Multi-level lighting control: resiliency of solutions and products

Multilevel lighting control is designed to implement simple and energy-efficient control of lighting systems, it is used where it is required to realize turning on or off lighting from several places, turning on or off lighting in groups, general central turning on or off.

Consider a few basic solutions and products in terms of hardware resiliency, and therefore real long-term operation.

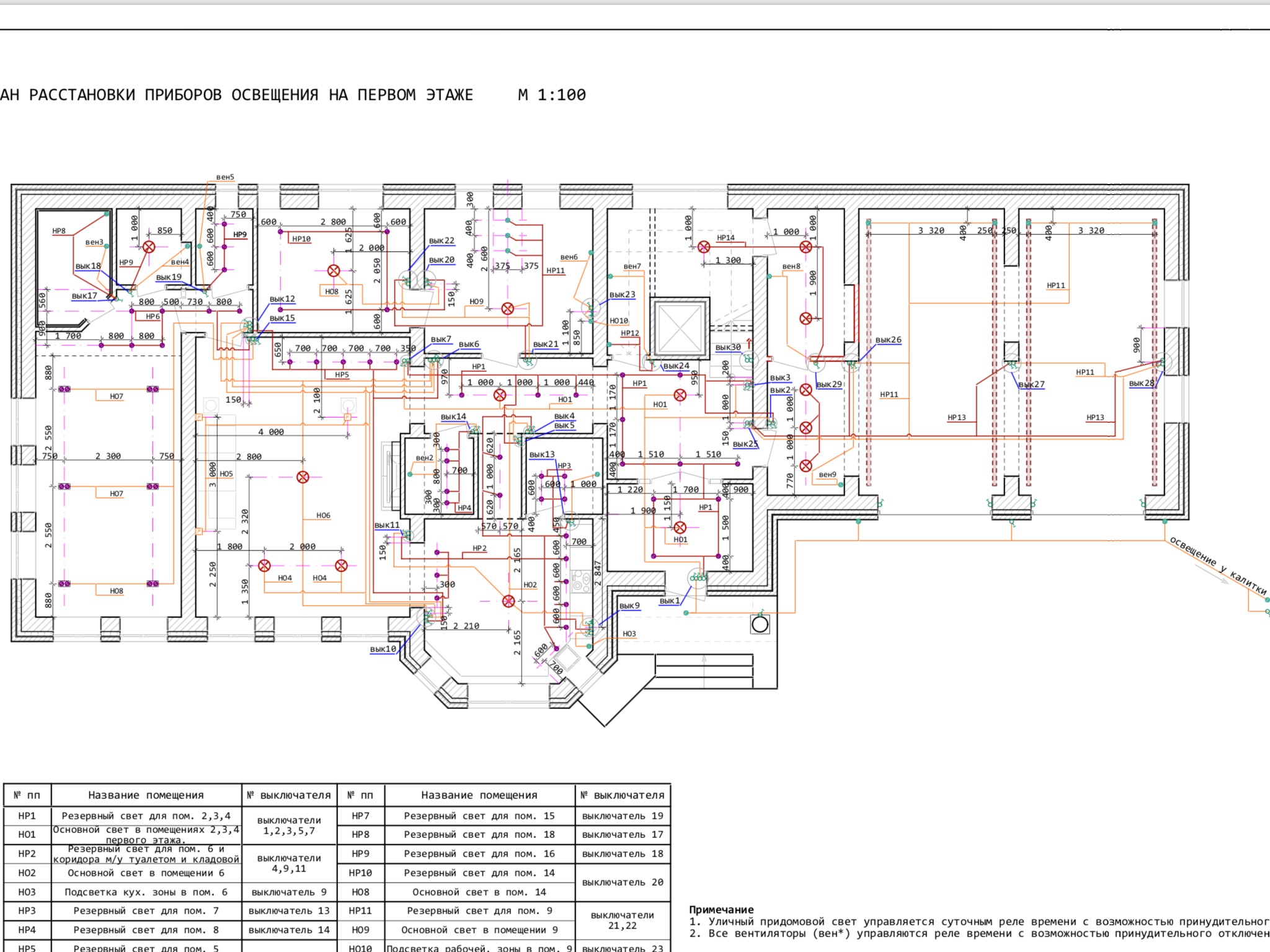

An example of a multi-level lighting control system

Level 1 control - all lighting sources in the building, including those controlled from several places.

2 level of control - light sources combined in a group in the left wing of the first floor, light sources combined in a group in the right wing of the first floor, light sources combined in a group in the left wing of the first floor, light sources combined in a group in the right wing of the second floors.

