Tech Insights: Are LED filament-lamps so good?

- Translation

Saluting my LED lamp fans!

Saluting my LED lamp fans!Today we will talk about the palpitating and extremely popular subject in recent years — filament LED (Light-Emitted Diode) lamps. Numerous articles have been published here on Habr (1, 2, 3) and on the web, but none of them tells us a word about in-depth analysis of the lamps (what is actually inside) and comparison of their temperature characteristics. Therefore, especially for you — my dear LED-lovers — I conducted a detailed analysis of such lamps from different manufacturers, including temperature measurement of LEDs themselves.

Afterwards we will try to answer the question: are filament lamps as good as marketers present them to us?

Disclaimer: this is my very first attempt to translate and adopt an article from Habr into English, so I will ask you to give a fruitful feedback and correct some mistake if any present.

Background

When а new technology comes, one of the most important questions arises: how does that technology fit to the overall “tech-environment”? Typically, the revolutionary one simply does not fit into everyday routine, thus, there is many efforts needed to implement innovative products and bring them to the market.

For example, it was the case with renewable energy, installed in private houses. Success of the technology was provided by continuous decreasing of “kit” price, and in some places of the world, extra payment from the government for produced electricity. In turn, this required the revision of relationships between producers and consumers of electricity. A quite similar story happened with electric cars. The industry had to split into two: hybrids and full electric machines with separate “refueling” stations. The latter increased the involved “audience” and the amount customers, so increased penetration the technology to our society. Today, in 2019, Tesla is the brand, but “unknown” Chinese BYD is feeding right now the national market with electric cars & buses.

About 5 years ago, LED lighting and solution based on this technology began to rapidly conquer its followers. For a long time, engineers have tried to adapt two-dimensional light sources (LEDs) to three-dimensional conventional lighting systems (for example, corn-shape bulbs). Recently, it has been published here and there.

Finally, the filament lamps stroke the market. Seems an optimal solution has been found: a lamp does not differ much from “Ilyich” one either in shape or content, and only a single tungsten filament has been replaced with several LED ones. Even the oldest glass factories and workshops found their place in this “business”. Nowadays usage of a translucent ceramic substrate has been proposed to improve radial distribution of the luminous flux from lamps (eg, Crystal Ceramic MCOB).

What is that mysterious filament? Briefly about the filament

The filament is a “cake” consisted of several components. A thin piece of glass (not so good for heating dissipating) or sapphire/ceramic (pretty good in heat conductance) substrate with two contact on both sides. The choice of the substrate depends on producer greed. Then ultra-small LEDs chips are installed on that substrate and are connected in series with super tiny gold wires. Finally, some polymer matrix with luminophore covers the whole cake. Voi-la, the filament is ready to install in the bulb.

Scheme of the internal filament structure

The idea behind this type of LEDs is very simple: we could gain a bit more lm/W due to «double» side interaction of the emitted blue light with luminophore (to generate red and green components). Because LED is transparent, substrate is transparent and light propagates almost 360 degree around the LED. Thus, it doesn't matter where blue light goes, but in SMD (surface mounted device) LEDs it does matter.

Scheme of the internal filament structure

The idea behind this type of LEDs is very simple: we could gain a bit more lm/W due to «double» side interaction of the emitted blue light with luminophore (to generate red and green components). Because LED is transparent, substrate is transparent and light propagates almost 360 degree around the LED. Thus, it doesn't matter where blue light goes, but in SMD (surface mounted device) LEDs it does matter.

Despite the undeniable advantages over SMD LED, filament lamps still have some problems, which for some reasons are concealed. For example, in the «standard» layout with SMD-diodes, there is quite massive aluminum substrate and radiator to remove effectively all generated heat. While in filaments the only way to remove the heat is convection and dissipation through air and the glass wall of the bulb and a bit from supporting substrate, because it is small.

In other words, the overheating will slowly kills the diodes (the drop in brightness and lifetime with increasing of the temperature) same as luminophore (affecting color rendering index, CRI or Ra, and color temperature, CCT). This method of “overheating” works for the tungsten lamp, because the gas inside partially contributes to the regeneration of the filament, but not more than that. More information about the overheating from scientific point of view can be found here. Consequently, from this article relatively harmless temperature is about of 60-70 degrees, not more.

In a nutshell: the overheating or insufficient heat dissipation from LEDs means only one thing — multiple degradation of LED lamp characteristics.

