Topics of the Top 3D Expo 2019: “Anisoprinting - the technology for the production of composite structures of a new generation”, Fedor Antonov

In anticipation of the upcoming Top 3D Expo exhibition and conference , which will be held April 19 in Technopolis Moscow, we talk about the participants in the conference.

Anisoprint will be delivered by its CEO Fedor Antonov.

Anisoprint created a new technology for 3D printing with composites - anisoprinting, develops and manufactures equipment and materials for it and takes part in projects where it is in demand. Read more below.

Fedor Antonov

Fedor Antonov - one of the creators of the new technology of 3D printing with composite fibers anisoprinting. Born in Moscow in 1985, graduated from the Moscow State University; in 2010, defended his Ph.D. In 2015, he founded the Anisoprint company together with colleagues from Skoltech.

Developments in the field of 3D-technologies:

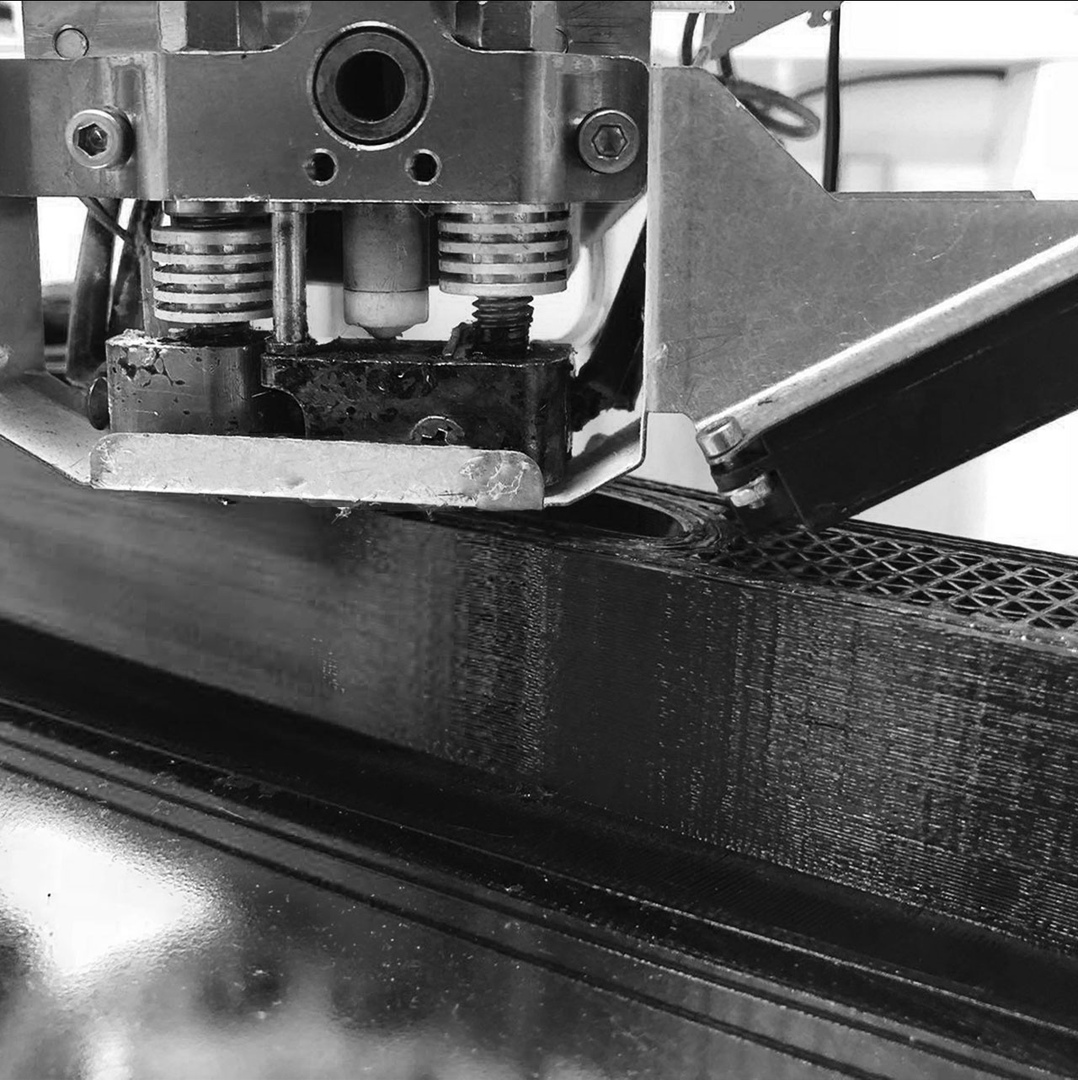

- Technology and equipment for 3D printing of composites reinforced with continuous fibers, what is its importance and advantages read on;

