3D printing and airsoft: how I printed “drive”

Hello! I will try to talk a little about how I tried to make an airsoft drive using a 3D printer, what came of it and what difficulties I had to face. This article may be interesting for those who like airsoft, DIY or 3D printing. For those who are not familiar with airsoft, but want to read about an interesting and complex 3D printing project, there is a brief explanation about what is at stake and why it is not easy to build an airsoft drive.

TLDR:

On a 3D printer, you can print a working airsoft drive, including the gearbox housing. A pair of relevant models published in the public domain. The article describes how they were developed.

Legal note

Electro-pneumatic weapon with a muzzle energy of less than 3 joules, according to the legislation of the Russian Federation, is a toy. This article is not related to the manufacture of 3D-printing firearms or any other weapons.

Educational program

Having written the article, I realized that many of the readers, in principle, are not familiar with what airsoft is and what the drive is for. I will try to tell in a couple of paragraphs with an emphasis on the technical side of the issue.

Airsoft (in the former Soviet Union is better known as airsoft) is a team tactical game, a competitor to paintball or laser tag. It differs from paintball at large distances with less need for protection. From laser tag - in that bullets are transmitted from participant to participant, not information. An alternative option - "a bunch of adult men firing at each other from toy guns."

For the game, the most widely used electro-pneumatic guns (usually called “drive”) under plastic balls of 6mm caliber. How it works:

Animated Wikipedia picture: A

balloon flying out of a barrel has a small mass (0.2-0.4 grams) and a fairly high speed (100-170 m / s). A battery is used as an energy source, currently it is usually li-po with high current efficiency. When fired, a 11.1V battery gives off current in the region of 30A. The efficiency of the system is small - ~ 300VA per second at the input turns into ~ 20 Joules at the output (16-18 balls per second with an energy slightly higher than 1J each or 10 balls with an energy of 2 J). These measurements were carried out for the last of the drives described in the article, but are quite typical for most analogues.

In case of any serious problems (loss of tightness, misalignment of parts, contamination or mechanical damage), the speed of the shot drops or gets a large spread, which fatally affects accuracy. It is widely believed among enthusiasts that good repeatability results can only be obtained using the highest quality components, secured in a molded or milled metal case made with minimal tolerances. This case is called gearbox (gearbox) and is the heart of the whole system. The load on the gearbox increases rapidly with increasing power of the main spring and with an increase in rate of fire.

Later in the article I will talk about how I tried to build a compressor casing out of plastic and what results I achieved.

Airsoft (in the former Soviet Union is better known as airsoft) is a team tactical game, a competitor to paintball or laser tag. It differs from paintball at large distances with less need for protection. From laser tag - in that bullets are transmitted from participant to participant, not information. An alternative option - "a bunch of adult men firing at each other from toy guns."

For the game, the most widely used electro-pneumatic guns (usually called “drive”) under plastic balls of 6mm caliber. How it works:

- The motor cockes a piston through the gear system.

- A special draft sends a ball to the barrel.

- When released, the piston moves forward under the action of the main spring, air pressure is created in the cylinder.

- An optional module at the beginning of the barrel, hop-up, provides ball twisting. (Twisting the ball along the horizontal axis allows you to increase the persistence of the ball's trajectory due to the Bernoulli effect)

- Air pressure pushes the ball out of the barrel.

- With a single fire, the cycle stops; when firing a burst, it starts anew.

Animated Wikipedia picture: A

balloon flying out of a barrel has a small mass (0.2-0.4 grams) and a fairly high speed (100-170 m / s). A battery is used as an energy source, currently it is usually li-po with high current efficiency. When fired, a 11.1V battery gives off current in the region of 30A. The efficiency of the system is small - ~ 300VA per second at the input turns into ~ 20 Joules at the output (16-18 balls per second with an energy slightly higher than 1J each or 10 balls with an energy of 2 J). These measurements were carried out for the last of the drives described in the article, but are quite typical for most analogues.

