Easel for a microcontroller programmer

Good day. In this short article I want to talk about how I came up with the idea of making a large mock-up board and how I realized this idea. It all started ... Yes, in general, it doesn’t matter. The essence of the idea is this: to make a very large breadboard based on breadboards. It turned out like this:

The whole structure consists of the following elements:

Crosspiece, gas lift, support and wheels purchased in a furniture online store. Plywood and paint purchased from Leroy Merlin. I cut the plywood to the right size right in the store, very high quality and even, otherwise I would have to tinker. The assembly process, in principle, is quite obvious, although, unfortunately, I did not fix it in the photo or video.

The selection of components for the breadboard took a considerable time, and the acquisition cost a pretty penny. Breadboards cost the most. There are about 120 pieces of them on the board, I don’t remember exactly, their total cost was about 20 thousand rubles. All other components pulled another thousand by 15. Plus, the work took some time, which took us to think through the design, purchase, process and assemble. But in general I am satisfied.

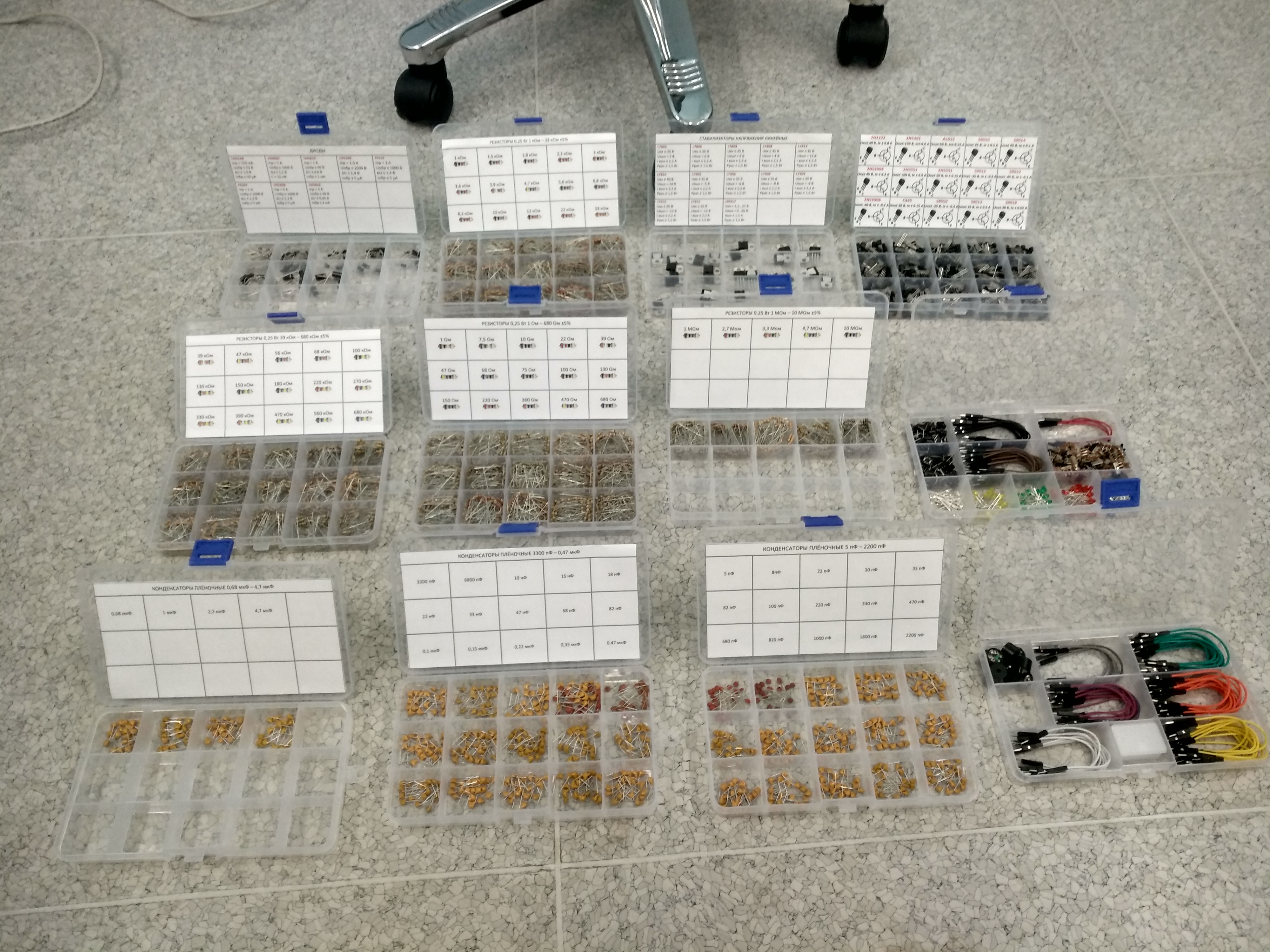

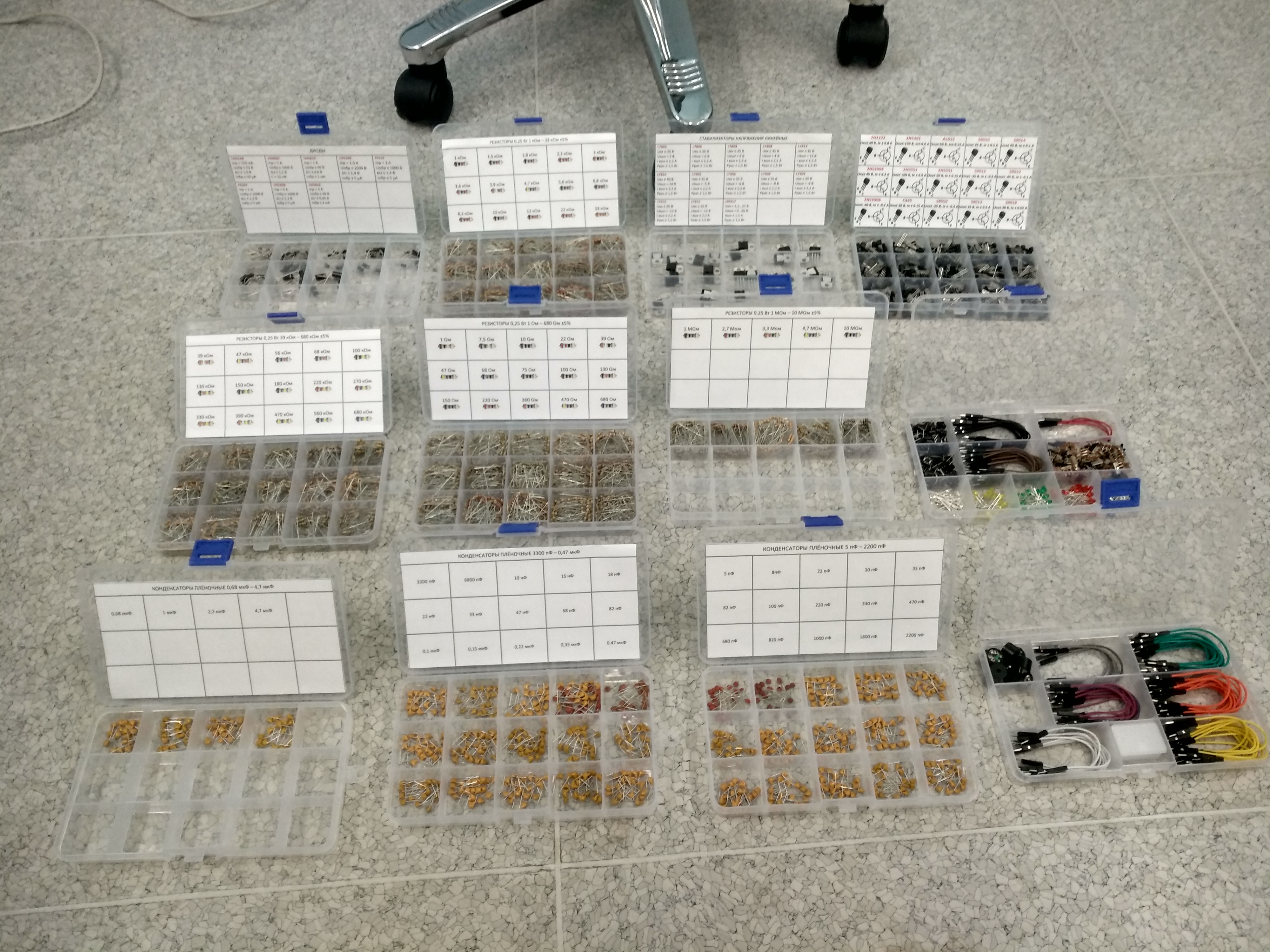

Over time, I got some radio parts for prototyping. And here they are: Actually,

since I have to deal with microcontrollers manufactured by Milander PKK JSC , the first thing I ordered was a adapter board for the K1986BE1QI microcontroller , which I often use at the debugging stage. The riser board is now inserted into the breadboard, and I am too lazy to take it out, so I am enclosing a photo of the assembled circuit. In the center of the photo is a riser board with a microcontroller. In the upper right corner is the JTAG programming connector, in the lower left is the power circuit that lowers the 5V input voltage from the USB connector to the rated voltage of the microcontroller, i.e. up to 3.3 V.

