3D printing with metals: 5 obvious benefits from a practical example

Swirl made using SLM technology. With the serial production of such parts, the reduction in the pre-production stage can reach 50% . A lot has been written

about the features and benefits that the enterprise can provide with selective laser melting technology (SLM). The advantages of such innovative methods are best demonstrated by practical examples, and in this article we describe in detail the technological chain of additive production based on a project in the field of power engineering. Using a metal 3D printer SLM Solutions, the German company PRÄWEST manufactured a swirl, which significantly increased the efficiency of fuel injection in a stationary gas turbine.

The use of SLM technology in the manufacture of a swirler

The SLM technology was selected by PRÄWEST to facilitate the production of a modified fuel injector. This so-called "swirler" is used for injection and uniform distribution of fuel in the combustion chamber. Crucial here is to ensure fast, uniform and complete combustion of fuel due to its optimal distribution.

The swirler is made of an IN 718 nickel-based alloy, which is extremely resistant to corrosion. When using the SLM process, the typical tensile strength (Rm) for a given material is 1230 N / mm².

The use of SLM technology in the production of swirler provided a reduction in production costs by more than 65%

Stages of the process of selective laser melting: how it happens

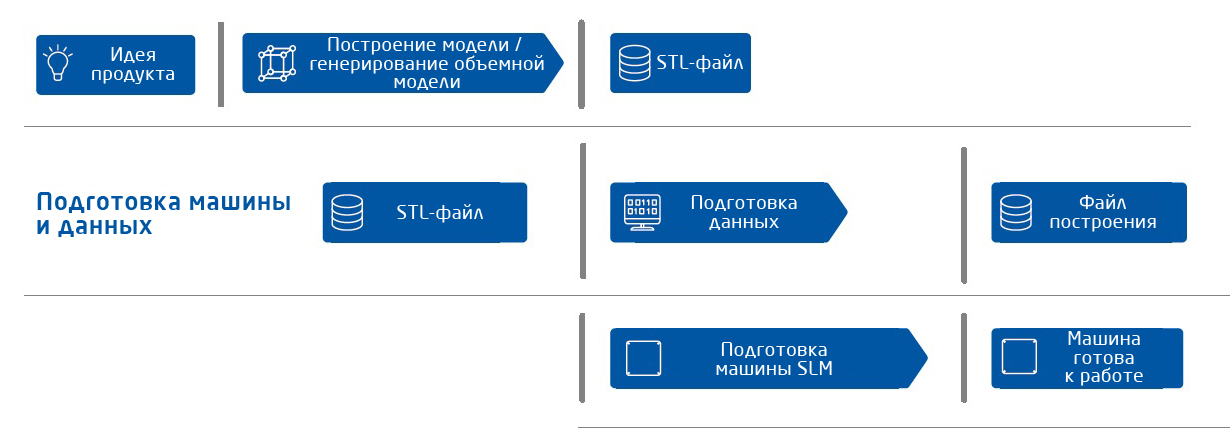

The entire manufacturing chain can be divided into three stages: preparation for printing, the main process and post-processing.

1. Preparing for 3D printing

The basis for each component is a three-dimensional CAD model, which is created individually, taking into account the needs and requirements of the customer. After that, the data is transferred from the CAD software tool to the Magics software .

At the next stage of data preparation, a 3D printer and materials are selected , and the position of the components on the construction platform is also set. Components can be placed next to each other, inside each other (insertion) or one above the other (packaging). Improved product layout combined with the possibility of simultaneous production can significantly reduce costs, because, depending on the component, you can significantly reduce the installation time and auxiliary procedures.

The creation of supports helps to ensure stable component fixation and heat dissipation during the selective laser melting process.

After that, the SLM Build Processor program (post-processor) automatically or based on the set values generates process parameters such as exposure vectors, exposure speed, laser radiation power and the distance between the hatching lines. The selected parameters determine the thickness of the component layers, the accuracy of the surface, and the mechanical properties. After the component is “sliced” into separate layers parallel to the construction platform, layer data is generated - this process is called “hatching”. The layer thickness (usually 30-50 microns) significantly affects the quality parameters of the component, such as dimensional accuracy and surface quality, as well as the duration of the build. Simultaneously with the preparation of data, the preparation of a 3D printer is also carried out.