In case of any serious problems (loss of tightness, misalignment of parts, contamination or mechanical damage), the speed of the shot drops or gets a large spread, which fatally affects accuracy. It is widely believed among enthusiasts that good repeatability results can only be obtained using the highest quality components, secured in a molded or milled metal case made with minimal tolerances. This case is called gearbox (gearbox) and is the heart of the whole system. The load on the gearbox increases rapidly with increasing power of the main spring and with an increase in rate of fire.

Later in the article I will talk about how I tried to build a compressor casing out of plastic and what results I achieved.

A bit of history

I took a great interest in tuning soft pneumatics about 20 years ago. At first it was the external and internal refinements of Chinese toys, with the advent of the widespread availability of Japanese electro-pneumatics, he switched to it. Probably about a thousand and a half drives were repaired or tuned. For a while I monetized this hobby, but I work slowly and for myself I like it more.

In 2007, I tried to make my first milled gearbox. It worked if you clamp it in a vice and hold it in some places;) By the volume of work, several things became clear:

- You can make the hull of the gearbox yourself.

- The volume of efforts, attempts and errors is so great that doing this is only for custom, in which an ordinary gearbox can not be crammed.

When I got a 3D printer, I decided to make a milled gearbox again. The ability to prototype parts and see how they work together should save a number of mistakes.

The first 3D printer

The first 3D printer is Prusa Mendel. Shaky, loud, under 3mm bar. Parts were printed from some kind of ABS plastic (at that time I was not particularly interested in specific manufacturers). Layers - 0.3 mm. I got this printer in 2012.

After printing and assembling the first prototype, it turned out that the printed gearbox did not fall apart immediately. To see a working gearbox, for the creation of which you did not have to stand behind the milling machine - it was cool. The work was accelerated many times, it was possible to draw a drawing, put a seal on the night and collect the details the next day.

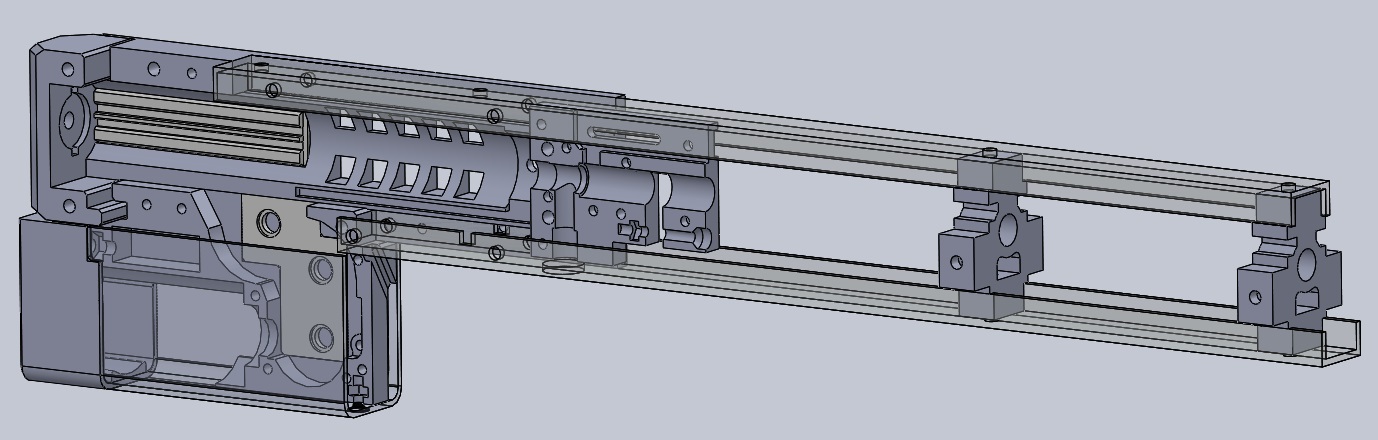

View of an early version of the upper part of the gearbox assembly.

First version

I decided to make a plastic gearbox, which will be reinforced with aluminum plates in difficult places. It was supposed: plates for fastening the gear bushings, plates with milled grooves for guiding the piston and, if necessary, ties from the outside of the box. Of course, the prototypes of these records were first made of plastic. As a result, the parts remained plastic - it turned out that they themselves are quite strong.