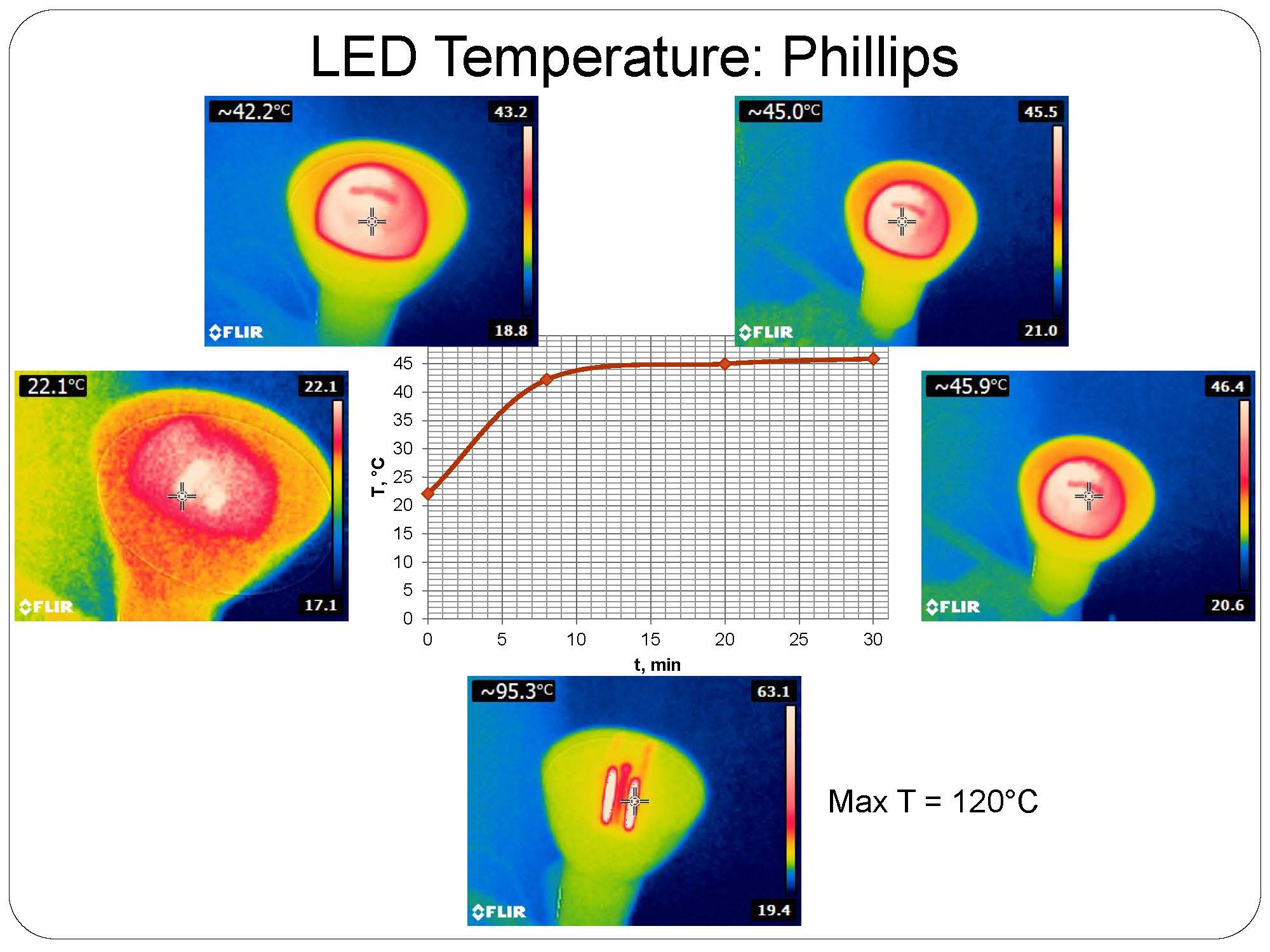

To confirm or to disprove this point of view, I will take my stock of usual LED lamps and compare them in some experiments including temperature measurements with a thermal imaging camera (Flir 5 Series, 240 by 320 pixels). With the help of this camera, temperature on the bulb was measured for half an hour, as well as on the LEDs themselves after the removal of the bulb.

Traditionally, conclusions for rushers are presented in two final tables at the end of the article. Of course, enthusiasts are very warm welcome to the Experimental Part.