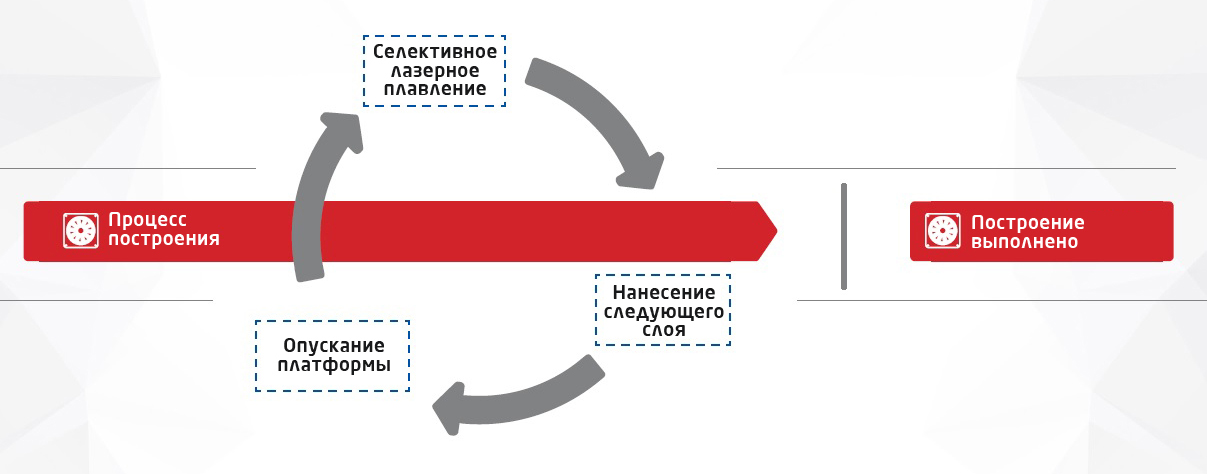

2. The main process

The build file is loaded into the additive installation using the Windows-based user interface , after which the component is built layer by layer. The construction process is a cyclic repetition of the operations of applying a layer of powder and exposure to it with a laser. Powder particles are fused with each other along the contours of the component and on those surface areas that were determined at the preliminary stage.

Then the lifting and lowering platform with the platform is lowered to the thickness of one layer, and another layer of powder is applied . This sequence of actions is cyclically repeated with the connection of the geometries of the current layer with the geometries of the previous layer. When the last component layer is reached, the build session completes.

3. Postprocessing

Unused powder is removed from the build chamber and sieved for reuse. The platform with the component is removed from the 3D printer; residual powder is sucked off using a vacuum device. At this stage, depending on the requirements for the component, heat treatment can be applied.

After the component is separated from the platform , the supporting structures inside the flow channel are manually removed . In the next next step, the surfaces are manually ground to the required roughness in the channel; alternatively, the surface can be machined.

Then, finishing turning is carried out taking into account the size tolerance of the component and the required final external contour. This removes all support that may have remained on the external circuit. The final post-processing operation is the final testing. At this stage, using various measuring equipment, coordinate measuring machines and 3D scanners , the component is checked for compliance with the requirements specified in the customer’s drawing and model.

Advantages and features of selective laser melting

Cost reduction

The use of SLM technology in the production of swirler provided a reduction in production costs by more than 65%. The elimination of the two stages of the traditional process also allowed more than one percent reduction in manufacturing time.

Functionality

Freedom of working with geometry when designing products is one of the main features of SLM technology, which can improve the functionality of components. In this example, selective laser melting helped optimize the geometry of the swirl.

The internal lattice structure and additional channels allowed for functional optimization and integration. Thanks to the lattice structure, it was possible to reduce the mass of the component and at the same time reduce the amount of necessary materials and resources.

Efficiency

The broadest possibilities when making design changes also allow you to integrate new features. In this example, the efficiency of the gas turbine system was improved. Thus, the high flexibility of SLM technology helps increase component efficiency. Production without accessories allows you to make structural changes at lower cost and shorter manufacturing time. Thanks to this, the process of selective laser melting is ideally suited for both piece and mass production.

Flexibility

SLM technology makes it possible to make design changes that would not be possible using traditional production methods for technical or economic reasons. In the process chain of selective laser melting, these changes require less time and money, which makes flexible modifications more economical and efficient.

Time saving

One of the main advantages of SLM technology is the reduction in manufacturing time due to the integration of production through the use of a process that eliminates the need for such additional steps as fixing the part and setting up. With serial production, the reduction in the pre-production stage can reach 50 percent. Another type of auxiliary production processes is also virtually eliminated - data preparation, which requires significant time and money.

PRÄWEST: 70 years of success

PRÄWEST: competitive manufacturer using additive technology

PRÄWEST was founded in 1945 and over the years of its activity has become a dynamic and innovative enterprise. Engaged in contract manufacturing in the aerospace and turbomachinery industries, the company eventually began to specialize in the refinement of complex component designs. Its state-of-the-art equipment fleet includes tools for milling, turning and grinding work, including 130 CNC milling machines and 24 robots.

PRÄWEST is constantly investing in new technologies to meet the needs of its customers, and one of her areas of interest is the simultaneous five-axis machining of complex components. These systems allow processing components with a diameter of up to 2500 mm and a weight of up to 15 metric tons in five axes.

One of PRÄWEST's priority tasks is to provide a high level of customer service. The highly qualified service staff of the company provides constant round-the-clock support, solving a wide range of problems that arise with customers. The success of the company is primarily based on establishing long-term trusting relationships with customers and suppliers, striving to associate the word PRÄWEST only with the highest level of service.

Material provided by SLM Solutions