Level 3 control - lighting sources combined in a group on the entire first floor, lighting sources combined in a group on the entire second floor.

Level 4 control - lighting sources combined in a group throughout the house.

Solutions on which to build such a system

- PLC

- Impulse relays.

- Complex of Technological Means of Non-Programmable Logic (KTS NPL) based on modular lighting control devices of our own design.

You can read about CTC NPL in the article multilevel lighting control based on CTC NPL .

The electromechanical lighting control unit is a compact control module for installation on a 36 mm wide DIN rail (2 modules).

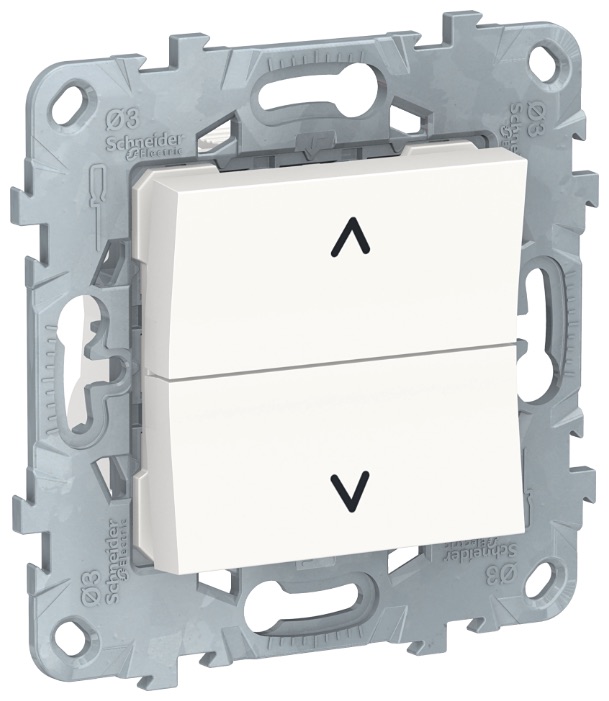

Control

Management is carried out using a double button without locking with two normally open contacts.

The reason for the development of the KTS NPL

The reason for the development of the KTS NPL was the technical task of a customer who wanted to implement the functionality of a multi-level lighting control system without using a PLC (because it is very expensive to reserve).

An example of the functionality of a multi-level lighting control system in a cottage

Consider a fail-safe system based on lighting control devices

Composition:

1. Lighting control devices.

Cost of equipment: $ 47 per light source.

Electrical endurance: 100,000 cycles for AC-1.

If one of the lighting control devices fails, all other devices of the lighting control system will continue to work.

This means that if the lighting control device breaks down, the lighting will continue to work, with the exception of one light source, or one group switch, while the wizard will install new equipment and put it into operation.