Experimental Part

For the experiment I took three lamps from different manufacturers: cheap Chinese lamp from Ebay from CroLED (in fact, at a price equivalent to Eglo), another lamp from Eglo distributed by Leroy Merlin and, of course, greatly respected and very popular Phillips. Additionally, I admit that probably the lamp from Ebay has no relation to this CroLED.

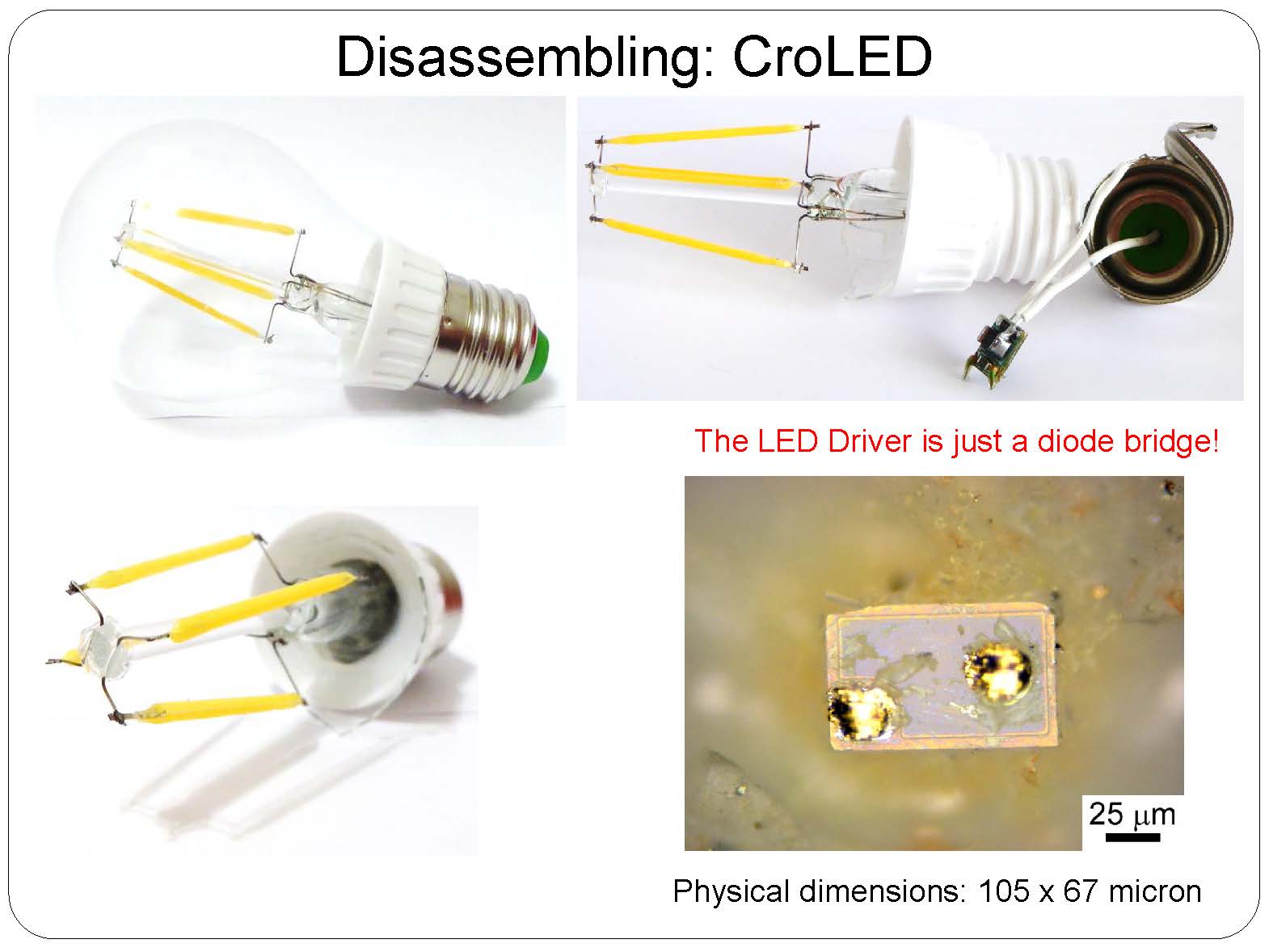

CroLED: «Chinese» Quality on Ebay

Let's start with a filament-lamp from China. This lamp arrived in a simple cardboard box with a minimum of information on it (temperature, power, and power supply – that’s all). To be honest, my expectations were very different, but the reality punched much harsher. Pulsation rate was 67% (!) — seems, we have a new record! In fact, the lamp died out and flame up again with intervals of every 10 ms. Color temperature turned out to be at the border with 3000K.