- Material - reinforcing thread for 3D printing, an integral part of the technology;

- Software - Aura slicer for printing parts with continuous reinforcing fiber, a unique slicer for working with this technology.

Topic

The theme of the speech of Fedor Antonov:

“Anisoprinting - the technology of production of composite structures of a new generation”.

In the speech, the speaker will talk about the development and application of anisoprinting - the method of printing composite products with the addition of continuous fibers.

The technology allows you to print parts 2-3 times lighter than metal, while maintaining the same strength and reducing cost up to 10 times.

This will reduce the cost of production and improve the properties of products in areas such as the creation of engineering structures, the automotive industry, the aerospace industry, the production of sports goods and much more.

About Organization

Anisoprint was founded in 2015 by a team of engineers from the Skolkovo Institute of Science and Technology. The organization was purposefully created in order to develop a new technology for 3D printing with composites - anisoprinting.

About technology, briefly

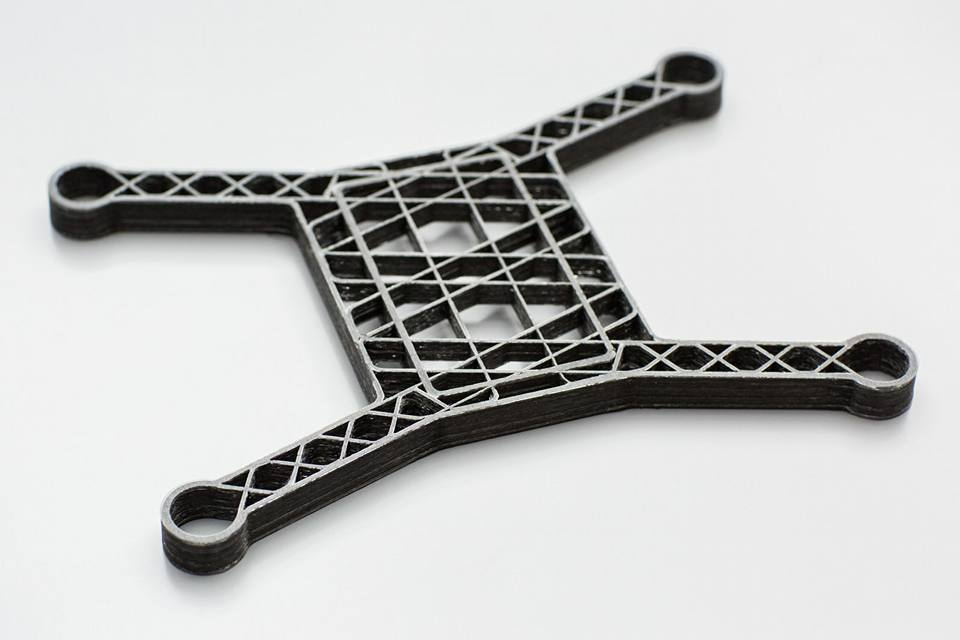

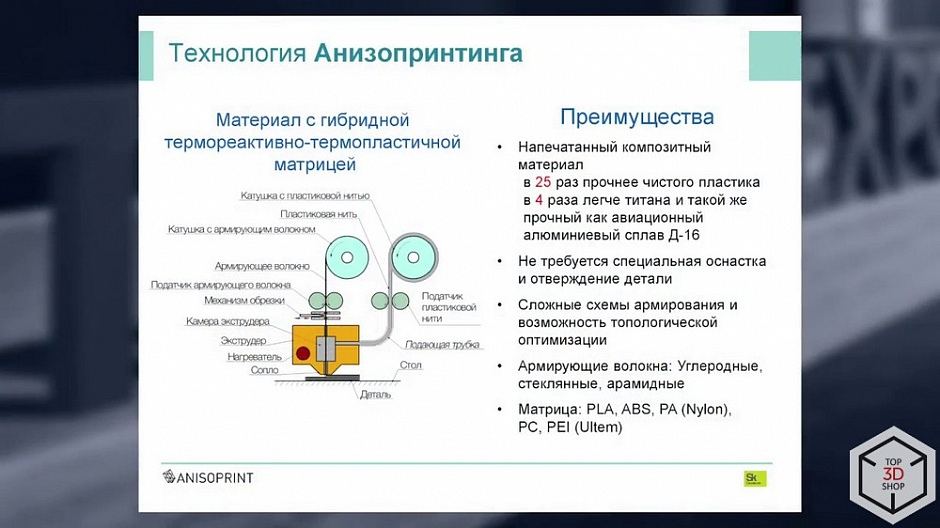

The essence of anisoprinting: 3D printing with a two-component filament, the first part of which is a matrix or base, can be used by any common thermoplastic for 3D printing, such as ABS or PLA, and the second part, reinforcing, is continuous carbon, glass or aramid fiber.

The technology allows you to place the reinforcing fiber in the part in the directions of the highest loads, which greatly increases the strength of the printed model.

The parts obtained using this technology are 25 times stronger than pure plastic, while those printed with carbon-filled filament (plastic with an admixture of chopped fibers) are only twice as strong.

Learn more about the technology from a speech by Fedor Antonov at the Top 3D Expo. Do not forget to buy a ticket , they will rise in price very soon.

Cases

Handicapped scuba diver

Dmitry Pavlenko is a para-athlete diver, the owner of the world record for independent dives in open water.

For Dmitry it was necessary to create a system for compensating for buoyancy. Part of this system was a lever for purging ballast to maintain buoyancy and maneuverability.

The original part, made from a steel spoon, was not particularly convenient and broke during the 14th dive. The levers printed from ABS made by students of the Moscow Polytechnic University turned out to be insufficiently durable: upon lifting, they broke due to impacts on the side.