It was also supposed to independently manufacture the cylinder head, to make it more massive to ensure strength in the place experiencing maximum shock loads. In general, the idea did not materialize itself - in the following drives I used a standard cylinder head and a massive hop-up housing, the fastening of which acts as a tie-rod ties.

A housing has been developed for the created gearbox.

In 2013, the scorpion evo3 airsoft has not yet been made, which seemed very beautiful to me. However, I did not set myself the task of exact copying - I wanted to make a similar compact submachine gun, light, narrow, but with a full gearbox.

Scorpion EVO3 S1. Image source - Wikipedia.

The work turned out to be much more painstaking than planned - for the assembly of printed parts very often the details had to be finalized with a file. But to hold in your hands the world's first printed airsoft drive warmed the soul. Cool achievement, in my opinion =) I should say a special thank you to my wife, who supported my experiments and was engaged in the final painting of the finished project. Probably, with less understanding and support, the project would be abandoned.

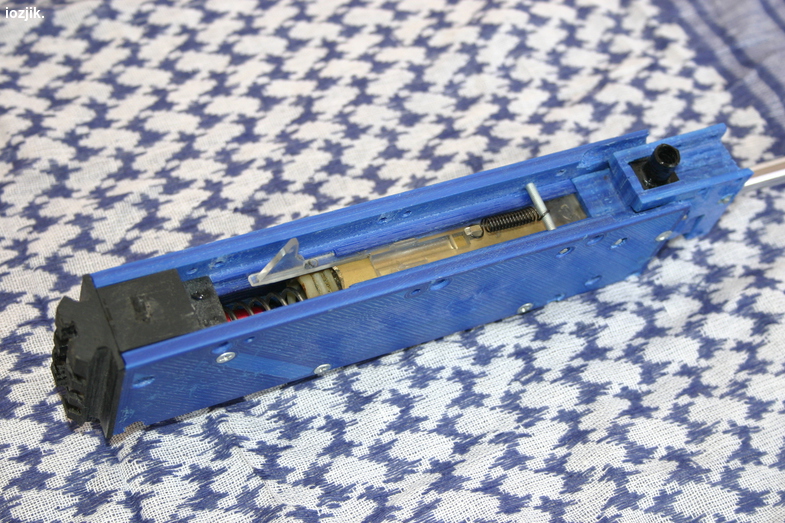

The disassembled drive shows how other modules are connected to the upper receiver

STL files for those wishing to repeat the design were published on Thingiverse. Thus, the first print drive became open source - a product. I don’t know if anyone could print it for themselves and make it work. Sources were published in 2014. There were over 50,000 views, almost 5,000 downloads, so maybe someone stubborn was found. For those who are interested, STL can be found at https://www.thingiverse.com/thing:461896 .

Ready and painted drive

After the first drive was ready, I wanted to do more - more, more perfect and more interesting. A bullpup was designed, from which only bad photos and a bunch of details were left in one of the “projects” boxes. For the first time, the concept of reinforcing the body with an aluminum channel was tested on it - it practically does not add excess weight and makes the body resistant to bending. Actually, factory-made drives in plastic cases also suffer from this problem, so the problem is caused by not using 3D printing.

Printer Replacement

At the end of 2016, I developed and assembled a new 3D printer, with a sturdy frame, machine guides (MGN-12), a core-XY scheme and an enlarged hot table. The new printer supports a higher speed, is much quieter, has water cooling of the extruder and a number of experimental developments (24v electrics, quiet drivers, a hot table on 220v). Unfortunately, it was never completed, although it works and all of the following drives were printed on it. On good, the carriage requires alteration, the hot box is not assembled, you need to make flexible cable channels. Printer imperfections and settings will be perfectly visible in some of the following photos, I apologize in advance to the perfectionist printers.

All further drives were printed from an FD-plast ABS bar, 0.2 mm thick. I did not conduct experiments with other plastics for printing gearboxes, it seems to me tedious if ABS works well.

All further drives were printed from an FD-plast ABS bar, 0.2 mm thick. I did not conduct experiments with other plastics for printing gearboxes, it seems to me tedious if ABS works well.

Second version

All the time I played airsoft, I tried to find the most convenient drive for myself. Probably replaced more than a hundred options, from widespread to very exotic, but never found a definitely suitable one. So the idea came up to make the drive as modular as possible - let each user be able to print a set of parts that he likes the most.