NB: All the lamps presented in this article have a glass bulb. Although it can stand a drop to the floor, be careful when handling them!

Analysis of lamp interior revealed another interesting design feature — the driver, or rather complete absence of the driver. Lamp was powered by a MB10F diode bridge with a couple of resistors and huge solid-state capacitors. It is very space «efficient»!

18 LEDs were arranged on a matte (!) substrate. Each LED chip was made of textured sapphire substrate («asterisk»). The chips are very small in their dimensions — thinner than a human hair.

Why is it profitable for manufacturer to make ultra-small LEDs?

An interesting question! One of the reason is just economical one. Small LED chips are easy to produce and they do not require additional gold contacts on the top electrode for redistribution of the electric field, which increase working performance.

Another reason is heat conductance. If you can't remove given amount of heat, there is no reason to use more powerful diodes — they will die very fast.

Another reason is heat conductance. If you can't remove given amount of heat, there is no reason to use more powerful diodes — they will die very fast.

Well, and what about the temperature? — The reader shall ask. The temperature at the bulb in 5-7 minutes reached about 40 degrees, and remained the same for an hour.

Now let’s have a look under the cover. Temperature measurement after glass bulb removal revealed that the filaments heated very fast (~1 minute) to about 90 degrees, and in some locations — presumably where the LEDs were placed — temperature reached over 100 degrees.

Eglo: Ordinary Lamps with Conventional Characteristics

The next lamp is Eglo. This company incidentally has a representative office in Russian Federation. In general, I was pleased with its performance: pulsations at the frequency of 100 Hz were approximately 6%, and the color temperature and CRI were consistent with the specifications.

To the question about pulsation

Have no idea about other countries, I can say that in Russia pulsation of the light in LEDs lower than 300 Hz is under control and should obey certain rules. Regulation documents (1 and 2) tell:

Therefore, pulsation of the light flux lower than 300 Hz is not desirable.

Remark — Pulsation coefficient of illumination takes into account only pulsation below 300 Hz. Pulsation above 300 Hz does not affect for the total and visual efficiency, as show in [1].

Therefore, pulsation of the light flux lower than 300 Hz is not desirable.

Inside this lamp, there are 4 filaments, similar to the above mentioned Chinese one. Also, there is a hidden driver based on capacitors ballast. LED chips are a bit bigger than in the previous case — 113 x 57 microns. However, they are very poorly mounted on a matte substrate.

As for temperature, the lamp quickly (in the same 5-7 minutes) heated up to about 50 degrees measured on the bulb. But filaments again demonstrated temperature of ~ 90 degrees – heating source!