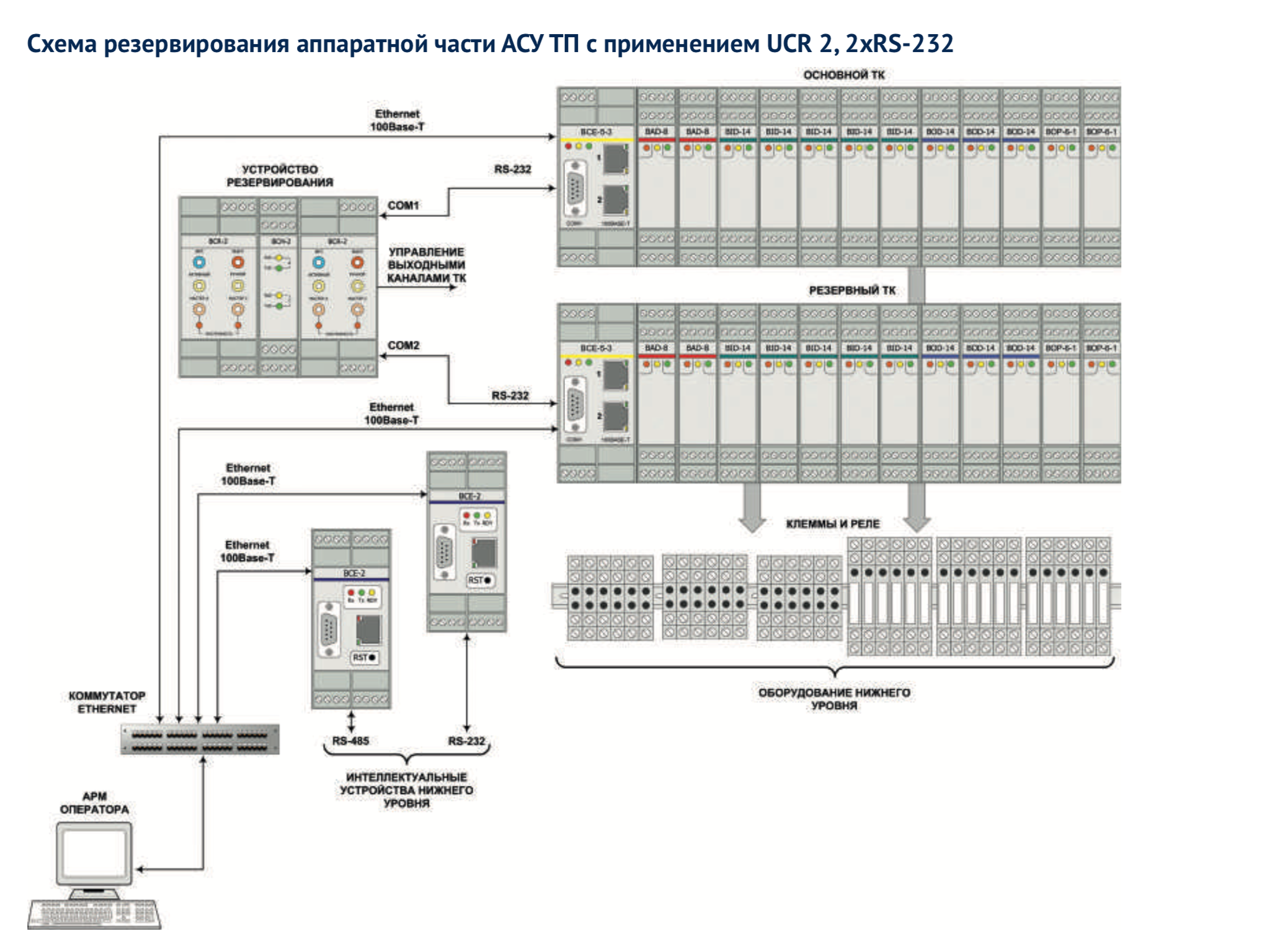

Consider a fault tolerant PLC system

Composition:

- Programmable logic controller.

- Redundant programmable logic controller.

- I / O Modules

- Redundant I / O Modules

- Redundancy device (provides control switching to the standby PLC and standby I / O modules).

- Intermediate relays.

- Actuators (relays / contactors).

Equipment cost: $ 237 for one light source.

Electrical endurance: 100,000 cycles for AC-1.

In the event of a failure of the PLC or I / O modules, the redundant device in real time switches control to the redundant PLC and redundant I / O modules and signals an accident.

This means that if the PLC breaks down, the lighting will continue to work, while the master will install new equipment and put it into operation.

Consider a non-redundant PLC system

Composition:

- Programmable logic controller.

- I / O Modules

- Intermediate relays.

- Actuators (relays / contactors).

Cost of equipment: $ 69 per light source.

Electrical endurance: 100,000 cycles for AC-1.

When a PLC or I / O modules fails, the lighting will completely stop working until the master installs and puts into operation new equipment.

Consider the most common PLC-based system in the residential sector

Composition:

- Programmable logic controller

- Input / output modules

- Input Relays

Equipment cost: $ 41 for one light source.

Electrical endurance: 25,000 cycles for AC-1.

If the PLC or I / O modules fail (this will happen much faster than in the previous versions, since the electrical durability is four times lower), the lighting will completely stop working until the wizard installs and commission the new equipment.

Consider a system based on pulse relays

Composition:

- Impulse relays.

- Group Management Modules.

- Central Management Modules.

Equipment cost: $ 73 for one light source.

Electrical endurance: 100,000 cycles for AC-1.

If one of the relays fails, all other lighting control relays will continue to operate.

This means that if the pulse relay breaks down, the lighting will continue to work, with the exception of one light source or one group switch, while the master will install new equipment and put it into operation.

At first glance, pulse relays are not much different from lighting control devices, but this is not so, pulse relays have a number of limitations:

- Switching limit: 5-15 shifts per minute / 100 shifts per day.

- Pulse duration limitation: 50 ms - 1 s.

- Vibrations can lead to spontaneous switching, that is, if necessary, it will not be possible to install contactors in such a control cabinet.

- When switching adjacent neighboring pulse relays on / off, ventilation and cooling of the control cabinet may be required.

- As the number of control levels increases, the complexity of constructing a circuit increases.

Conclusion

A fault-tolerant multi-level PLC-based lighting control system has a rather high cost for the residential sector, a system based on pulse relays has serious limitations, a system based on lighting control devices is the golden mean.