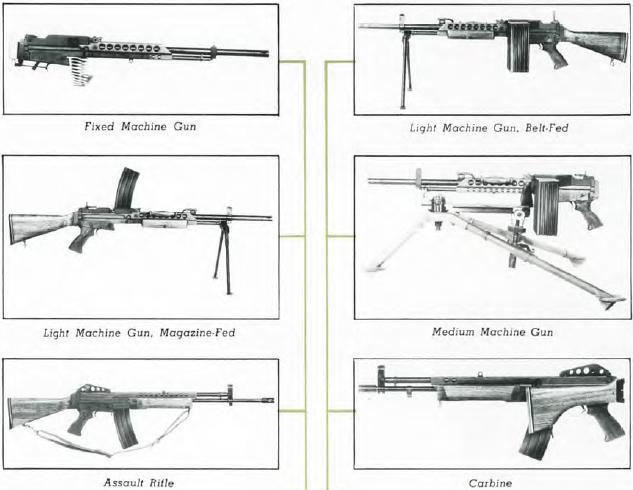

The idea itself is not new; attempts to manufacture modular firearms for solving various problems are undertaken by gunsmiths around the world. An example is the Stoner 63 weapon system, which, depending on the assembly, can change the look from a carbine to machine guns.

Photo of various Stoner 63 build options taken from forgottenweapons.com

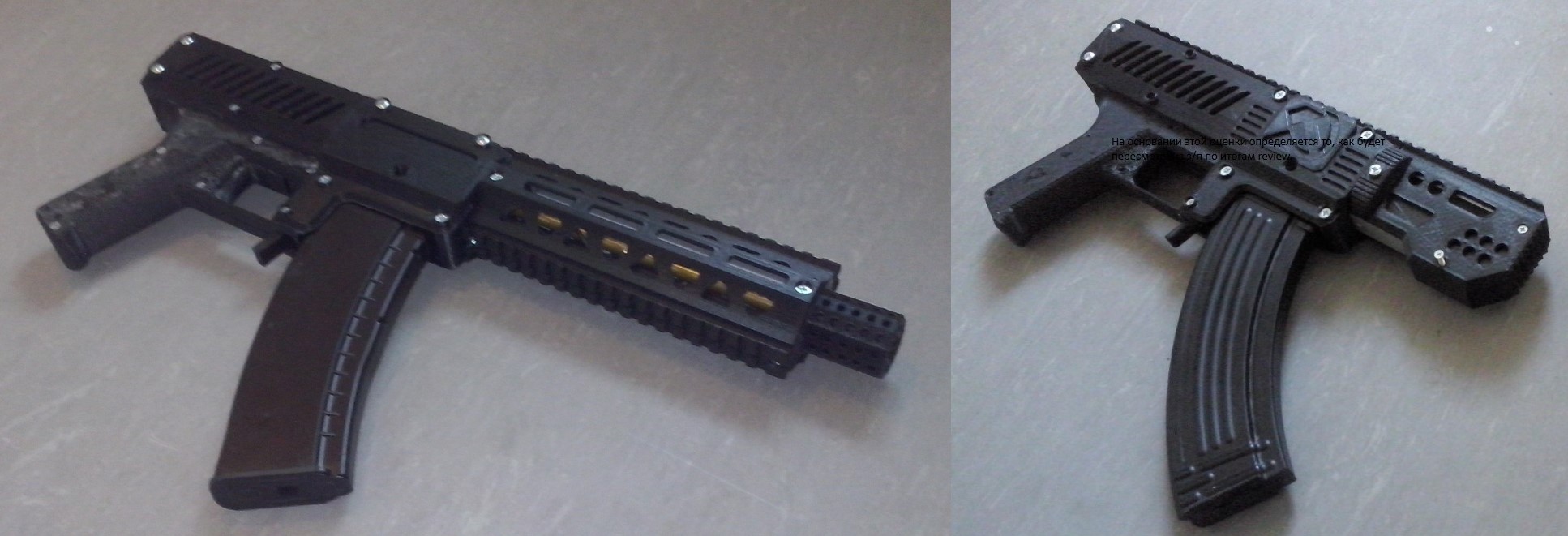

The second version of the open-source 3D printing drive was an upper receiver with rather thick walls and a frame of aluminum channels, to which a lower receiver with gears and a motor (usually in a pistol grip), a store receiver and external panels of the case were mounted. Several versions of the cases were printed, however, by the time I could start publishing, I was already captured by another idea.