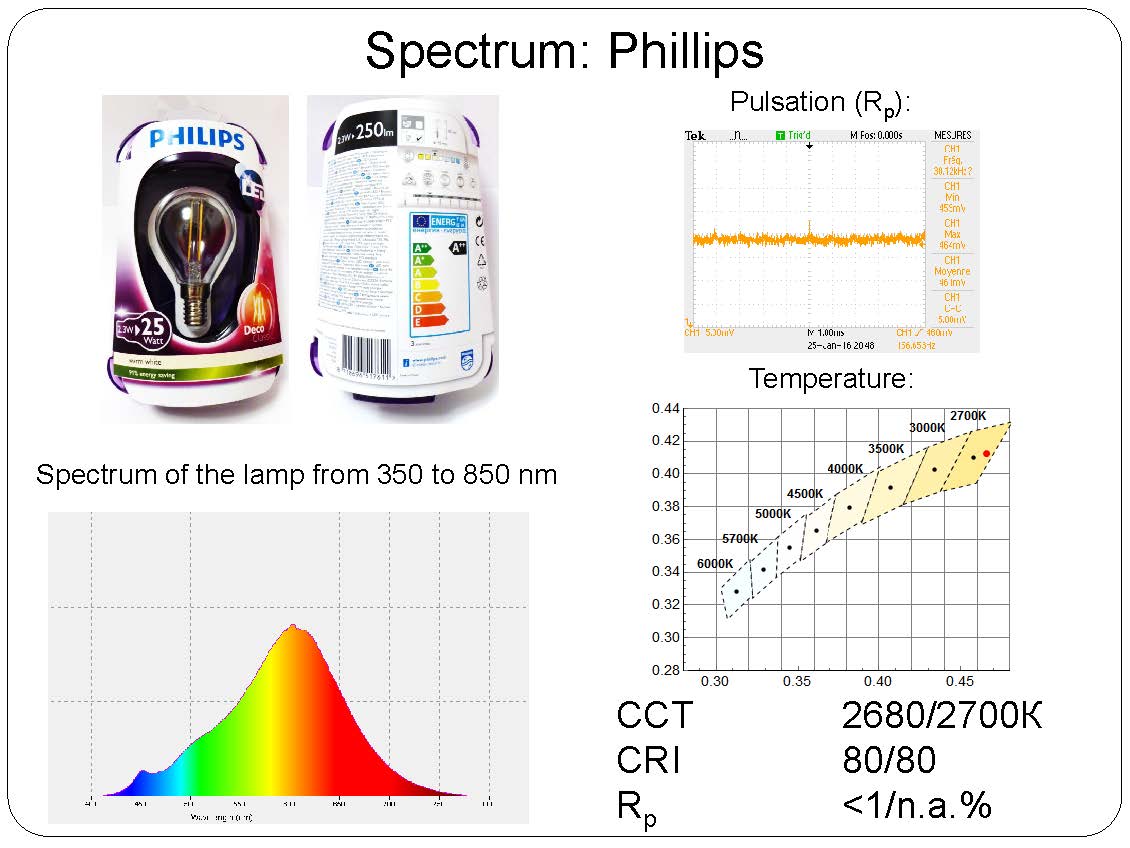

Philips: when Quality above Everything

The last tested lamp was produced by Phillips. Surprisingly, this lamp in the E14 case demonstrated excellent conformity to the declared characteristics and very low pulsation.

What is the reason for such nice behavior if the base of E14 is much smaller than E27? – you may ask me. Everything is pretty simple: Philips have very good engineers who were capable to create an ultra-compact driver (a flyback converter) so it fitted into small E14 compartment. This driver provided an extremely low pulsation (<1%).

In this lamp, there are only two LED filaments, as it consumes only 2.3 W of energy. LED chips were fixed on a transparent substrate. They were similar in size to those used in lamps Eglo, but with a different substrate texture («shield»).

As mentioned above, you can’t go against laws of thermal physics. In about 10 minutes the lamp bulb heated up to ~ 45 degrees (two filaments slowly «warm up» the entire lamp). However, filament temperature without glass bulb was still ~95 degrees, and in some places — again, probably, where LED chips were mounted on the substrate — reached values of 110-120 degrees.

In order to conclude I added some pictures and measurements of IKEA lamps and powerful, smart lamps from Prestigio. IKEA lamp heated up to 75 degrees for half an hour, and smart lamps Prestigio to 58. Both of those “SMD LEDs” lamps heated up to a specified at the beginning of the article «safe» temperature of 60-70 degrees.

Conclusions

Let’s now sum up the results and try to answer the question: Is it the worth to buy a filament lamp nowadays?

0. I tirelessly repeated, repeating now and will repeat again and again: we must admit 2D nature of LED light and use it as-is. This means we have to obey 2D design of LED «lamps». The future of LED light should be ultimate "Nanoleaf" — lighting wallpaper.

1. All collected data is presented in tables below. In my opinion, I would not trust the declared luminous flux for Chinese lamp, as well as other characteristics. Producers of mass-consuming products have a habit to overestimate results. The rest of the lamps Eglo and Phillips have relevant characteristics — well done! China – well… hope you understand.

Please, save your health and time — ask for test results before purchasing LED-lights on Ebay, and in regular stores the same procedure have to be taken soon…