This microcontroller has full Ethernet, that is, both MAC and PHY sublevels, and you can solder the RJ-45 connector to the terminals of the microcontroller using several resistors and capacitors and connect it to a local network or to the Ethernet port of the PC. And I have a set of very thoughtful software solutions with which you can set up extensive telemetry between PC and MK via Ethernet. I will write about these decisions in a separate article. As well as the fact that a microcontroller requires software implementation of the TCP / IP protocol stack to connect to the LAN. So for now, back to the breadboard. I did the routing of the motherboard using the Lite version of the Topor autorouter, because it is free, and I did not want to buy a fully functional version because of one motherboard. And although I ran into a limit on the number of lines (in the free version, it seems

In addition, a number of adapters for various connectors were manufactured or purchased, primarily, of course, for the JTAG connector. I bring power to the board through the USB connector, for example, from a laptop’s USB connector, from charging from a cell or from a power bank.

As a result, instead of drawing a diagram in CAD, tracing, ordering a prototype and subsequent tests, I start by making a layout. Just insert the components into the board, connect them with jumpers. After the layout is ready, I feed it. As a rule, I have some basic firmware with initializing the MK and organizing the exchange over the network. I am starting to build up this firmware until the layout is ready for operation tests. Typically, this approach saves time, and the time saved is spent on education and the development of other tools. Since I'm not the only one working, and my job is to develop a microcontroller connection diagram and write software, after debugging the circuitry solutions, I pass on the results to my colleagues and develop the firmware.

That's all, thank you for your attention :)

PS: Since I am a person who is quite enthusiastic, in case you have an interesting enough project (i.e. not just blinking LEDs and bouncing legs, but, for example, making a sound-reproducing device, connect the display, well, and the like), then you can try to mock it up on the board. In this case, you get the means for prototyping, and I get some variety in my developer's life :) Maybe I will tell you something, maybe I will learn something. Although the offer is limited - I have a rather busy schedule ...

The whole structure consists of the following elements:

- Cross and wheels from an office chair.

- Gas lift from the bar stool.

- Prop from the bar stool.

- Ceiling bracket for TV.

- Painted plywood sheet.

- Development Boards

Crosspiece, gas lift, support and wheels purchased in a furniture online store. Plywood and paint purchased from Leroy Merlin. I cut the plywood to the right size right in the store, very high quality and even, otherwise I would have to tinker. The assembly process, in principle, is quite obvious, although, unfortunately, I did not fix it in the photo or video.

The selection of components for the breadboard took a considerable time, and the acquisition cost a pretty penny. Breadboards cost the most. There are about 120 pieces of them on the board, I don’t remember exactly, their total cost was about 20 thousand rubles. All other components pulled another thousand by 15. Plus, the work took some time, which took us to think through the design, purchase, process and assemble. But in general I am satisfied.

Over time, I got some radio parts for prototyping. And here they are: Actually,

since I have to deal with microcontrollers manufactured by Milander PKK JSC , the first thing I ordered was a adapter board for the K1986BE1QI microcontroller , which I often use at the debugging stage. The riser board is now inserted into the breadboard, and I am too lazy to take it out, so I am enclosing a photo of the assembled circuit. In the center of the photo is a riser board with a microcontroller. In the upper right corner is the JTAG programming connector, in the lower left is the power circuit that lowers the 5V input voltage from the USB connector to the rated voltage of the microcontroller, i.e. up to 3.3 V.

This microcontroller has full Ethernet, that is, both MAC and PHY sublevels, and you can solder the RJ-45 connector to the terminals of the microcontroller using several resistors and capacitors and connect it to a local network or to the Ethernet port of the PC. And I have a set of very thoughtful software solutions with which you can set up extensive telemetry between PC and MK via Ethernet. I will write about these decisions in a separate article. As well as the fact that a microcontroller requires software implementation of the TCP / IP protocol stack to connect to the LAN. So for now, back to the breadboard. I did the routing of the motherboard using the Lite version of the Topor autorouter, because it is free, and I did not want to buy a fully functional version because of one motherboard. And although I ran into a limit on the number of lines (in the free version, it seems

In addition, a number of adapters for various connectors were manufactured or purchased, primarily, of course, for the JTAG connector. I bring power to the board through the USB connector, for example, from a laptop’s USB connector, from charging from a cell or from a power bank.

As a result, instead of drawing a diagram in CAD, tracing, ordering a prototype and subsequent tests, I start by making a layout. Just insert the components into the board, connect them with jumpers. After the layout is ready, I feed it. As a rule, I have some basic firmware with initializing the MK and organizing the exchange over the network. I am starting to build up this firmware until the layout is ready for operation tests. Typically, this approach saves time, and the time saved is spent on education and the development of other tools. Since I'm not the only one working, and my job is to develop a microcontroller connection diagram and write software, after debugging the circuitry solutions, I pass on the results to my colleagues and develop the firmware.

That's all, thank you for your attention :)

PS: Since I am a person who is quite enthusiastic, in case you have an interesting enough project (i.e. not just blinking LEDs and bouncing legs, but, for example, making a sound-reproducing device, connect the display, well, and the like), then you can try to mock it up on the board. In this case, you get the means for prototyping, and I get some variety in my developer's life :) Maybe I will tell you something, maybe I will learn something. Although the offer is limited - I have a rather busy schedule ...