Two options for the second version. They differ in the decoration of the upper receiver and front set.

Third version

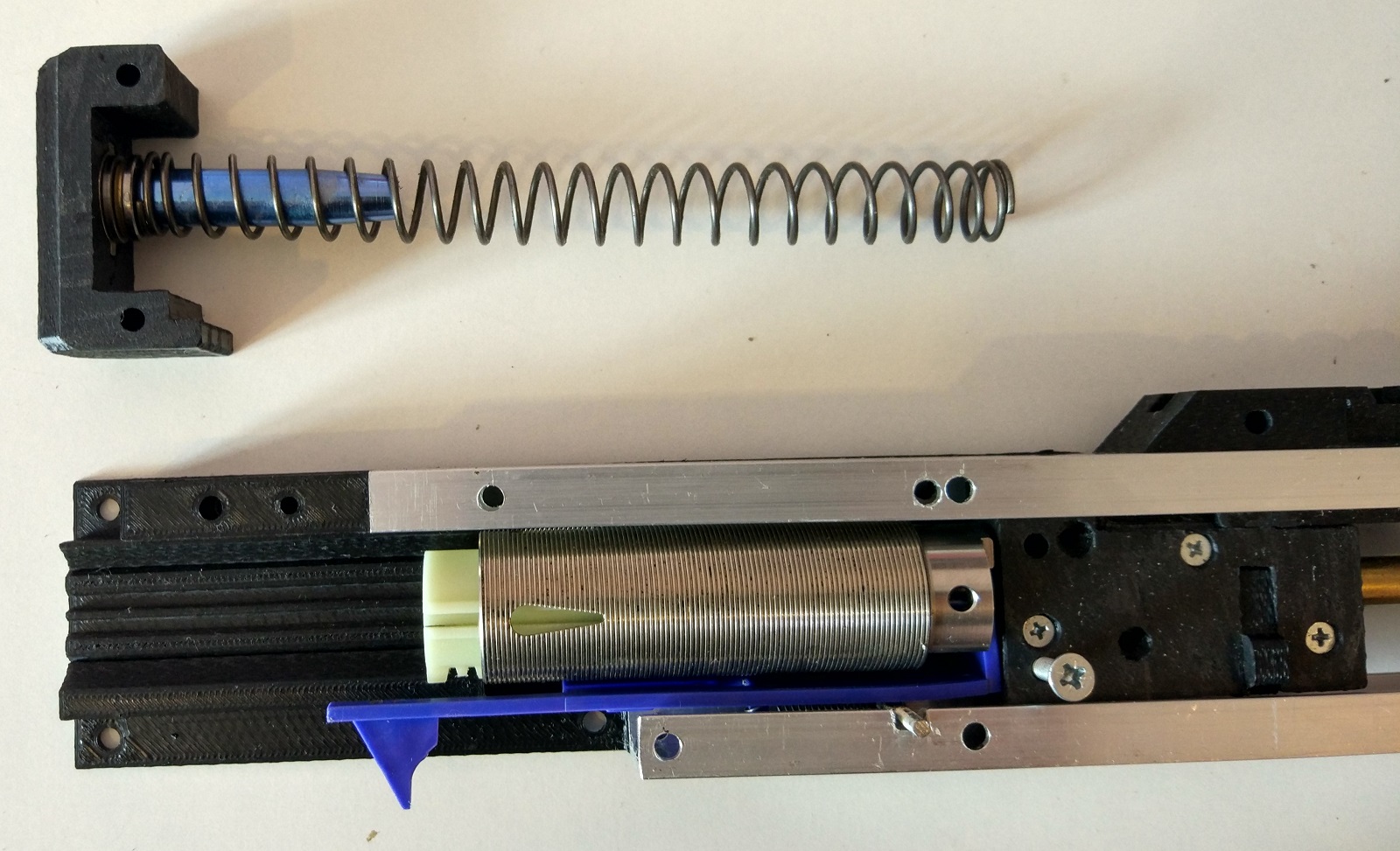

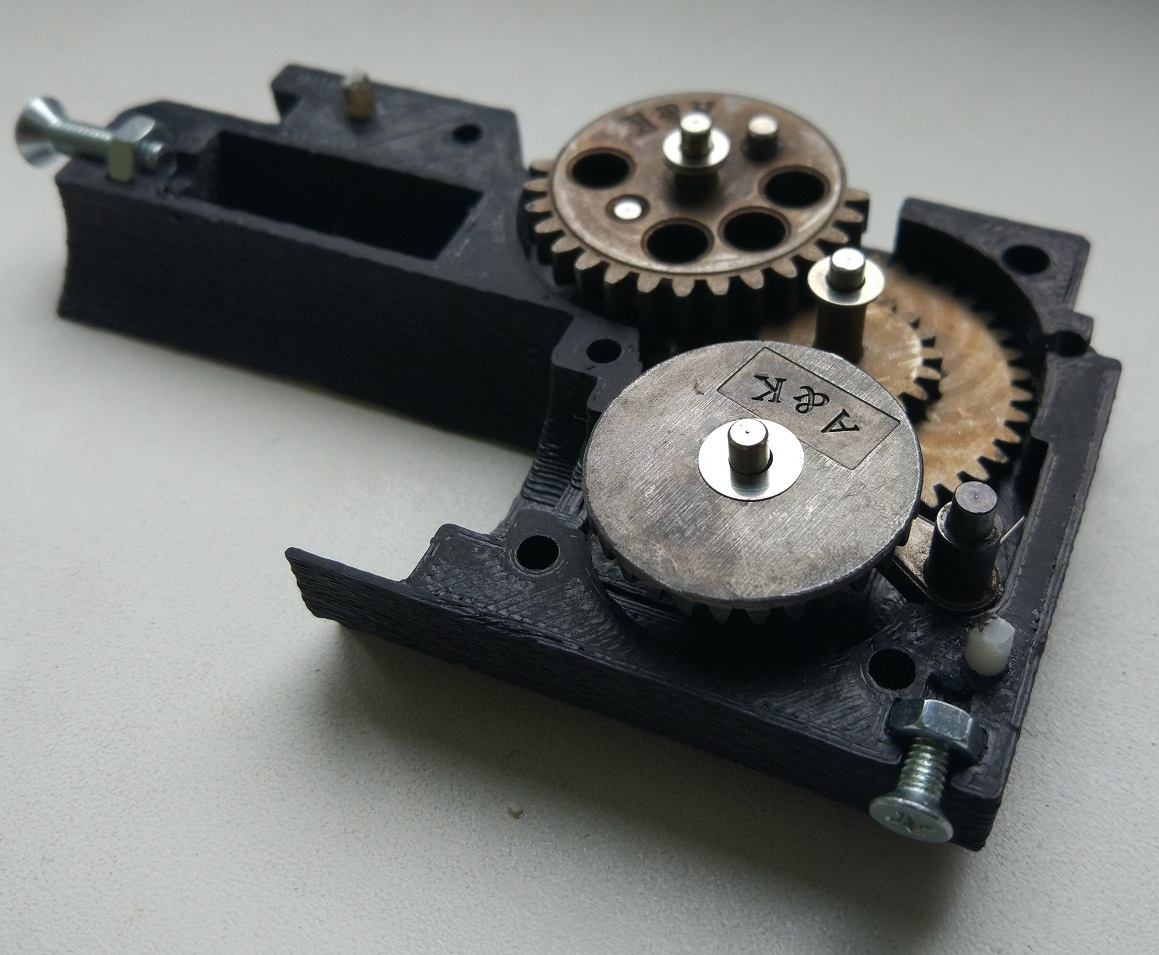

In the third version, the thickness of the hull of the upper part of the gearbox is reduced. It was assumed that this would make the outer walls of the case thicker and allow more room for design work without over-thickening the case. It turned out that even the walls of reduced thickness cope even with powerful (140) springs. Moreover, the walls around the cylinder can be further relieved by holes. This result was achieved due to the thickening of the walls "inward". Additional plastic flows around the cylinder and piston create a kind of “corner”, which is more difficult to bend than the plate.