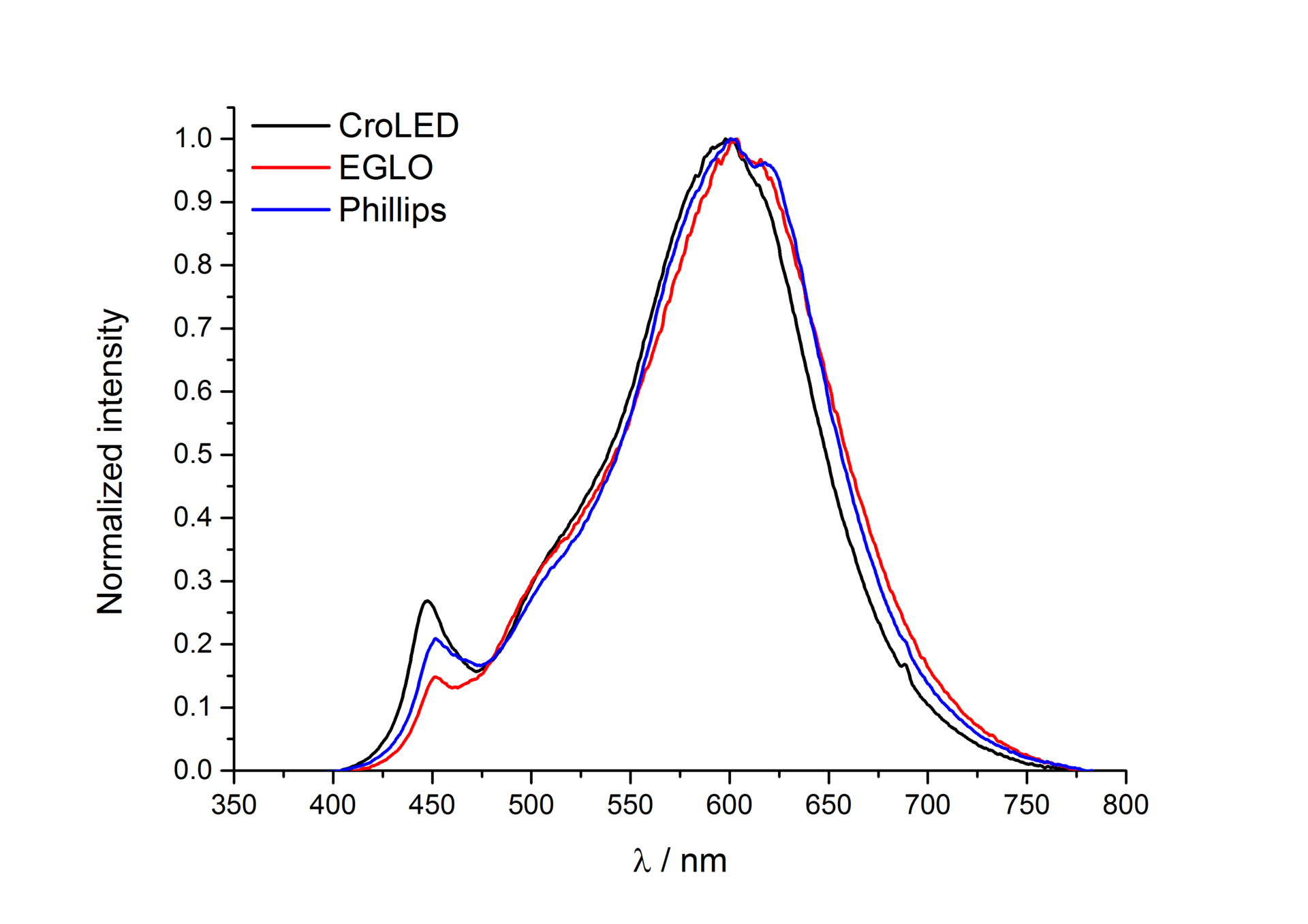

2. Comparison of the spectra did not reveal any significant difference between mentioned lamps. All lamps are very likely to use the same phosphor (luminophore), which gives warm «filament»-light. There are slight variations in the blue component that can be also observed in the color temperature in Table 1: Eglo was very warm, Phillips was in the middle, CroLED had “the most cold” CCT.

3. If we talk about technologies, only Phillips has a right to be called as «good and safe lamp» with a normal non-pulsing driver. Philips confirms once again the status of a leading player on the market.

All tested lamps had surprisingly similar order of values for a specific luminous flux and a specific power. These values are comparable to an average SMD-lamp. Apparently, the heat transfer and heating LEDs substantially restrict these characteristics in comparison with the conventional LEDs packed in SMD cases.

4. Finally, the most delicious is for dessert. Temperature measurements of filaments using infrared camera showed and, I guess, proved that the filament technology could not be a complete substitute for conventional SMD lamps with an aluminum radiator (a much more effective heat sink). Plus, significantly limited space for a driver should be taken into account. As a result we will find out that the bright and powerful filament-lamps with long-life would be very hard to create (12 W lamps are often equipped with a radiator).

Do not be shy and do not not forget to subscribe: it’s not difficult for you — I am pleased & encouraged!

Yes, this text is not ideal, so about all errors and mistakes noted in the text, please, drop me a PM.