate polymers and soft structures with exceptionally smooth surfaces in a gelatin methacrylate hydrogel.

“The fact that you can take a metal component or something from another manufacturing process and add a new part with custom geometry, I think, can change the way you design products.

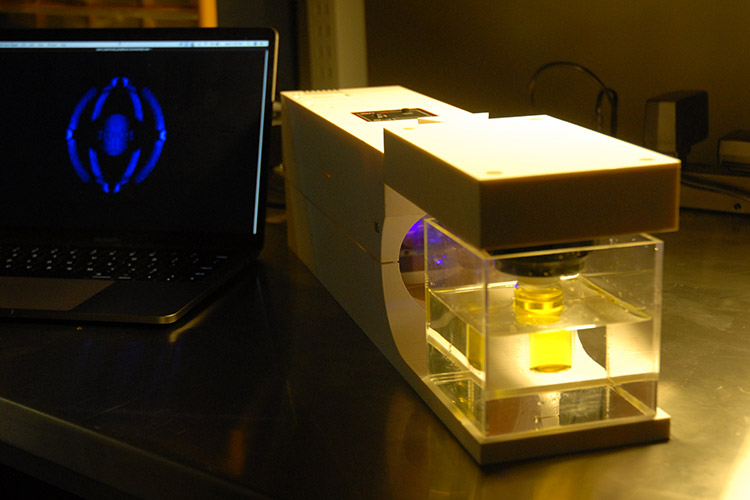

In fact, you can take a regular video projector, literally bring it from home, connect it to a laptop and use it to project a series of calculated images onto a rotating cylindrical container with a thick photopolymer resin.

Obviously, there are also subtleties here, first of all, in the calculation of projected images, but there will be no significant difficulties with the creation of the hardware , ”Taylor said.

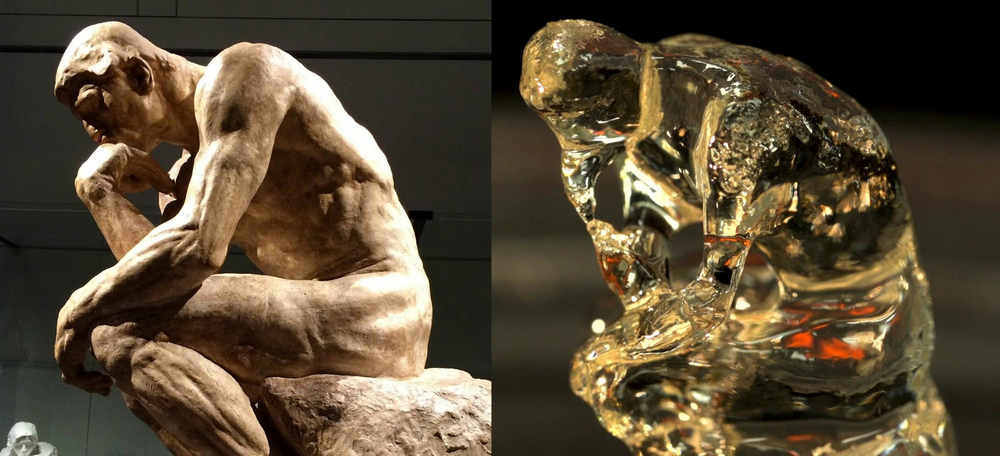

Taylor and the team used the printer to create a series of test objects — from the tiny model of the Rodin Thinker statue to the custom-made jaw model.

Currently, they can make objects with a diameter of up to 10 cm.

“This is the first case when we do not need to create three-dimensional parts in layers; this makes 3D printing truly three-dimensional , ”says Brett Kelly, co-author of the paper.

For their new technology, the researchers formulated a thick syrupy photopolymer that polymerizes only at a strictly defined intensity of the incident light.

Resin for 3D printing consists of liquid polymers mixed with photosensitive molecules and dissolved oxygen. Light activates a photosensitive compound that depletes oxygen. Only in areas where all oxygen has been used, do polymers form bonds that convert the resin from liquid to solid. Unused resin can be recycled by heating oxygen in an atmosphere.

“Our methodology creates virtually no waste, and uncured material can be reused 100% ,” says Hossein Heidari, a graduate student at the Taylor Laboratory at the University of California at Berkeley and co-author of the work.

“We hope that this will open the way for many other researchers in this exciting field of technology,” said Maxim Shusteff, engineer, co-author of the work.

This is one of those ideas that is “in the air”, and it remained just an idea until these guys guessed to create a special suitable photopolymer.

The detail of the obtained samples is not yet impressive, but the method itself is at least interesting. It is possible that upon receipt of a photopolymer with an even more precise transition boundary (chemists have a word here), as well as improvement of image calculation algorithms, the detail of prints created using this method will increase.

Do you think this method can be used for home 3D printing? Where will it be most sought after?

Will there be serial models of 3D printers working on this principle soon? Would you buy one for yourself? Share your opinion in the comments.