View of the open top of the gearbox

In general, on this frame you can also assemble a submachine gun, similar to those presented earlier. But I wanted to make a beautiful and most effective solution - to put the most productive option in compact dimensions. A thin barrel 455 mm long was adopted as the base of the length (such a barrel is for Kalashnikov airsoft rifles). The inside of the gearbox - any tm-compatible for the gearbox 3 version. For compactness, the bullpup form factor was chosen (the location of the magazine behind the pistol grip). Stores used from M16 - selected for the wide distribution and location of the ball-feeder in front of the store. This, in turn, allows you to maintain an ergonomic distance from the butt to the trigger with a sufficiently large gap between the handle and the magazine (it sounds easy, but this is one of the most critical moments for criticizing real weapons in such a form factor). The battery compartment should have enough space.

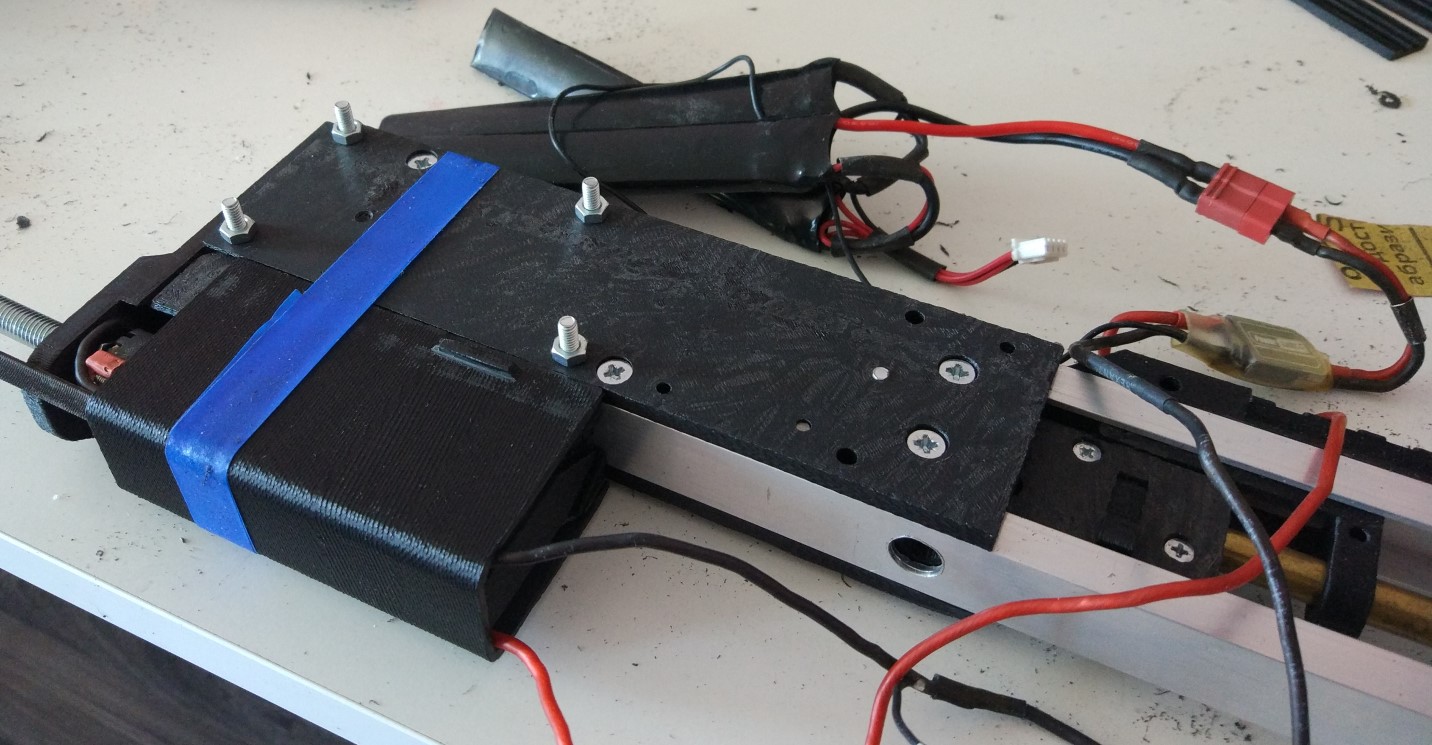

The open bottom of the gearbox. A severe

additional restriction - any part must be placed on the hot table of a budget printer (200x200 mm). I had to rack my brains a lot to make the details printable on compact tables.

The concept for the outer case was deliberately chosen futuristic - I wanted to make a drive that would be recognized at a glance. The design was very difficult for me - I had to look at thousands of reference images of fantastic weapons, look for the best solutions, and then understand how a working mechanism and human ergonomics can fit into this.

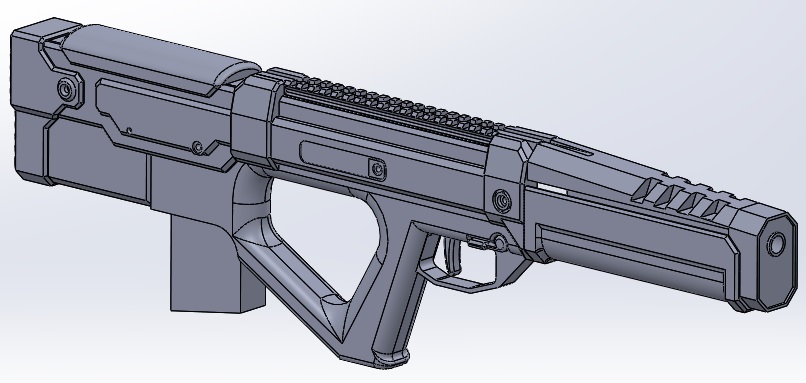

Here is the design of the building

As part of the testing of the gearbox for reliability, it was tested with the springs m100 Systema and m130 Guarder. The given initial speed corresponds to rather high-quality assemblies for factory drives (unfortunately, I do not have 0.20 balls, I had to chronograph .28 and recount). The approximate speed is 100 m / s for the spring m100 and 148 m / s for 130 springs. This is not the best performance, but not below average. It should be borne in mind that we used basic spare parts left from tuning other drives, so there is no doubt that the printed gearbox does not have chronic defects affecting the efficiency. The gearbox withstands a long line of blanks (spring guarder m130, about 200 shots) and after that no hardening forms on the plastic.