The solution was a lever printed using the two-component Anisoprint Composer 3D printer anisoprinting technology.

The material was PETG with reinforcing carbon fiber thread.

The composite lever became part of the system that helped Dmitry Pavlenko to independently dive in the open sea for 40 meters, which became a world record, which was also listed in the Russian Book of Records.

Dmitry Pavlenko:

“Composite material makes the lever more durable. In addition, it is less slippery. I use it with more confidence. I hope your lever will serve me much longer. The lever from ABS had serious defects after 10 dives, and your goal was after the same period. In my opinion, he will survive 100 dives. ”

Wheelchair Drive Mount

UNA wheel - an electric drive that can make any wheelchair motorized and give additional freedom to each user.

The owner of Supreme Motors, which produces these drives, had the task of reducing the cost and speeding up the production of some critical components, such as mounting the drive to the wheelchair.

The simplest solution is to order steel pipe fittings made using laser cutting and welding. But it is too long and expensive when you need only a few details.

The first solution was 3D printing of parts made of high-strength Ultem plastic (PEI, polyetherimide). This made the part 5 times lighter, cheaper and, more importantly, allowed to produce small batches using their own resources. Here are just a test of strength samples failed.

An alternative was printing on Composer A4. Printing was done with continuous carbon fiber PETG. This part withstood a dynamic load of 117 kg on a cobblestone pavement and off-road conditions, at the intersections of tram tracks and other obstacles typical of urban conditions. The overall structural strength was confirmed by tests at critical loads: impacts on the ground from a height of 40–50 cm.

Nikolay Yudin, founder of Supreme Motors:

“Composer prints unique pieces! 7.3 times lighter while maintaining the functions of our prototype. Ultim did not succeed. Now we want to print longer parts, based on nylon. ”

Thanks to anisoprinting, the UNA wheel was able to focus on small-scale production without the involvement of contractors, with lightweight, durable and functional parts that completely replaced traditional metal counterparts.

Exhibition Materials

Video materials that will be shot at the upcoming exhibition of the Top 3D Expo 2019 conference will be available only to business and VIP ticket holders.

Ticket prices and differences between them - see the expo website.

Hurry to register before April 14, before the ticket prices increase.