Gearbox assembly during tests

At a speed of 100 m / s, hop-up successfully spins the balls, the flight distance of 0.28 balls, although slow, exceeds 50 m (shot in an open sports shooting range, real meters). In the current assembly, accuracy is lame, but most likely this is due to the fact that the hop-up rubber bands that I have are already quite old (for the last 8 years I have not bought new spare parts, there are so many of them at home).

It should be noted that this time, not only STL files, but also the solidworks source code are posted in open access. I tried to follow certain standards for naming the elements of the drawings and make the details as clear as possible. In addition, I selected the tolerances of the parts so that they fit without the painstaking work of a file. Gearboxes had to print 10 pieces, until the quality began to suit me.

I printed some details from colored plastic to emphasize the controls and the aesthetic solution in general. As a result, the drive began to look like this:

View of the finished drive

Sources published on thingiverse .

The model was laid out from mid to late 2018. At the moment, the root node of the model has more than 25 thousand views and 4.5 thousand downloads, I hope it will be useful to enthusiasts for repetition or upgrade.

When there is time for a hobby, I plan to add more detailed assembly instructions, perhaps try to assemble the drive from the parts in front of the camera. The basic version requires an electronic key and only automatic fire. There is a functional prototype of an electronic cut-off of a single lamp by current strength and operating time by a battery monitoring system. However, for this you will have to make a new case, a little larger. There is an idea to try to create a Patreon account and lay out alternative options for the external case and electronics for subscribers. I will be glad to advice on organizing Patreon in the comments.

Thanks!